Tool magazine and automatic tool changer comprehensive performance detecting system

A technology of automatic tool change and comprehensive performance, which is applied in the direction of automatic control devices, positioning devices, feeding devices, etc., can solve the problems of difficult comprehensive performance detection, meet the requirements of lowering the technical level, and have strong portability and strong pertinence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

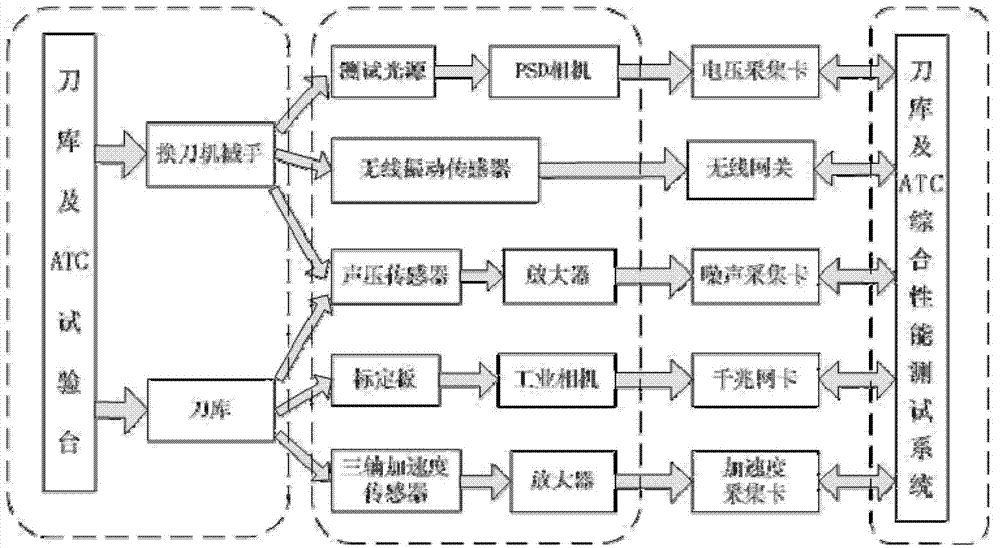

Method used

Image

Examples

specific Embodiment approach

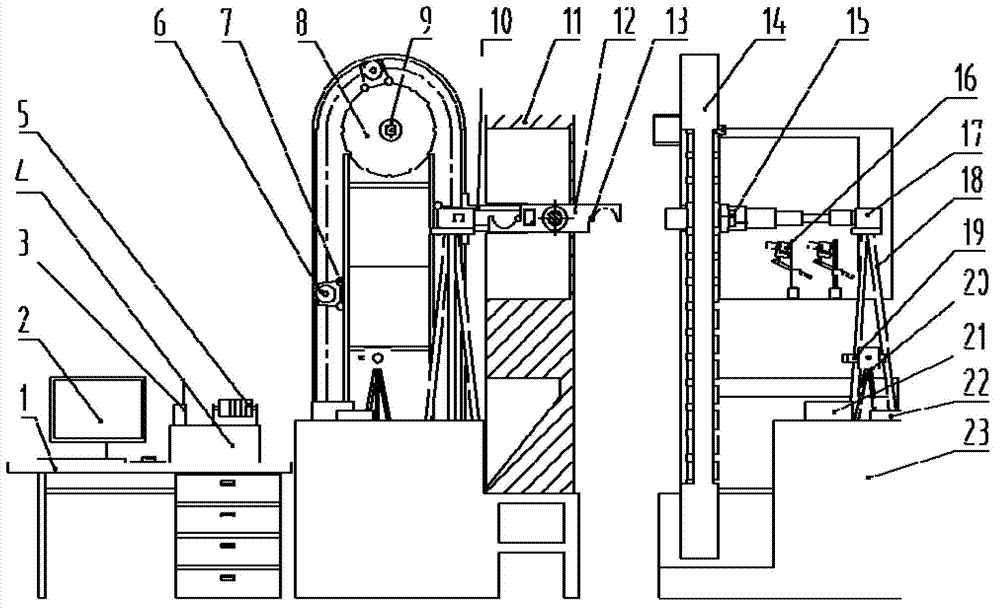

[0026] (1) Detection system hardware selection

[0027] The tool magazine 14 used in the experiment of the present invention is a large-scale chain tool magazine LS5040Z and a high-speed disc magazine YP5030G produced by Dalian Gaojin CNC Group. The test light source 13 used in the measurement of the motion accuracy of the tool changing manipulator is a 3W high-power infrared planar LED light source with a center wavelength between 800nm and 950nm. The driving power and control unit are provided by a remote control circuit composed of a single-chip microcomputer. The PSD camera 16 is composed of the C10443-03 PSD module produced by Japan Hamamatsu Photonics Co., Ltd., the Taiwan Inkon 6205 magnetic base and the connecting plate. stiffness. The power supply and signal processing unit of the PSD module adopts the C10460 type of Japan Hamamatsu Photonics Co., Ltd., and its typical analog voltage output is ±10V, which corresponds to the coordinate value of the projected light s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com