Piston rod of damper and preparation method of piston rod

A technology of piston rod and shock absorber, applied in the direction of shock absorber, spring/shock absorber, shock absorber, etc., can solve the problems of air density and product density, etc., to improve product density, improve product hardness, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

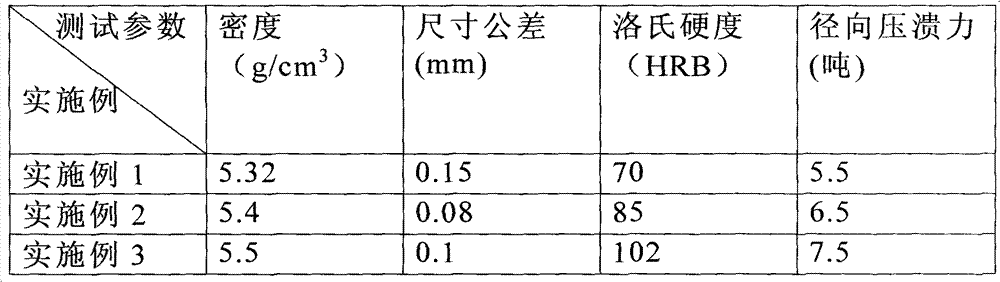

Examples

Embodiment 1

[0036] This embodiment prepares the shock absorber piston rod in the following way:

[0037] (1) Ingredients

[0038] Select 30 parts by weight of reduced iron powder with an average particle diameter of 100 mesh, 0.5 part by weight of electrolytic copper powder with an average particle diameter of 250 mesh, 0.1 part by weight of colloidal graphite, 0.35 part by weight of zinc stearate, and 0.25 part by weight of manganese sulfide, and put them into the cone Fully mix in the conical powder mixer; then add 30 parts by weight of reduced iron powder with an average particle diameter of 100 mesh into the conical powder mixer again. The mixing time is 40 minutes to achieve a full mixing effect.

[0039] (2) Repression

[0040] Put the uniformly mixed powder into an automatic molding machine with a pressing tonnage of 50 tons for pressing.

[0041] (3) Sintering

[0042] The sintering step was performed in a mesh belt furnace; the pre-firing temperature was 750° C., and the pre-...

Embodiment 2

[0048] (1) Ingredients

[0049] Select 55 parts by weight of reduced iron powder with an average particle size of 130 mesh, 0.7 part by weight of electrolytic copper powder with an average particle size of 200 mesh, 0.06 part by weight of colloidal graphite, 0.3 part by weight of paraffin wax, and 0.35 part by weight of manganese sulfide, and put them into the conical mixing powder Mix thoroughly in the machine.

[0050] (2) Repression

[0051] Put the uniformly mixed powder into an automatic molding machine with a pressing tonnage of 30 tons.

[0052] (3) Sintering

[0053] The sintering step was performed in a mesh belt furnace; the pre-firing temperature was 800° C., and the pre-firing time was 30 minutes; the sintering temperature was 1150° C., and the sintering time was 3 hours. During the sintering process of the mesh belt furnace, the flow rate of the combustion gas hydrogen is 30 cubic meters, and the flow rate of the protective gas helium is 30 cubic meters.

[00...

Embodiment 3

[0059] 1) Ingredients

[0060] Select 70 parts by weight of reduced iron powder with an average particle diameter of 100 mesh, 0.6 part by weight of electrolytic copper powder with an average particle diameter of 180 mesh, 0.08 part by weight of colloidal graphite, 0.25 part by weight of polyvinyl chloride emulsion, and 0.3 part by weight of manganese sulfide, and put Mix thoroughly in a cone mixer.

[0061] (2) Repression

[0062] Put the uniformly mixed powder into an automatic molding machine with a pressing tonnage of 50 tons for pressing.

[0063] (3) Sintering

[0064] The sintering step was performed in a mesh belt furnace; the pre-firing temperature was 800° C., and the pre-firing time was 60 minutes; the sintering temperature was 1100° C., and the sintering time was 4 hours. During the sintering process of the mesh belt furnace, the flow rate of the combustion gas hydrogen is 30 cubic meters, and the flow rate of the protective gas helium is 40 cubic meters.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com