Cascade pressurization belt type pressure filter

A pressurized belt and filter press technology, applied in filtration and separation, moving filter element filters, separation methods, etc., can solve the problems of poor holding capacity, low pressurization pressure, poor dehydration effect, etc., and improve dehydration effect. , The pressing pressure is large, and the effect of improving the dehydration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

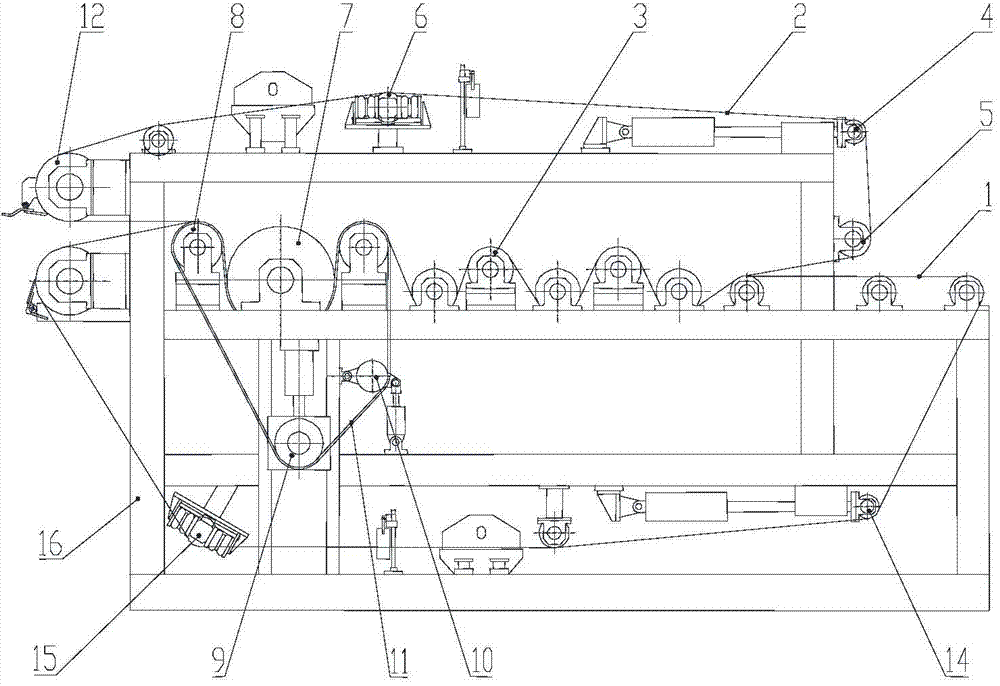

[0032] see figure 1 , which shows a cascaded pressurized belt filter press according to a preferred embodiment of the present invention. The stepped pressurized belt filter press includes an upper filter belt 2, a lower filter belt 1, a filter belt squeezing roller 3, an upper filter belt tensioning roller 4, an upper filter belt deflecting roller 6, a lower filter belt tensioning roller 14, Lower filter belt deflection adjustment roller 15, metal mesh belt 11, metal mesh belt squeezing roller 7, metal mesh belt reversing roller 8, metal mesh belt tensioning roller 9, and metal mesh belt deflection adjustment roller 10.

[0033] The quantity of described metal mesh belt 11 is one or more, and each metal mesh belt 11 is connected with one or more metal mesh belt pressing rollers 7, two or more metal mesh belt redirecting rollers 8, one The metal mesh belt tensioning roller 9 and a metal mesh belt deflection roller 10 together form a metal mesh belt pressing unit, wherein the m...

Embodiment 2

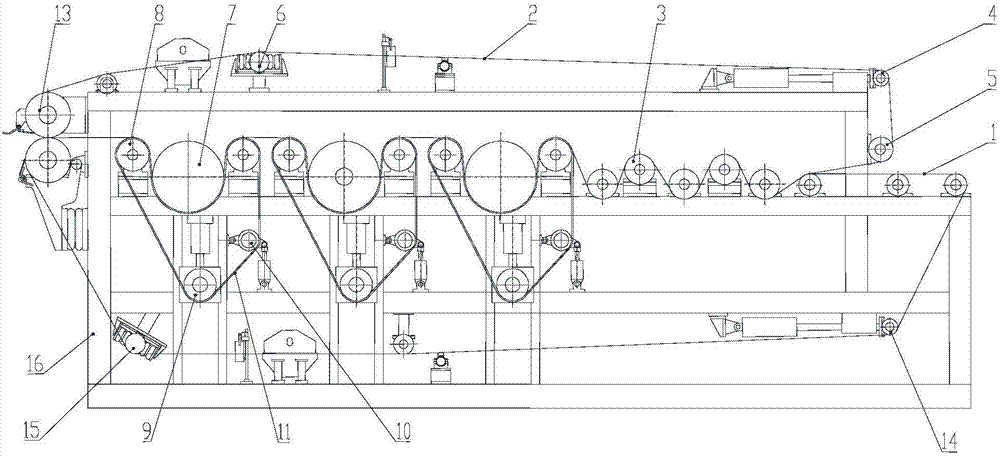

[0056] See you again figure 2 , which shows a cascaded pressurized belt filter press according to a preferred embodiment of the present invention. The stepped pressurized belt filter press includes: lower filter belt 1, upper filter belt 2, filter belt press roller 3, upper filter belt tension roller 4, filter belt guide roller 5, upper filter belt deflection roller 6, metal Mesh belt squeeze roller 7, metal mesh belt reversing roller 8, metal mesh belt tension roller 9, metal mesh belt deflection adjustment roller 10, metal mesh belt 11, pair press roller 13, lower filter belt tension roller 14, lower filter Belt adjustment roller 15, frame 16. Wherein filter belt squeezes roller 3, filter belt guide roller 5, metal mesh belt squeezes roller 7, metal mesh belt redirection roller 8 is installed on the frame 16 and can rotate around the axis of oneself. The upper filter belt tensioning roller 4 is installed on the frame 16 through the upper filter belt tensioning mechanism, ...

Embodiment 3

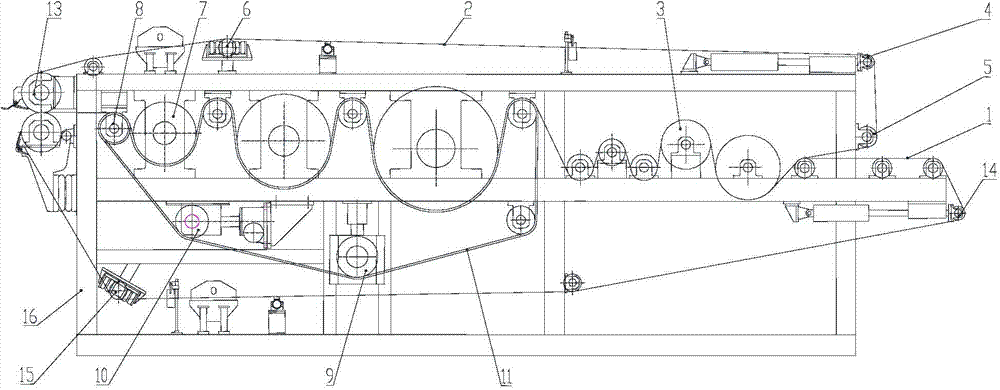

[0061] See you again image 3, which shows a cascaded pressurized belt filter press according to a preferred embodiment of the present invention. The stepped pressurized belt filter press includes: 1 lower filter belt 1, 1 upper filter belt 2, 5 filter belt pressing rollers 3, 1 upper filter belt tensioning roller 4, 6 filter belt guide rollers 5 , 1 upper filter belt deflection adjustment roller 6, 3 metal mesh belt squeezing rollers 7, 5 metal mesh belt deflection rollers 8, 1 metal mesh belt tensioning roller 9, 1 metal mesh belt deflection adjustment roller 10, 1 metal mesh belt 11, 2 pairs of press rollers 13, 1 lower filter belt tensioning roller 14, 1 lower filter belt deflection adjustment roller 15, and frame 16. Wherein filter belt squeezes roller 3, filter belt guide roller 5, metal mesh belt squeezes roller 7, metal mesh belt redirection roller 8 and is installed on the frame 16 by bearing seat and can rotate around the axis of oneself. The upper filter belt tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com