Air-float magnetic controlled precision movement platform

A precision motion and platform technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as mechanical friction and heat generation, and achieve the elimination of friction and wear, avoid mechanical contact, and fast response control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

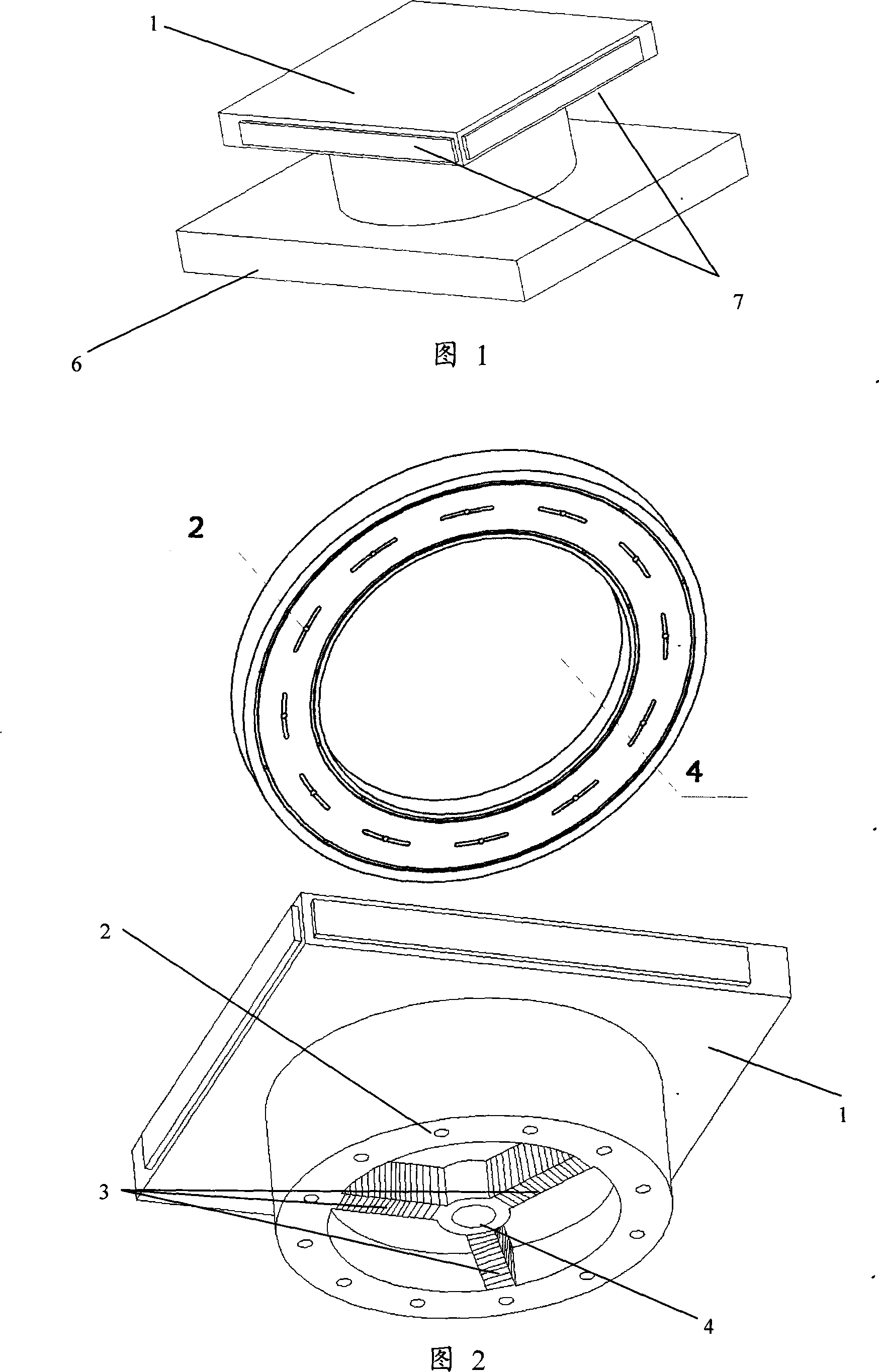

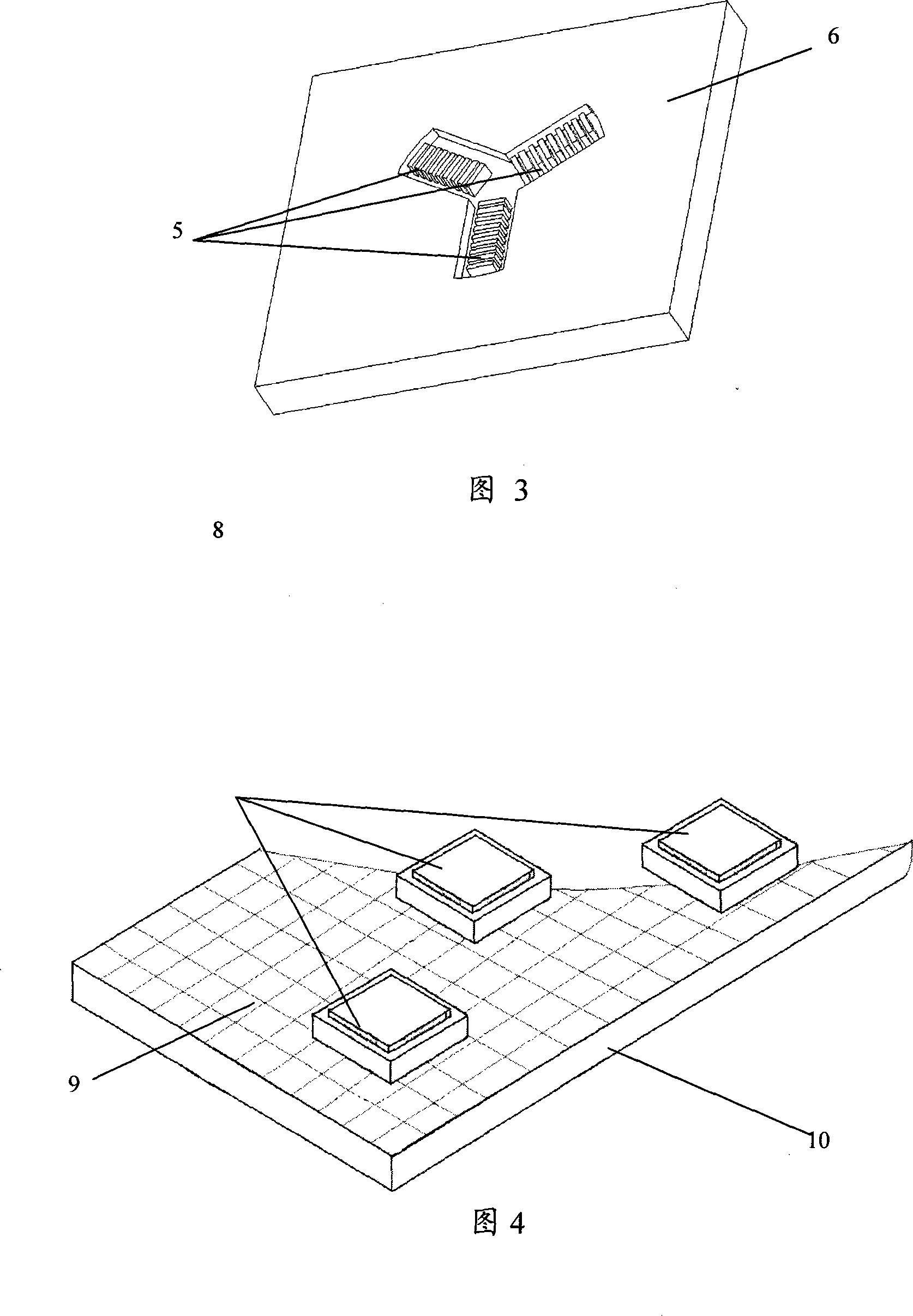

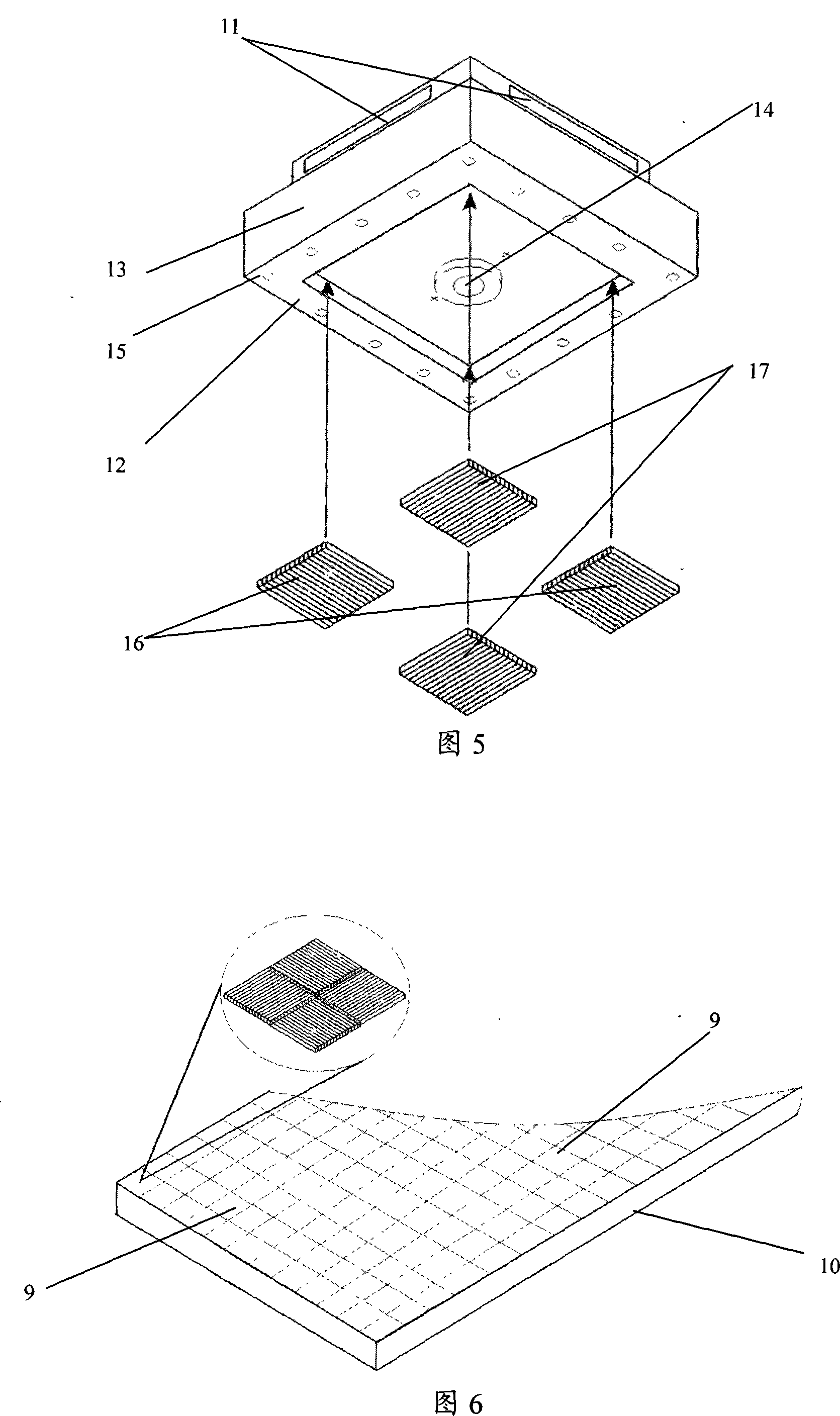

[0023] Figures 1, 2 and 3 are the single mover and single stator air-floating magnetic control precision motion platform of the present invention. It is mainly used for short-stroke motion and can be used as a micro-motion stage for ultra-precise plane positioning. Figures 4, 5 and 6 are multi-mover and single-stator air-floating magnetic control precision motion platforms of the present invention. It can be used as a parallel multi-station large-stroke precision motion platform.

[0024] As shown in FIG. 1 , the single mover and single stator precision motion platform of the present invention includes a suspendable mover platform 1 and a stator platform 6 . As shown in Figure 2, there are three sets of thrust coils 3 equally distributed on the bottom of the single mover platform, and the arrangement direction of each set of thrust coils 3 points to the center of the bottom of the mover platform. The air bearing 2 of the mover platform 1 is an outer annular structure, and ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com