Hydraulic vibration active isolation platform

A technology for isolating platform and hydraulic vibration, applied in non-rotating vibration suppression, machine platform/bracket, supporting machine, etc., can solve the problems of low-frequency and large-amplitude vibration isolation, etc., achieve high positioning accuracy, eliminate hinge gap, and high motion accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in conjunction with the accompanying drawings.

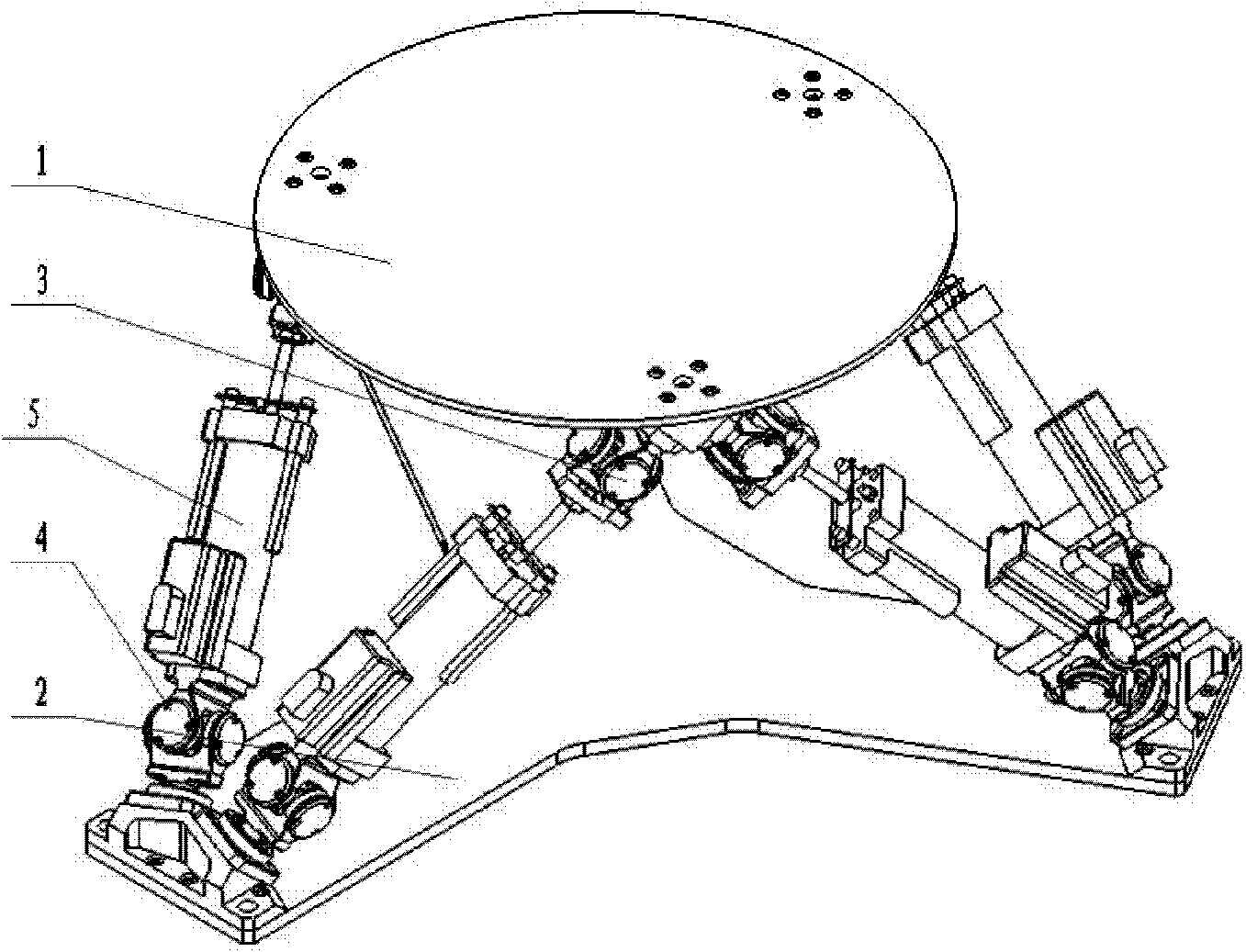

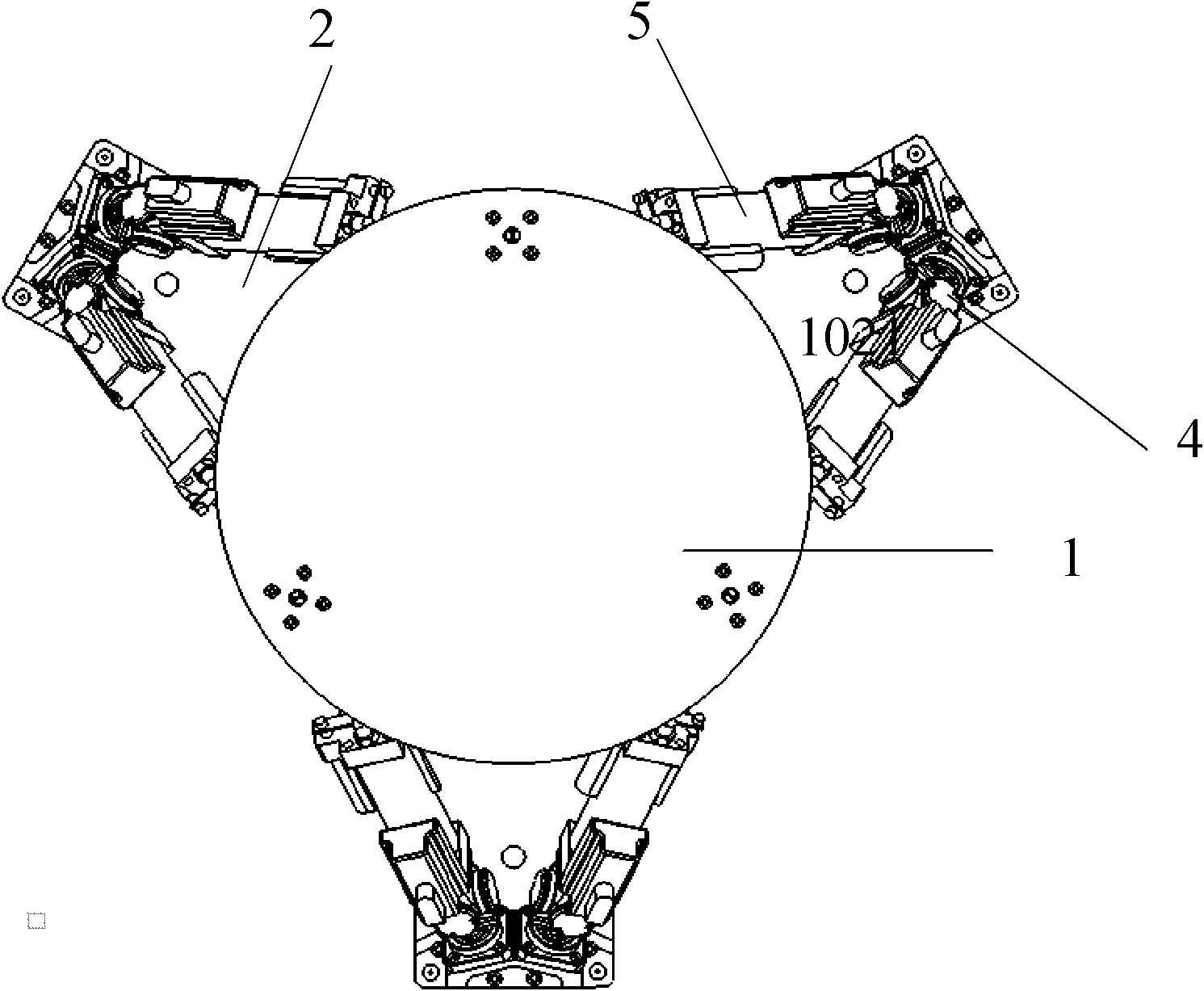

[0043] A hydraulic vibration active isolation platform proposed by the present invention, such as figure 1 and figure 2 As shown, it includes an upper platform 1, a lower platform 2, a two-degree-of-freedom Hooke hinge 3, a three-degree-of-freedom Hooke hinge 4, and a hydraulic active lever 5.

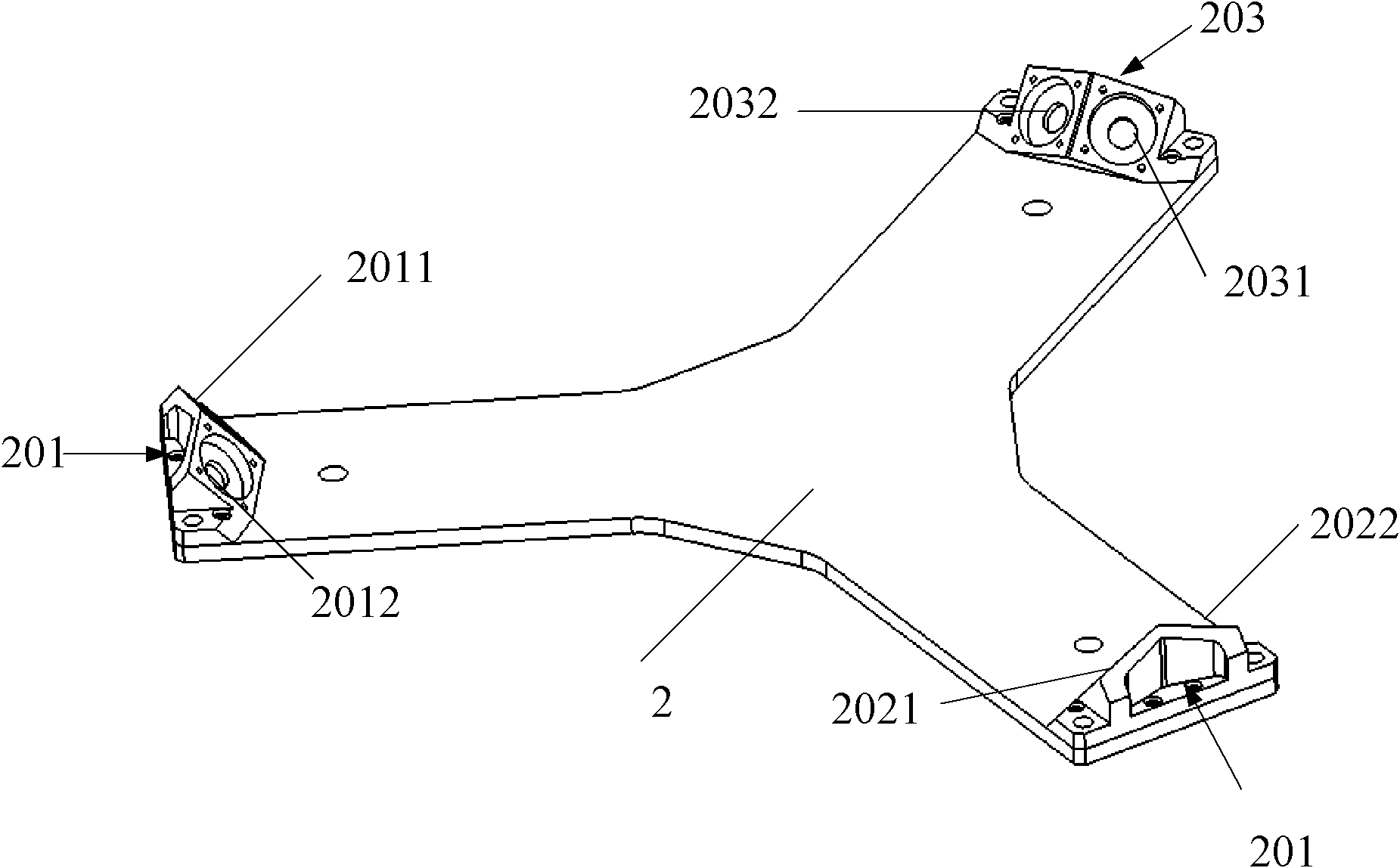

[0044] The lower platform 2 is preferably a plane herringbone structure to reduce weight, such as image 3 As shown, a lower base A201, a lower base B202, and a lower base C203 are symmetrically arranged on the edge of the lower platform 2, and the lower base A201, the lower base B202, and the lower base C203 are connected to the lower platform by bolts. 2 The upper and lower bases A201 are provided with centering holes a2011 and centering holes b2012, the lower base B202 is provided with centering holes c2021 and centering holes d2022, and the lower base C203 is provided ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Resolution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com