Method for friction compensation of ball screw feeding system

A ball screw and feed system technology, applied in general control systems, control/adjustment systems, instruments, etc., can solve problems such as control rules relying on experience and expert knowledge, and fuzzy control learning ability is not strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

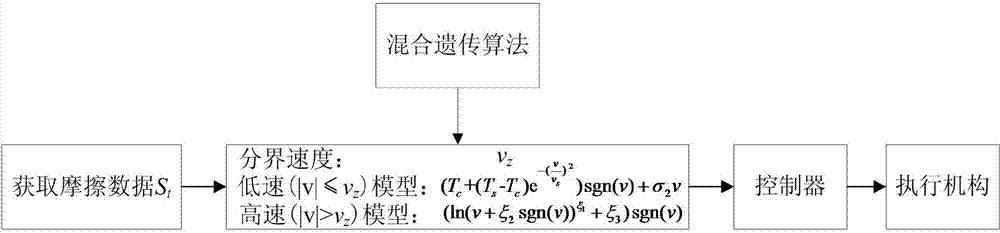

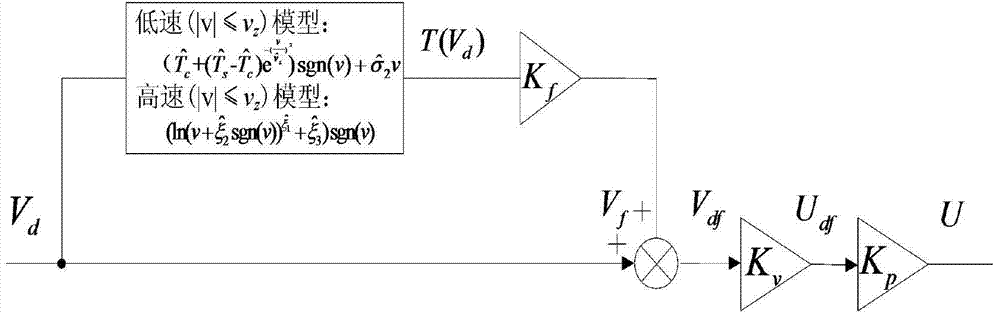

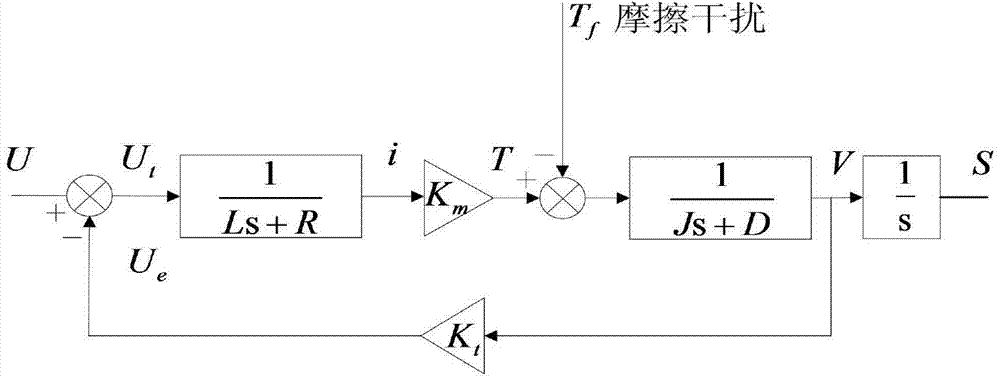

[0091] The present invention is a model-based friction feed-forward compensation method. The compensation strategy is firstly to collect the friction data of the system, and at the same time establish a mathematical model that can accurately describe the friction of the system. Perform offline identification. Then, use this friction model in the controller to estimate the friction disturbance at the command speed of the system, and add the corresponding speed compensation amount to the command speed. Finally, use the compensated signal to control the operation of the feed mechanism.

[0092] The concrete steps of the specific embodiment of the present invention are as follows:

[0093] 1. Specify the speed v when the ball screw runs at a constant speed i , to obtain the armature current I(v i ) and moment constant k t .

[0094] speed v i When , the motor output torque and armature current satisfy the following relationship:

[0095] m i =k t ·I(v i ) (1)

[0096]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com