Particle material uniform paving apparatus for pneumatic conveying

A technology for pneumatic conveying and granular materials, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problems of reduced efficiency, economic loss, large power demand, etc., and achieve the effect of simple structure and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

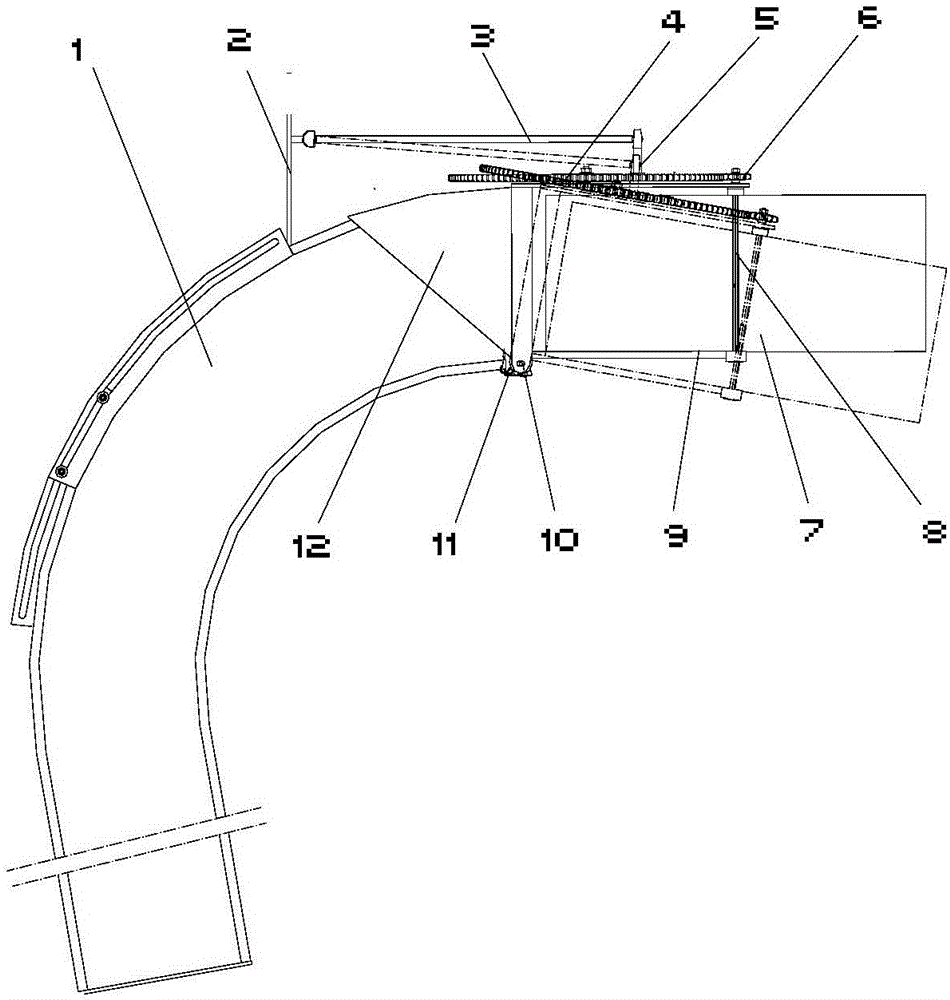

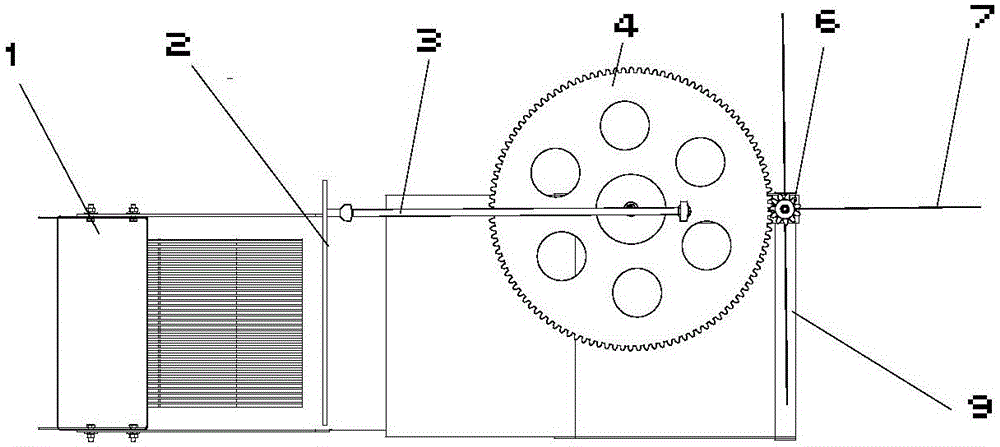

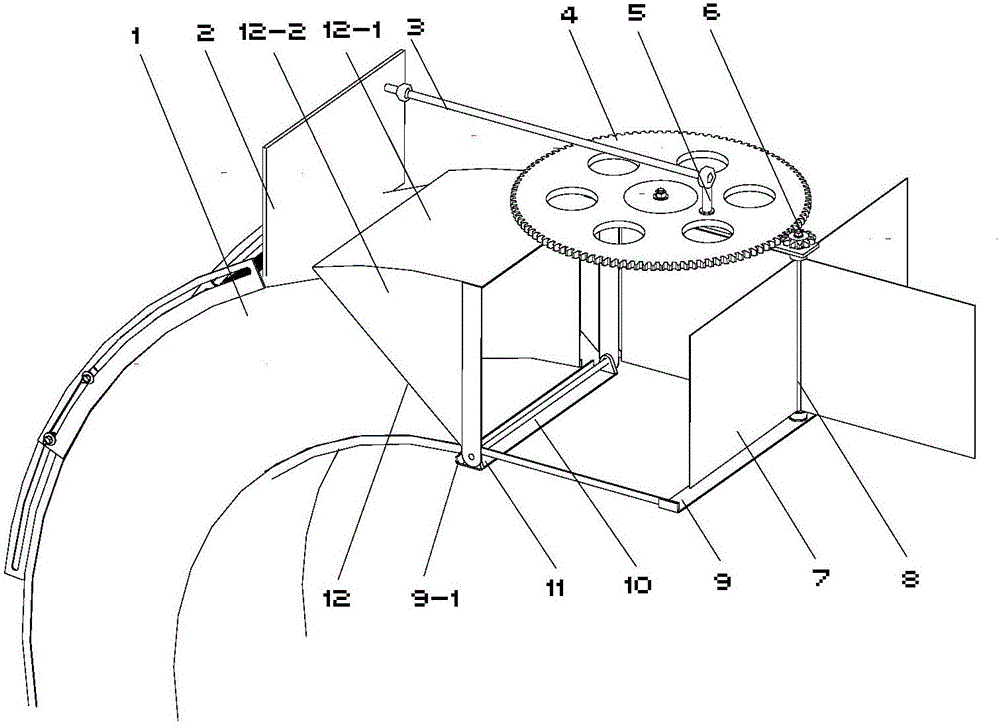

[0019] The structure of the device for uniform spreading of granular materials for pneumatic conveying in this embodiment is as follows: figure 1 , 2 , 3, including a horizontal mounting support 11 fixed on the lower edge of the arc pneumatic conveying end pipeline 1 outlet, the mounting support 11 supports a horizontal hinged shaft 10 perpendicular to the outlet airflow direction, and the hinged support frame is mounted on the hinged shaft 10 9 hinged support sides 9-1 of the rectangular bottom frame. A vertical blade rotating shaft 8 is installed on the opposite side corner of the hinge support limit 9-1 of the rectangular frame, and the blade rotating shaft 8 radially extends out four blades 7 evenly distributed in the circumferential direction. The coaxial pinion 6 is equipped with on the top of the blade rotating shaft 8, and the pinion 6 meshes with the large gear 4 hinged on one side of the support frame 9. The large gear 4 is hinged to one end of the connecting rod 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com