An Orthogonal Configuration Six Degrees of Freedom Vibration Simulation System and Method for Full Vertical Actuators

A technology for simulating systems and actuators, used in vibration testing, testing of machine/structural components, measuring devices, etc. It can solve problems such as bulky volume and complex structure, and achieve good output linearity, fast response, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0083] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

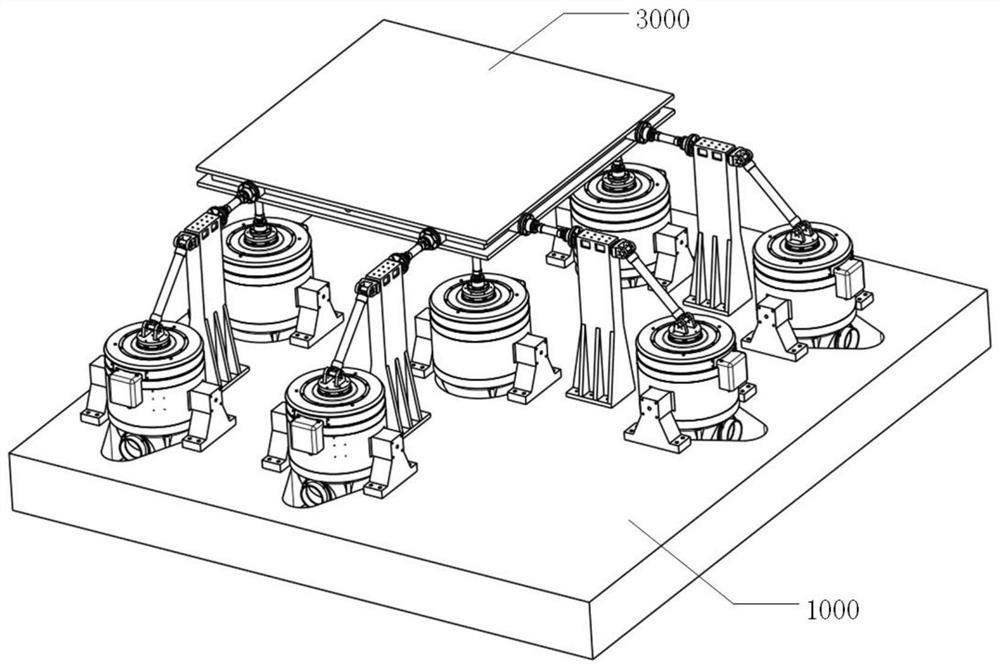

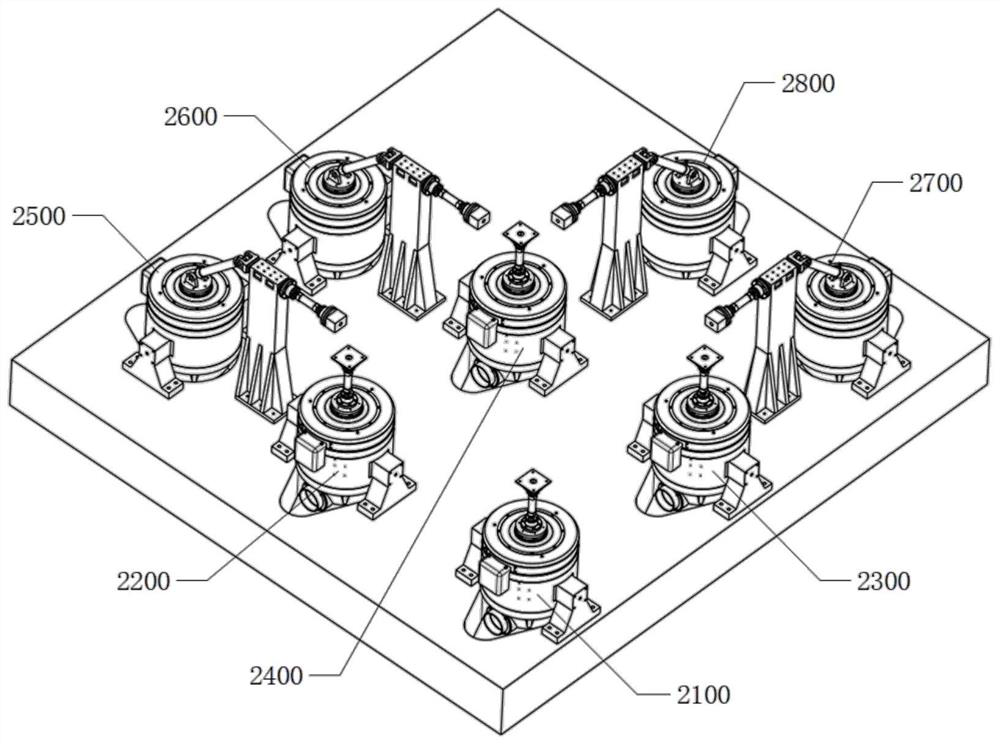

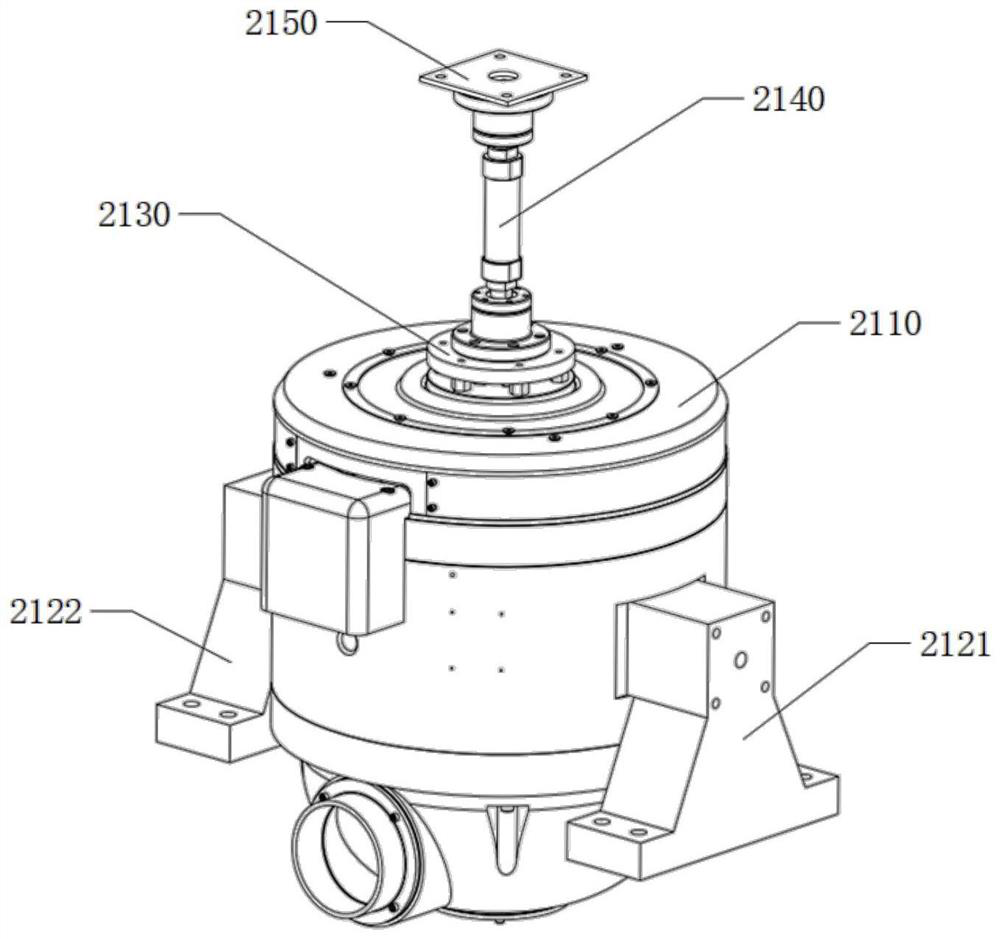

[0084] An orthogonal configuration six-degree-of-freedom vibration simulation system with full vertical actuators of the present invention includes an upper platform assembly, eight actuator branches, a lower platform and a real-time control hardware system; the upper platform assembly and the lower platform pass through Eight actuator branches are connected, of which four vertical output actuator branches are located under the upper platform, and the other four oblique output actuator branches are divided into two groups and arranged on two sides of the upper platform perpendicular to each other. All the actuators are installed in the vertical direction. The four actuators under the upper platform output the vertical force, and the four actuators on the side transmit the force to the horizontal direction through the guide rail slider mechanism. The a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com