Self-locking bolt

A bolt and self-locking technology, applied in the directions of bolts, screws, nuts, etc., can solve the problems of poor self-locking effect of bolts, small number of clips, and difficult disassembly, and achieve good anti-theft effect, good resistance effect, and difficult disassembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

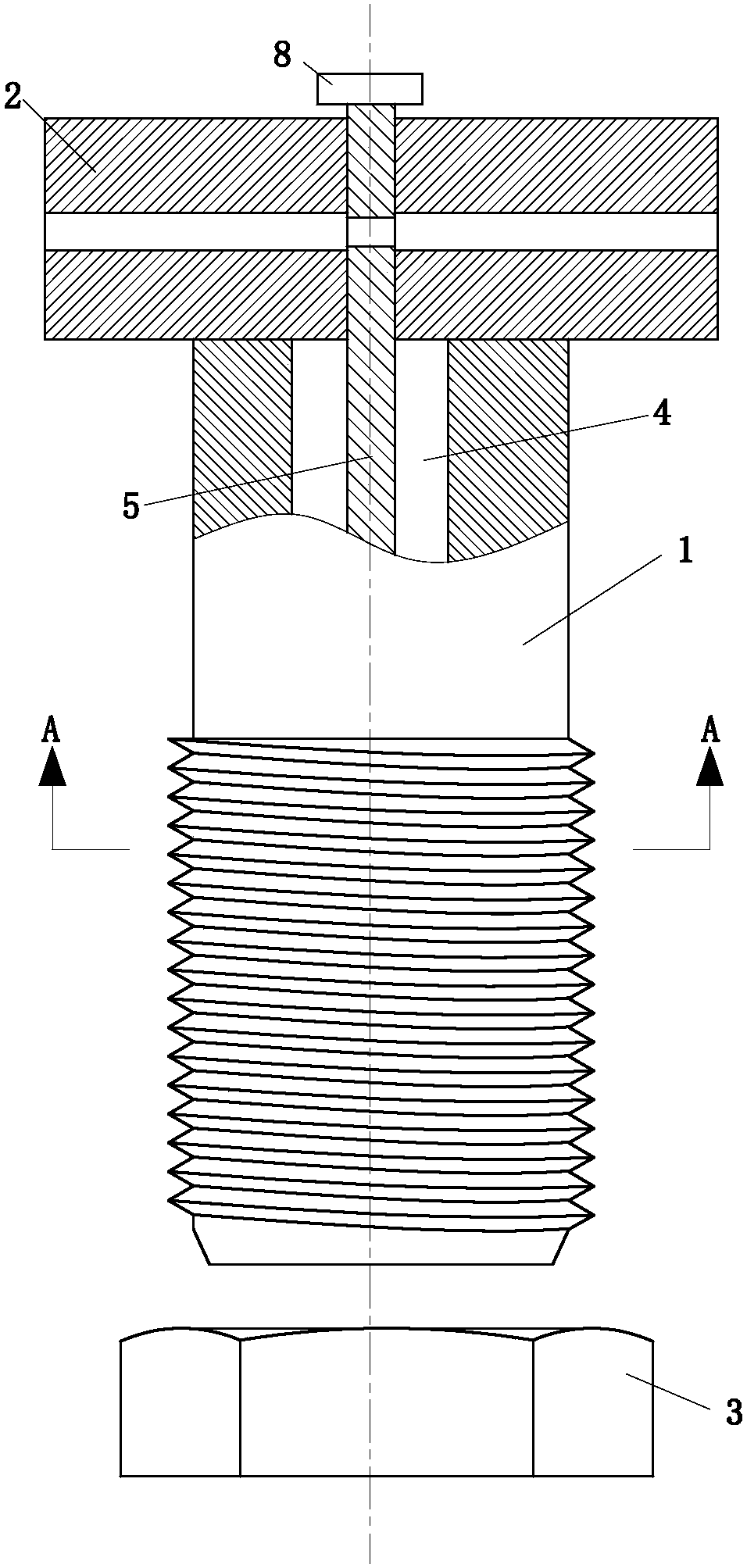

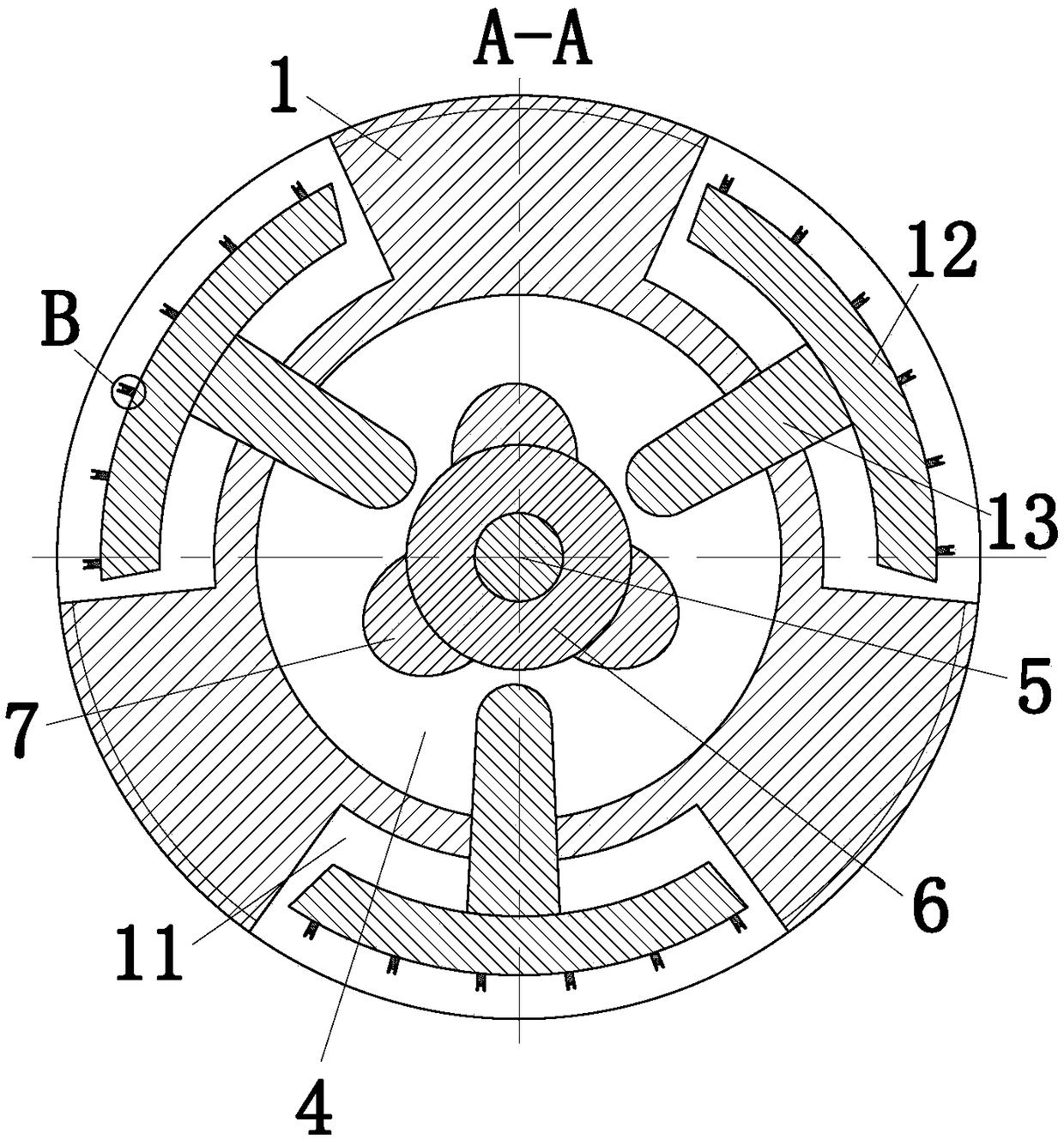

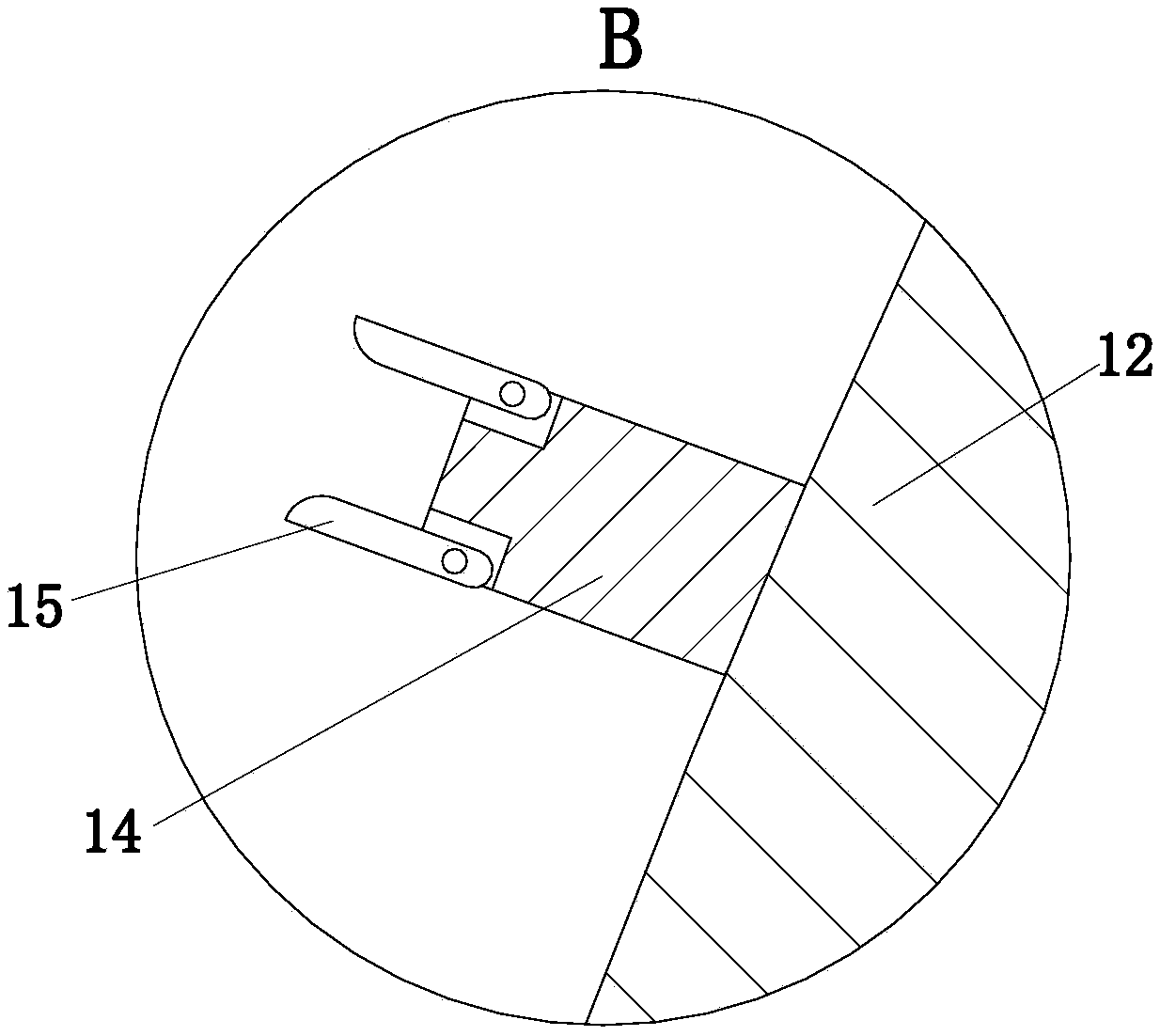

[0031] After the nut 3 is screwed onto the screw rod 1, turn the rotating handle 8 so that the rotating shaft 5 rotates, the rotating shaft 5 drives the ring block 6 to rotate, the semicircle block 7 rotates with the ring block 6, and the semicircle block 7 makes the guide rod 13 to rotate The outer side moves, and the guide rod 13 pushes the arc block 12 to move. When the arc block 12 moves to the outside, when the bar 15 touches the nut 3, the bar 15 rotates to both sides, and the bar 15 blocks the nut 3, and the nut 3. After being stuck, after utilizing the through hole of the pin to pass the screw head 2 and the passage of the rotating shaft 5, the pin is welded dead.

Embodiment approach 2

[0033] After the nut 3 is screwed onto the screw rod 1, turn the rotating handle 8 so that the rotating shaft 5 rotates, the rotating shaft 5 drives the ring block 6 to rotate, the semicircle block 7 rotates with the ring block 6, and the semicircle block 7 makes the guide rod 13 to rotate Moving outside, the guide rod 13 pushes the arc block 12 to move. When the arc block 12 moves to the outside, the rack 16 follows the arc block 12 and moves to the outside. When the rack 16 is pressed against the nut 3, the rack 16 As soon as the groove of the fixed block 14 moves inwardly, the tooth bar 16 moves to make the gear 17 rotate, and the gear 17 rotates to spread the clip bar 15 and be stuck in the thread of the nut 3, so that the nut 3 is stuck. After the nut 3 is stuck, use After the passing of the pin through the through hole of the screw head 2 and the turning shaft 5, the pin is welded dead.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com