Walking and positioning device for walking and positioning on workpiece

A technology of workpiece and walking unit, which is applied in metal processing and other directions, can solve the problems of additional installation rails, high burr height, and more tooling requirements, and achieve the effect of meeting processing requirements, large range of motion, and more range of motion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

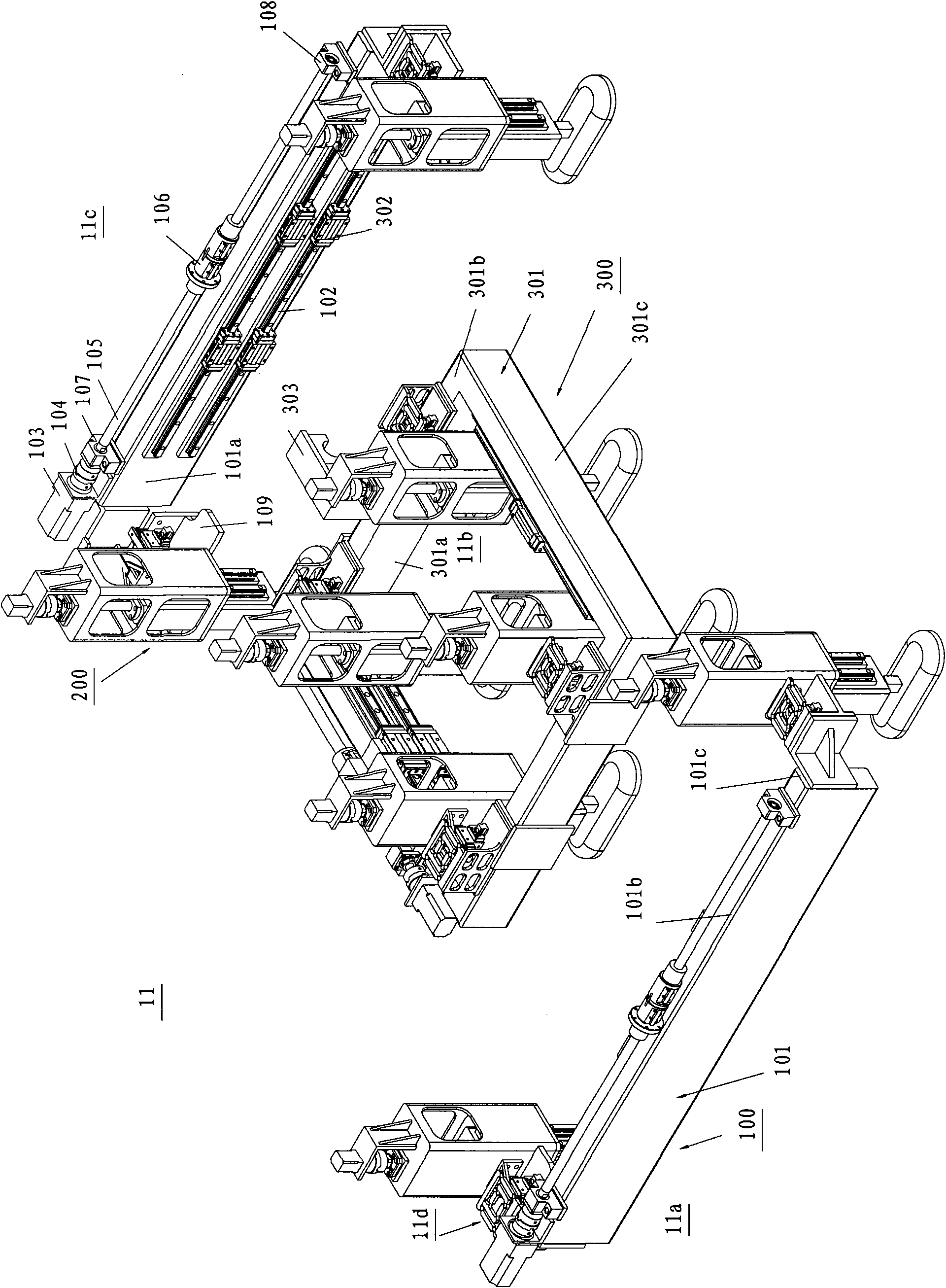

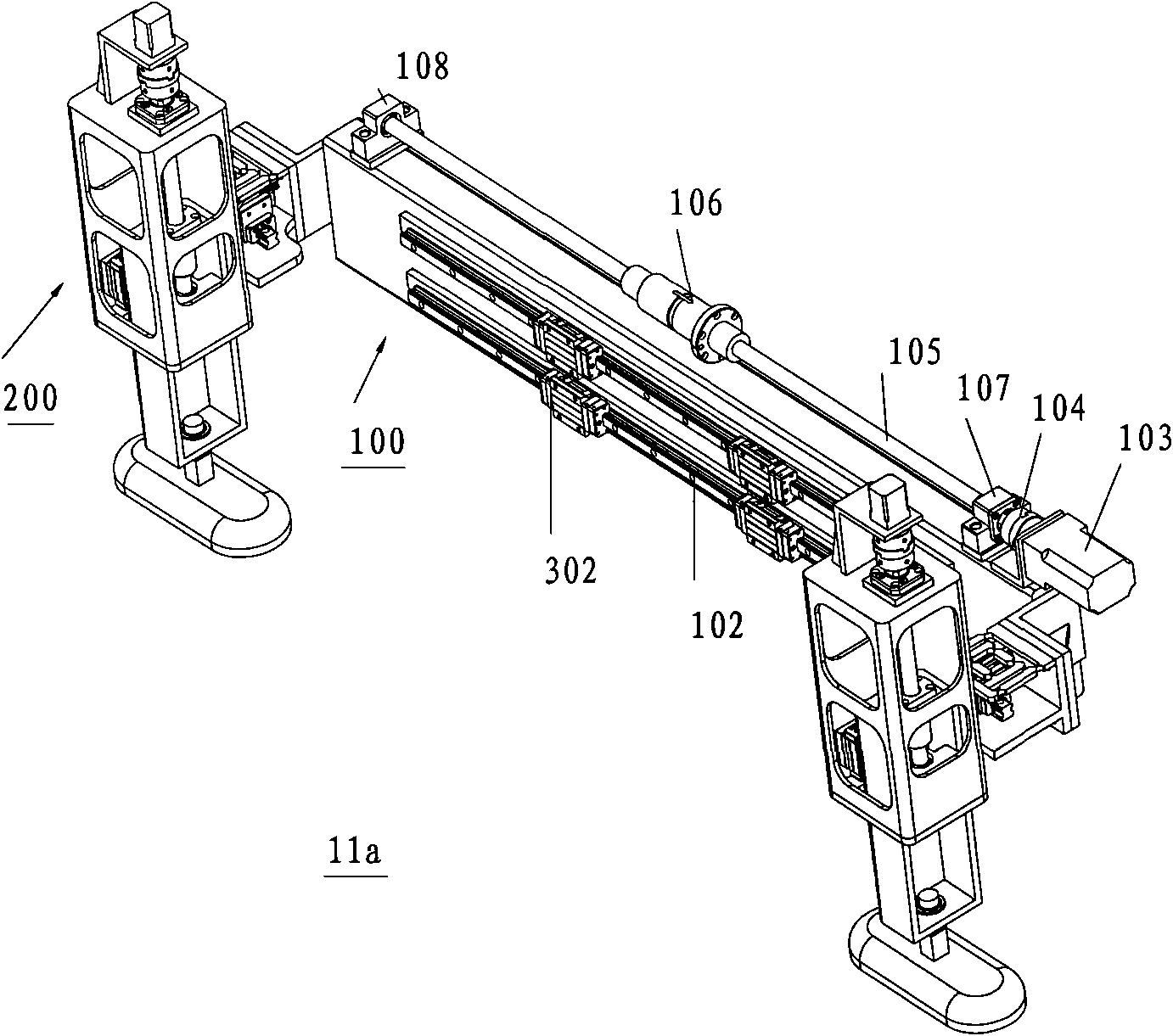

[0041]The relationship between the X direction, the Y direction and the Z direction described below is that the X direction and the Y direction are perpendicular to each other on the horizontal plane, and the Z direction is perpendicular to the X direction and the Y direction on the vertical plane. However, it can be understood that X, Y and The Z direction is indicative rather than specific.

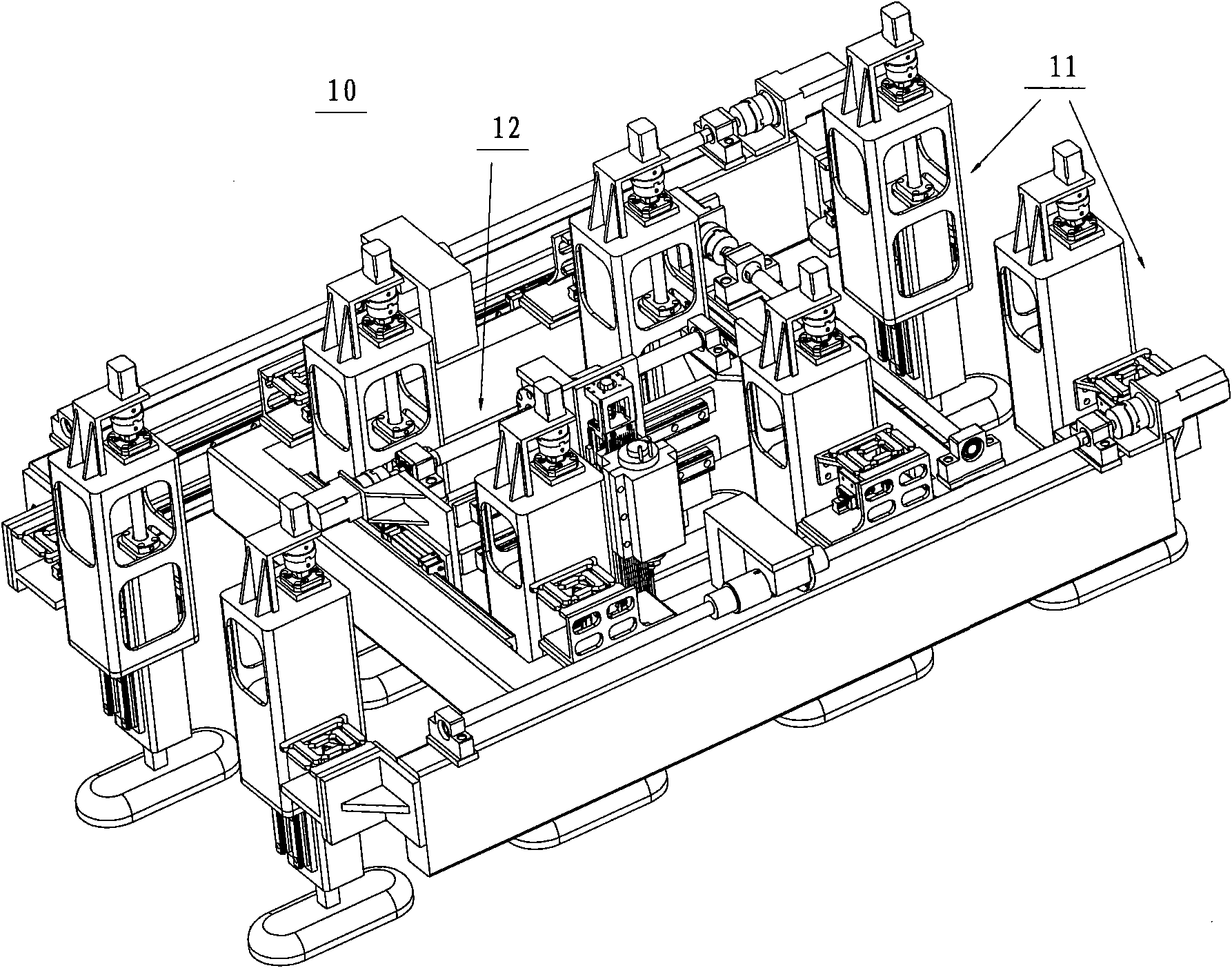

[0042] Such as figure 1 As shown, the walking positioning device (10) includes a traveling mechanism (11), a positioning mechanism (12), an actuator (not shown) and a central processing unit (not shown). The walking mechanism (11) can advance on the surface of the workpiece and reach the designated assembly area according to the instructions issued by the central processing unit, and the positioning mechanism (12) is used for precise positioning in the X and Y directions in the assembly area, that is, Find the X and Y coordinates according to the instructions issued by the central proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com