Network cluster-control-based numerical control machine tool error real-time compensation system and compensation method

A CNC machine tool and error compensation technology, applied in the general control system, control/adjustment system, program control, etc., can solve problems such as large hardware expenditures and inconformity with the management requirements of production materials, and achieve hardware cost savings and good online machine status Monitoring function, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. This embodiment provides detailed implementation and specific operation process based on the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

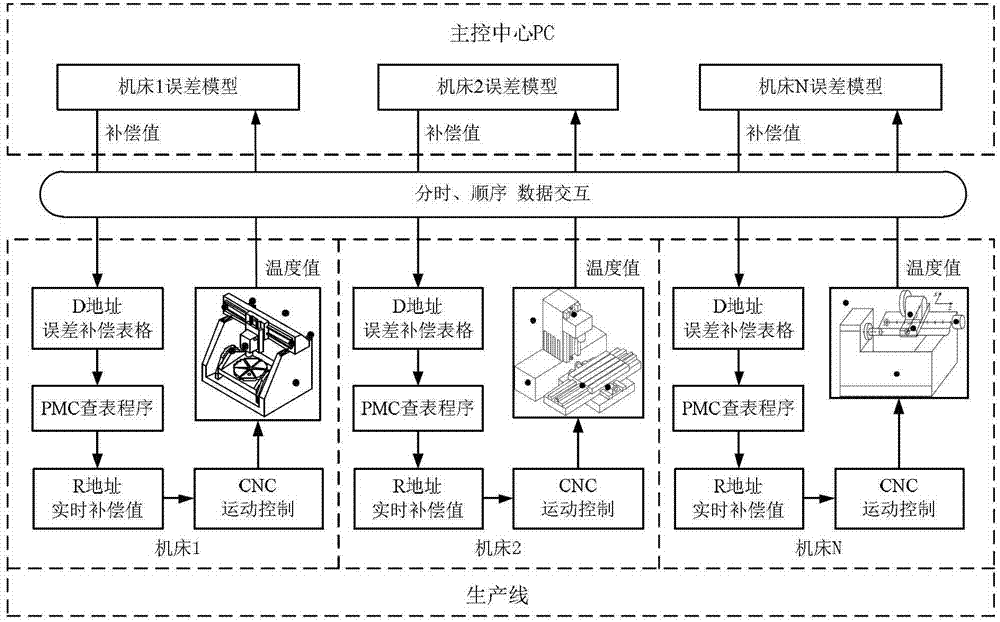

[0038] The real-time error compensation system of numerical control machine tools based on network group control of the present invention includes a hardware part and a software part. see figure 1 , The hardware part of the compensation system mainly includes: main control center PC, router, built-in Ethernet port of CNC machine tool, temperature sensor, temperature data acquisition card. Among them, the main control center PC is connected to the router, and the router is connected to the built-in Ethernet port of each CNC machine tool. The main control center PC realizes data interaction with different CNC machine tool...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com