Dewatering frame of cheese water extractor

The technology of a dehydrator and package yarn is applied in the field of dehydration frame, which can solve the problems of high production cost, easy thread breakage, easy deformation of package yarn, etc., and achieves the effects of simple structure, convenient use, and prevention of yarn deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0019] The invention will be described in detail below with reference to the accompanying drawings and examples.

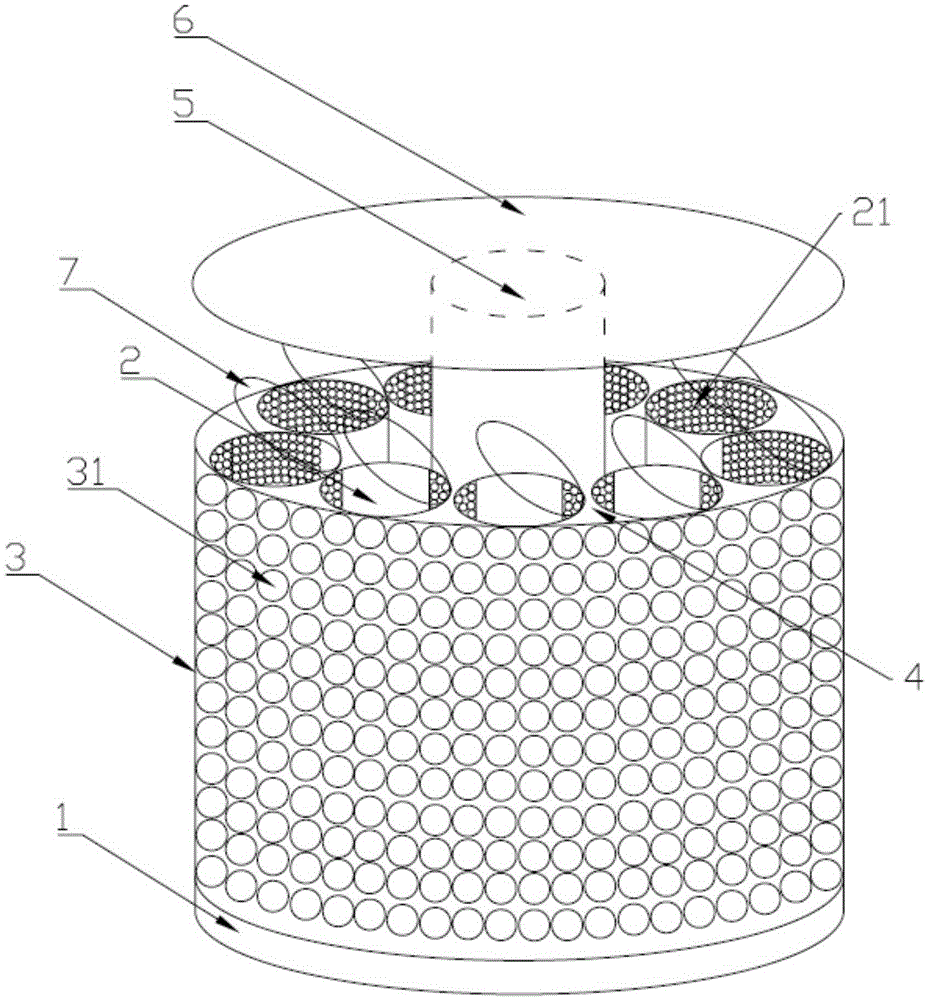

[0020] Such as figure 1 As shown, a dehydration frame on a cheese dehydrator includes a chassis 1 and a yarn holding tank 2. The chassis 1 is fixed with a surrounding edge 3 in the circumferential direction, and the surrounding edge 3 is evenly provided with a plurality of The first water rejection hole 31, the chassis 1 is uniformly fixed with a plurality of yarn holding slots 2, and the plurality of yarn holding slots 2 and between the plurality of yarn holding slots 2 and the surrounding edge 3 are connected through The connecting piece 4 is connected to the top of the edge 3, the connecting piece 4 is connected to the top of the yarn holding groove 2, and the side wall of the yarn holding g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com