Steel plate for stamping and quenching and manufacturing method thereof

A manufacturing method and technology for steel plates, which are applied to hot forming products, steel plates for stamping and quenching and their manufacturing fields, can solve the problems of complex steel components and difficult smelting control, and achieve the effects of simple component design and good hardenability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] 1. Production process route of stamping and quenching steel plate

[0037] Hot-rolled sheet: converter smelting→external refining→slab continuous casting→heating→rolling→laminar cooling→coiling→pickling→oiling→packaging.

[0038] Cold-rolled sheet: hot-rolled steel coil → pickling and rolling mill → coiling → bell furnace annealing → oiling → packaging.

[0039] The selection of hot-rolled and cold-rolled hot-stamped steel plates is determined according to the required steel plate thickness and the needs of actual hot-formed parts manufacturing.

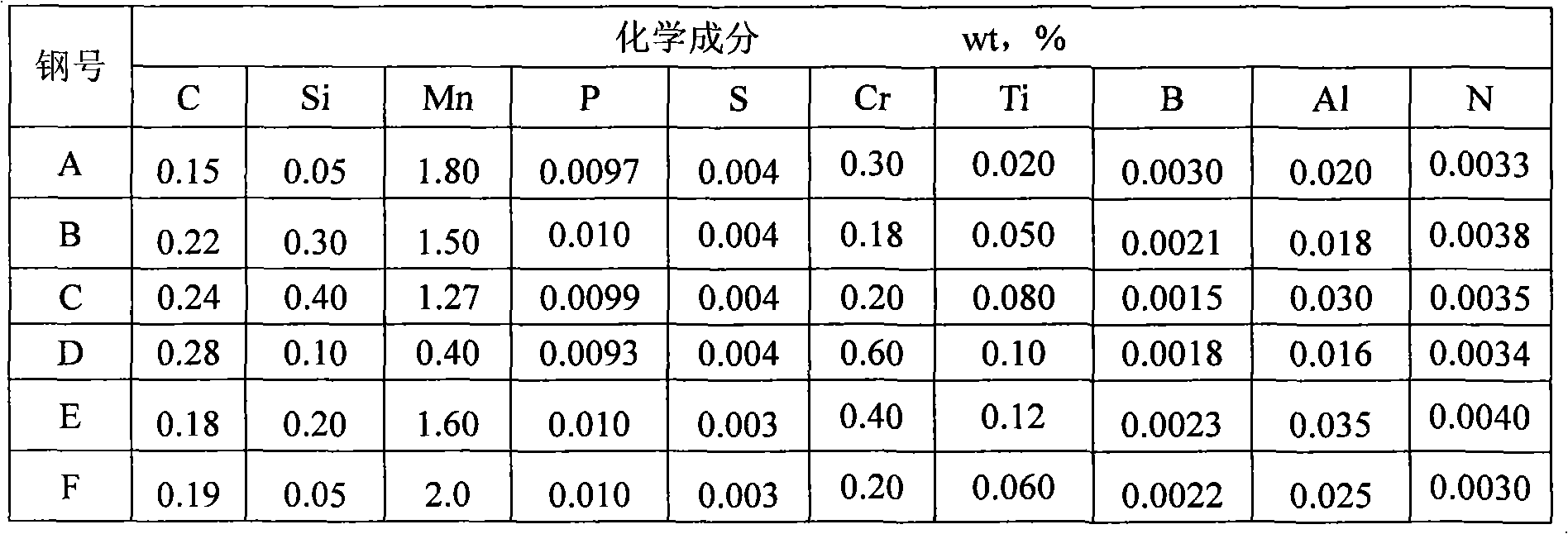

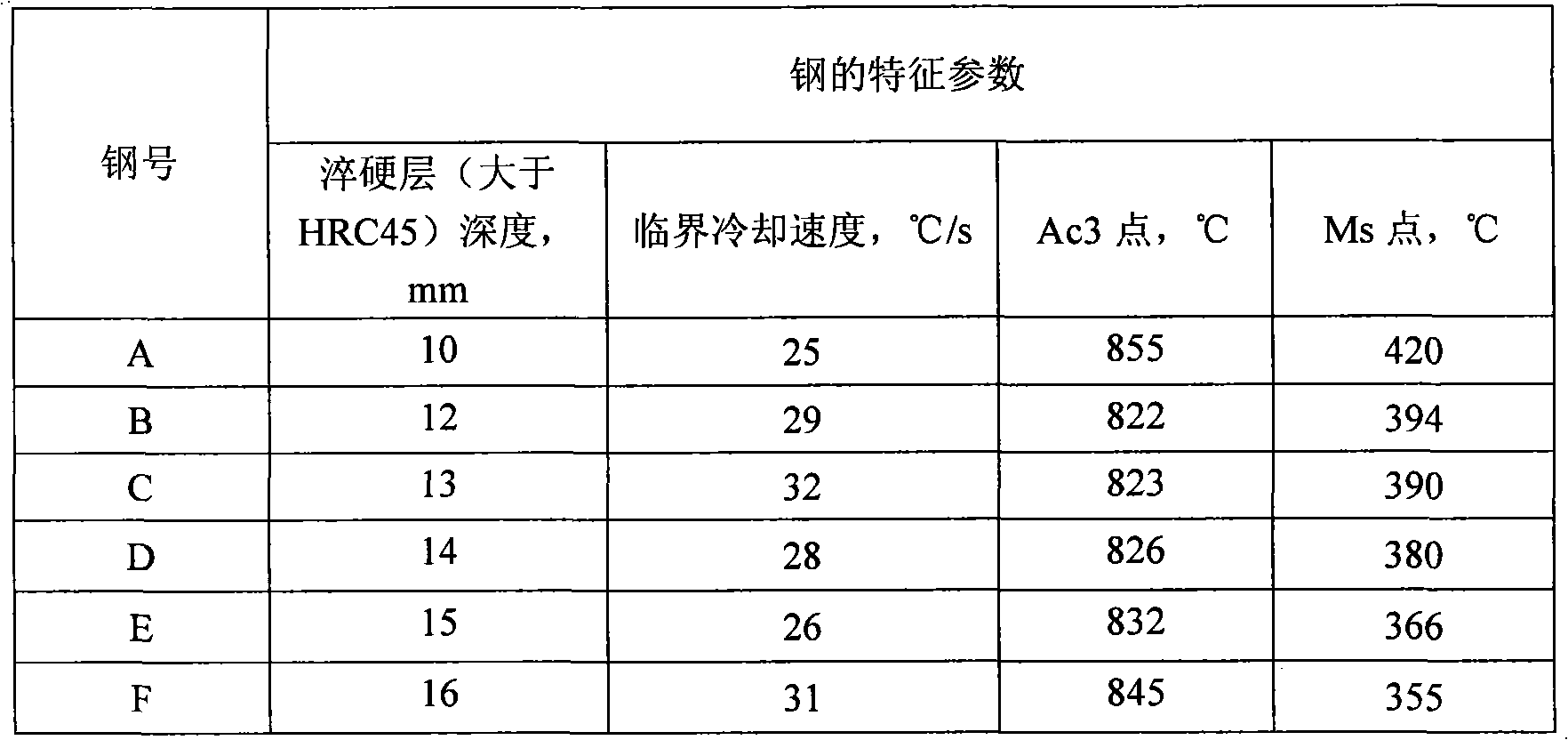

[0040] 2. Composition of the steel plate: Table 1 shows the chemical composition of the steel of the present invention, in mass percent.

[0041] Table 1 Chemical composition wt% of steel plate

[0042]

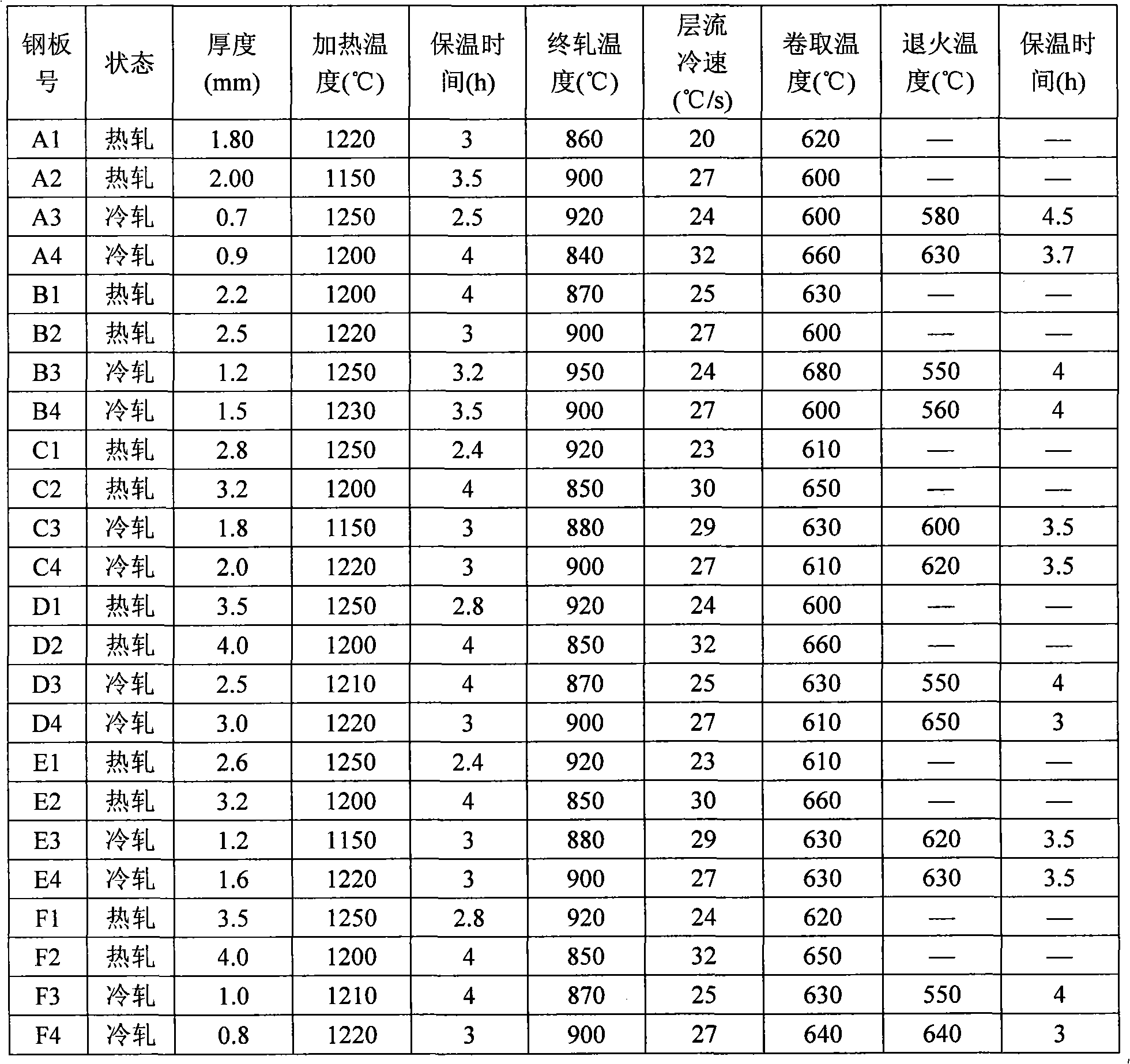

[0043] 3. Hot rolling system and cold rolling annealing system

[0044] The continuous casting billet with the smelting composition of the present invention is heated, kept warm, rough rolled and finished rolled, and la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com