Automobile beam steel with tensile strength of 590MPa and manufacturing method thereof

A tensile strength, automotive beam technology, applied in manufacturing tools, temperature control, heat treatment process control and other directions, can solve the problem of less research reports on tensile strength 590MPa grade beam steel, and achieve excellent cold stamping and roll forming and fatigue. Effects of stable properties, chemical composition and mechanical properties, good plasticity and low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

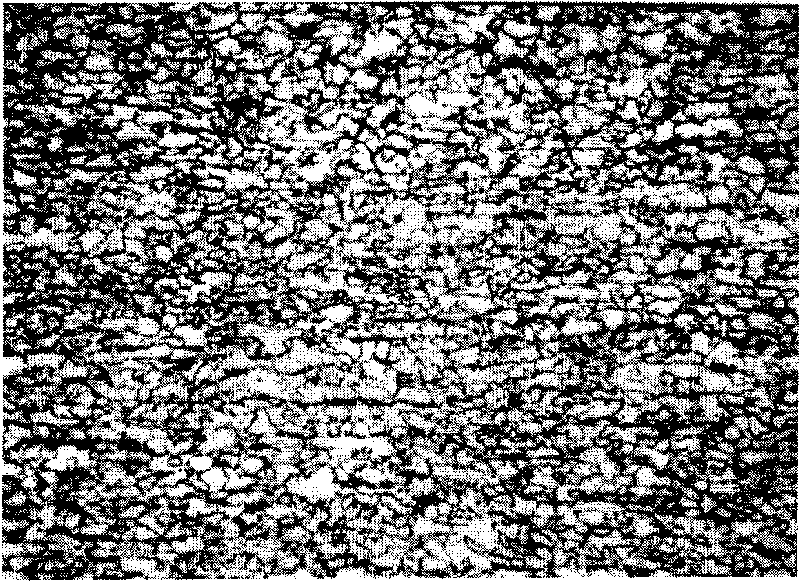

Image

Examples

Embodiment Construction

[0031] The steel for automobile frame with a tensile strength of 590 MPa and its manufacturing method of the present invention will be described in detail below in conjunction with the accompanying drawings and several specific examples.

[0032] Table 1 lists the chemical composition weight percentages (the balance is Fe and unavoidable impurities) of the specific examples 1-8 of the present invention for producing automobile frame steels with a tensile strength of 590 MPa.

[0033] Table 1 The chemical composition weight percent of specific embodiment steel of the present invention

[0034] Example

[0035] These eight kinds of embodiment tensile strength 590MPa level automobile girder steel preparation methods are as follows: Carry out top-bottom composite blowing on the 90 ton and 250 ton converters of the steelmaking plant, adopt the hot metal desulfurization technology, make the S in the hot metal≤0.008%; Ferro-alloy is added when 1 / 3 of the steel is tapped aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Lower yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com