Hot-rolled strip steel moderate sea profile shape controlling method

A technology for hot-rolled strip steel and corrugated sheet, which is applied in the field of corrugated sheet shape control method in hot-rolled strip steel, and can solve problems such as double-sided waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

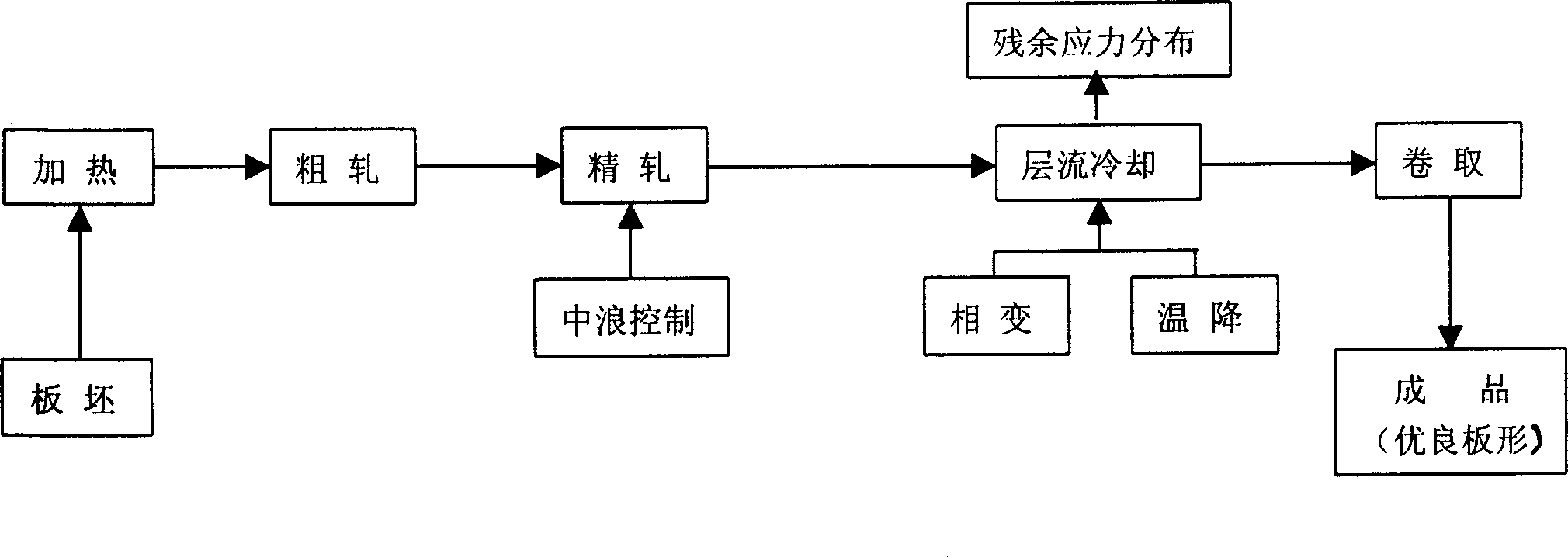

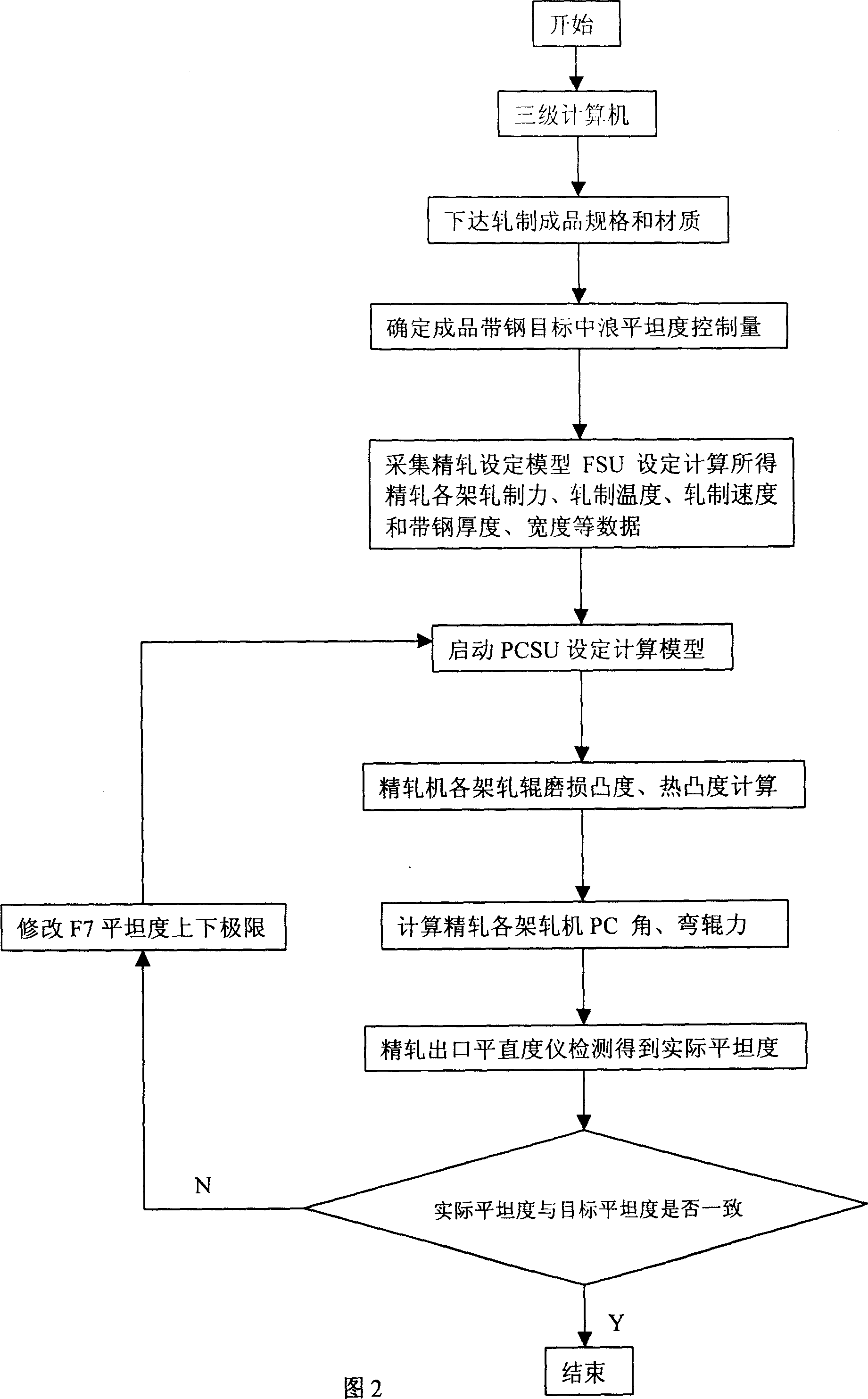

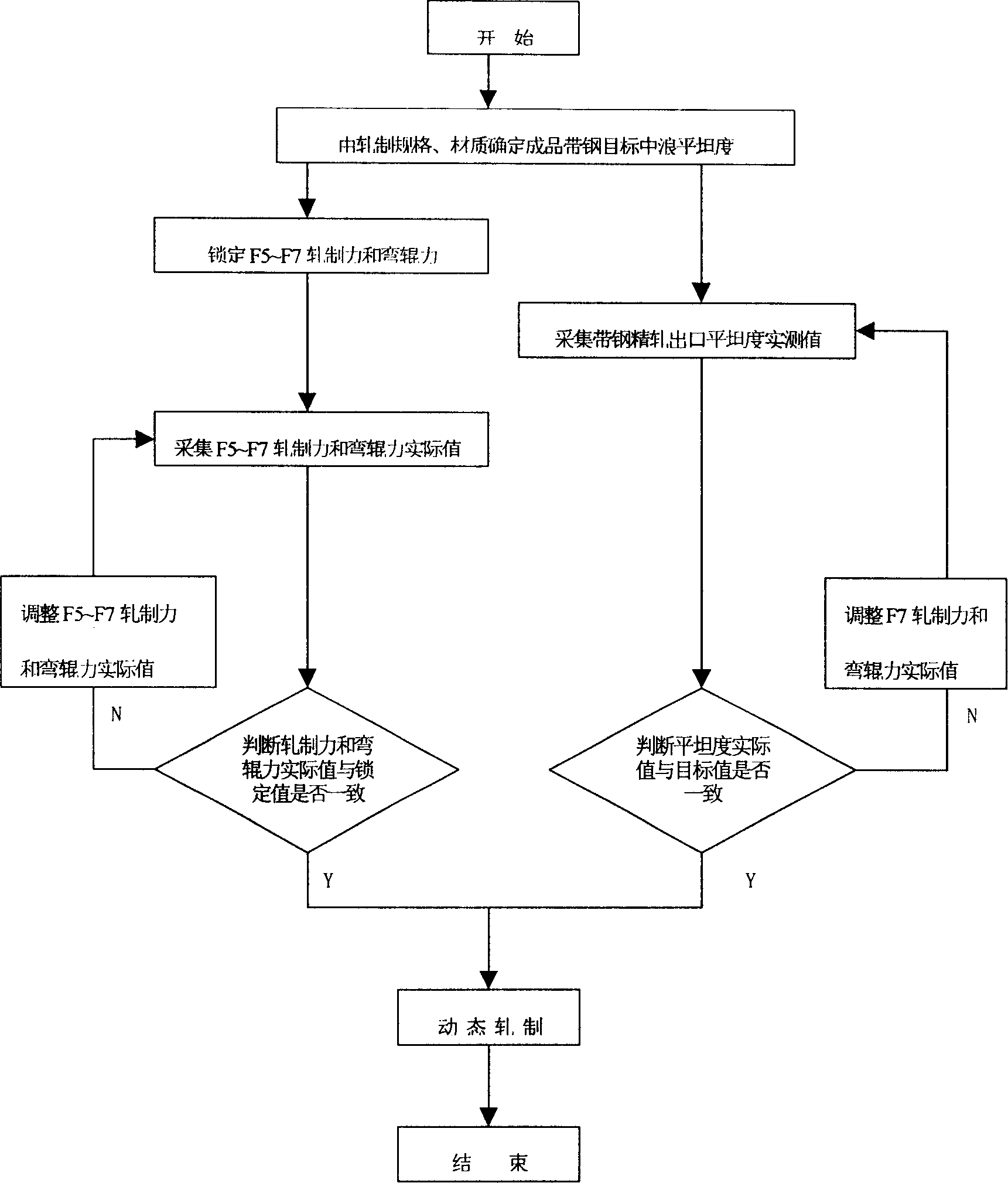

[0045] Such as figure 1 As shown, in the hot-rolled strip steel production line consisting of slab heating—rough rolling—finish rolling—laminar cooling—coiling—finished product, the wave shape control link is added to the finishing rolling unit, and its The purpose is to overcome the residual stress formed by the temperature drop and phase deformation caused by laminar cooling by adopting PCSU setting control for the strip head and ASC dynamic mid-wave control for the rear part, so that the double-sided waves of the strip are made The finished strip has good shape. As shown in Figure 2, the middle wave PCSU setting control process of the hot-rolled strip middle wave plate shape control method of the present invention is: adopt the middle wave PCSU control to the strip head, that is, the PC setting control,

[0046] The described Zhonglan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com