Ultra-precise silicon wafer positioning system with balance weight damping apparatus

A positioning system and balancing block technology, which are applied to photolithography process exposure devices, microlithography exposure equipment, etc., can solve the problems of increasing the volume of the positioning system, affecting the positioning accuracy of silicon wafers, and difficulty in controlling the temperature of silicon wafers or masks. , to achieve the effect of improving motion accuracy, eliminating vibration and reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

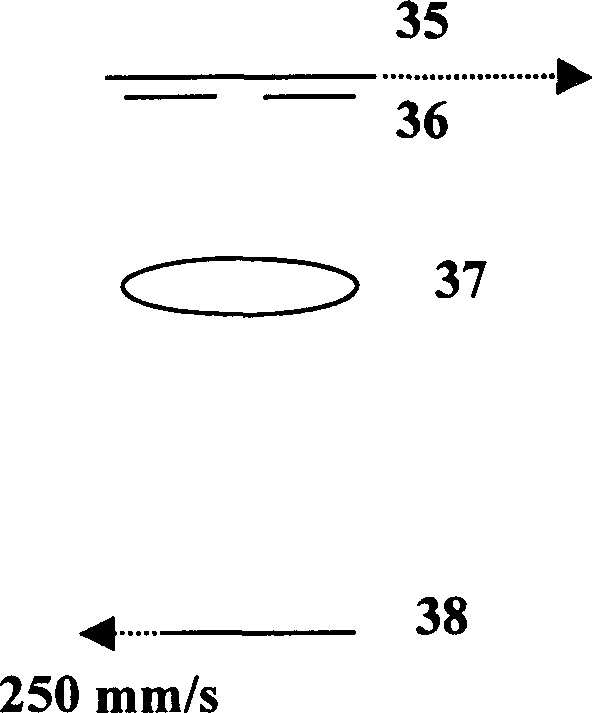

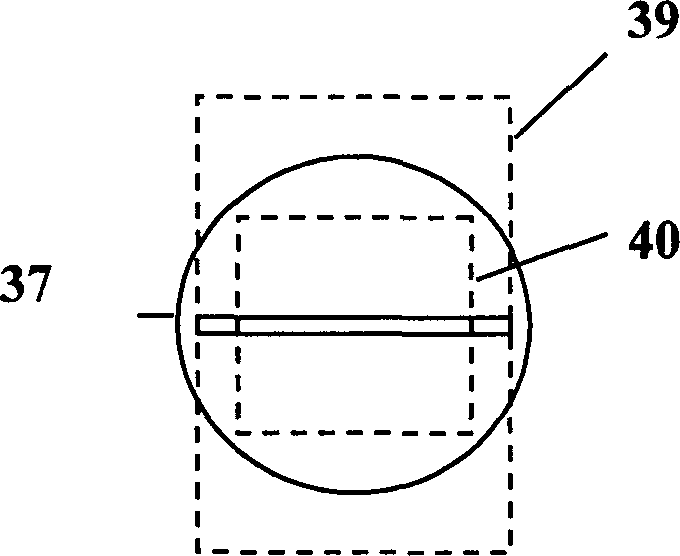

[0064] The invention uses the principle of momentum conservation to eliminate the vibration caused by the motion reaction force of the ultra-precision silicon chip positioning system in the photolithography machine during operation. The system includes silicon wafer carrying devices 7a, 7b, linear motors 8a, 8b, 9a, 9b for Y-direction scanning drive, linear motors 10a, 10b, 11a, 11b for X-direction stepping drive, and double-sided Linear guides 5a, 5b.

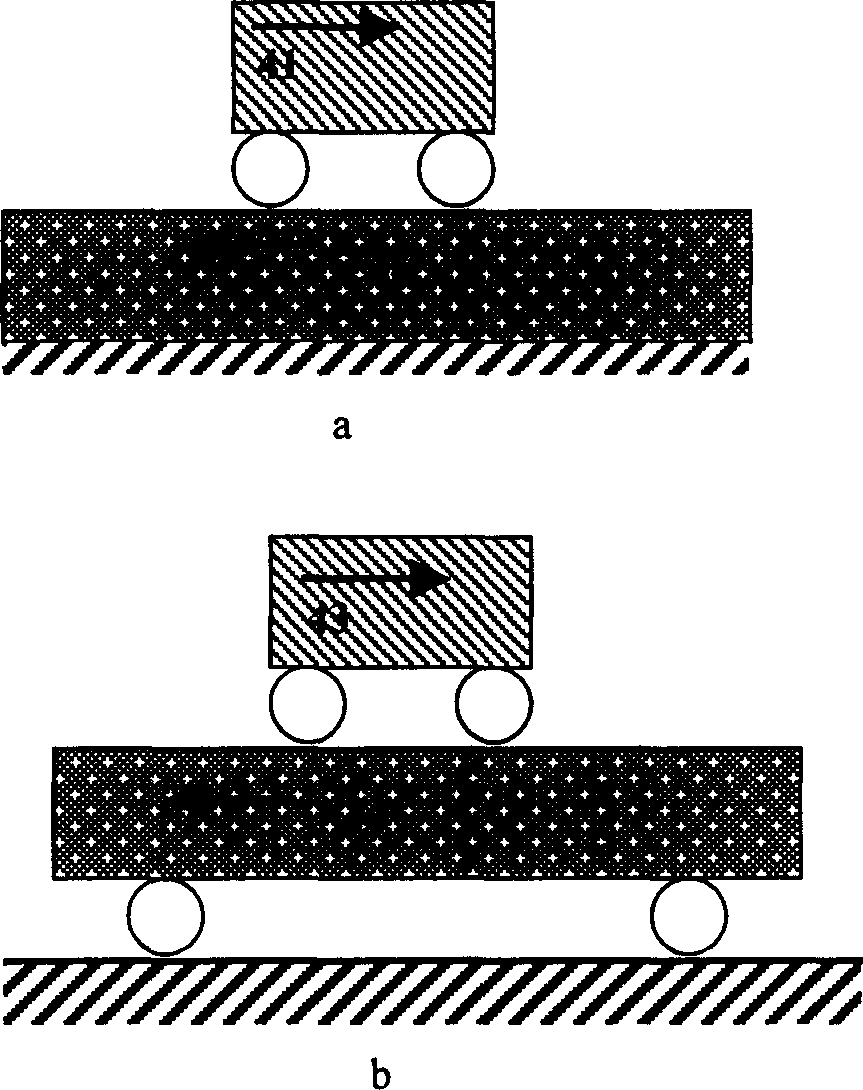

[0065] The balance weight 3 is supported on the sub-base 2 by air bearings and air bearings 4a, 4b, and can move freely along the X and Y directions. The momentum conservation system composed of the balance weight system, the wafer carrying device, its drive motor and guide rail can effectively reduce the vibration caused by the motion reaction force.

[0066] The interior of the balance block is equipped with a momentum wheel system composed of a momentum wheel 17, a rotary servo motor 16, a rotary air bearing 18 and an angu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com