After-rolling cooling system for hot rolled steel strip production line

A cooling system, hot-rolled strip technology, applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc., can solve problems such as uneven cooling, retention, steel plate deformation, etc., and achieve high-strength cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

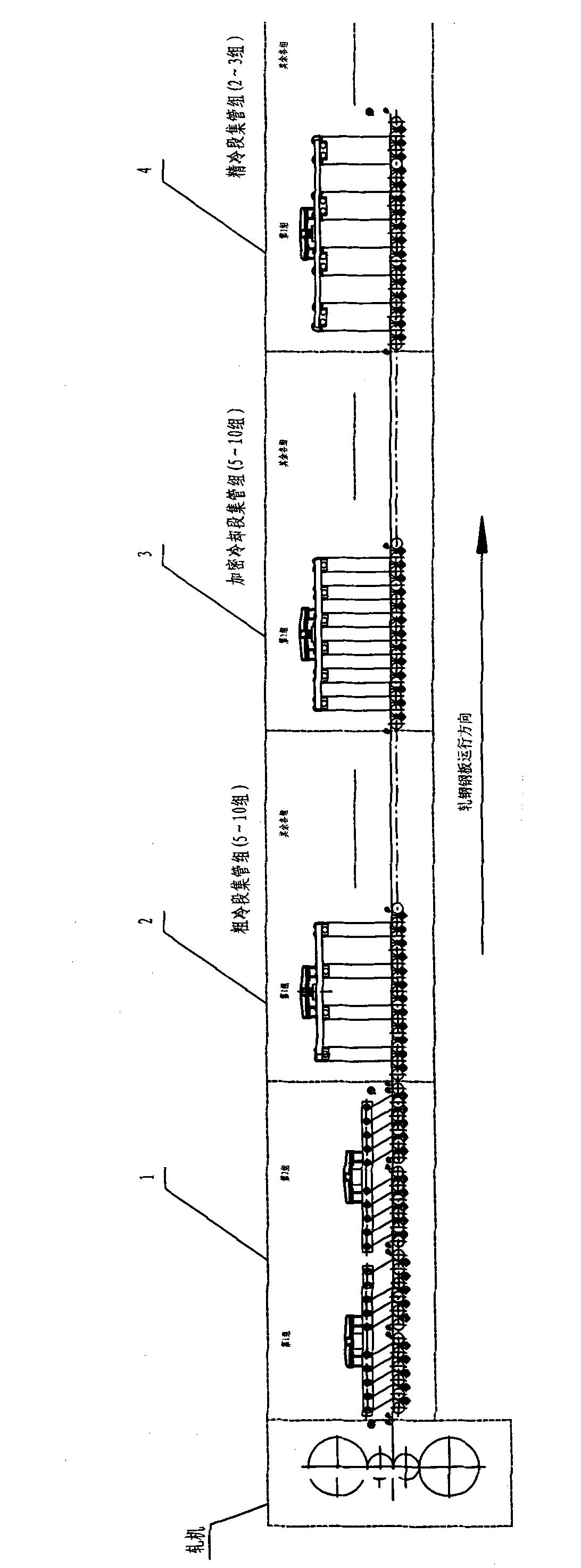

[0020] A post-rolling cooling system for a hot-rolled strip steel production line. Cooling devices with different water collection pipes and different densities are arranged sequentially on the rolling line along the rolling running direction of the steel plate. It is characterized in that an ultra-fast cooling zone and a layer flow cooling zone, see figure 1 .

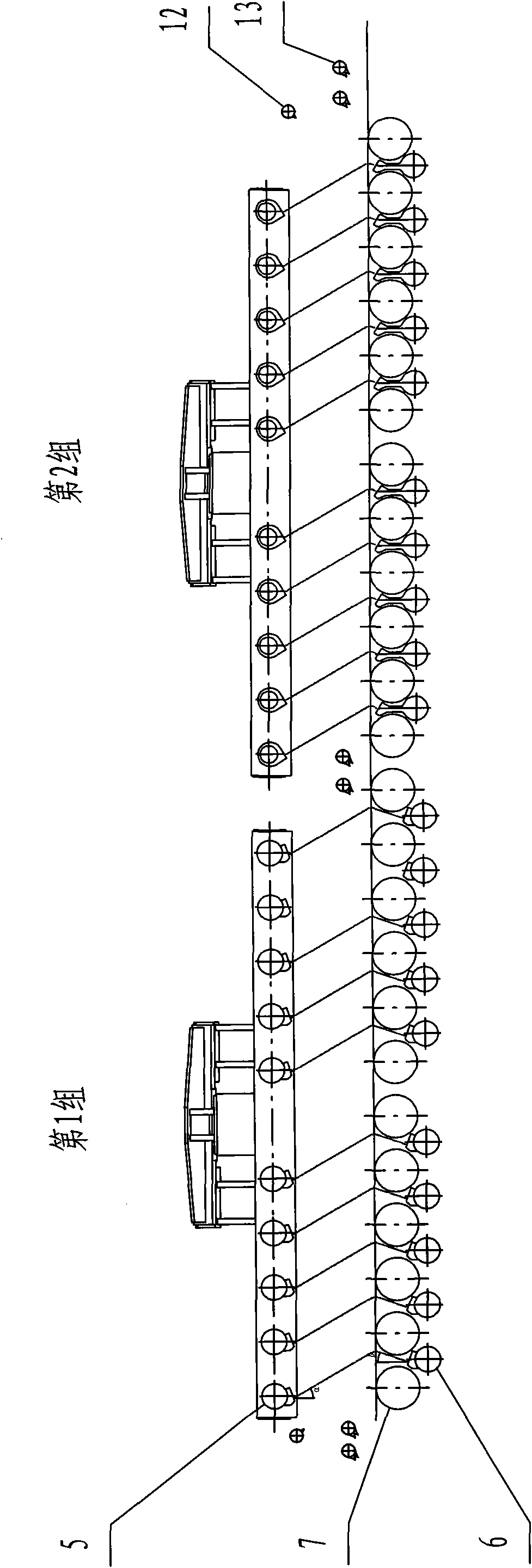

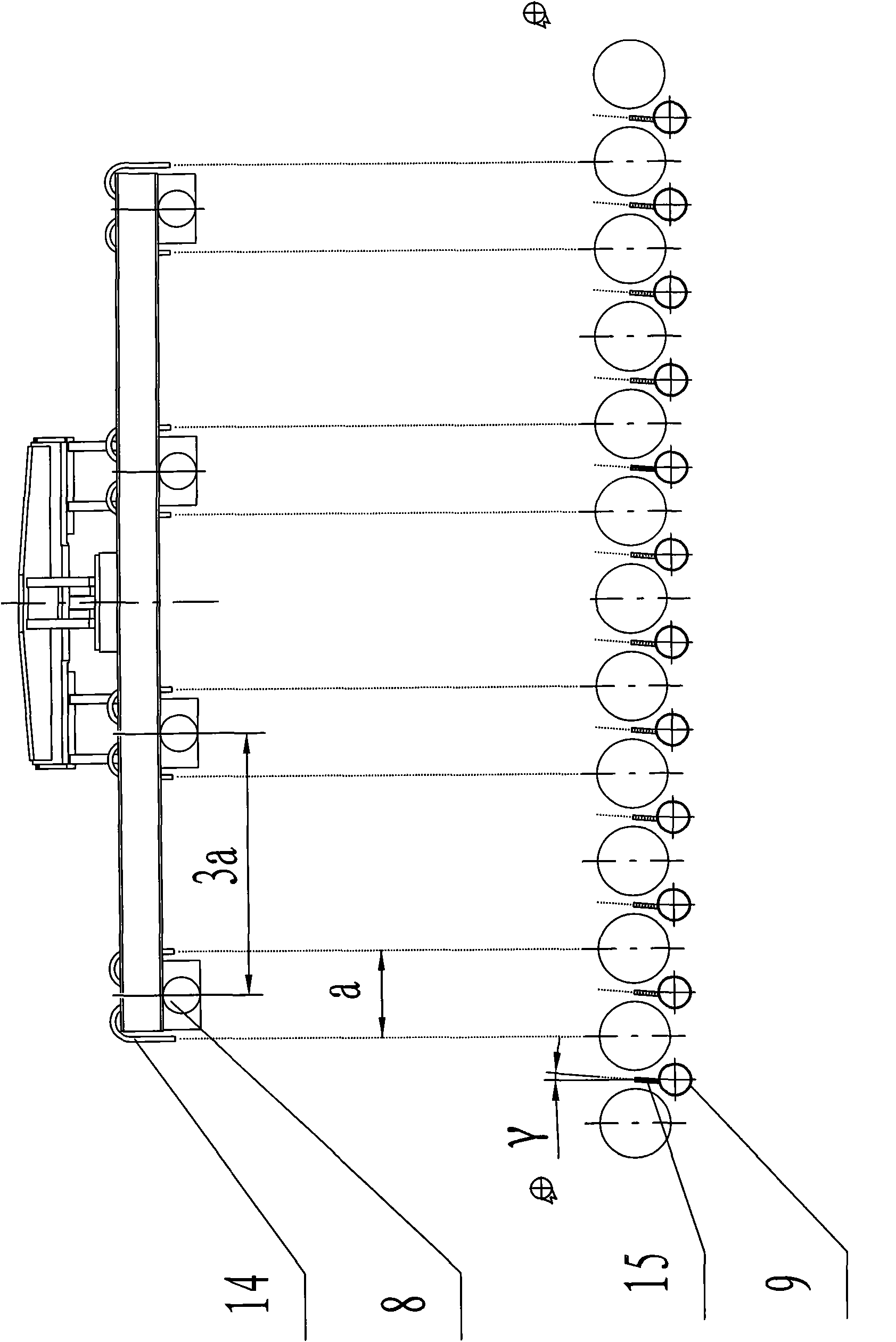

[0021] Ultra-rapid cooling zone 1 adopts a dense tube flow structure, and there are 2 groups in total, such as figure 2 As shown, each group is provided with 8 to 10 upper headers 5 and an equal number of lower headers 6, and the upper headers 5 and lower headers 6 are respectively arranged above and below each roller 7, arranged in parallel, and ultra-fast cooling The upper and lower headers 5 and 6 in Zone 1 are directly connected to the high-pressure water supply pipes. The nozzles of the headers are in the form of inclined jet slit structures (see patent number: ZL200710010745.6 cooling device that can form flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com