Roller type reducing branch artificial assistance blueberry picking device

A picker and roller-type technology is applied in the field of roller-type variable diameter branches artificially assisted blueberry pickers, which can solve the problems of different tensile strength, damaged skin, low picking efficiency, etc., and achieves fast picking speed, convenient operation, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

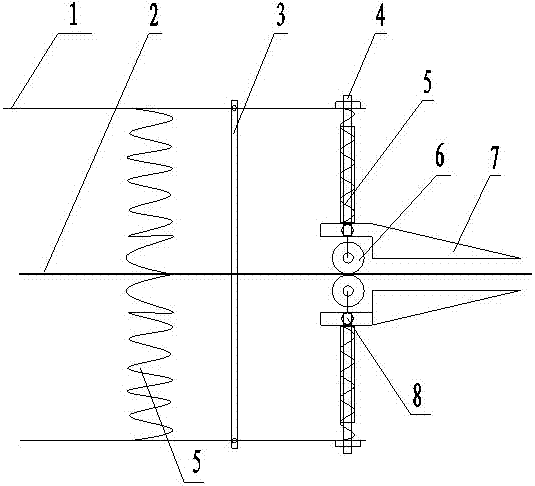

[0013] A roller-type variable-diameter branch artificial power-assisted blueberry picker, including a handle 1, a support rod 3, a spring 5, a picker and a collection bag, a spring 5, a support rod 3 and a picker are fixedly installed on the handle 1, and the support rod 3 is installed On the handle 1 and hinged with the handle 1, the picker is composed of a roller 6, a telescopic rod 4, a spring 5, a cutter 7 and a collection bag, the spring 5 is a compression spring, one end of the telescopic rod 4 is connected with the roller 6, and the other end runs through The through hole provided on the spring 5 and the handle 1 is connected with the handle 1, the cutter 7 is connected with the telescopic rod 4 through the bolt 8, the tip of the cutter 7 is U-shaped, the bolt 8 is loosened, and the cutter 7 is rotated to make the cutter The outer surface of knife 7 and blueberry branch 2 is 10 ° included angle, is provided with U-shaped groove on the outer circular surface of roller 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com