A threshing drum with adjustable threshing diameter and combine harvester

A technology for adjusting the diameter of threshing drums, which is applied to harvesters, threshing equipment, cutters, etc., can solve the problems of single line speed of threshing components in the threshing gap, cumbersome and difficult adjustment of threshing drum diameter, and unstable operation performance, so as to improve the transportation Through ability, improving adaptability and harvesting efficiency, and ensuring the effect of operation stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

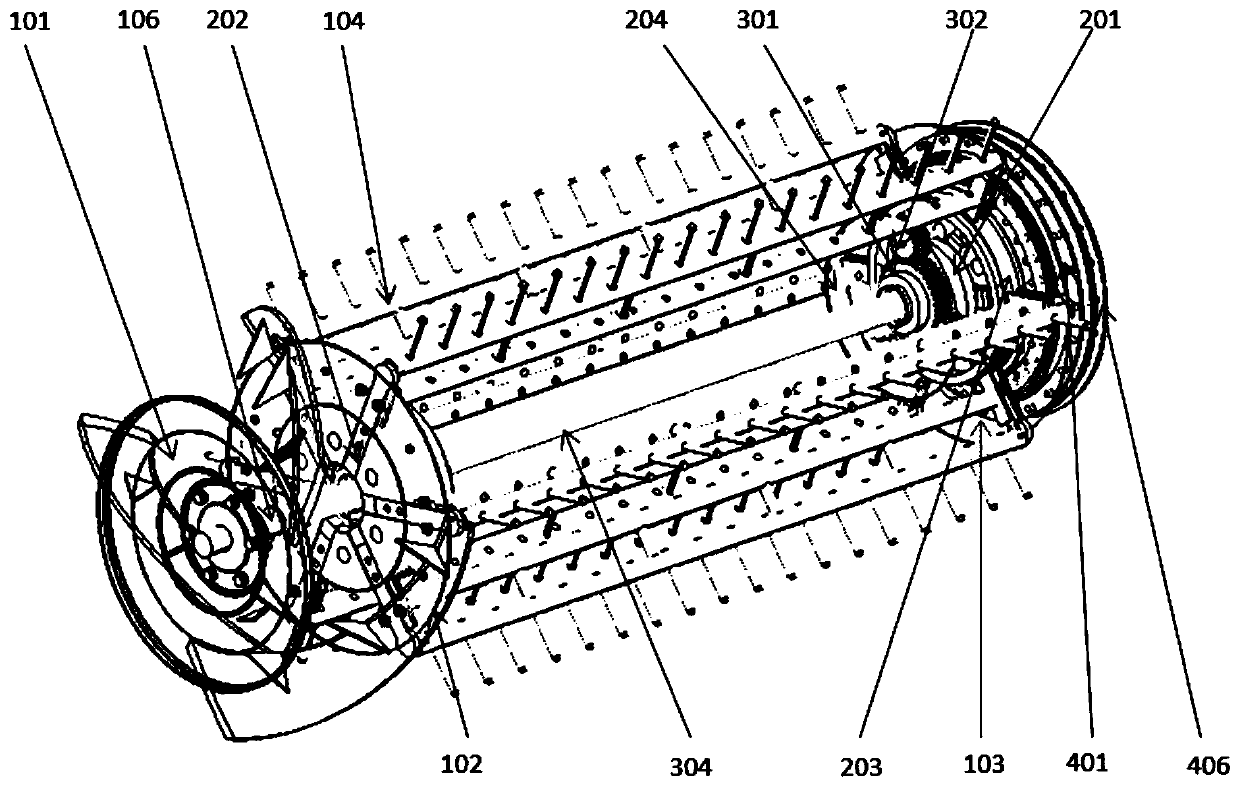

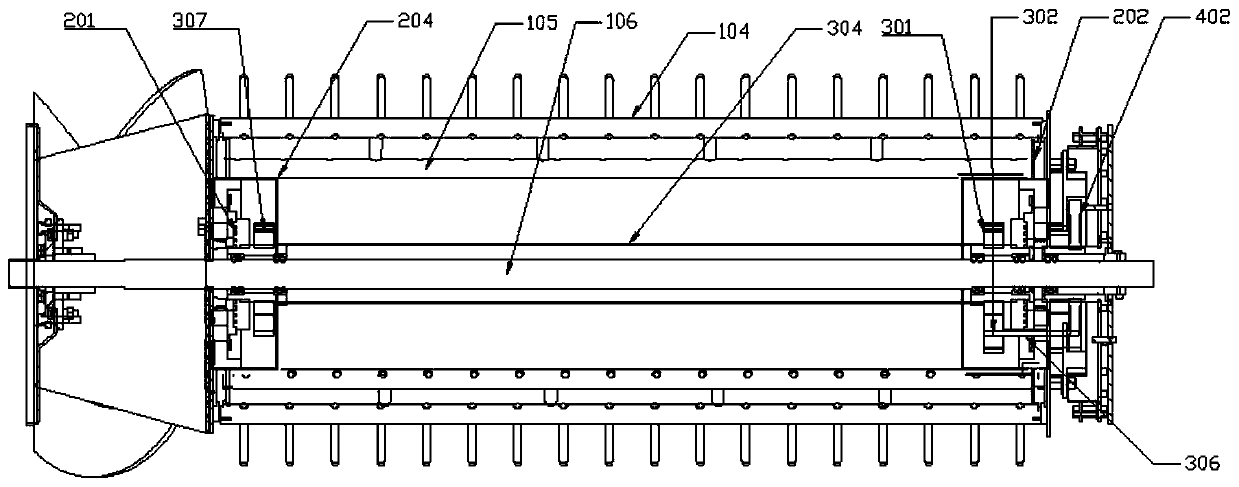

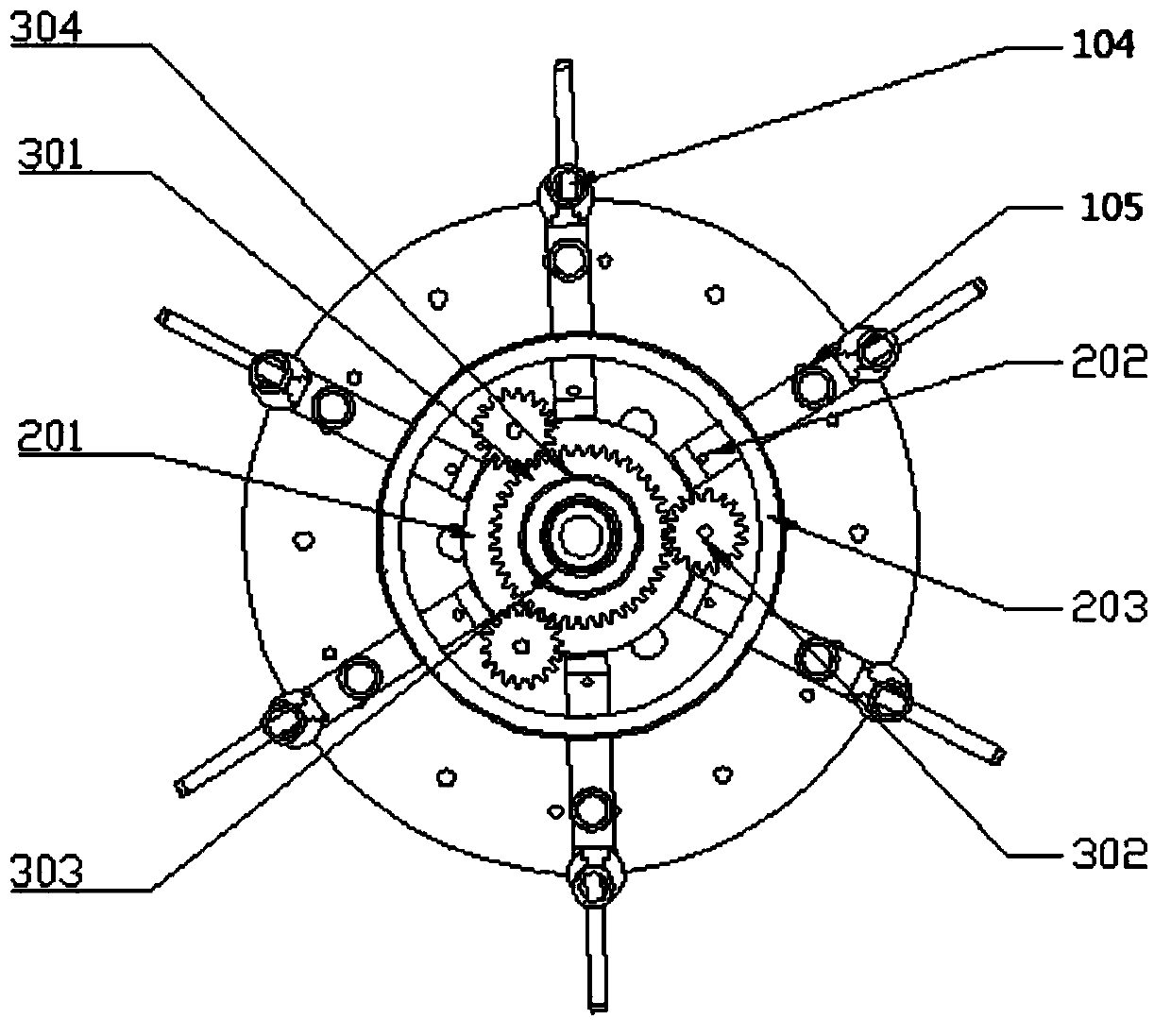

[0041] like Figure 1~2 As shown, the threshing cylinder with adjustable threshing diameter according to the present invention includes a threshing cylinder, a diameter adjustment device, a transmission device, and a self-locking device. And mutual symmetry, the self-locking device is located at the tail of the detachment cylinder, and is installed on the outside of the support disc 103 behind the threshing cylinder.

[0042] Described threshing cylinder comprises cylinder shaft 106, and the feeding wheel 101 that is installed on the cylinder shaft 106 sequentially from front to back along the feeding direction, front support disc 102, rear support disc 103, is installed on front support disc 102, The rear supports the threshing rack 104 on the web 103, and the threshing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com