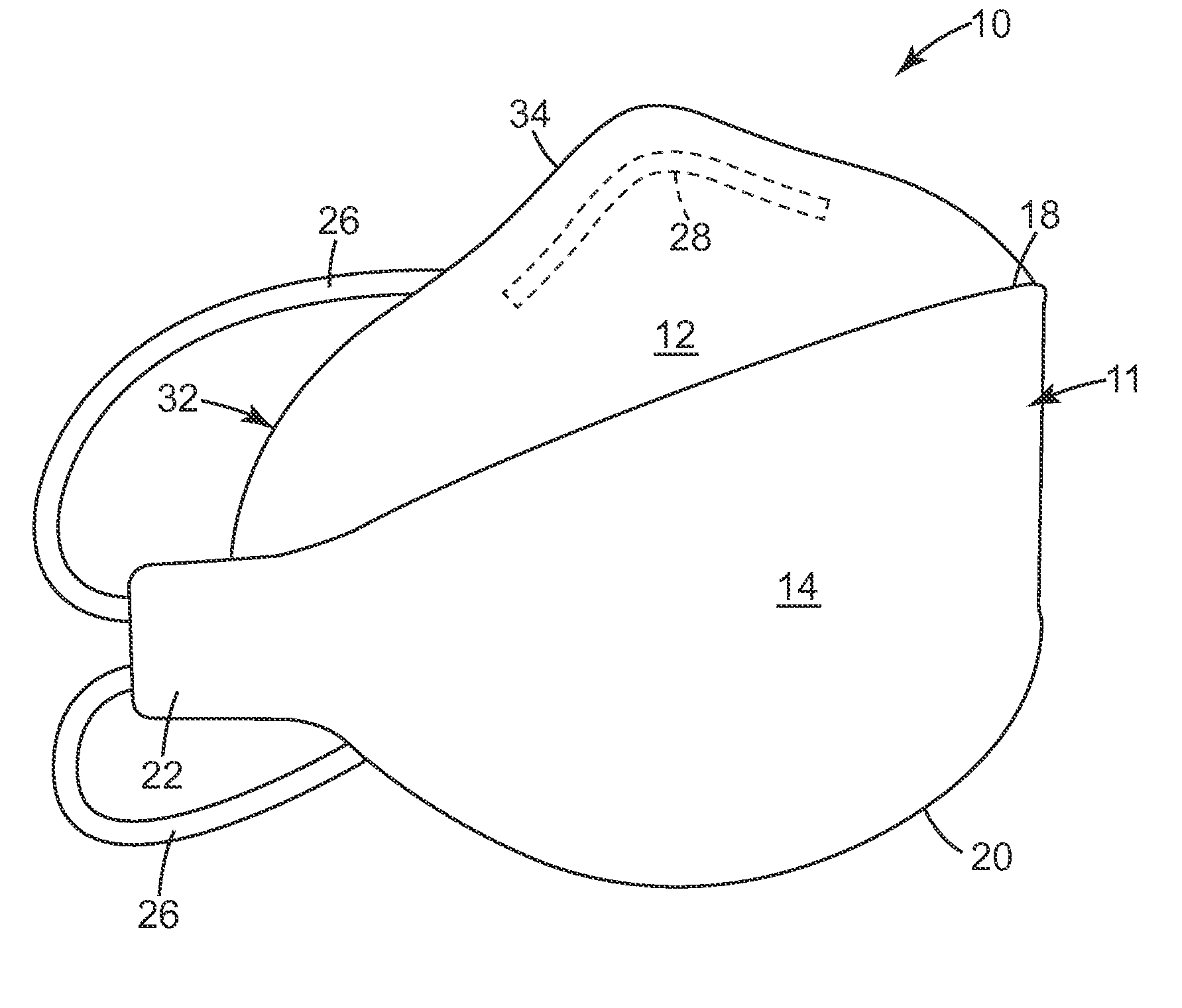

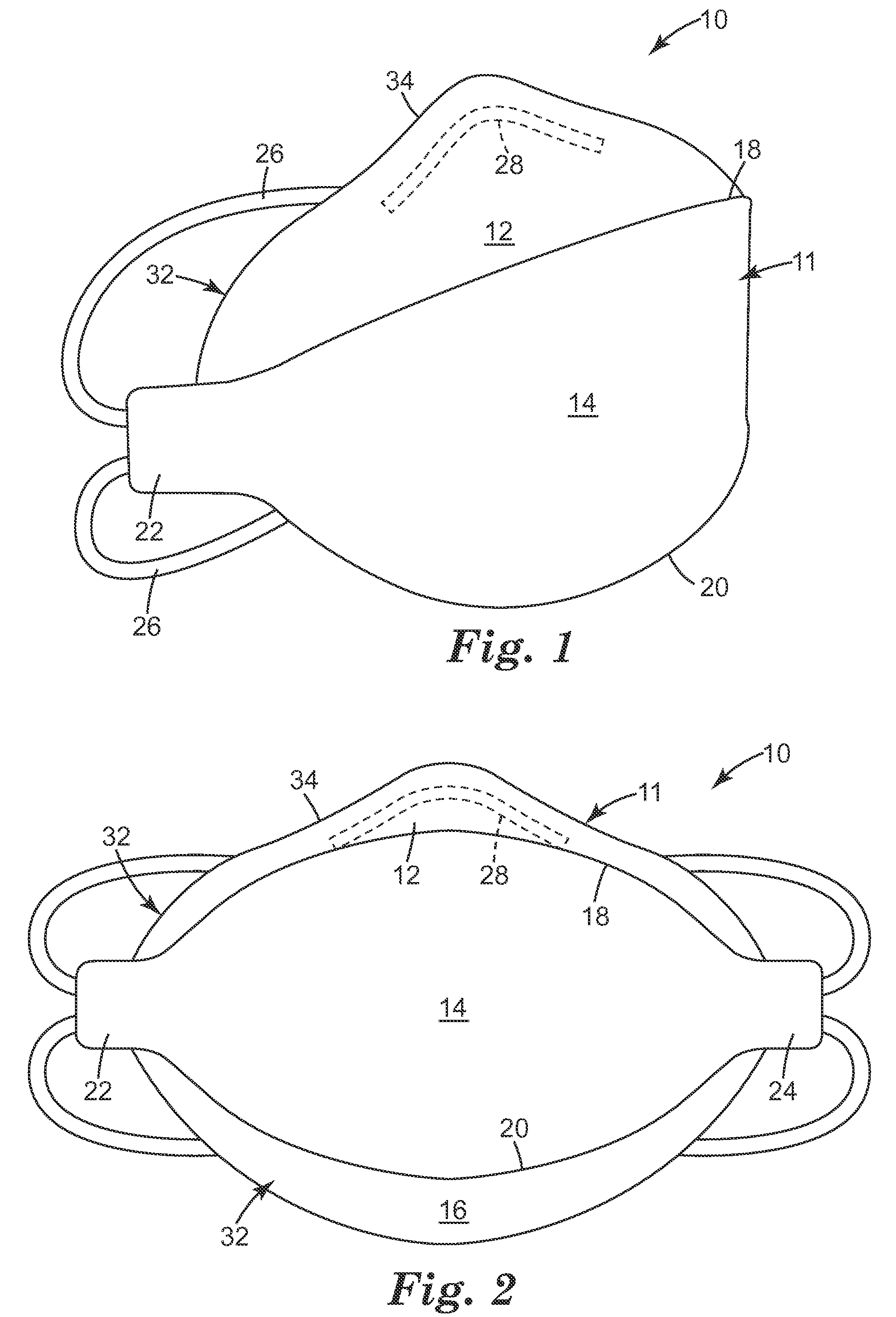

Maintenance-free respirator that has concave portions on opposing sides of mask top section

a technology of concave portions and mask top sections, which is applied in the direction of breathing masks, breathing protection, protective garments, etc., can solve the problems of wearer eyewear becoming fogged, contaminants entering the wearer's breathing track, and difficulty in achieving snug fit, etc., to achieve the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

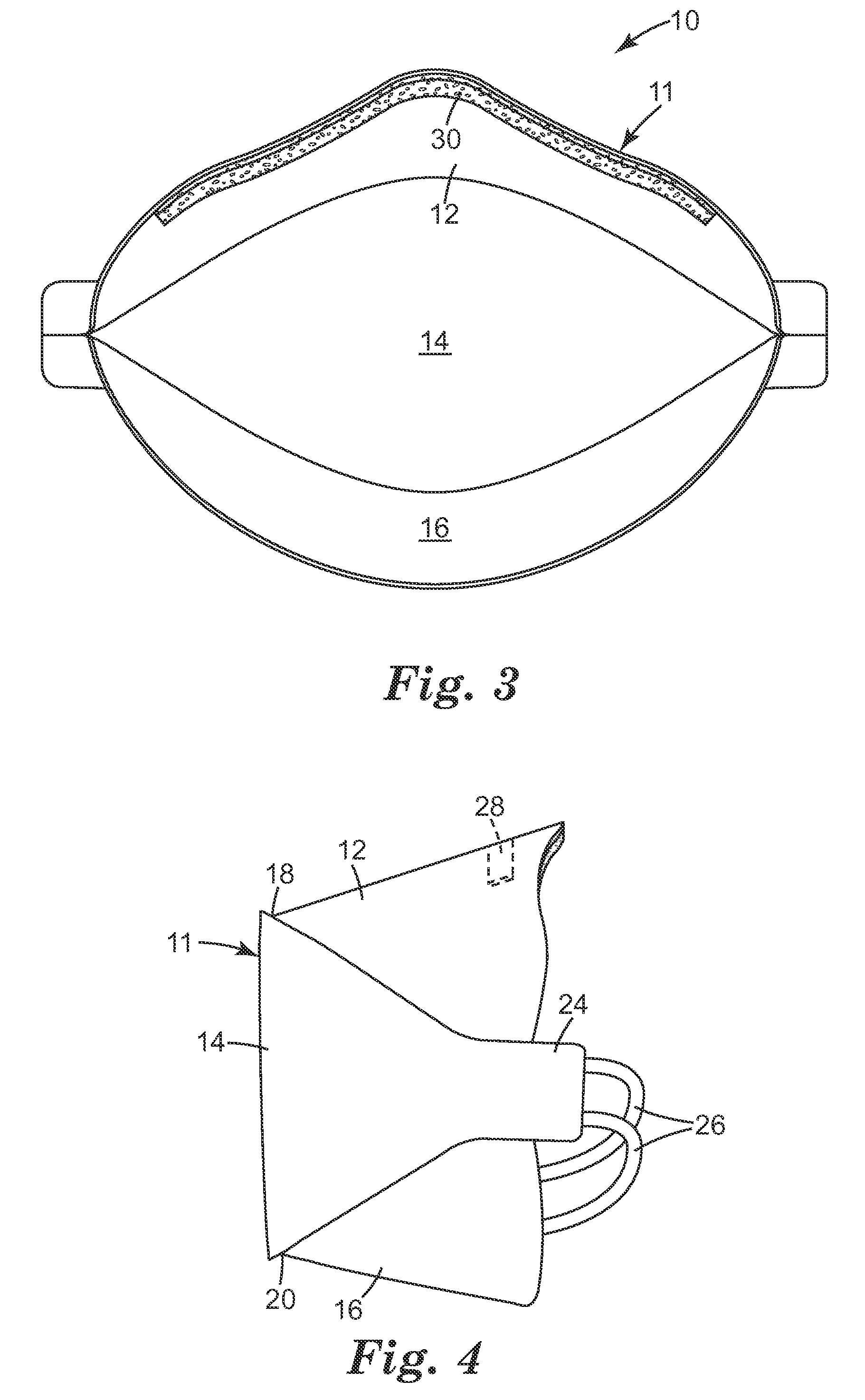

Top and Bottom Panels:

[0072]One 50 grams per square meter (gsm) spunbond polypropylene coverweb, Type 1050B1U00, available from Don and Low Nonwovens, Forfar, Scotland, United Kingdom (Outer layer);

[0073]Two electrically-charged, melt blown polypropylene microfiber filter layers having a basis weight of 100 g / m, an effective fiber diameter of 7 to 8 microns, and a thickness of about 1 mm; and

[0074]Smooth melt blown polypropylene microfiber (inner layer).

Central Panel:

[0075]One 90 gram per meter (gsm) spunbond polypropylene XAVAN 5261W Stiffening layer (inserted immediately under the outer cover web; available from E.I. DuPont de Nemours, Luxembourg, France).

[0076]Lengths of these panel constructions are laid up in to 5 meter (m) strips and die-cut using an hydraulic swing press into the correct shapes (approx 350 mm by 300 mm) for each of the three panels. The top, bottom, and the central panel blanks are each individually cut.

[0077]The bottom panel was placed into an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com