Steel with 1,300MPa-level tensile strength for automobile safety piece and production method thereof

A technology for tensile strength and safety parts, applied in the field of automotive steel, can solve the problems of poor dimensional accuracy of parts, serious springback, and difficult forming, and achieve the effect of high dimensional accuracy and ultra-high strength of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

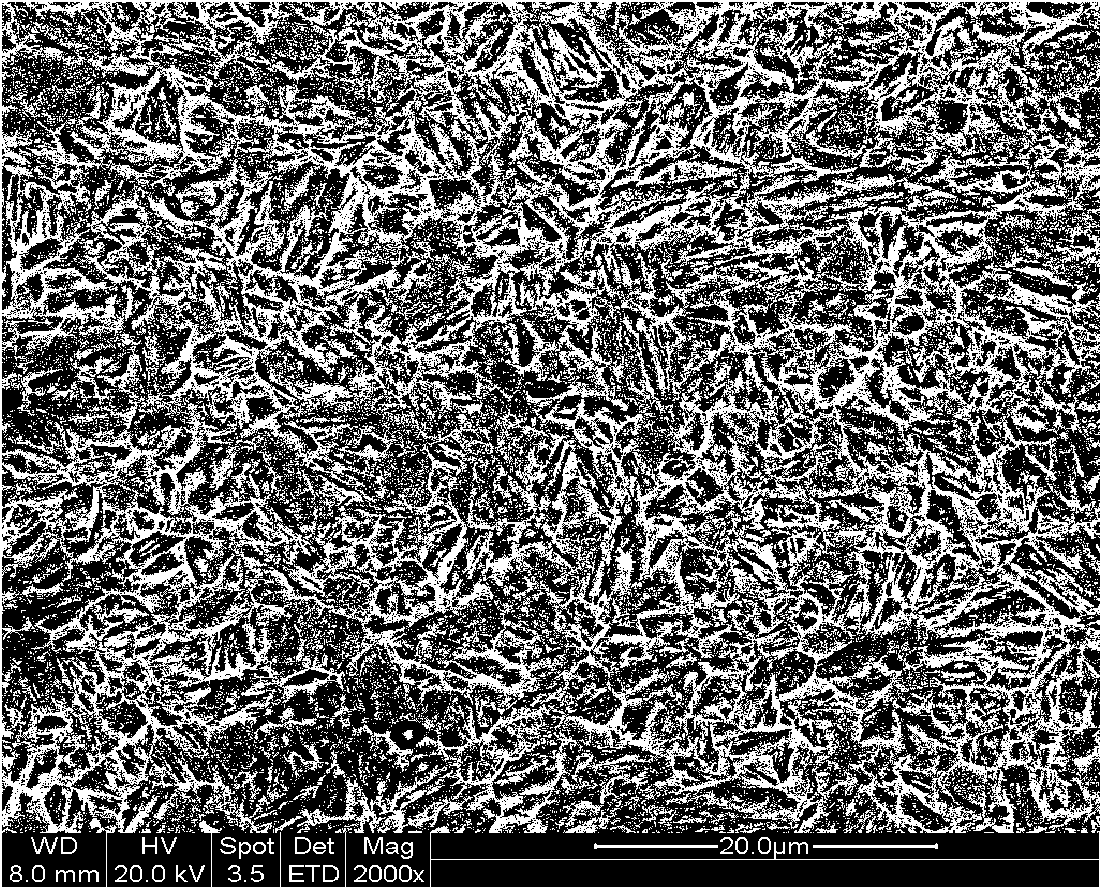

Image

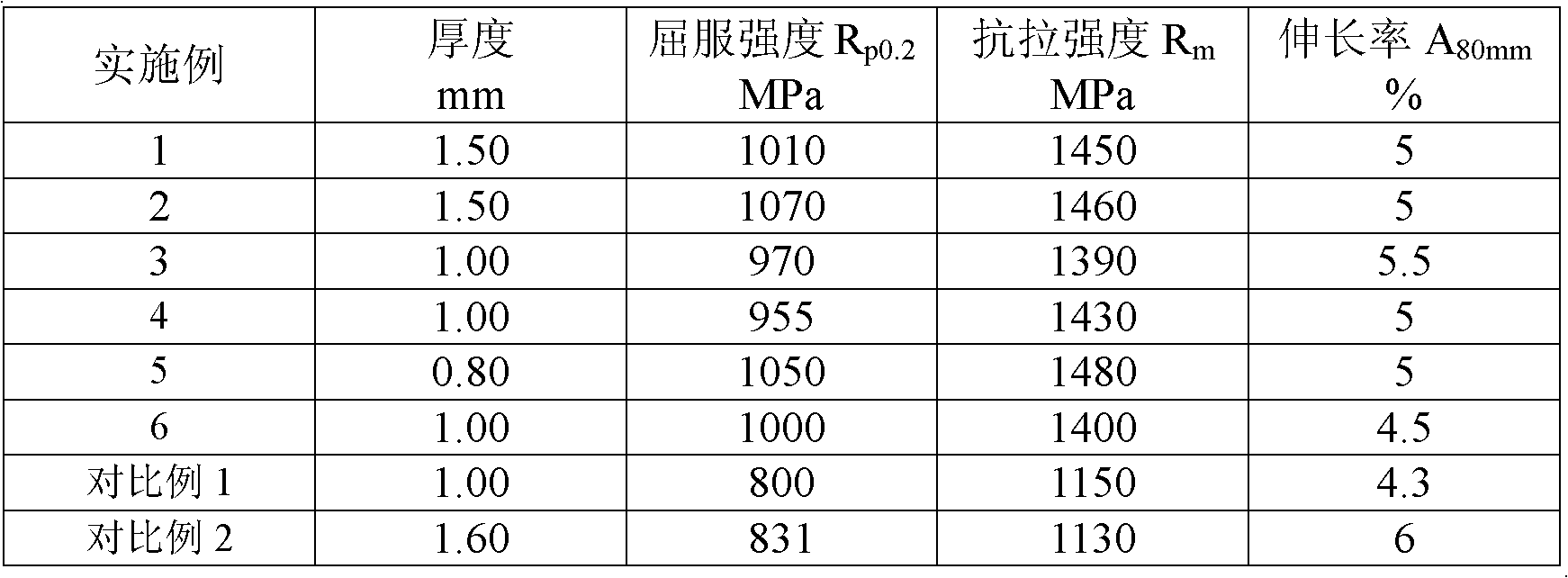

Examples

Embodiment Construction

[0050] A detailed description is given below:

[0051] Table 1 is the component and weight percent value of each embodiment;

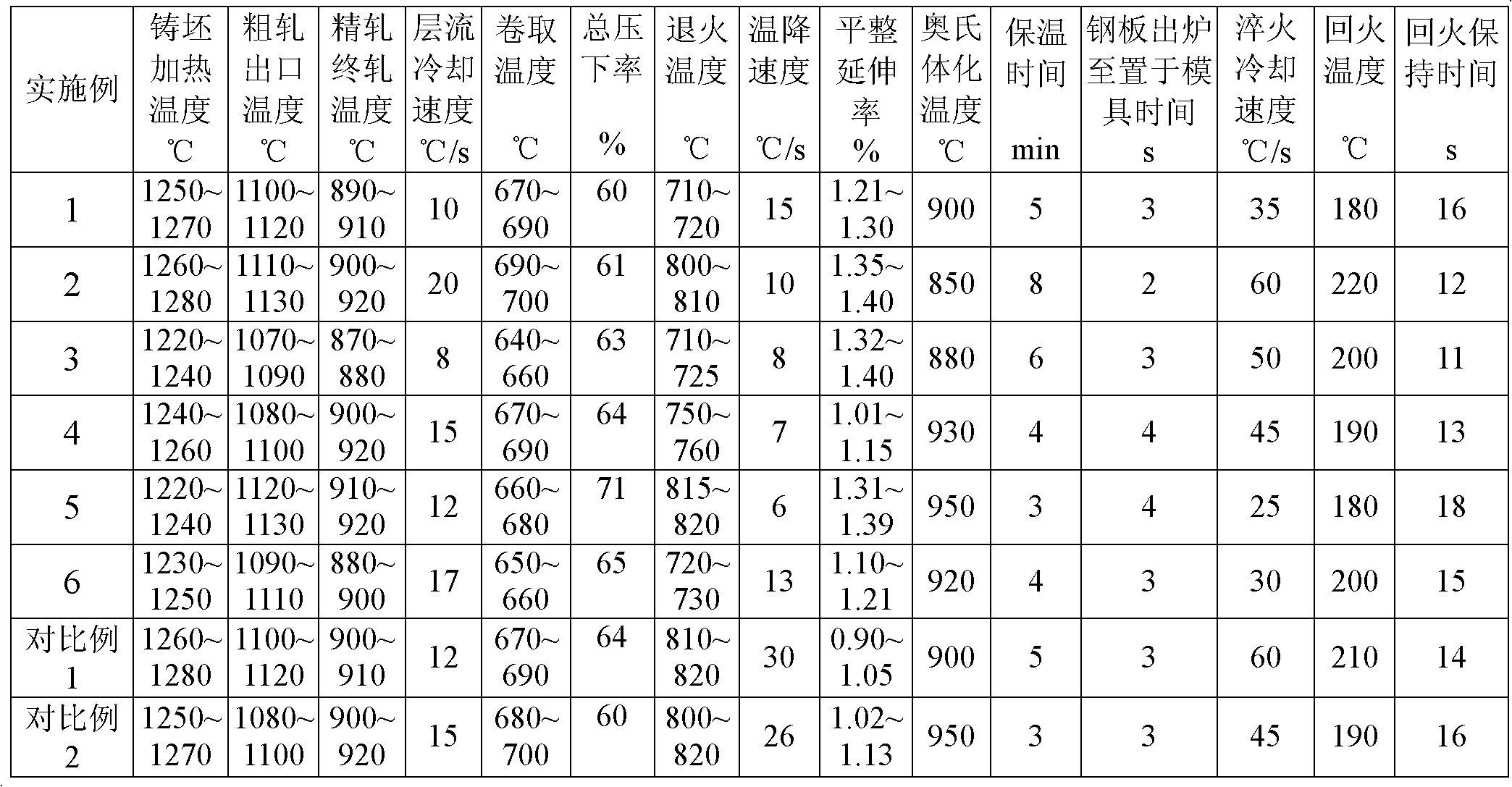

[0052] Table 2 is the selected main process parameters according to the following production steps;

[0053] A method for producing steel for automotive safety components with a tensile strength of 1300MPa, the steps of which are as follows:

[0054] 1) The hot metal is desulfurized and smelted in a converter, and the C: 0.04-0.06%, P: ≤0.008%, S: ≤0.003%, N: ≤0.005%, O: ≤0.005% are controlled at the smelting end point;

[0055] 2) carry out alloying;

[0056] 3) Vacuum treatment and composition fine-tuning;

[0057] 4) Continuous casting;

[0058] 5) Heating the billet to 1220-1280°C;

[0059] 6) Carry out rough rolling, and control the exit temperature of rough rolling at 1070-1130°C;

[0060] 7) Perform fine rolling, and control the finish rolling temperature at 870-920°C;

[0061] 8) Laminar cooling is carried out, and the cooling rate is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com