Three-coordinate positioner with large stroke, high rigidity and high precision

A three-coordinate locator, high-rigidity technology, used in workpiece clamping devices, assembly machines, metal processing equipment, etc., can solve the problems of large volume, long production cycle, large workload, etc., and achieve large working strokes and improve safety. Sex, safe use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

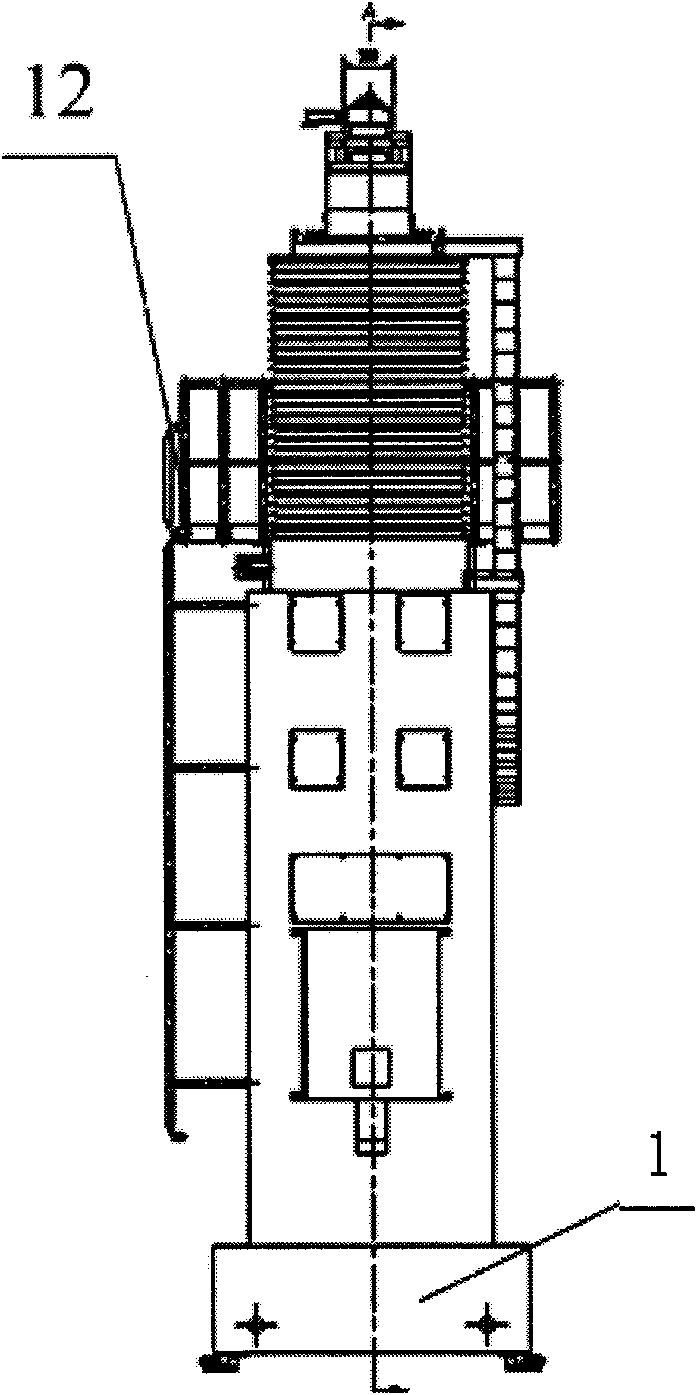

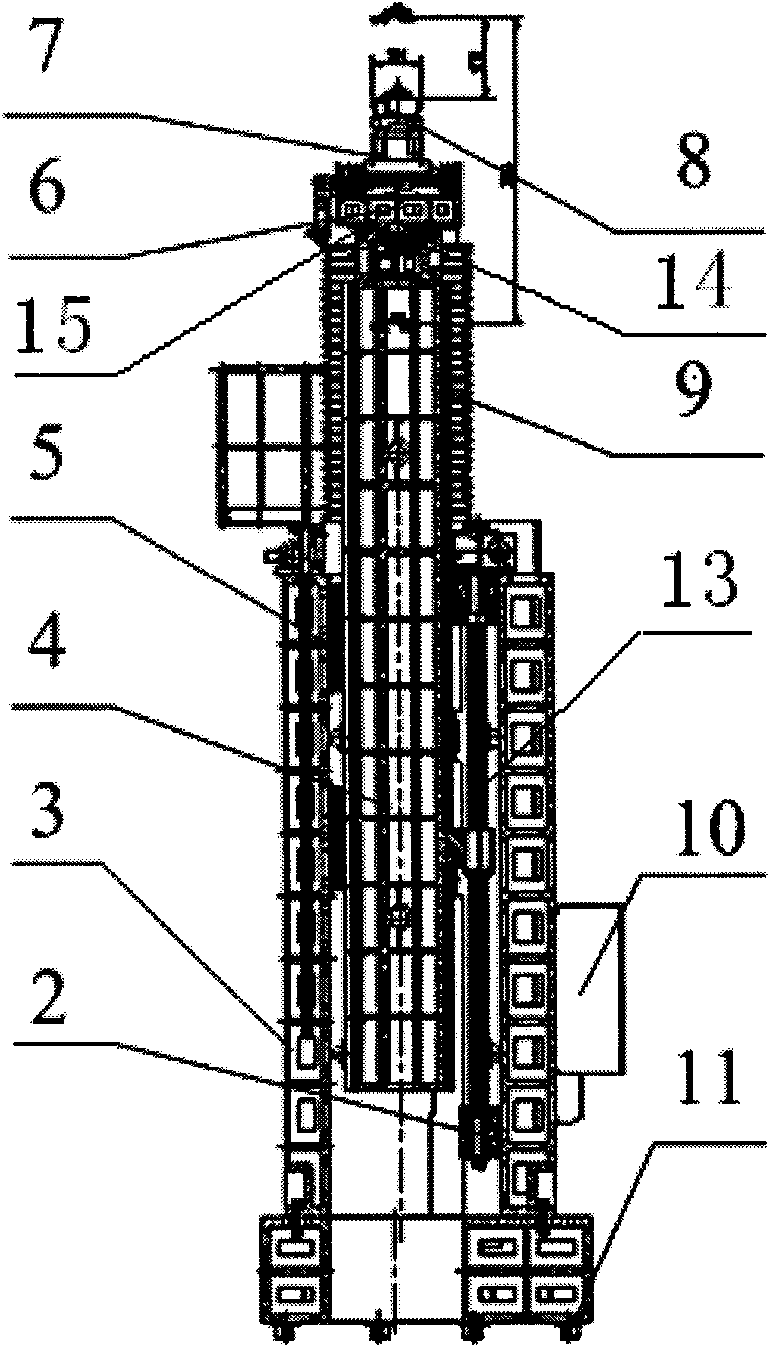

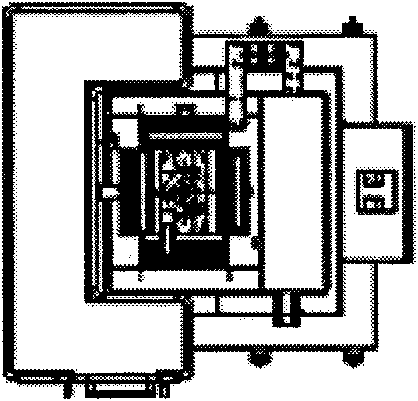

[0013] Such as Figure 1~3 As shown, the large-travel, high-rigidity, high-precision three-coordinate positioner includes base 1, main column 2, auxiliary column 3, Z-axis telescopic column 4, roller rolling block 5, X slider 6, Y slider 7, ball Head clamping device 8, Z-axis organ cover 9, control system 10, adjustment pad iron 11, lifting table 12, Z-axis transmission unit 13, X-axis transmission unit 14, Y-axis transmission unit 15; The main column 2 and the auxiliary column 3 are equipped with a Z-axis transmission unit 13, the Z-axis telescopic column 4 is connected to the main column 2 through the Z-axis transmission unit 13, and the Z-axis telescopic column 4 is connected to the auxiliary column through the roller sliding block 5 3 connection; the Z-axis telescopic column 4 is provided with an X vertical slide plate 6 and a Y horizontal slide plate 7, an X-axis transmission unit 14 is installed on the X vertical slide plate 6, a Y-axis transmission unit 15 is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com