Method for machining high-precision hexagonal shaft through ordinary numerical control boring machine

A hexagonal axis, high-precision technology, applied in the field of mechanical processing, can solve the problems of inability to accurately control the rotation angle of the workpiece, the difficulty of machining the high-precision hexagonal axis, and the low machining accuracy. It achieves low cost and easy operation. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings and embodiments.

[0026] A method for processing a high-precision hexagonal axis with an ordinary numerical control boring machine includes the following steps:

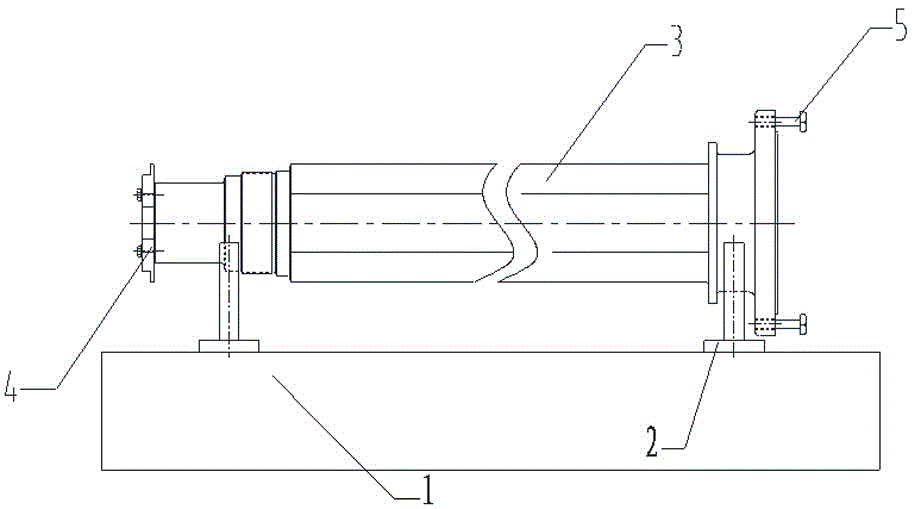

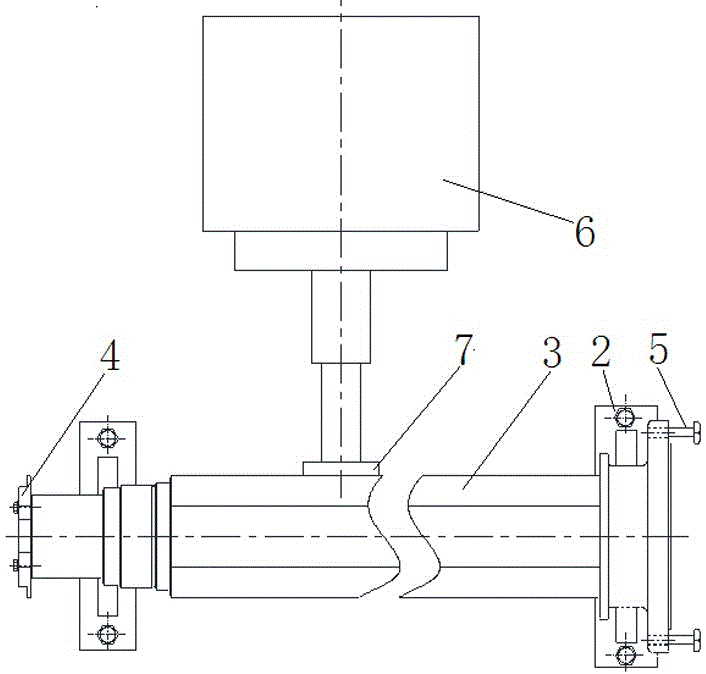

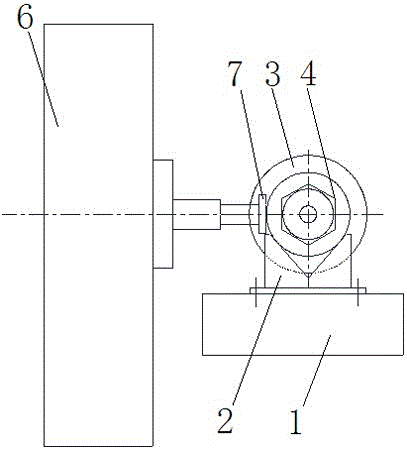

[0027] 1) Such as Figure 1 to Figure 5 As shown, the workbench 1 is set in the processing range of the ordinary CNC boring machine 6, and two symmetrical V-shaped seats 2 are fixed on the worktable 1, (through the dial indicator 8), the level and verticality of the V-shaped seat 2 are checked ; Place the circular parts at both ends of the workpiece 3 on the two V-shaped seats 2 respectively, and check the horizontality and verticality of the workpiece 3 (through the dial indicator 8).

[0028] 2) Compress the workpiece 3 (the two ends of the workpiece 3 can be compressed or loosened by an electric plate, a pneumatic plate or a hydraulic plate, or can be compressed or loosened by two Hough fits), and a hexagon is fixed on one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com