High-strength thin steel plate produced by CSP (cast steel plate) process and preparation method of plate

A thin steel plate, high-strength technology, applied in the field of micro-alloyed steel and its preparation, can solve the problems of reducing the micro-alloying effect of Ti element, limiting the effect of Ti solid solution, low carbon content, etc., and achieves the effect of good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

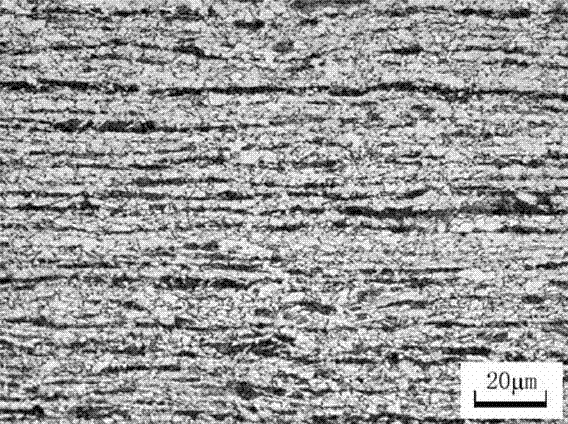

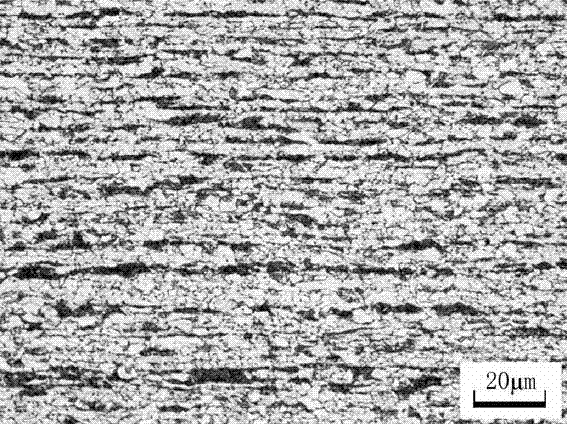

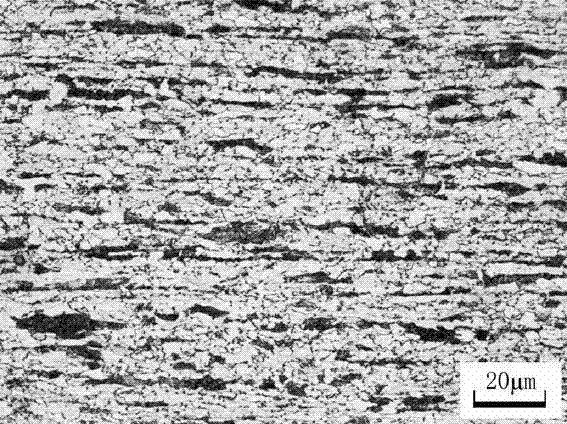

Image

Examples

Embodiment Construction

[0027] The present invention is described in detail below:

[0028] Table 1 is the value list of each embodiment of the present invention and comparative examples;

[0029] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0030] Table 3 is each embodiment of the present invention and comparative mechanical performance inspection result list;

[0031] Each embodiment of the present invention is produced according to the following steps:

[0032] Its steps:

[0033] 1) Smelting and continuous casting into billets;

[0034] 2) Perform soaking, control the soaking temperature at 1200-1300°C, and soaking time at 20-60 minutes;

[0035] 3) Carry out rolling, and control the starting rolling temperature not lower than 1200°C, and the finishing rolling temperature at 870-930°C;

[0036] 4) Perform laminar cooling, and cool to the coiling temperature at a cooling rate of not less than 20°C / S;

[0037] 5) Carry out c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com