Free cooling method of hot rolling band steel

A cooling method and technology for hot-rolled strip steel, applied in the field of metallurgy, can solve the problems of cooling of unstrip steel products, control differences, inability to realize the temperature rise of the head and tail of strip steel, etc., and achieve the effect of length control and free length control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

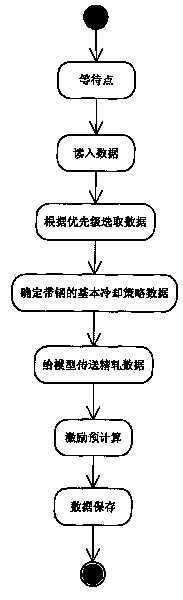

Method used

Image

Examples

Embodiment 1

[0061] Example 1 was implemented at Baosteel 1880 hot rolling site.

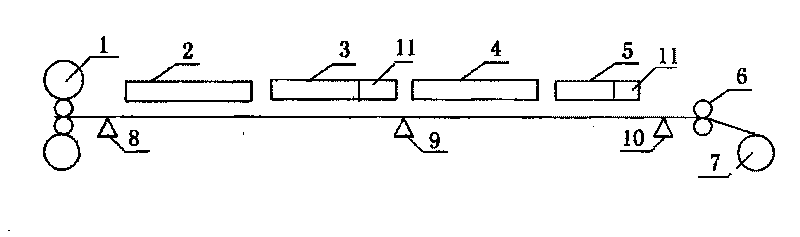

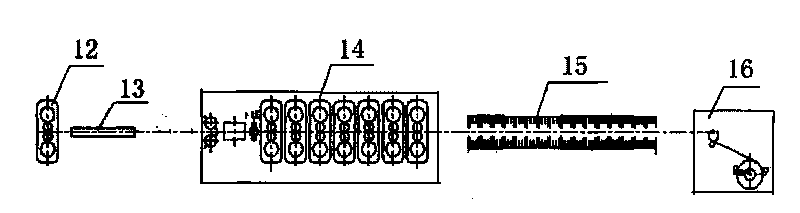

[0062] The 1880 hot rolling system divides the strip steel into certain length sections on the laminar flow cooling system for control. The segment generation and tracking of the strip is the basis for the implementation of the model control function of the 1880 hot rolling laminar cooling system.

[0063] According to the 1880 hot rolling laminar flow cooling system of this embodiment, the section length of each strip is determined according to the thickness of the strip.

[0064] The details are as follows: (The following data is the experience time, which is mainly determined according to the running speed of the strip;

[0065] thickness

<4mm

0.8-1.2m

>=4mm,<7mm

0.6-0.8m

>7mm

0.5-0.6m

[0066] According to the above method, combine the length of the strip to obtain the number of sections of the strip; for example, the thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com