Piston-cylinder arrangement, in particular for a clutch actuation system in a motor vehicle

A clutch control and motor vehicle technology, applied in the field of piston-cylinder devices, can solve the problems of unstable transition and weakening of the piston 5, and achieve the effects of simple installation, simple pre-installation, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

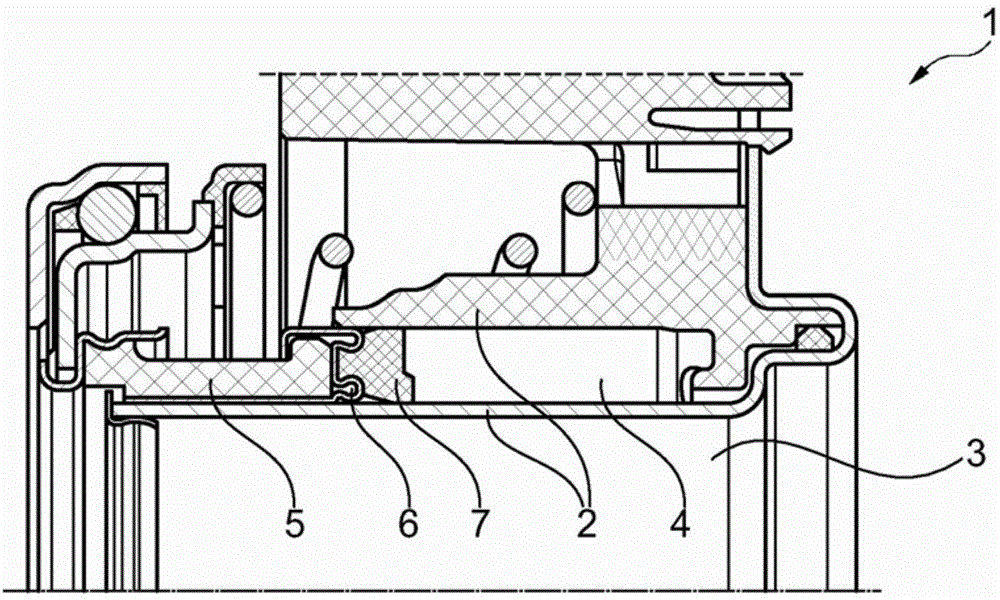

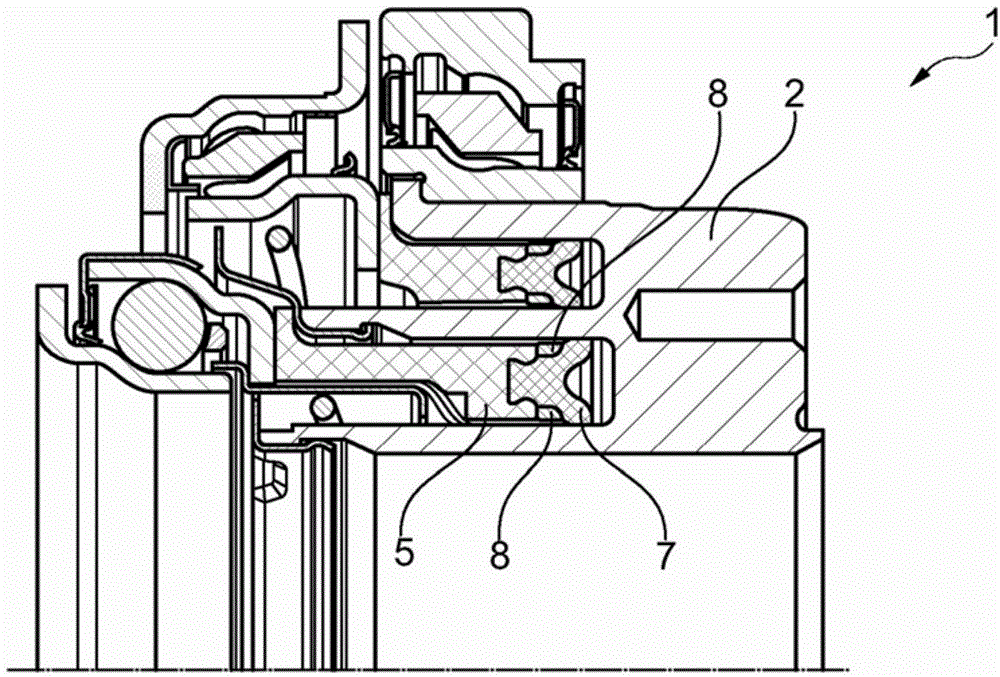

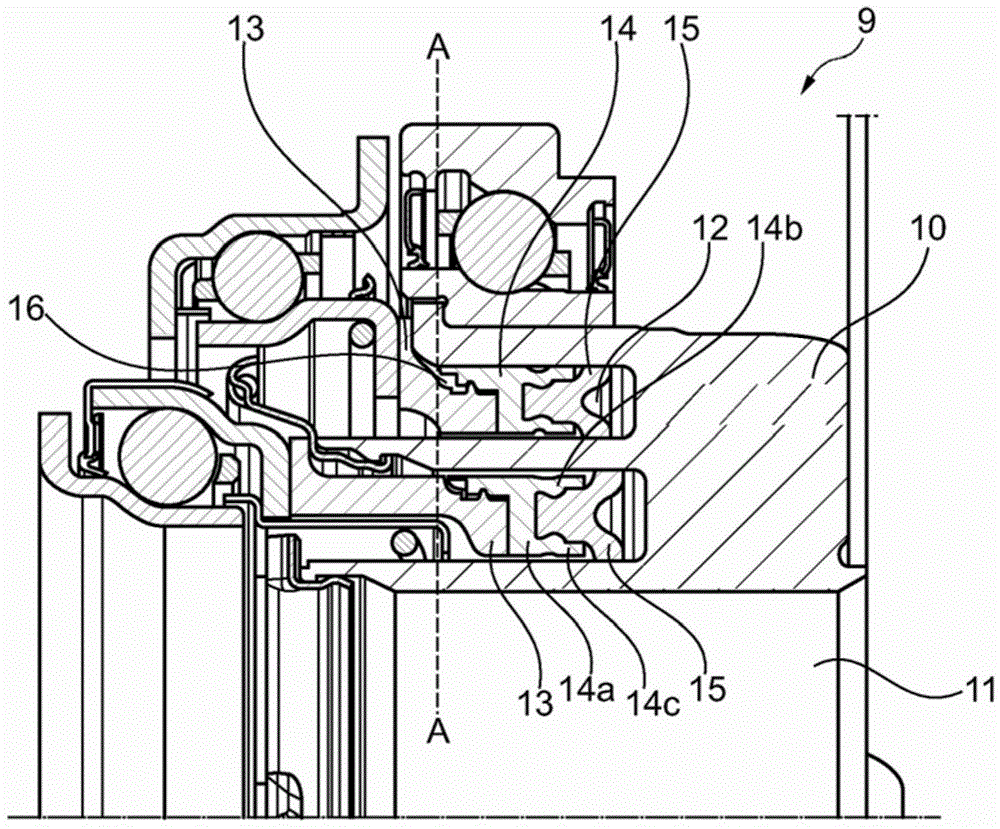

[0022] image 3 A piston-cylinder arrangement 9 is shown, such as is used as a clutch slave cylinder in clutch actuating devices of motor vehicles. image 3 A section from a dual clutch slave cylinder inserted in a dual clutch arrangement is shown here. It is also possible for the invention to operate a single clutch in a clutch slave cylinder.

[0023] The piston-cylinder arrangement 9 is formed by a housing 10 which extends rotationally symmetrically around an axis 11 . A ring-shaped pressure chamber 12 extends in housing 10 , in which pressure chamber a piston 13 is movably mounted. The piston 13 here has, facing the pressure chamber 12 , a sealing ring carrier 14 in which a seal 15 is arranged.

[0024] The sealing ring carrier 14 has an approximately U-shaped contour, wherein the base 14 a of the sealing ring carrier 14 rests directly on the piston 13 , while the sides 14 b, 14 c of the sealing ring carrier 14 extend axially along the housing 10 and contact it. body. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com