Method for implementing numerical control finish machining for large component of aeroplane based on digitalization error compensation template

An error compensation and large part technology, which is applied in the field of CNC finishing of the intersection of large parts of aircraft, can solve the problem that the motion positioning accuracy cannot meet the requirements of the finishing of the intersection of large parts of the aircraft.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

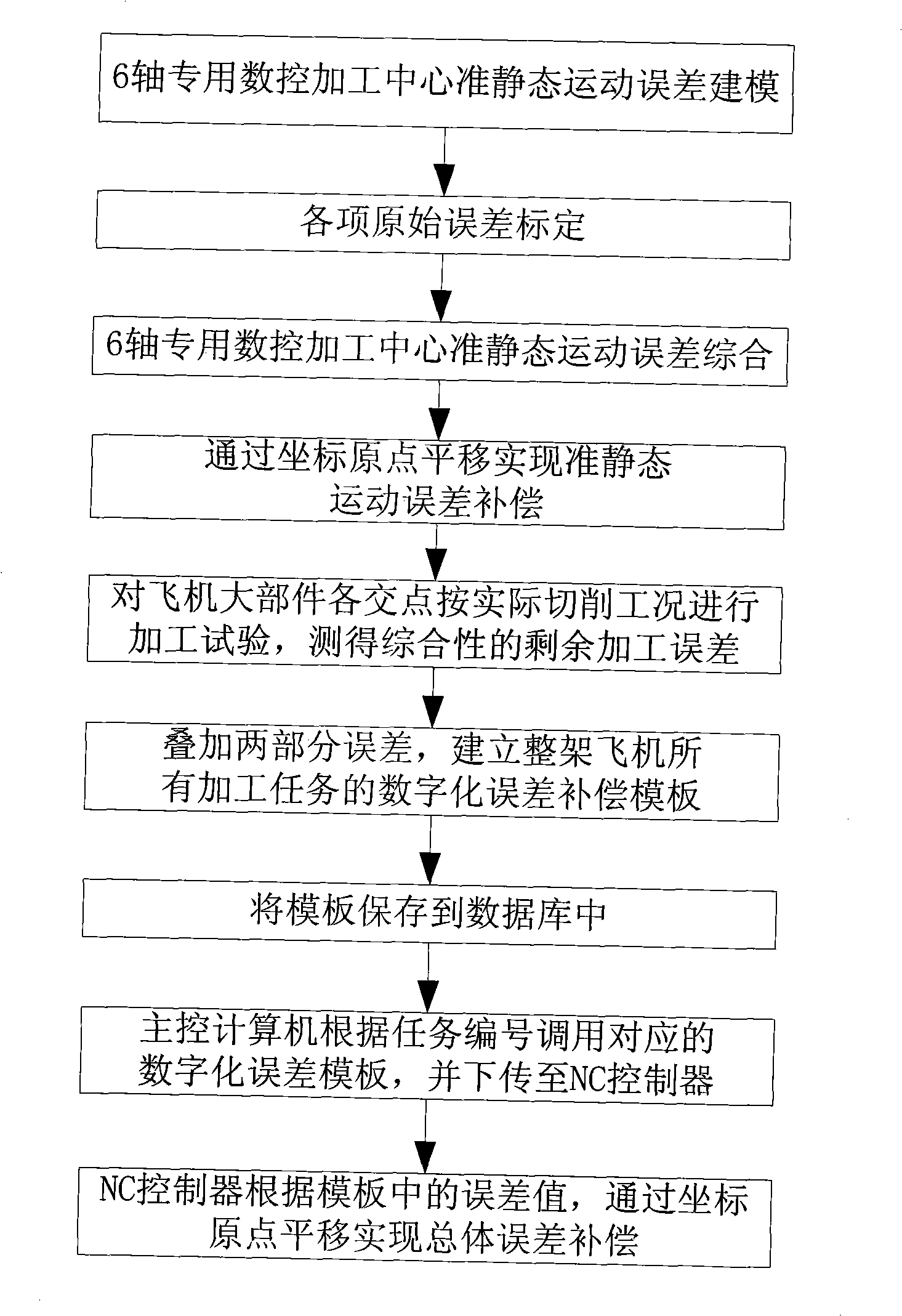

[0038] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment is based on the digitized error template to realize the error compensation method for finishing the intersection of large parts of the aircraft, which is realized according to the aforementioned scheme.

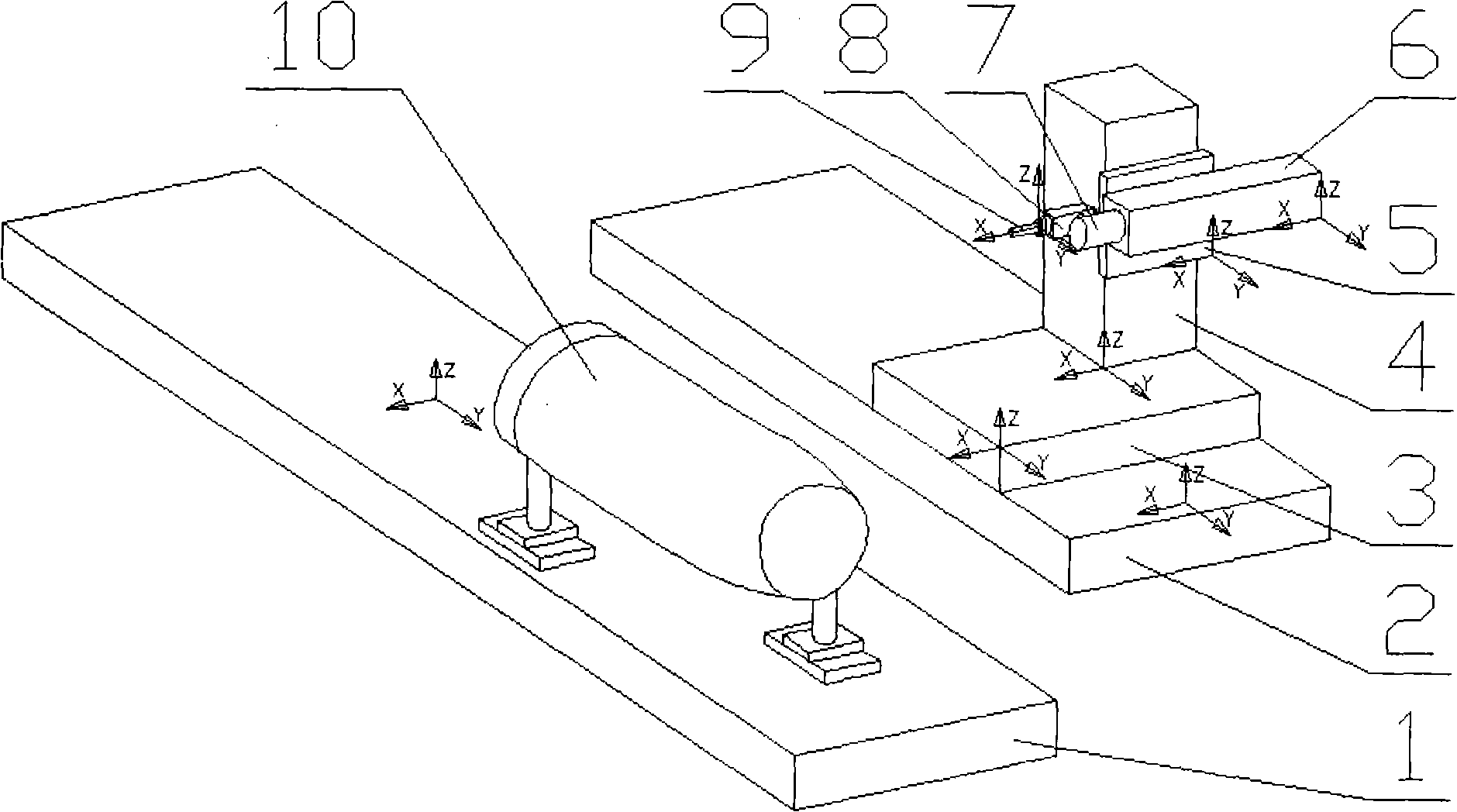

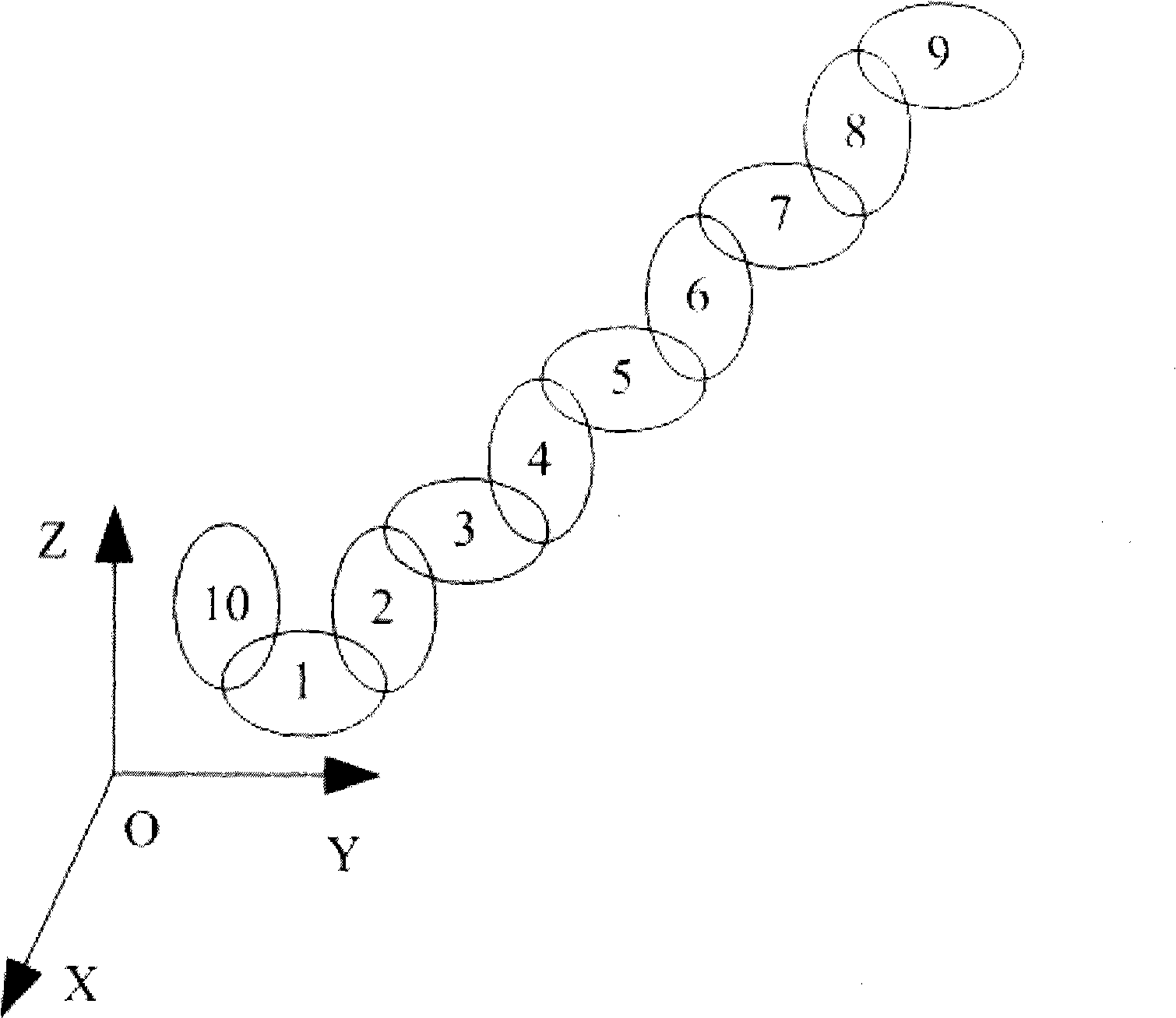

[0039] The processing equipment in this embodiment is a 6-axis special-purpose horizontal CNC machining center, and its structure is as follows figure 1 shown. The overall fuselage 10 as a large part is positioned and held on the middle base 1 by the flexible attitude-adjusting support system, and its posture is adjusted to be as consistent as possible with the theoretical digital model by the attitude-adjusting support system. Create a reference coordinate system for the butt assembly. The base 2 of the machining center and the intermediate base 1 are fixed on the same basic platform. The linear motion guide rail is arranged on the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com