Movable optical element adjusting and positioning device

A technology for adjusting positioning and optical components, which is applied to optical components, optics, photolithography process exposure devices, etc., can solve the problems of high cost of adjusting positioning devices, small adjustment and positioning range, and inaccurate positioning, and achieves compact structure and stable operation. , good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

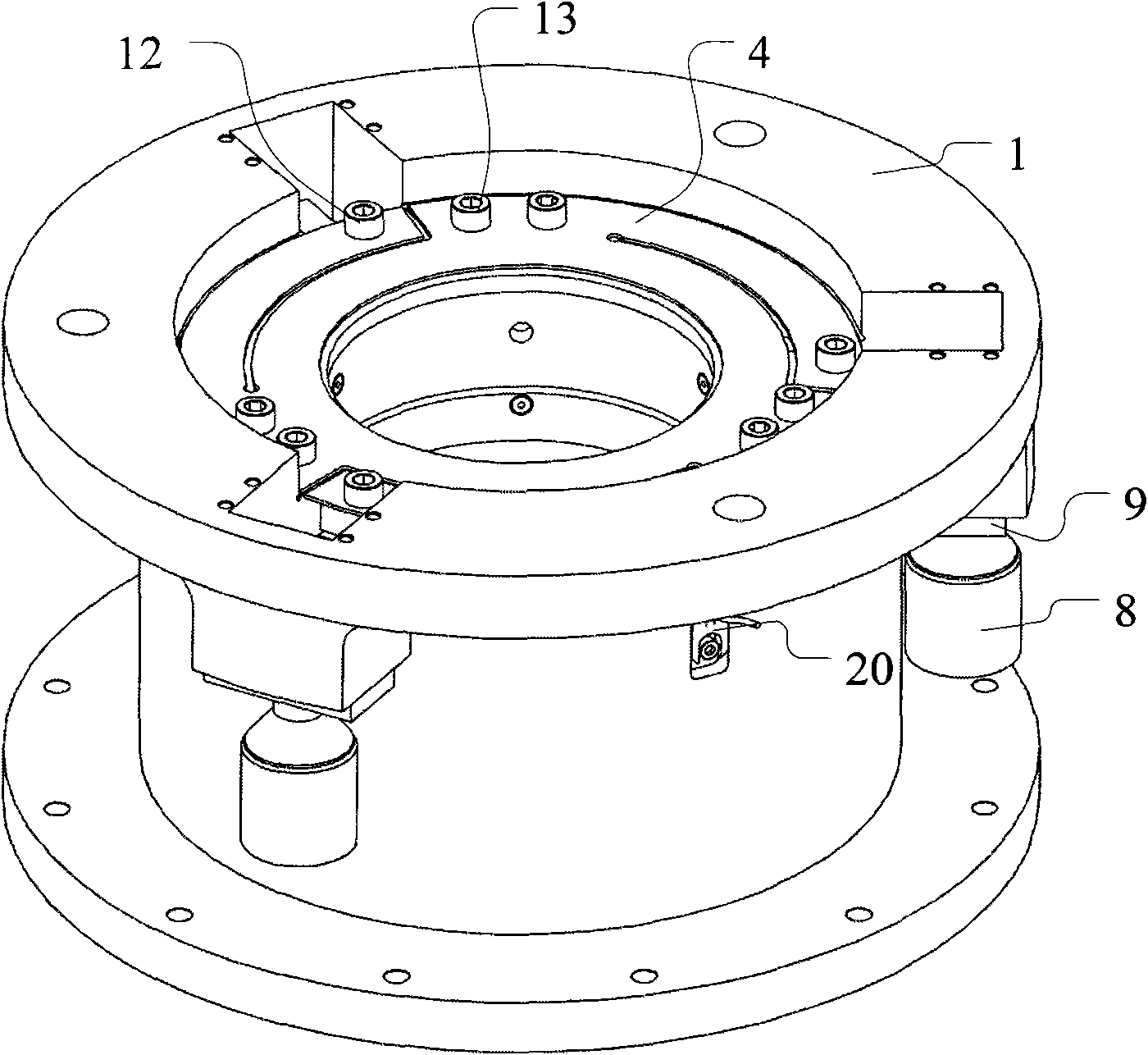

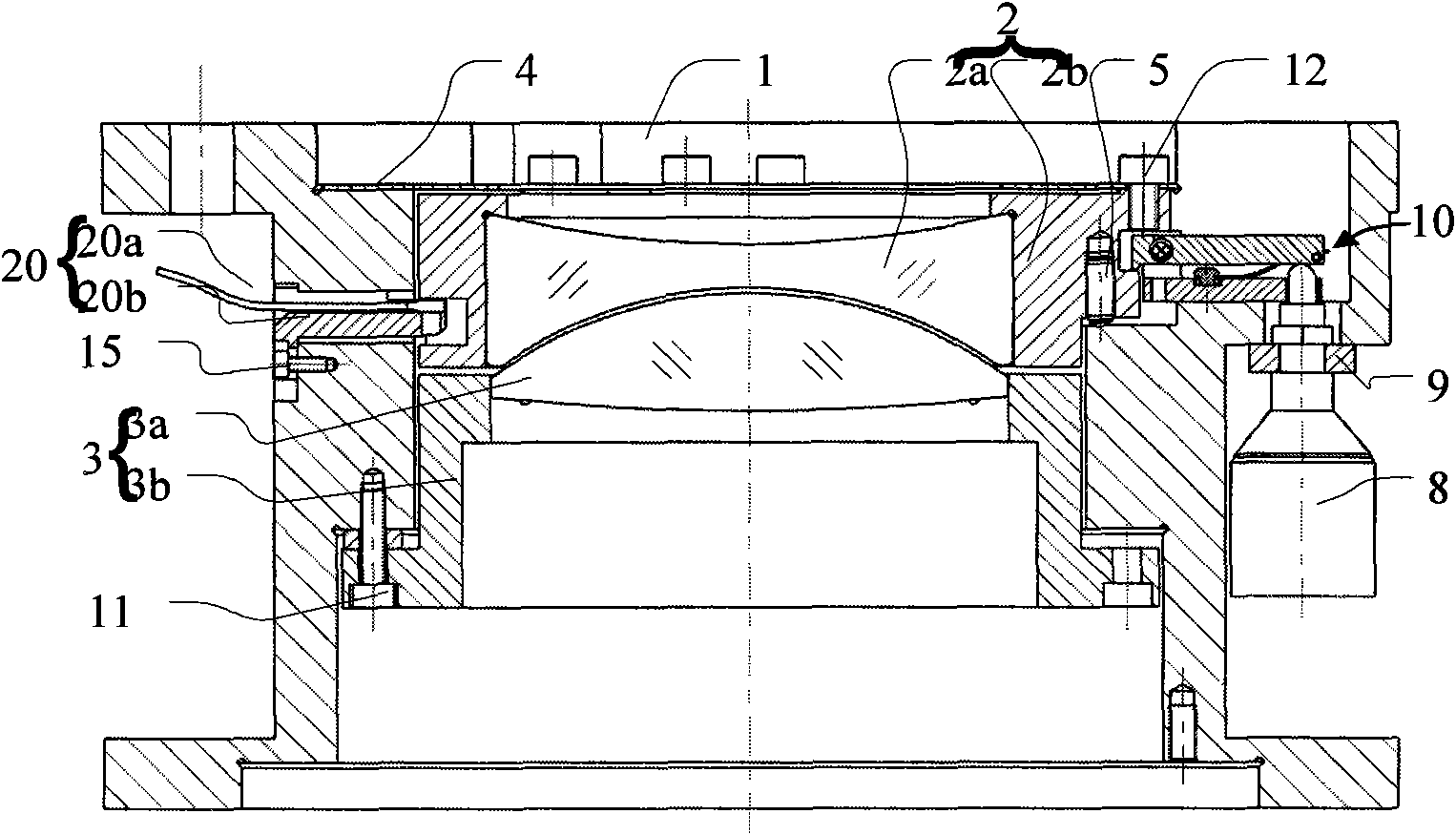

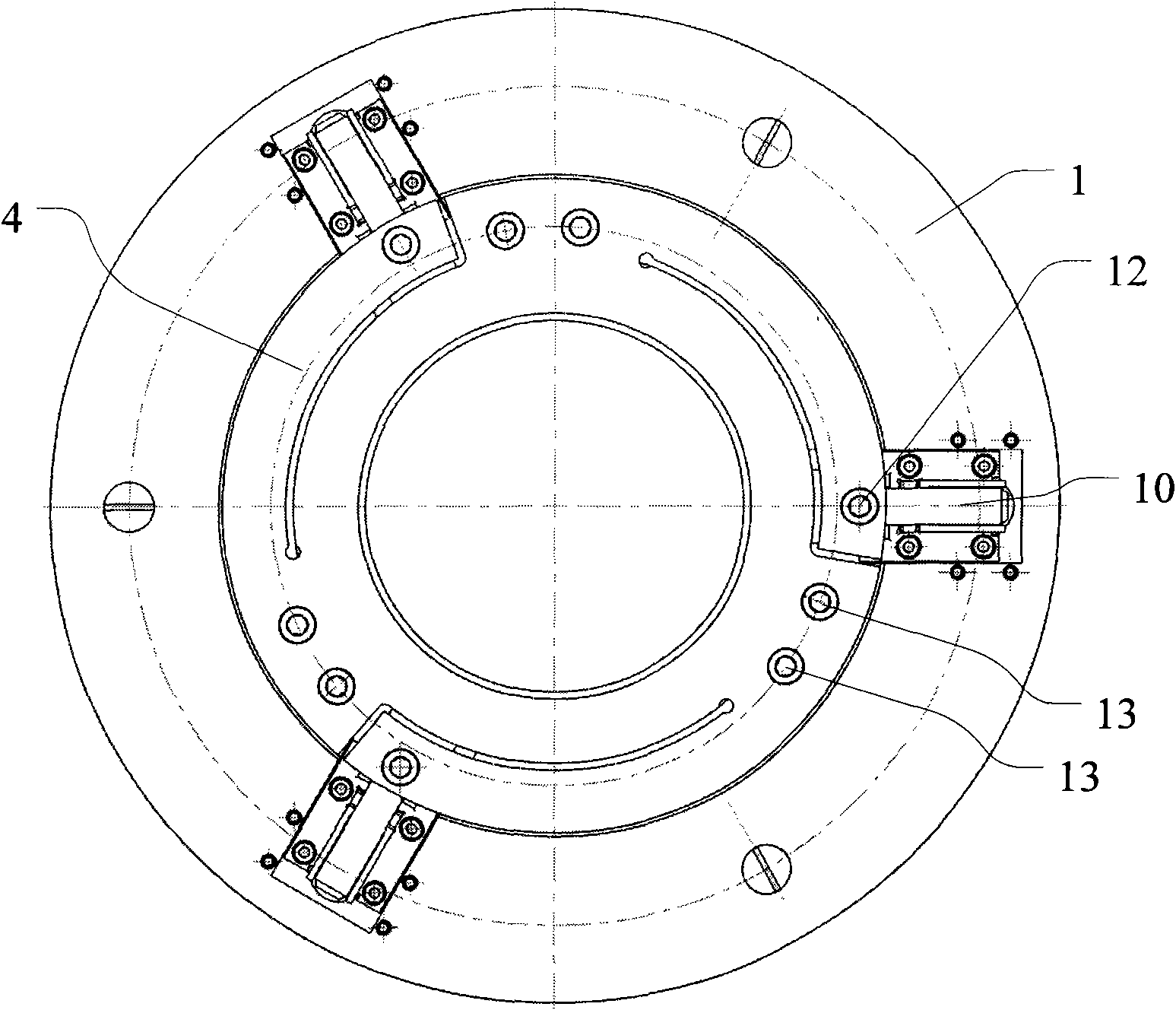

[0022] figure 1 The basic structure diagram of the adjustable positioning device for the movable optical element, figure 2 is a cross-sectional view of the basic structure, image 3 It is the bottom view of the basic structure, Figure 4 A schematic diagram of the motor drive mechanism.

[0023] combined reference Figure 1~4 , this embodiment provides an axial adjustment and positioning device for optical elements in exposure equipment, the device is to adjust the position of the movable mirror group lens 2a relative to the fixed mirror group lens 3a, including axial adjustment and horizontal tilt adjustment.

[0024] The axial adjustment and positioning device of the movable optical element mainly includes: the main lens barrel 1, the movable mirror group 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com