Open-type static pressure rotating table for controlling floating degree and manufacturing method thereof

A technology of rotary workbench and workbench, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. It can solve the problems of large changes in static pressure floating amount, difficulty in generating oil film on static pressure guide rails, poor rigidity of oil film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

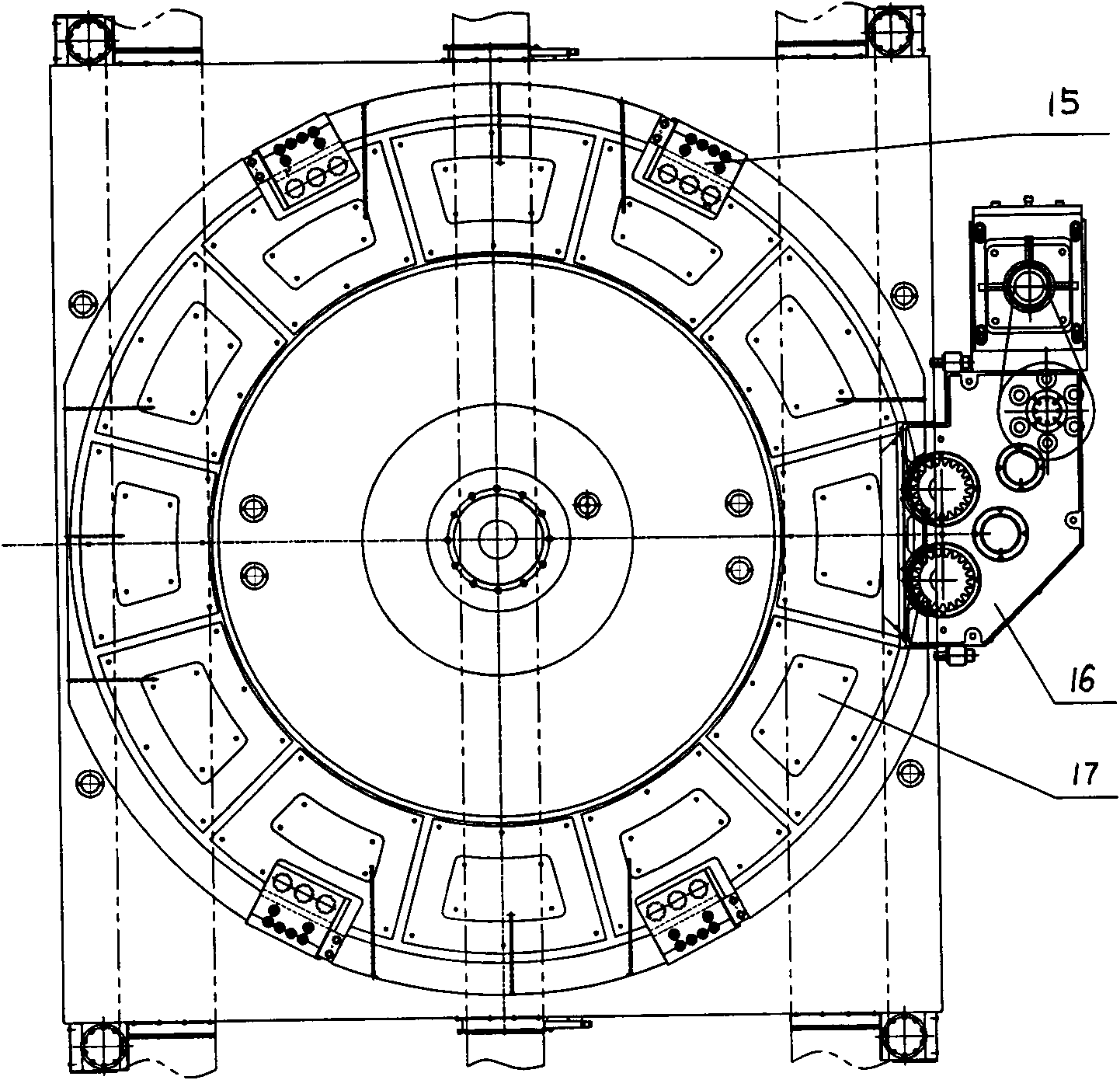

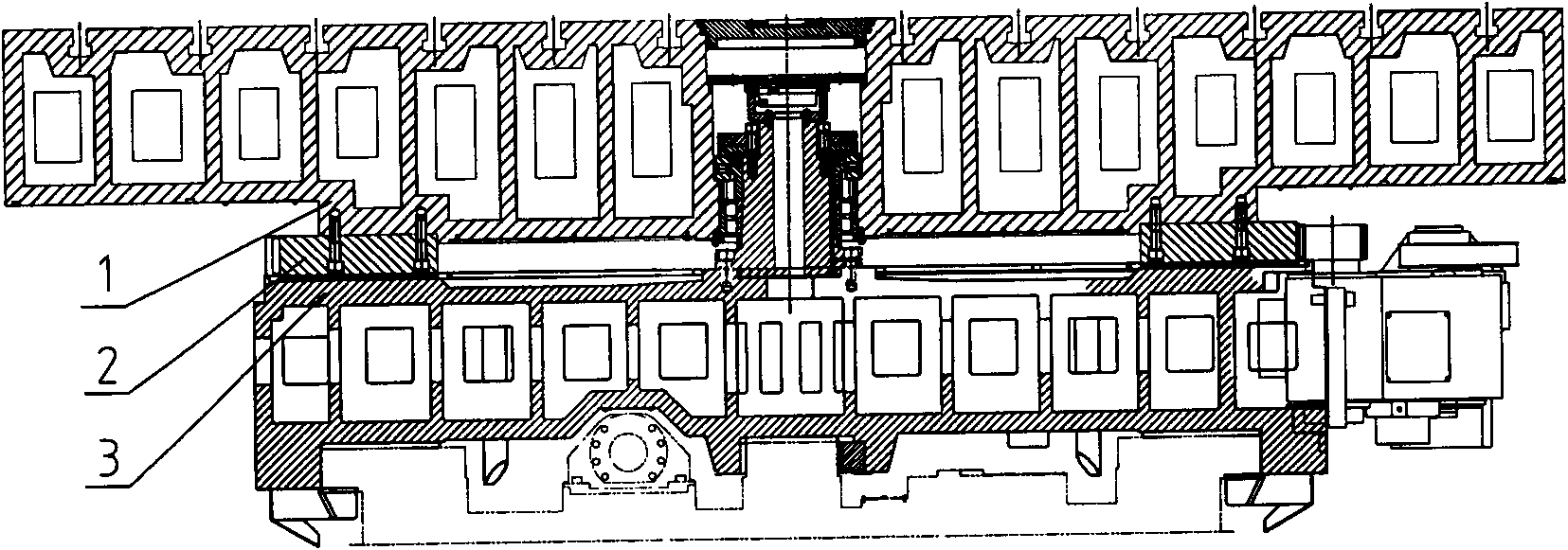

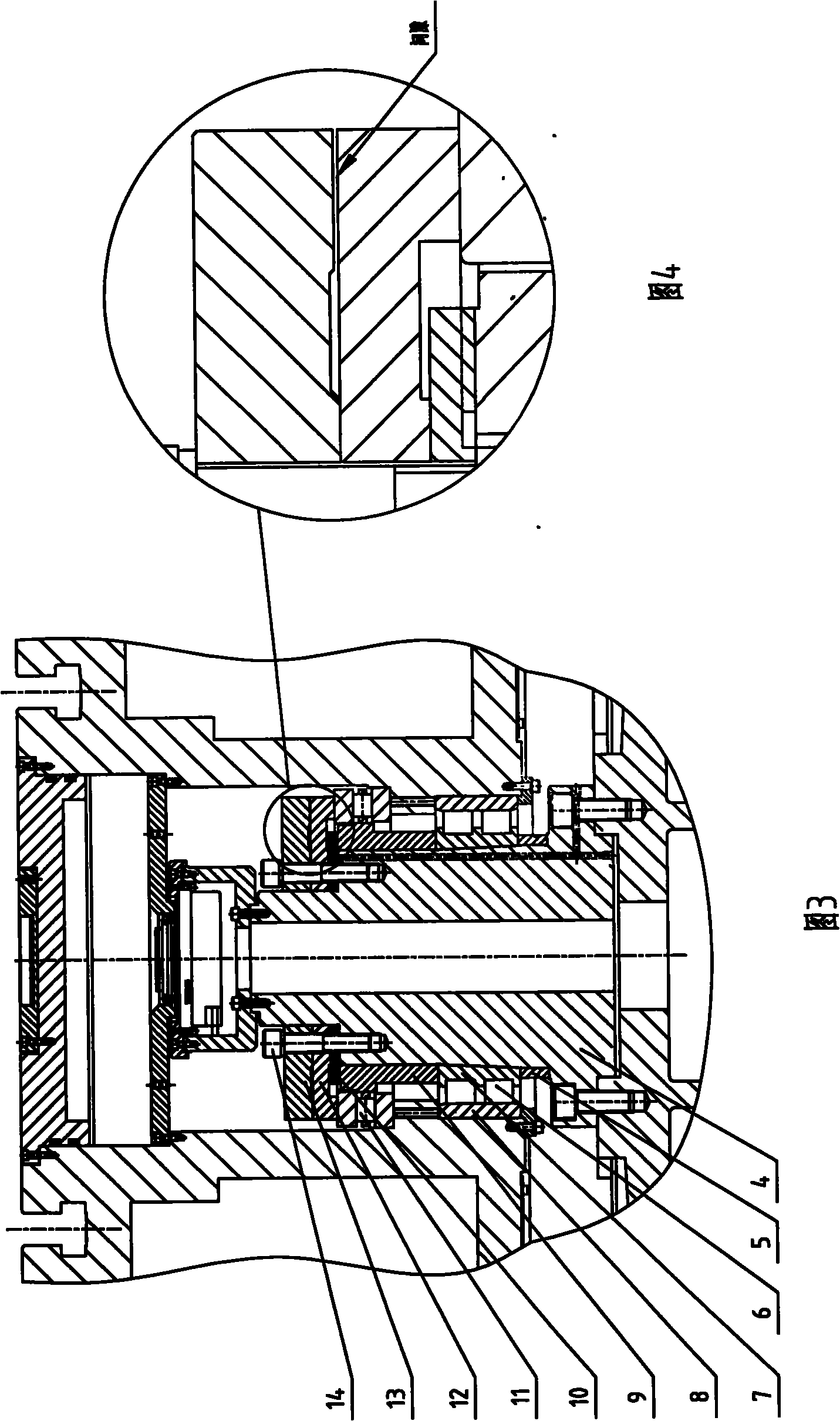

[0011] The open static pressure rotary workbench that controls the floating amount is equipped on the heavy-duty CNC rotary workbench, including the centering structure of the workbench rotary shaft, such as image 3 As shown, the hydraulic floating B-axis clamp 15, the rotary drive gearbox 16, the static pressure plate 17, and the multi-head pump for hydraulic oil supply are focused on its static pressure guide rail pair structure and its matching rotary centering shaft structure. It is characterized in that the lower cylinder of the turntable body 1 of the worktable and the inner hole of the large ring gear 2 adopt a coaxial base hole system clearance fit, see figure 2 At the same time, fasten the large ring gear 2 on the workbench with hexagon socket head cap screws, and use two cylindrical pins for positioning to ensure that the workbench and the large ring gear 2 are coaxial, and then put the workbench and the large ring gear 2 together on the slide On the seat 3, there ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com