Shield cutter for composite ground

A shield cutter head and composite stratum technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as abnormal wear of cutters, affecting shield construction efficiency, poor wear resistance of cutter heads, etc. The risk of mud cake, the effect of improving slag dynamic fluidity and improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

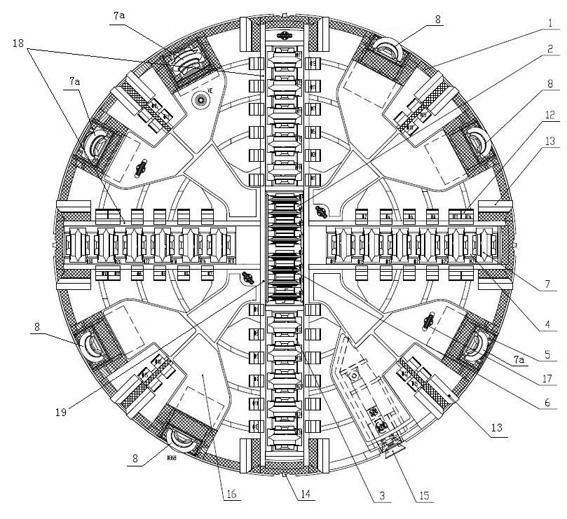

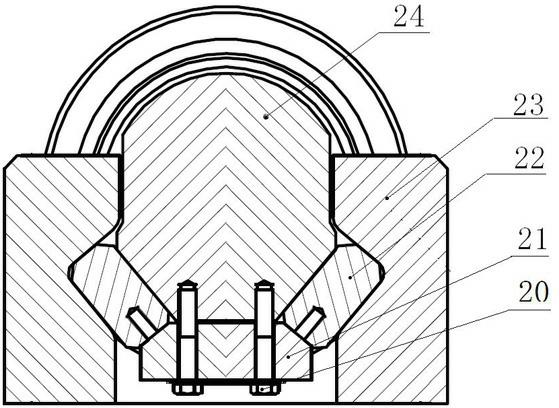

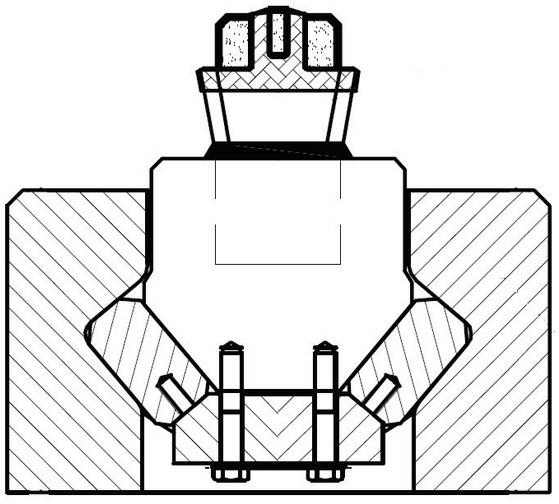

[0022] See figure 1 , a shield cutter head for complex formations, including a cutter head body 1 with a box structure, hobs are installed on the front of the cutter head body 1, and the hobs include cross-shaped knife beams 18 respectively installed through tool holders. Some single-edged standard hobs 7 on the top, some single-edged central hobs 6 installed on the inline knife beam 19 located at the center of the cross-shaped knife beam 18, 3 single-edged standard hobs 7a installed in the edge area and 4 single-edged eccentric hobs 8; wherein, five single-edged standard hobs 7 and six are cross-mounted on the cross-shaped knife beam 18 through five conjoined hob holders 3 and six conjoined hob holders 4 A single-edged standard hob 7; eight single-edged central hobs 6 arranged in concentric circles are installed on the inline knife beam 19 through eight conjoined central hob holders 2; the single-edged standard hob in the edge area The hob 7 and the single-edged eccentric ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com