Automatically-positioned power unit test bench

A power unit and automatic positioning technology, which is applied in the testing of mechanical components, testing of machine/structural components, testing of machine gears/transmission mechanisms, etc., can solve problems such as adverse effects of power units, and achieve good contact and uniform force Effect

Active Publication Date: 2016-07-13

ANHUI HELI CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this case, after the wheel of the power unit is under pressure, the force that does not pass through the center of the wheel is likely to generate additional partial load force, which makes the force on the gears in the gear box of the power unit inconsistent with the actual working conditions, and the noise of the test is difficult. In line with the actual situation, it is also easy to have adverse effects on the power unit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

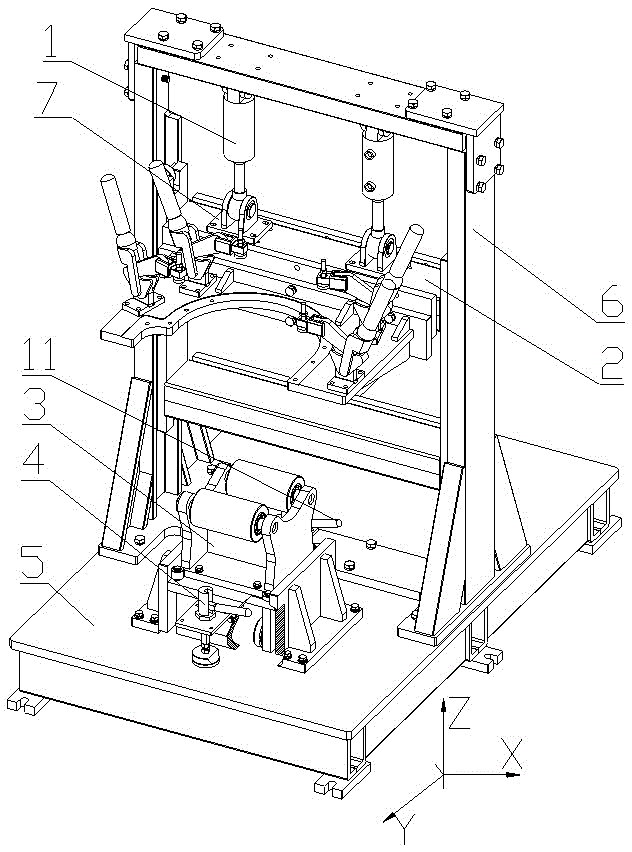

[0042] see figure 1 . An automatic positioning power unit test bench includes a test bench support, an assembly tool 2 and a carrying device 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

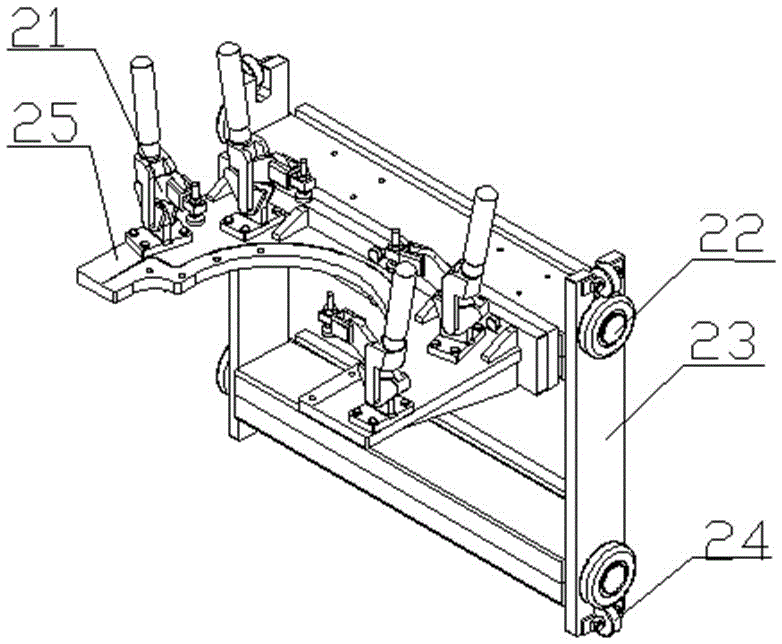

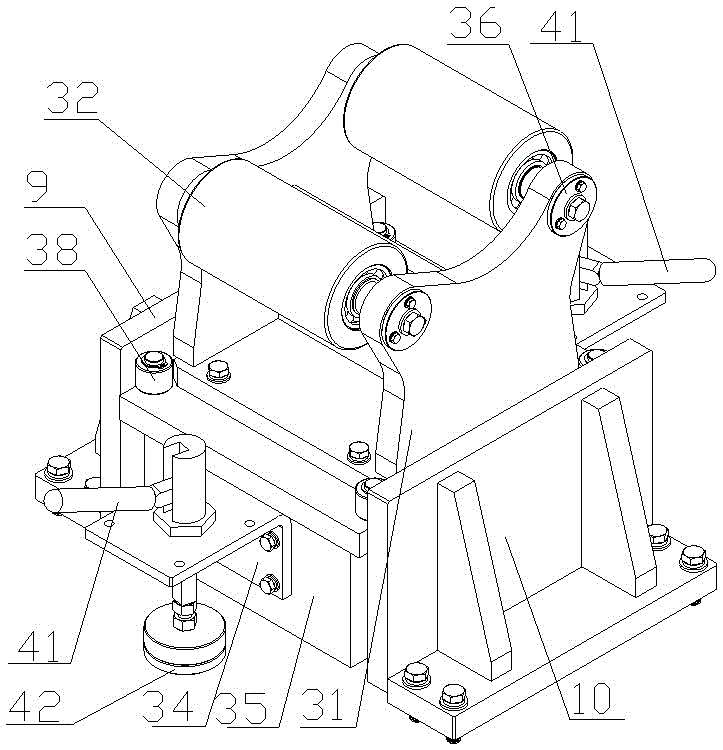

The invention relates to an automatically-positioned power unit test bench, which comprises a test bench support, an assembly tool and a bearing device, wherein the test bench support is composed of a flat plate-shaped base and a door frame-type frame; the frame is uprightly arranged on the top surface of the base; two oil cylinders are parallelly suspended in a channel steel frame; the tail part of each oil cylinder is connected onto the upper crossbeam of the channel steel frame; the piston rod end of the oil cylinder is hinged onto an upper plane of an upper crossbeam of a mounting pulley of the assembly tool; twalking rollers and adjusting rollers of the mounting pulley are respectively arranged in channel steel frame notches; the front part of the mounting frame is provided with a semi-arc notch connected onto the front side of the upper crossbeam of the mounting pulley; four quick clamping devices are arranged around the semi-arc notch on a rib plate upper plane of the mounting fame; and the central position of the arc is corresponding to that between a front bearing roller and a rear bearing roller of a roller supporting frame. The automatically-positioned power unit test bench has the beneficial effects that relative positions between a bearing device and a tested piece are kept consistent, and rolling friction is realized between wheels of the tested piece and the bearing mechanism.

Description

technical field [0001] The invention relates to a simulated power unit test bench, in particular to a power unit test bench capable of automatic positioning. Background technique [0002] For electric forklifts, it is necessary to develop a power unit detection test bench, which can test the noise and running resistance of the power unit under high speed and load conditions, and the test bench can simulate the force state of the power unit in the whole vehicle. [0003] When the whole vehicle is running at high speed, the power unit of the vehicle is subjected to the force of the weight of the whole vehicle, and its direction is vertically downward. It should also go through the center of the wheel. When the existing forklift power unit is tested, the test bench seldom simulates this stress state, and no test bench can accurately pass the downward force through the center point of the wheel. In this case, after the wheels of the power unit are under pressure, the force tha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01M13/02

CPCG01M13/027

Inventor 施文静

Owner ANHUI HELI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com