Needle bed structure of computerized flat knitting machine

A technology of flat knitting machines and needle beds, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve problems such as difficulty in guaranteeing the quality of knitted fabrics and the influence of knitting needle movement stability, so as to improve motion stability and ensure knitting effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

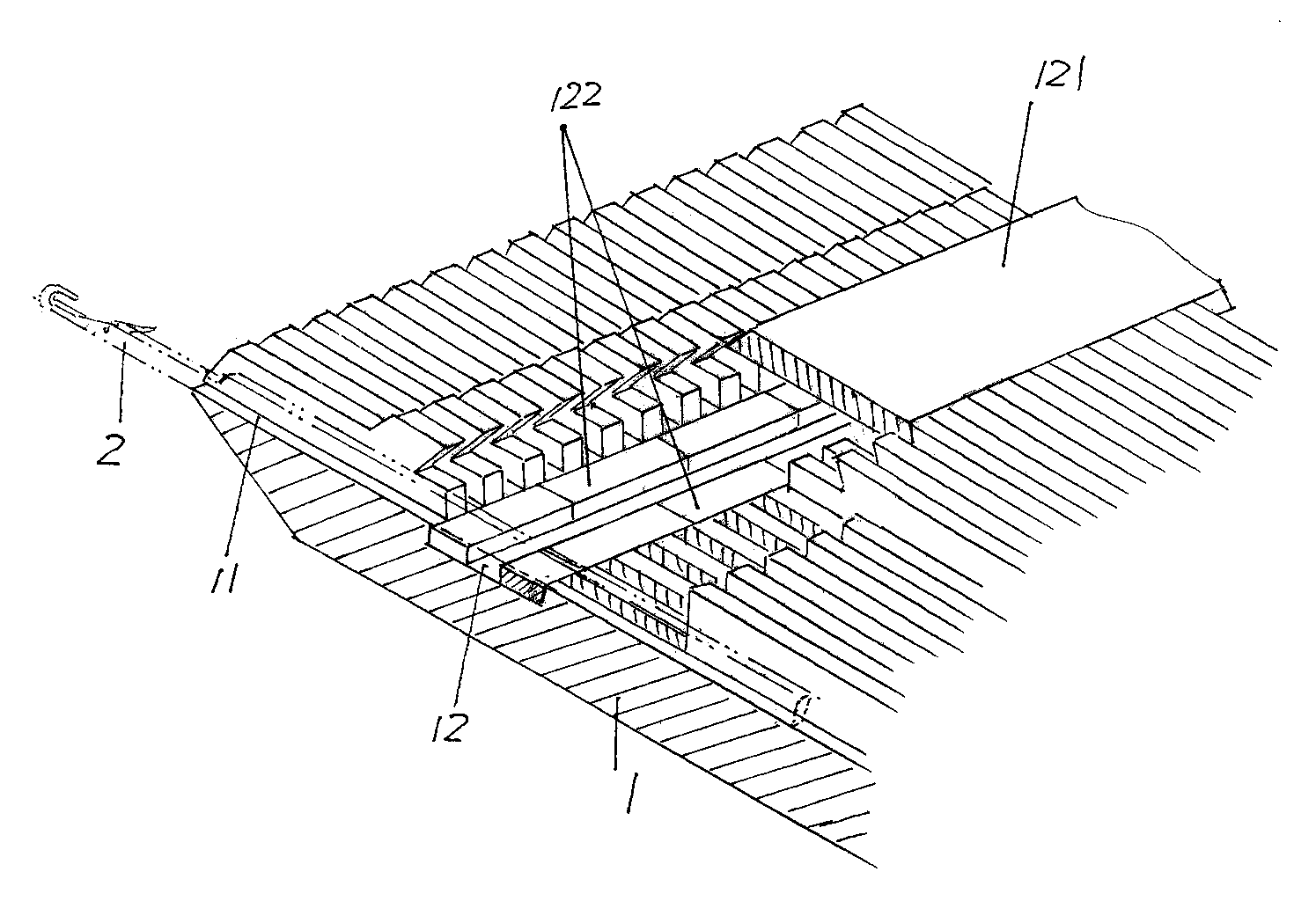

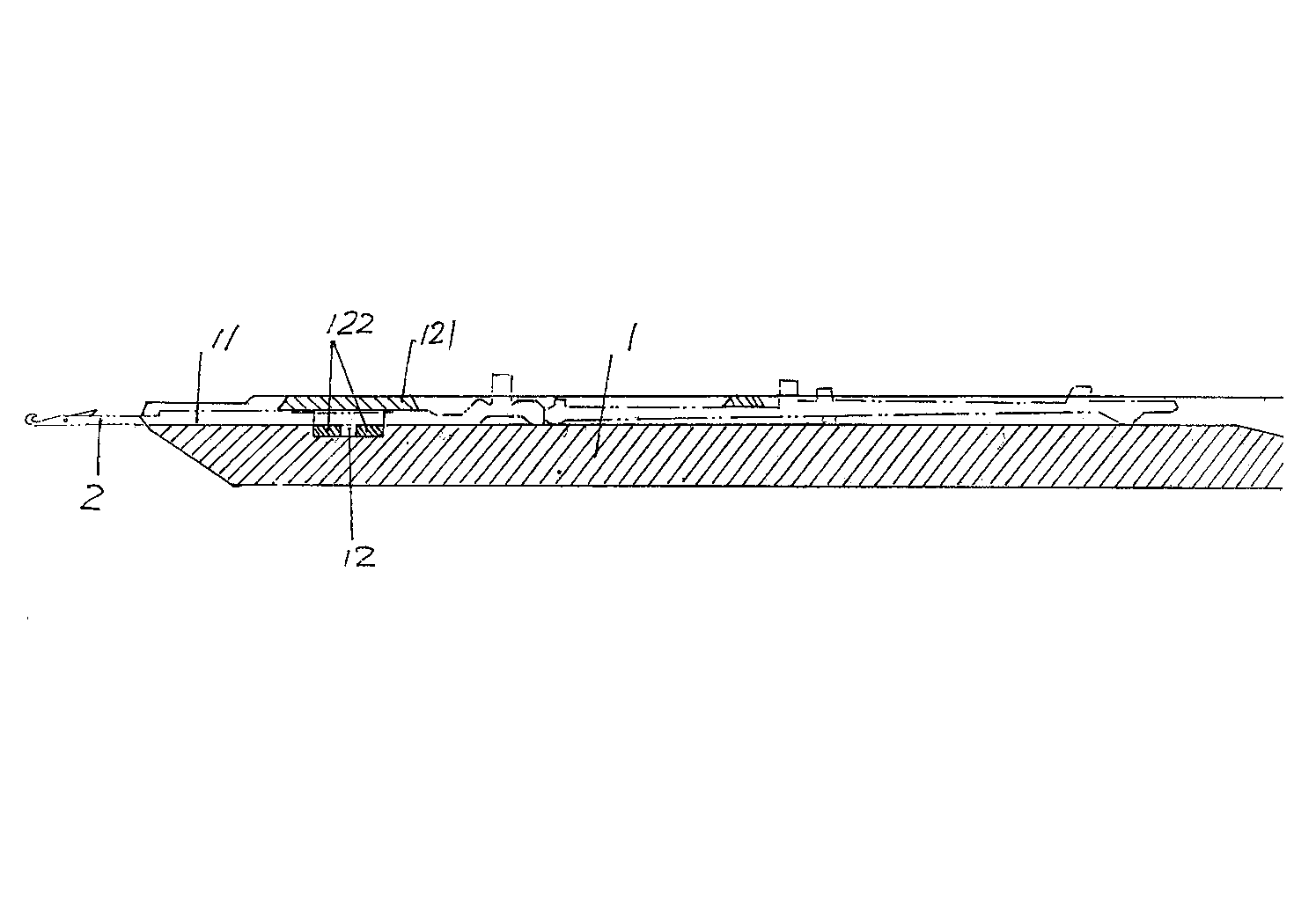

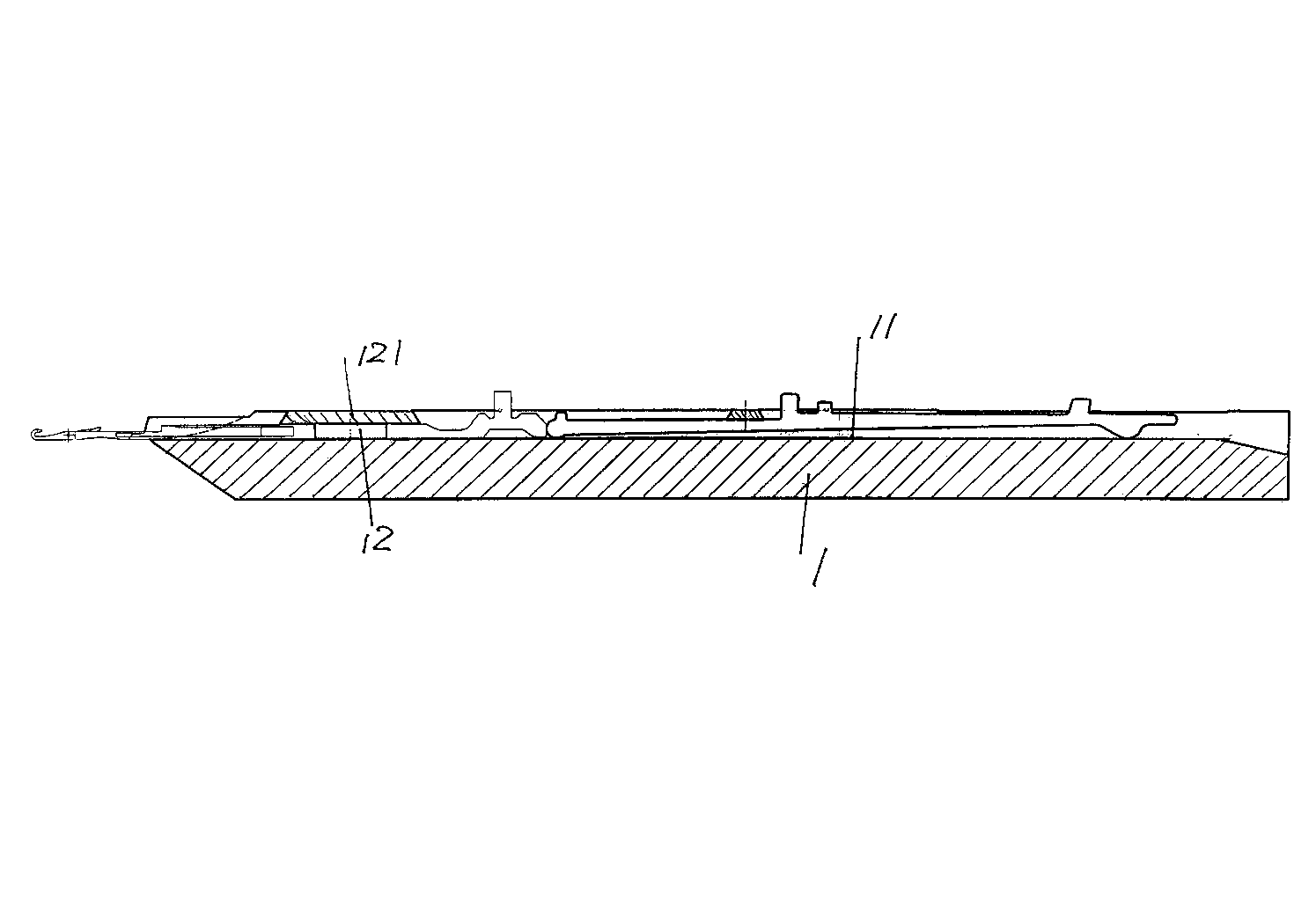

[0013] See figure 1 and figure 2 , a needle bed body 1 is given, the length direction of the needle bed body 1 is provided with needle grooves 11 equal to the number of knitting needles 2 of the knitting needle assembly described above in a spaced state from one end to the other end, each A knitting needle 2 is movablely arranged in a needle groove 11. In the state of use, the needle groove 11 faces the side of the head of the knitting mechanism of the computerized flat knitting machine, that is, it is in the figure 1 and figure 2 status shown. An insertion strip groove 12 is also provided on the needle bed body 1, and the insertion strip groove 12 forms a cross-shaped staggered relationship with the aforementioned needle groove 11, and an insertion strip 121 is inserted in the insertion strip groove 12, and the insertion strip 121 Also known as grating or layering.

[0014] Since there is a cavity between the bottom of the insertion strip groove 12 and the inse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com