Patents

Literature

41results about How to "Significant form" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

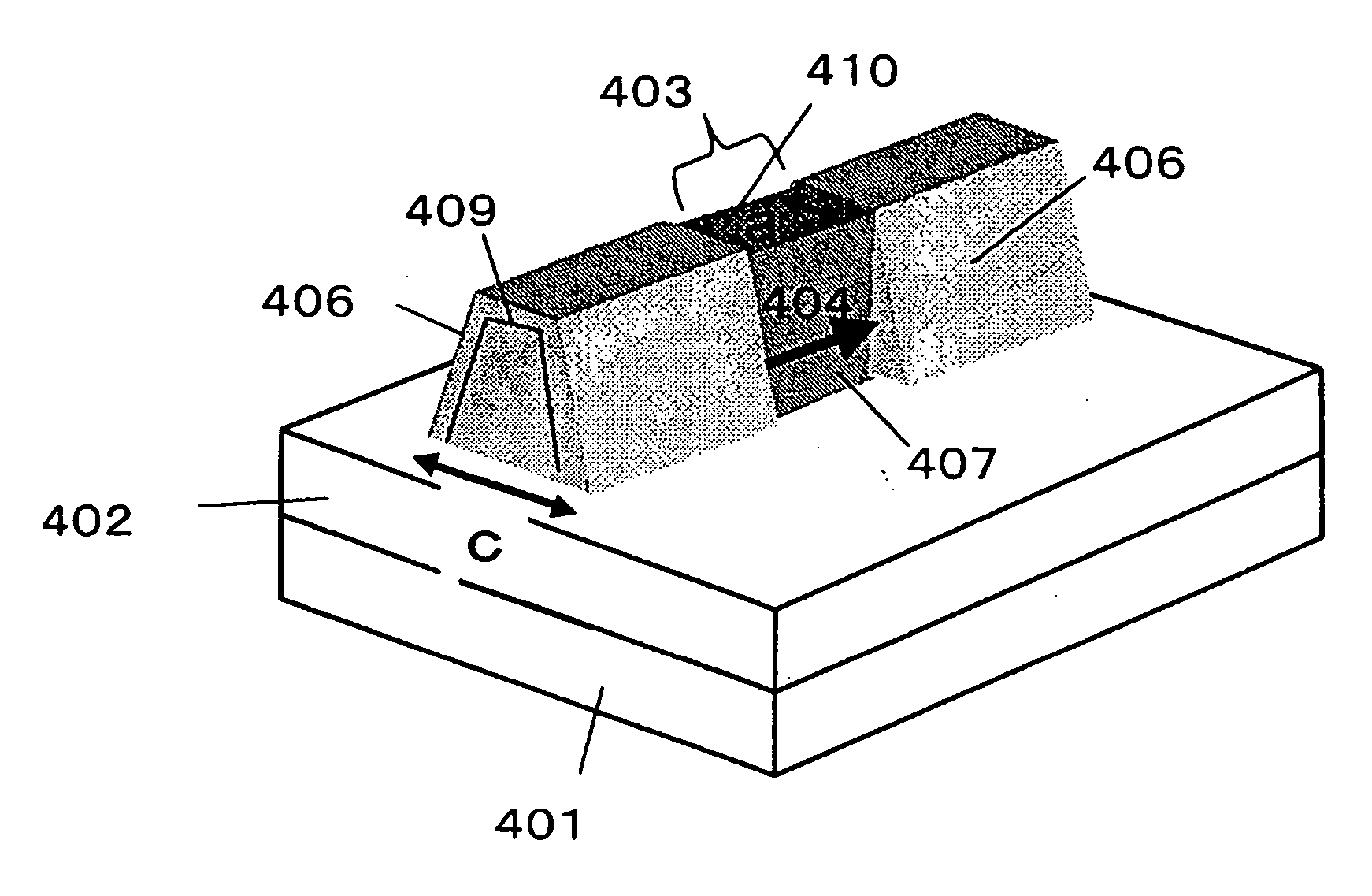

Semiconductor device and manufacturing process therefor

InactiveUS20070075372A1Easy alignmentReduce contact resistanceTransistorSemiconductor/solid-state device detailsSemiconductorSemiconductor device

There is provided a semiconductor device wherein at least the largest width of a source / drain region is larger than the width of a semiconductor region and the source / drain region has a slope having a width continuously increasing from the uppermost side to the substrate side, and a silicide film is formed in the surface of the slope.

Owner:NEC CORP

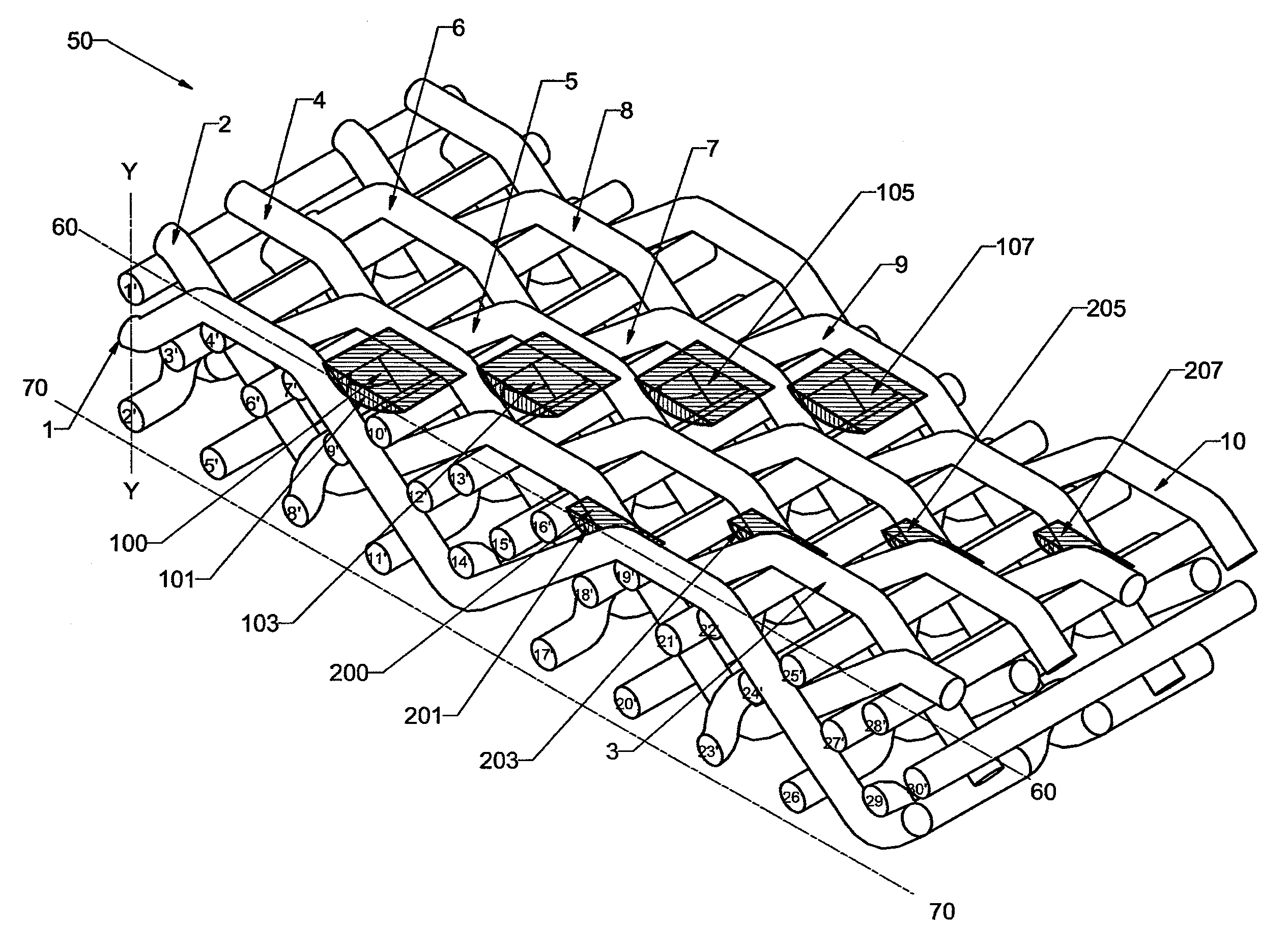

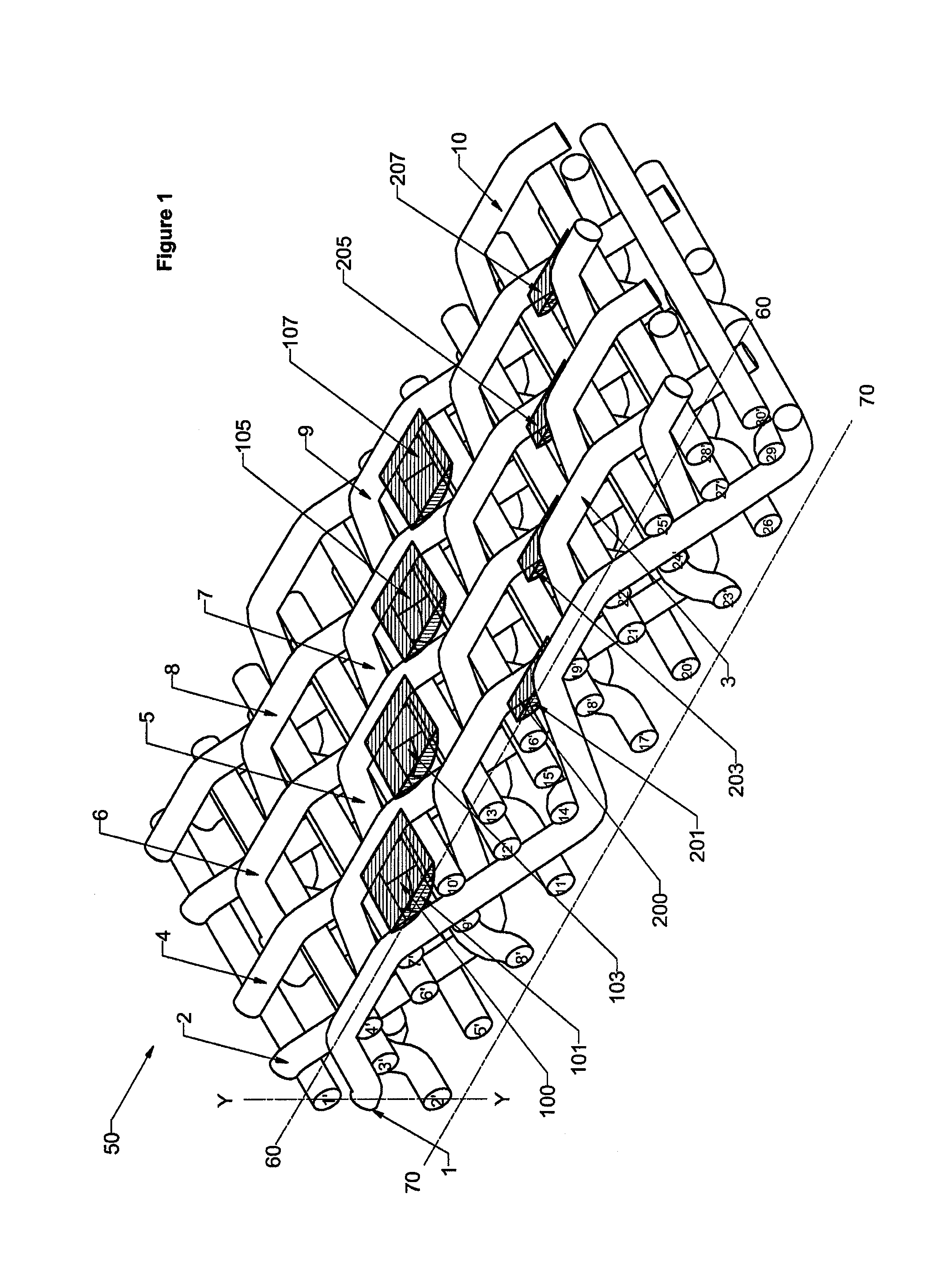

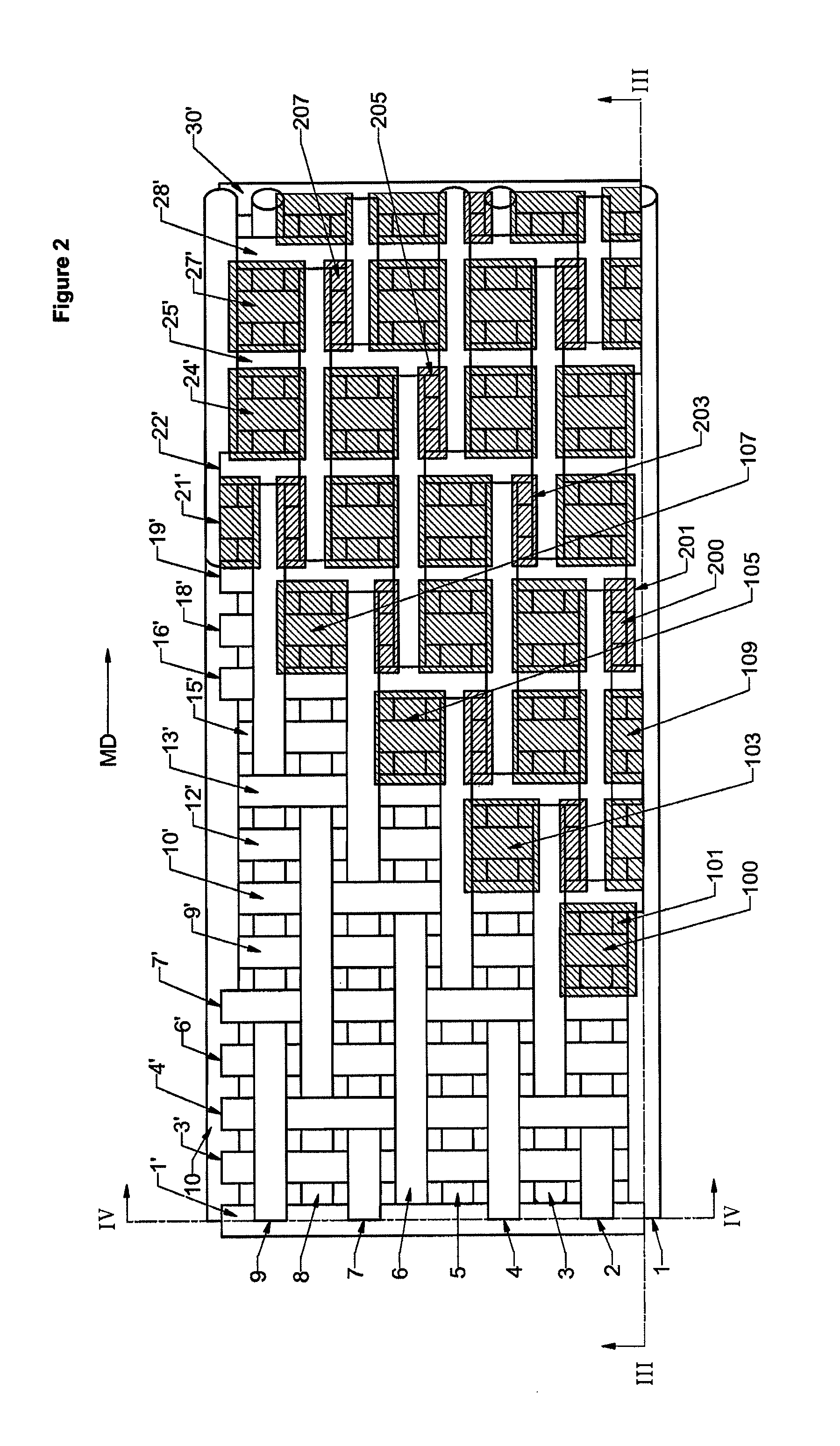

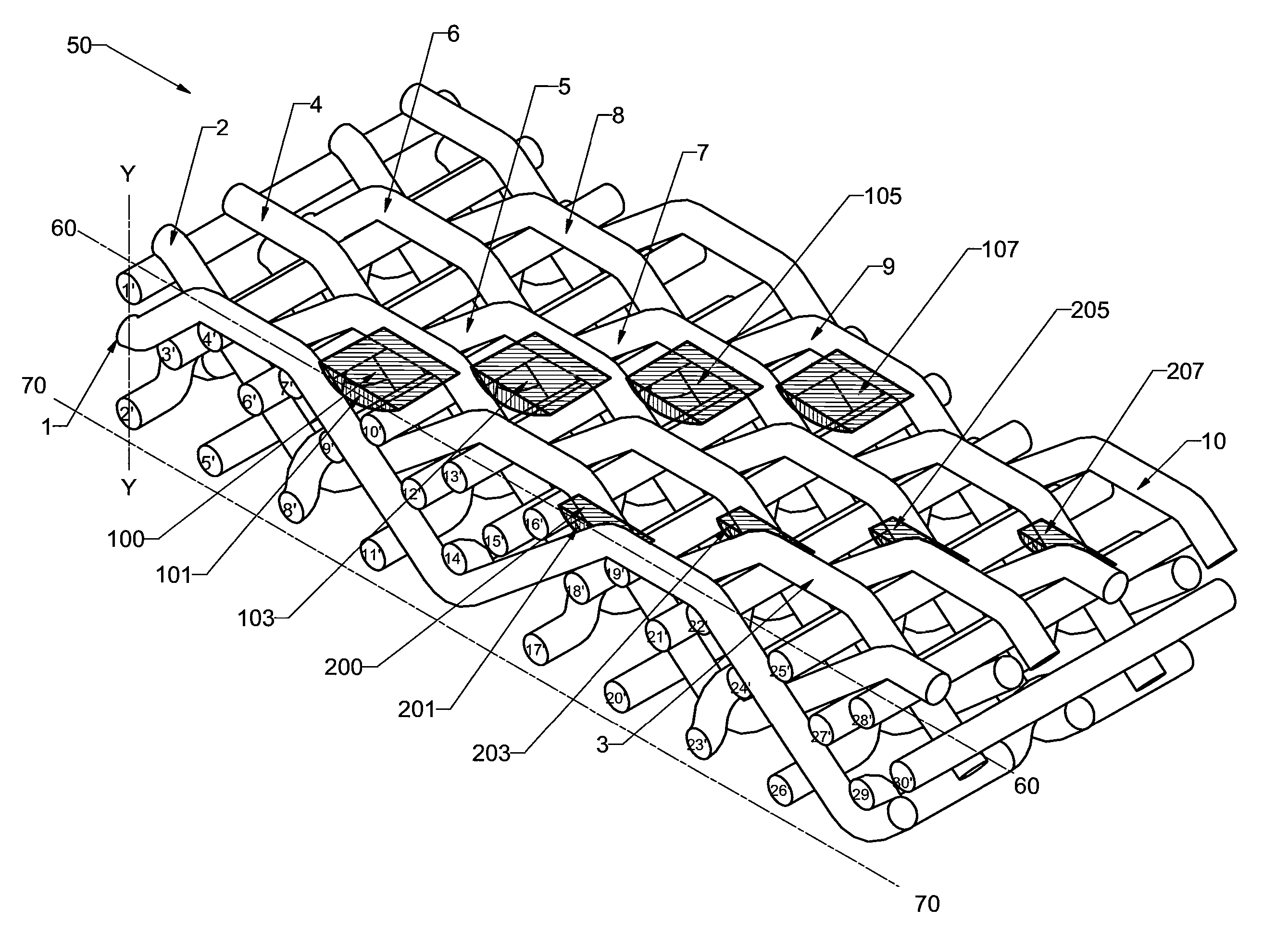

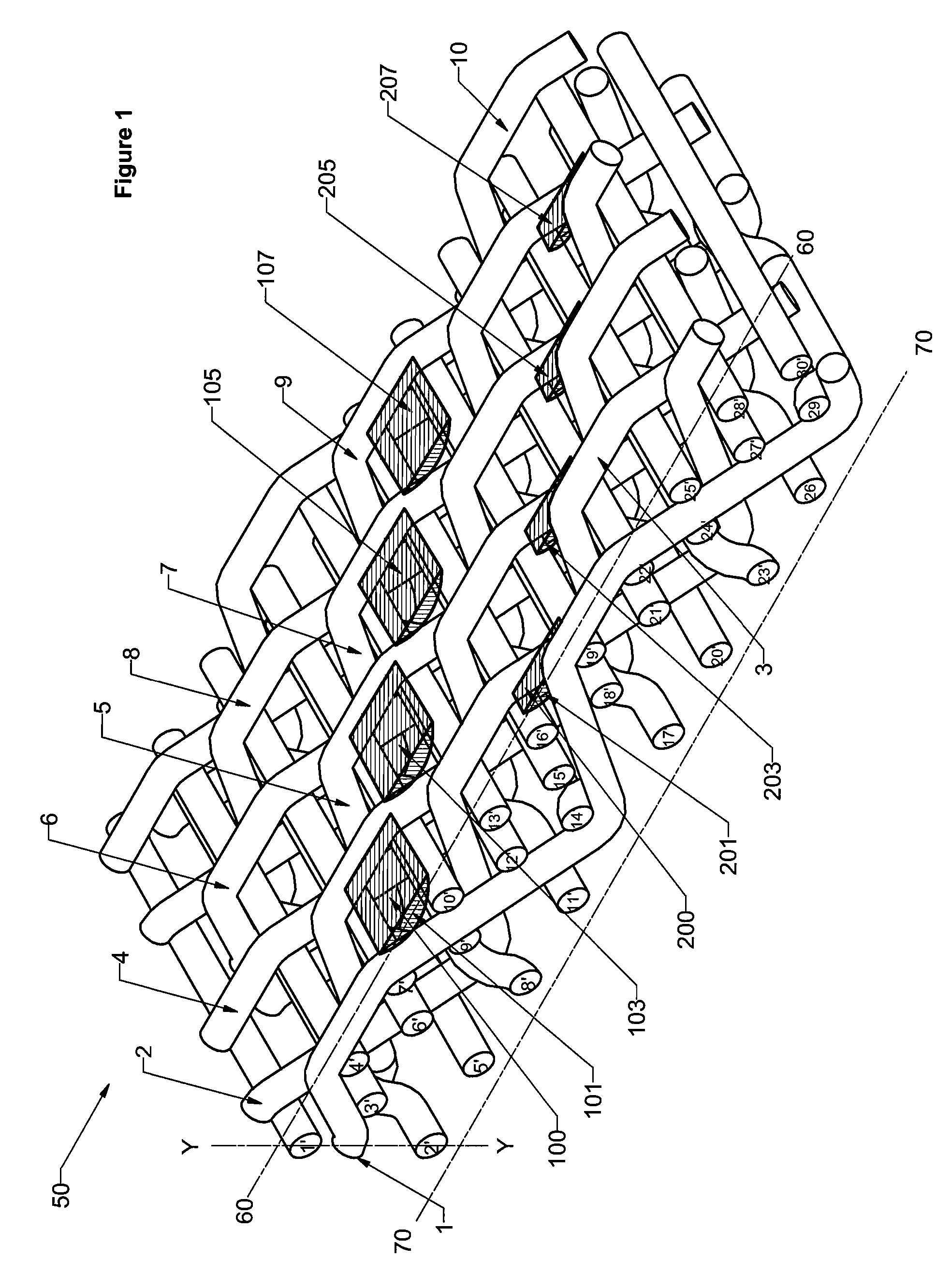

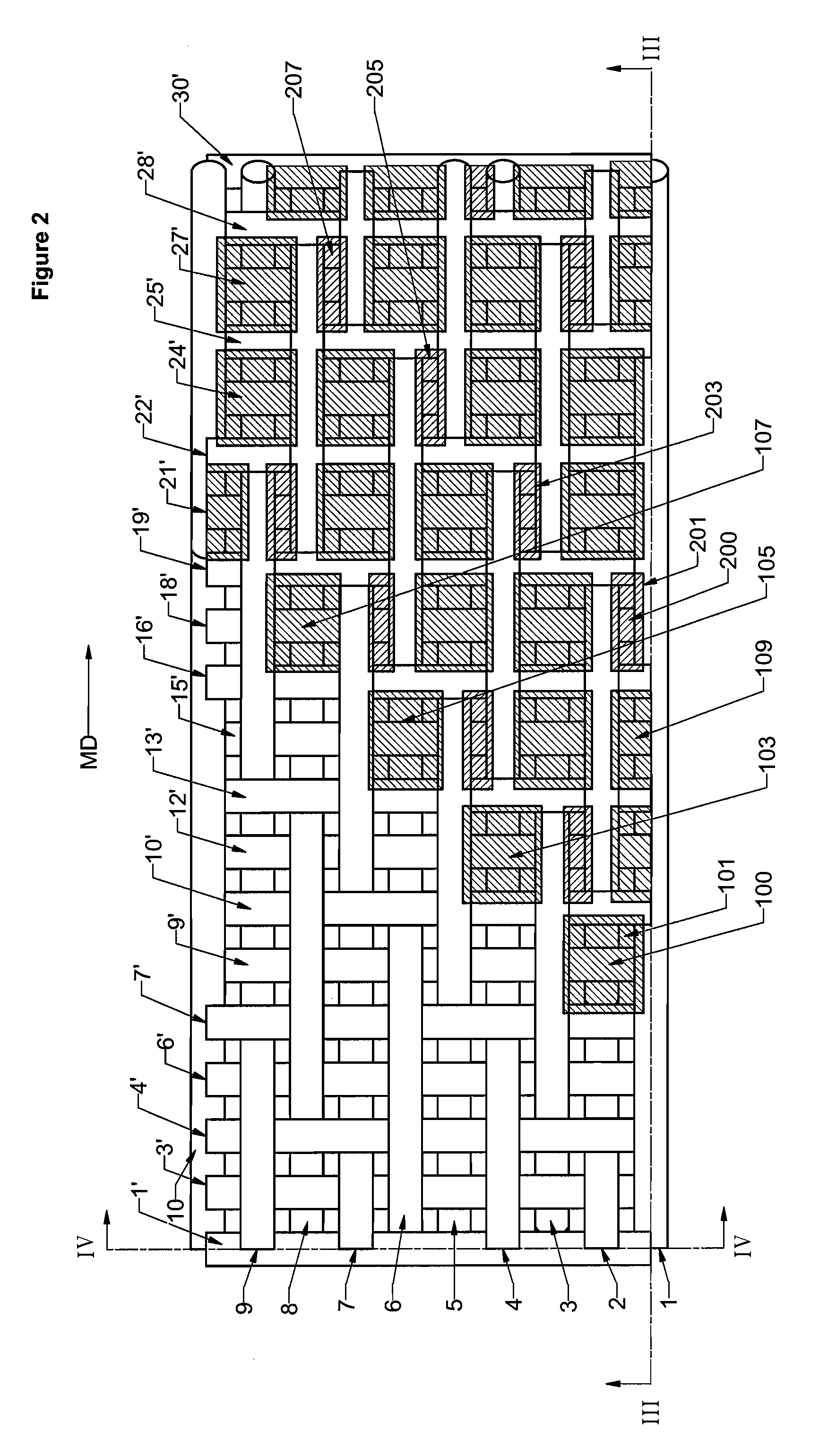

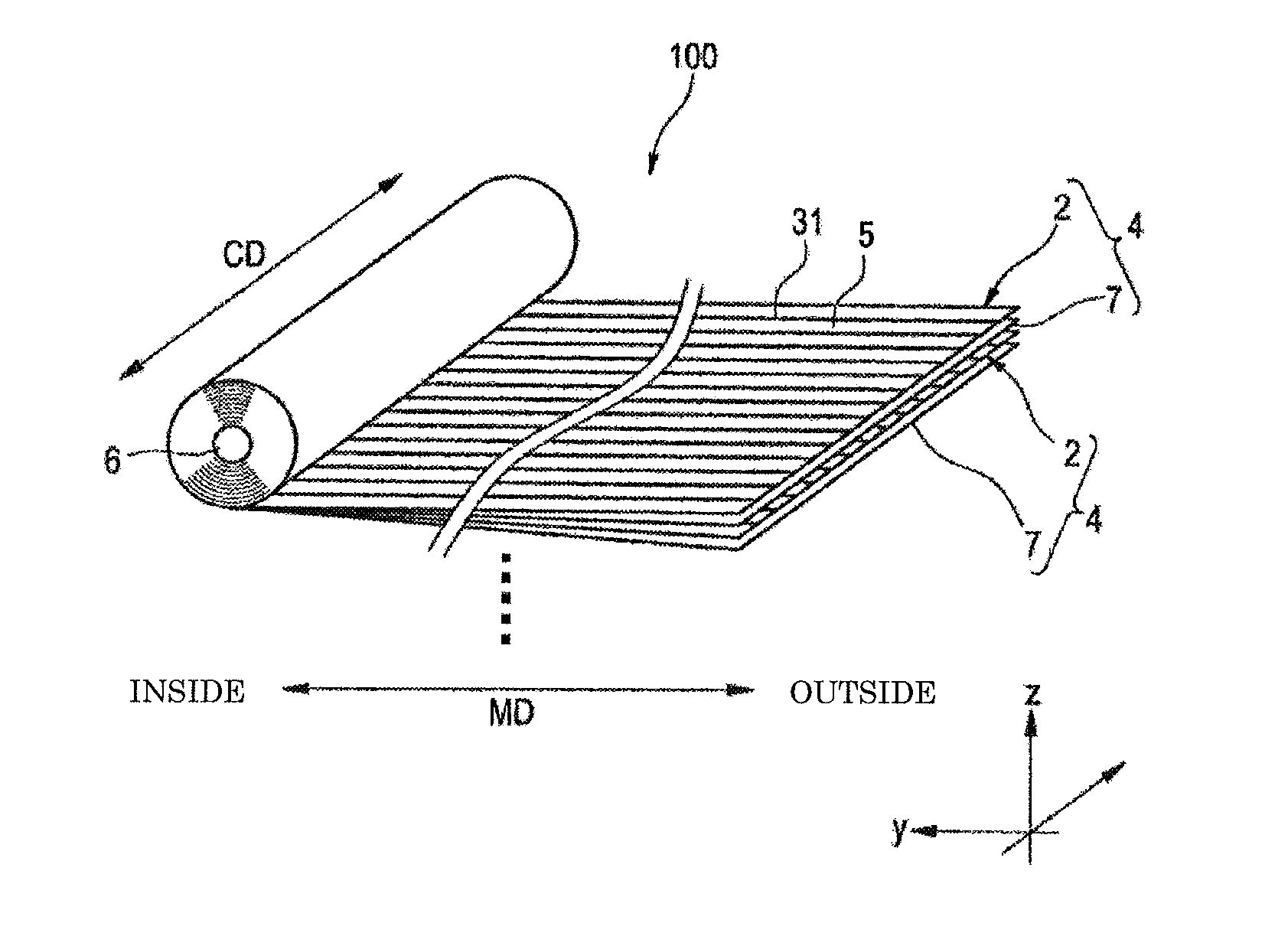

Double layer papermakers fabric with pockets for bulk enhancement

InactiveUS7493923B2Impart surface roughnessSignificant formMachine wet endPress sectionEngineeringWeft yarn

A double layer papermakers' fabric that is particularly suitable for forming or through-air drying (TAD) of high bulk tissue and towel product is provided. The fabric includes a single warp yarn system interwoven with three weft yarn systems such that: a first of the weft yarn systems is located on the paper side (PS) surface of the fabric; a second of the weft yarn systems is located on the machine side (MS) surface of the fabric; and the third weft yarn system is located intermediate between the first and second weft yarn systems. The yarns of the first and second weft yarn systems are interwoven with the warp yarn system such that they are vertically stacked with respect to one another in the fabric. The yarns of the third weft yarn system are interwoven so as to be located in a central plane of the fabric that is intermediate of the first and second weft yarn systems, and each yarn of the third yarn system is located in between the vertically stacked pairs of weft yarns of the first and second weft yarn systems. The warp and weft yarn systems are interwoven according to an asymmetric design which provides generally rectangular pockets on each of the PS and MS of the fabric with the yarns of the third weft yarn system forming the “bottom” of each pocket. There may be from about 50 to 750 pockets per sq. in. of fabric, each ranging in depth from about 0.1 mm to about 1.0 mm in depth; these pockets impart unevenness to the fabric surface which assists in creating bulk in the sheet formed or conveyed thereon. The fabrics of the invention also offer low sheet contact area, typically less than 30% of the total fabric surface, and generally in the range of from 15% to about 20%. The fabrics are also highly air permeable to ensure good air flow and drainage of the sheet.

Owner:ASTENJOHNSON

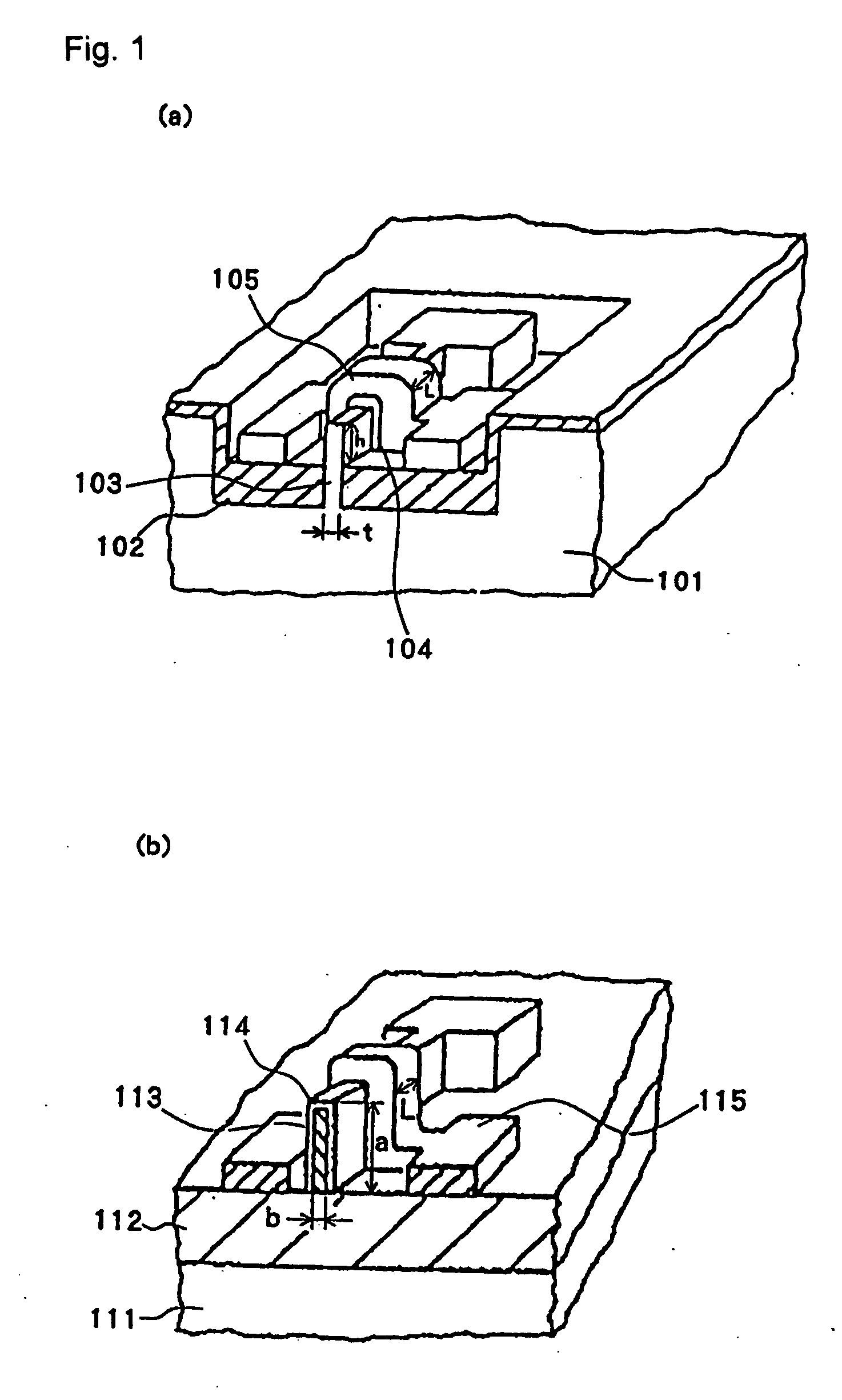

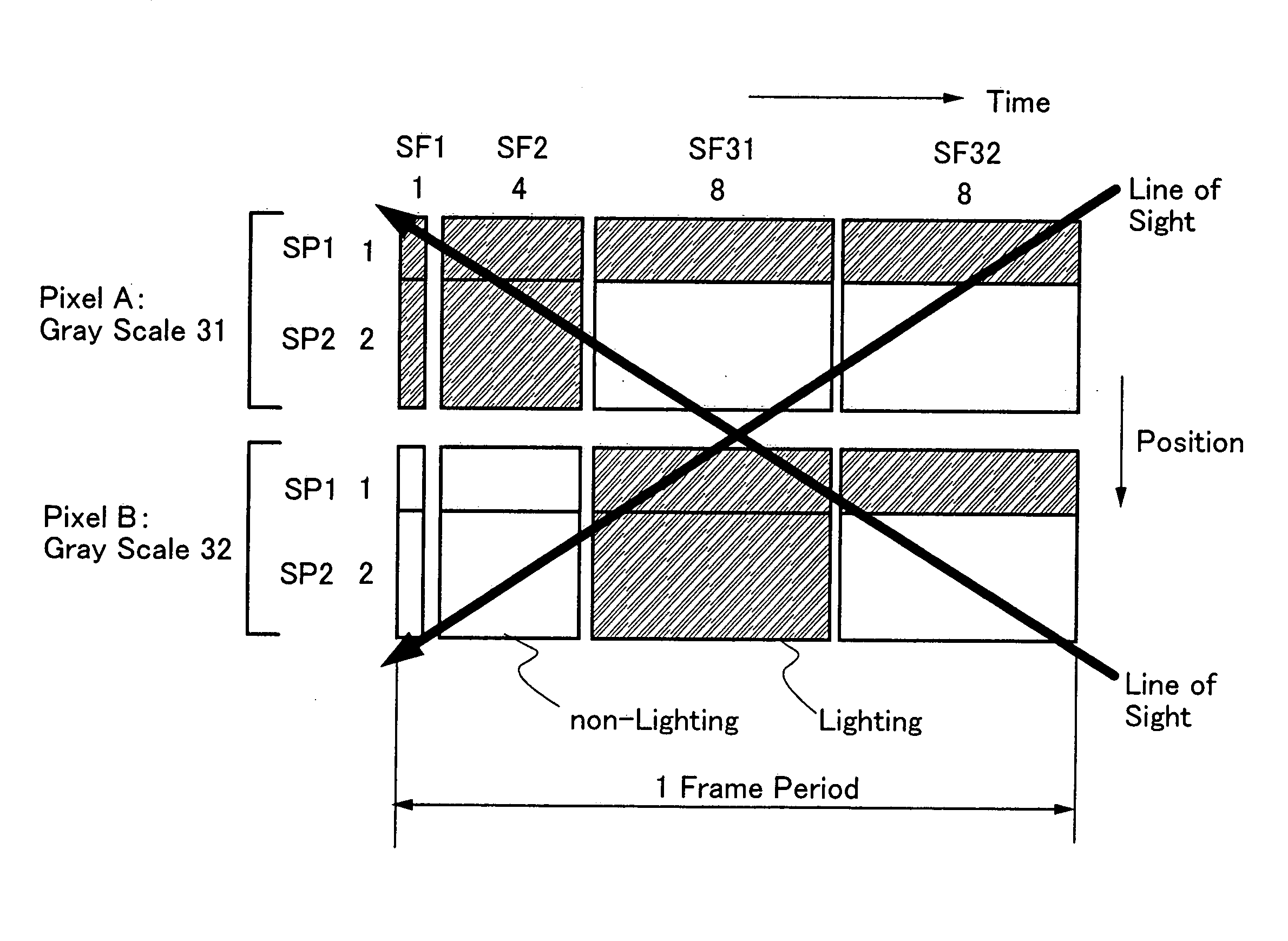

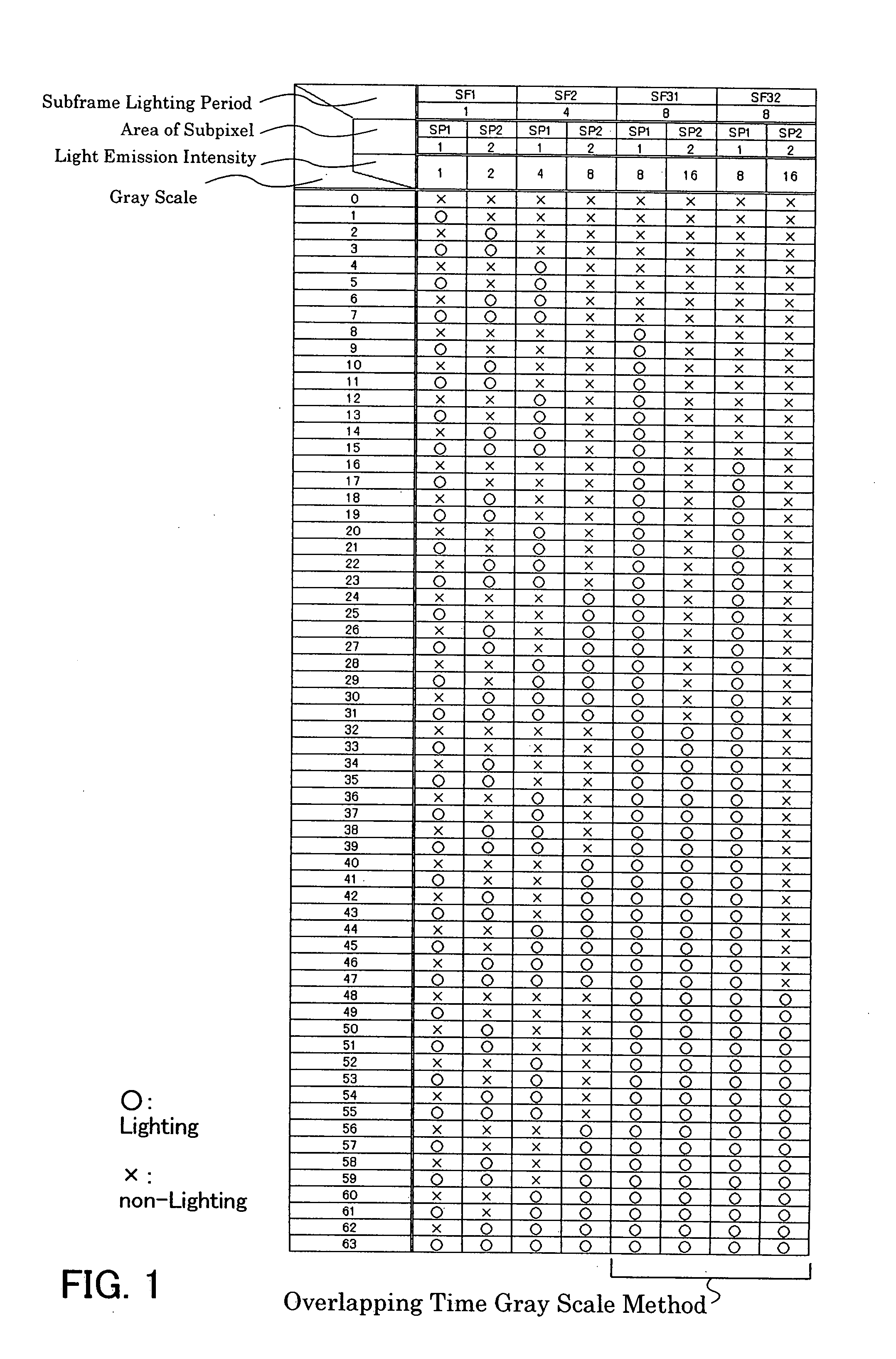

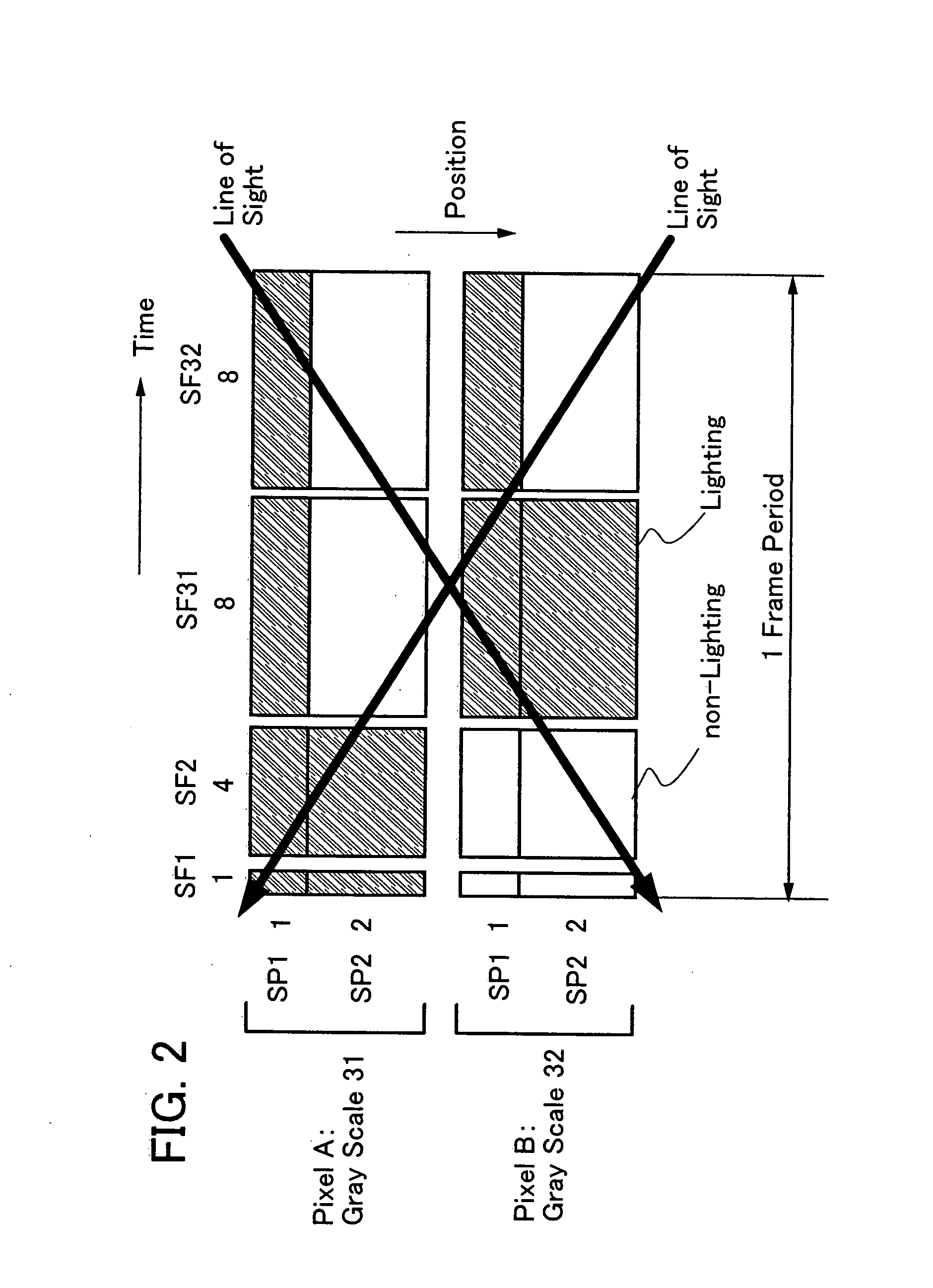

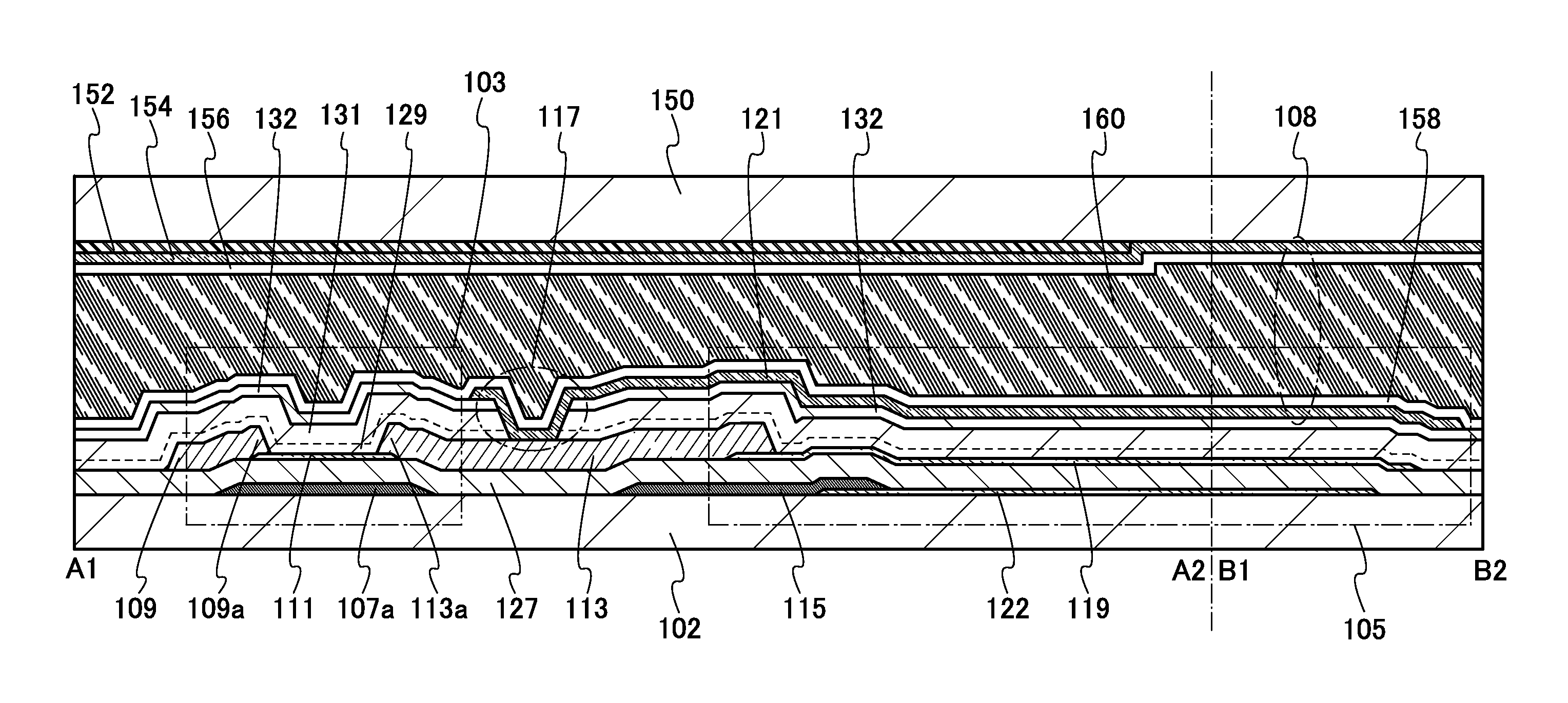

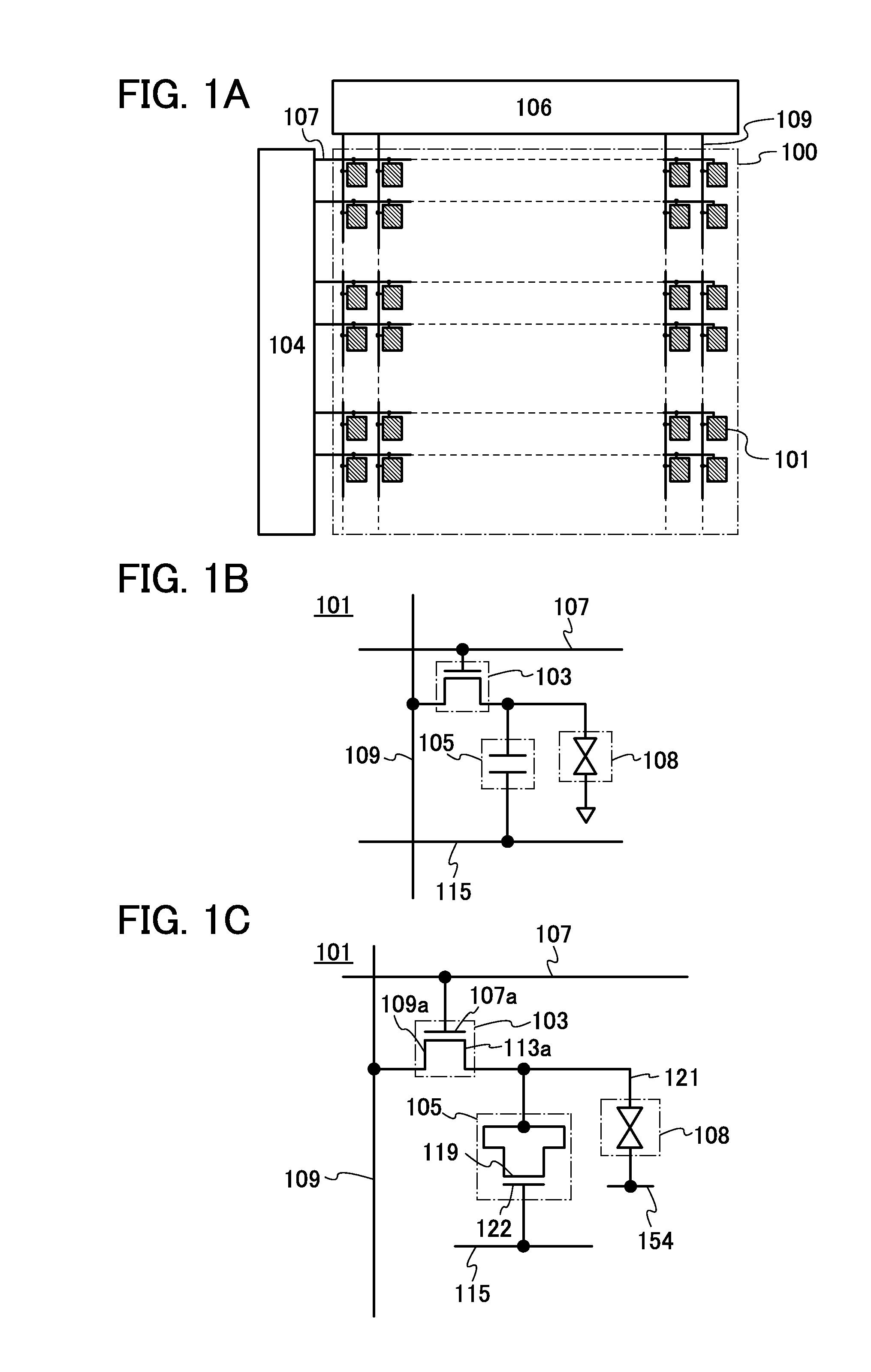

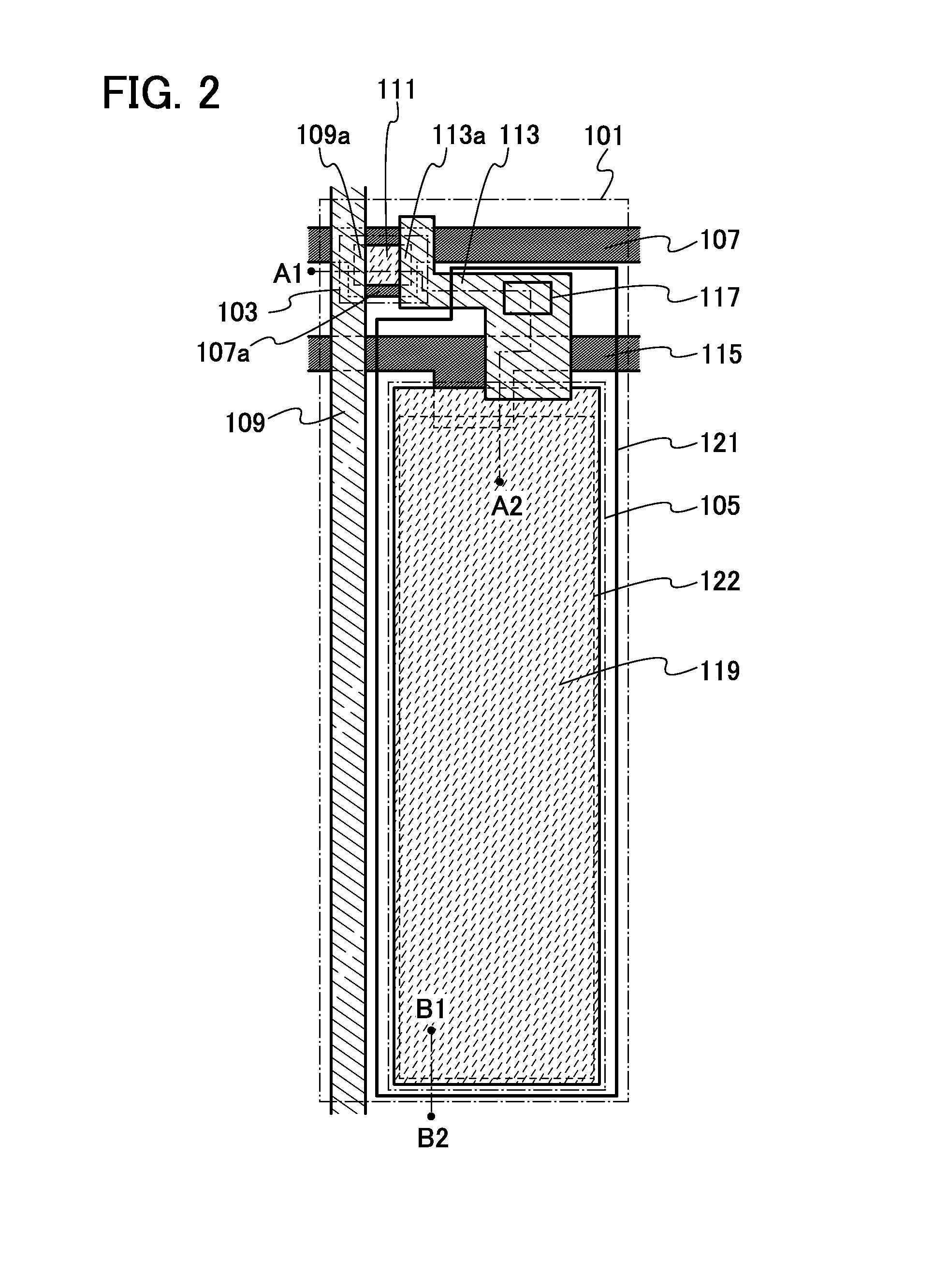

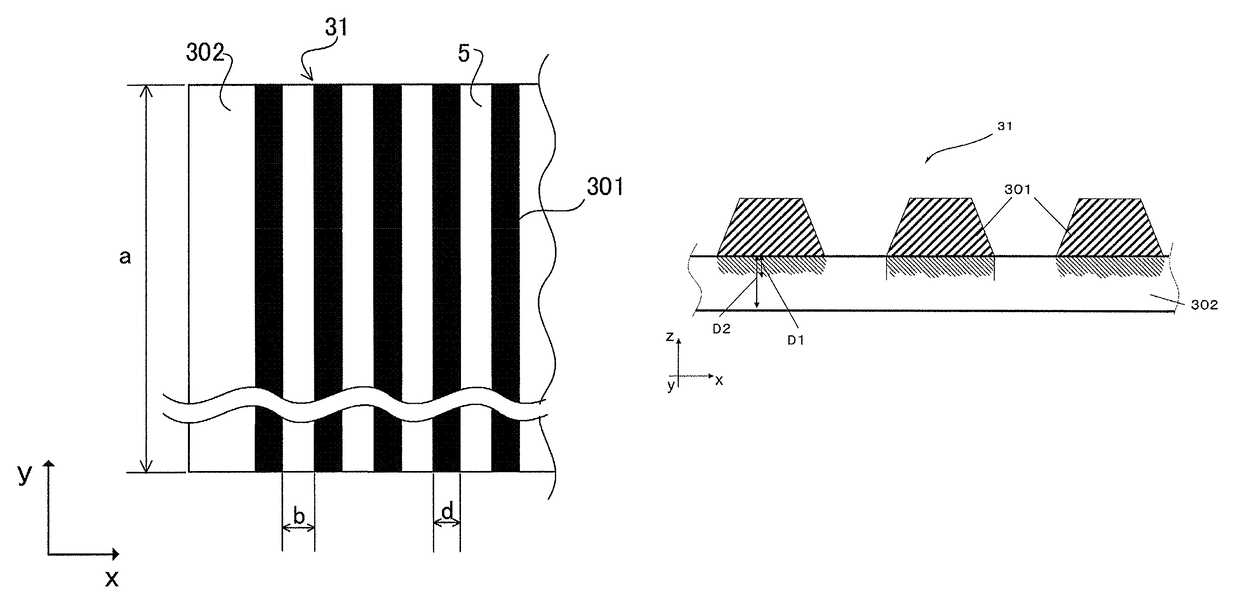

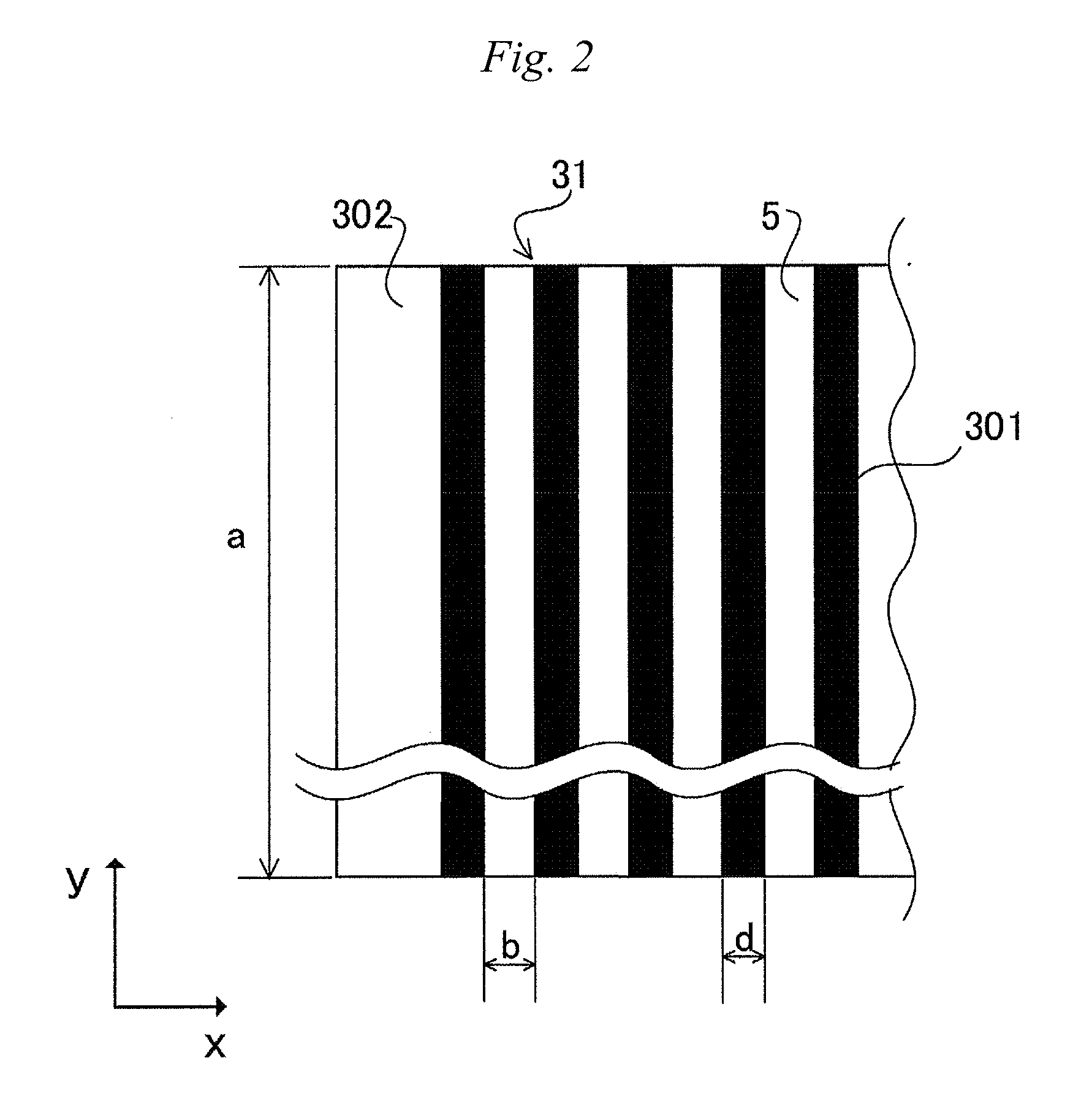

Display device, driving method of display device, and electronic appliance

InactiveUS20070279344A1Clear imagingImprove display qualitySolid-state devicesCathode-ray tube indicatorsDisplay deviceComputer science

An object is to reduce a pseudo contour occurring in time gray scale method display. One pixel is divided into m subpixels (m is an integer of m≧2), and the area of the (s+1)th subpixel (1≦s≦m−1) is twice the area of the s-th subpixel. Further, one frame is divided into n subframes (n is an integer of n≧2), and a lighting period of the (p+1)th subframe (1≦p≦n−1) is 2m times longer than a lighting period of a p-th subframe. Then, at least one subframe of the n subframes is divided into a plurality of subpixels each having a lighting period shorter than that of the subframe so that the n subframes are increased to t subframes (t>n). In at least one subframe of the t subframes, lighting periods of the subframes in a lighting state are sequentially added by the m subpixels, so that a gray scale of the pixel is expressed. (174 words)

Owner:SEMICON ENERGY LAB CO LTD

Double layer papermakers fabric with pockets for bulk enhancement

InactiveUS20070209770A1Reduce penetrationGood sheet formationMachine wet endPress sectionEngineeringWeft yarn

A double layer papermakers' fabric that is particularly suitable for forming or through-air drying (TAD) of high bulk tissue and towel product is provided. The fabric includes a single warp yarn system interwoven with three weft yarn systems such that: a first of the weft yarn systems is located on the paper side (PS) surface of the fabric; a second of the weft yarn systems is located on the machine side (MS) surface of the fabric; and the third weft yarn system is located intermediate between the first and second weft yarn systems. The yarns of the first and second weft yarn systems are interwoven with the warp yarn system such that they are vertically stacked with respect to one another in the fabric. The yarns of the third weft yarn system are interwoven so as to be located in a central plane of the fabric that is intermediate of the first and second weft yarn systems, and each yarn of the third yarn system is located in between the vertically stacked pairs of weft yarns of the first and second weft yarn systems. The warp and weft yarn systems are interwoven according to an asymmetric design which provides generally rectangular pockets on each of the PS and MS of the fabric with the yarns of the third weft yarn system forming the “bottom” of each pocket. There may be from about 50 to 750 pockets per sq. in. of fabric, each ranging in depth from about 0.1 mm to about 1.0 mm in depth; these pockets impart unevenness to the fabric surface which assists in creating bulk in the sheet formed or conveyed thereon. The fabrics of the invention also offer low sheet contact area, typically less than 30% of the total fabric surface, and generally in the range of from 15% to about 20%. The fabrics are also highly air permeable to ensure good air flow and drainage of the sheet.

Owner:ASTENJOHNSON

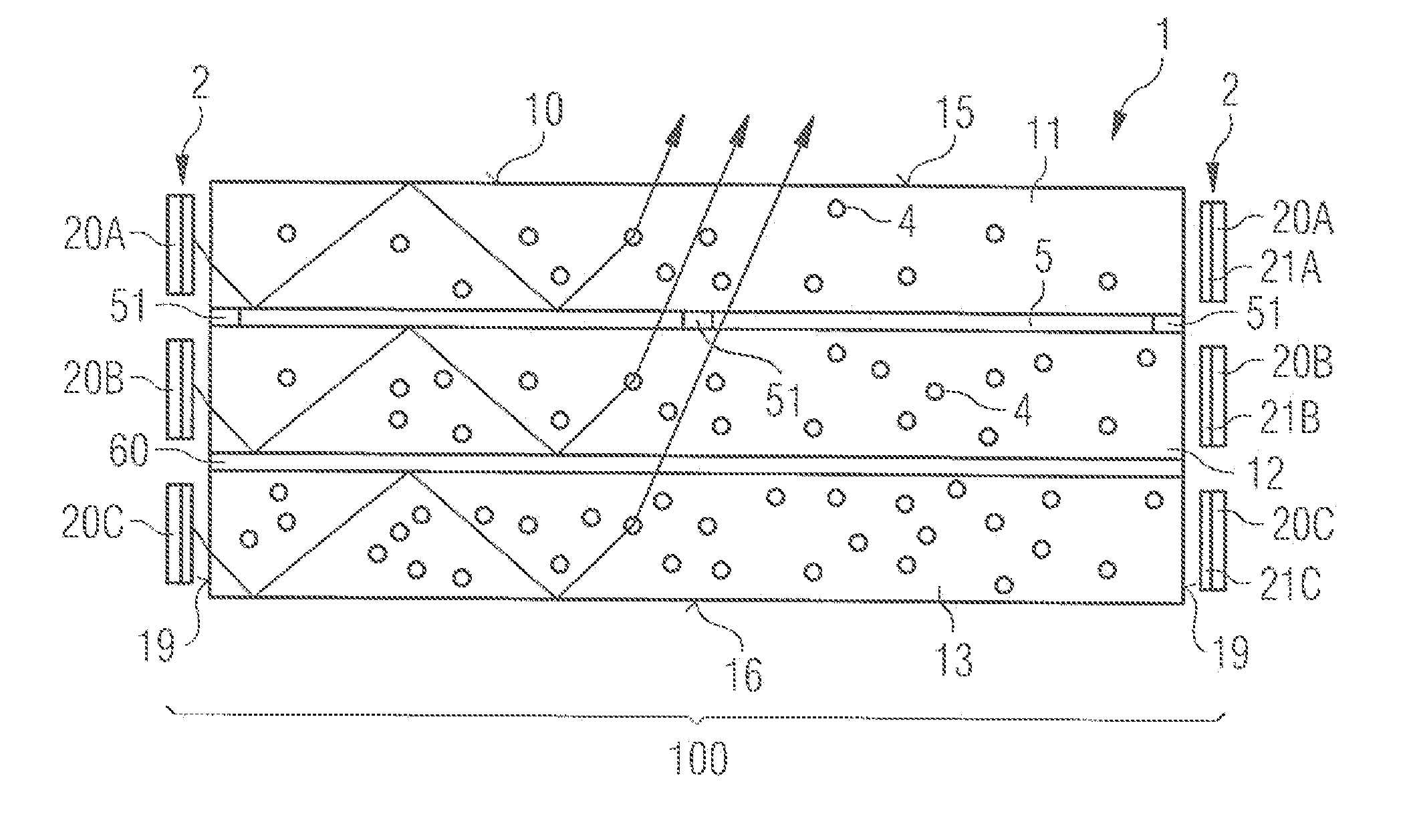

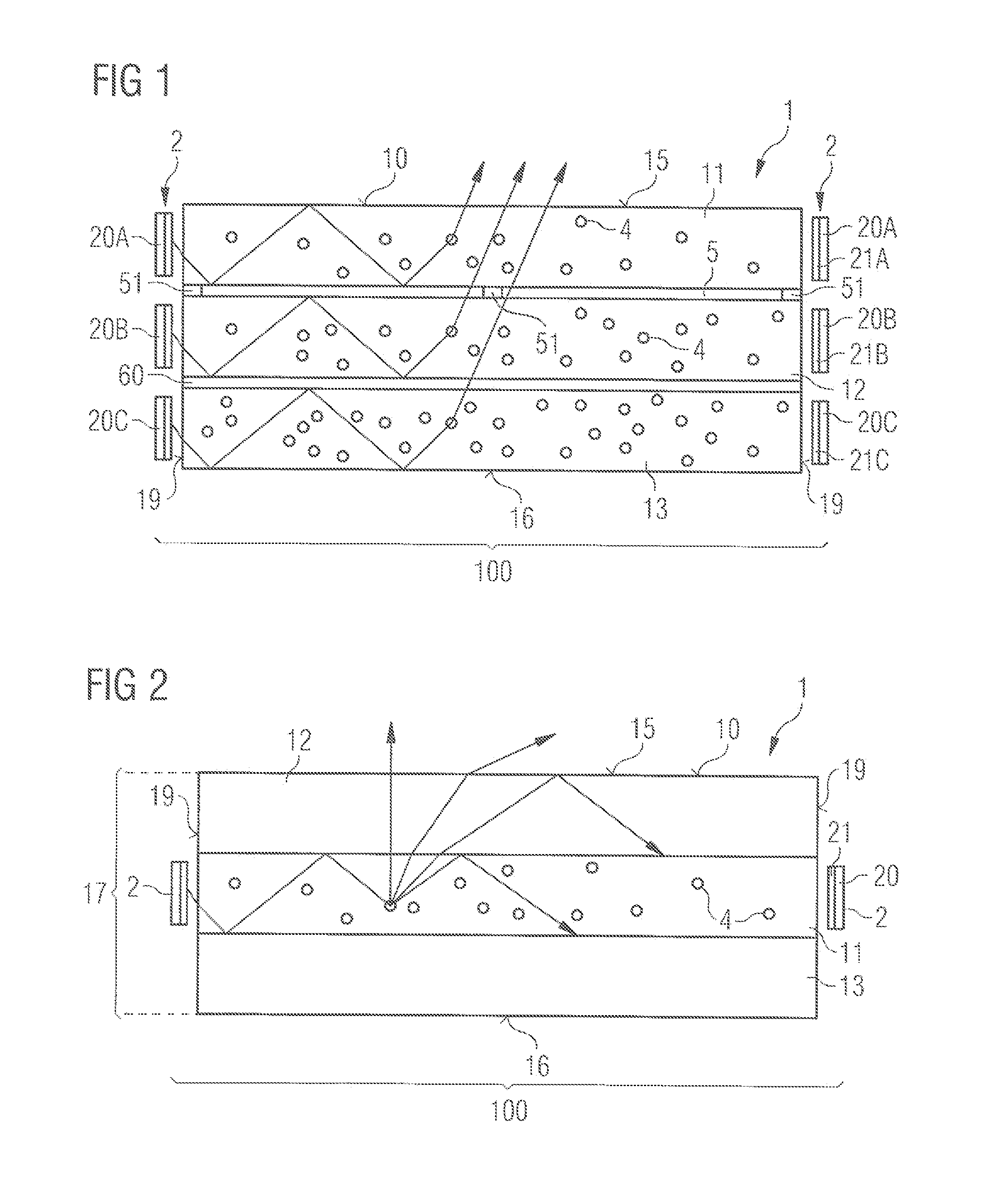

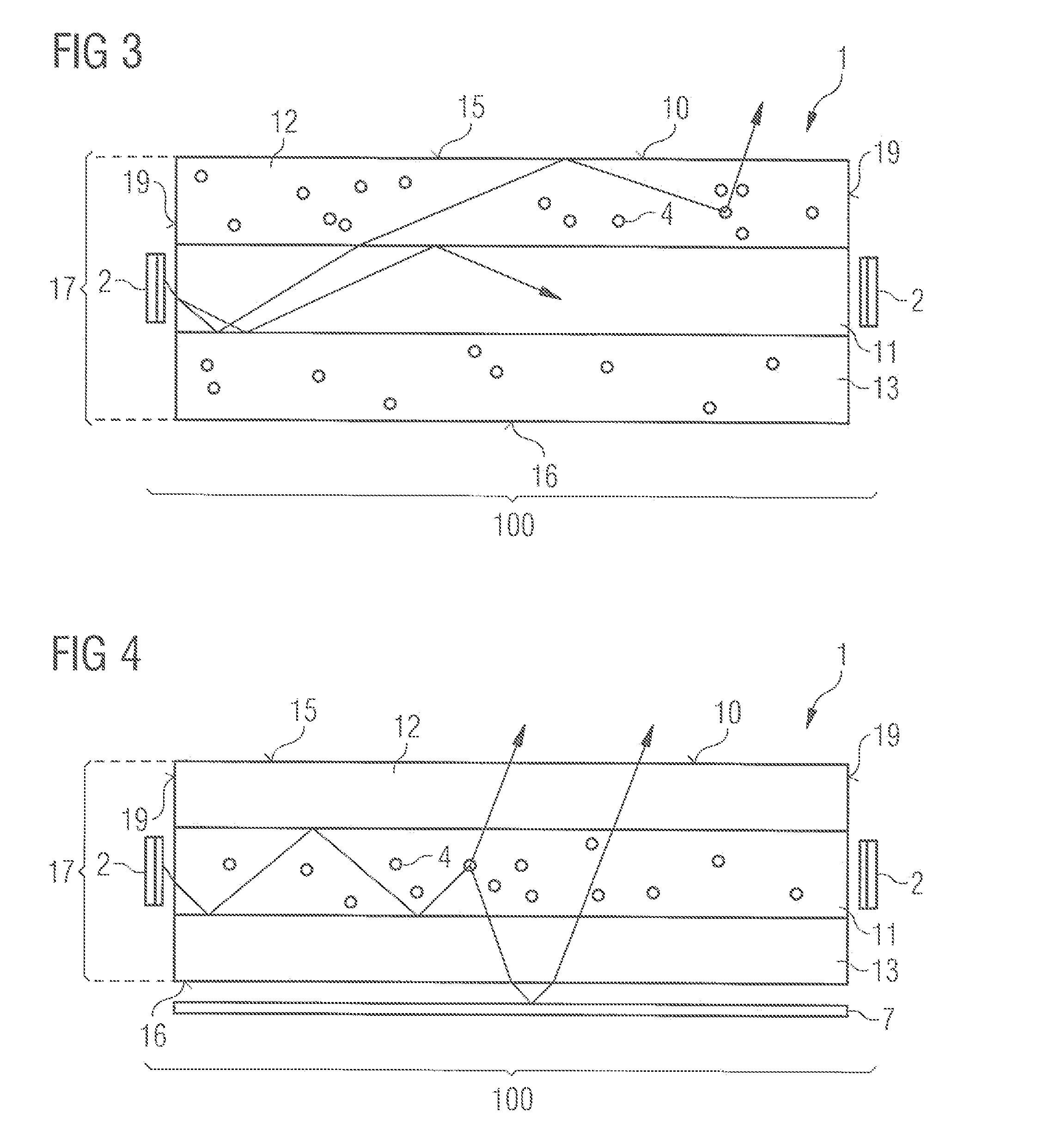

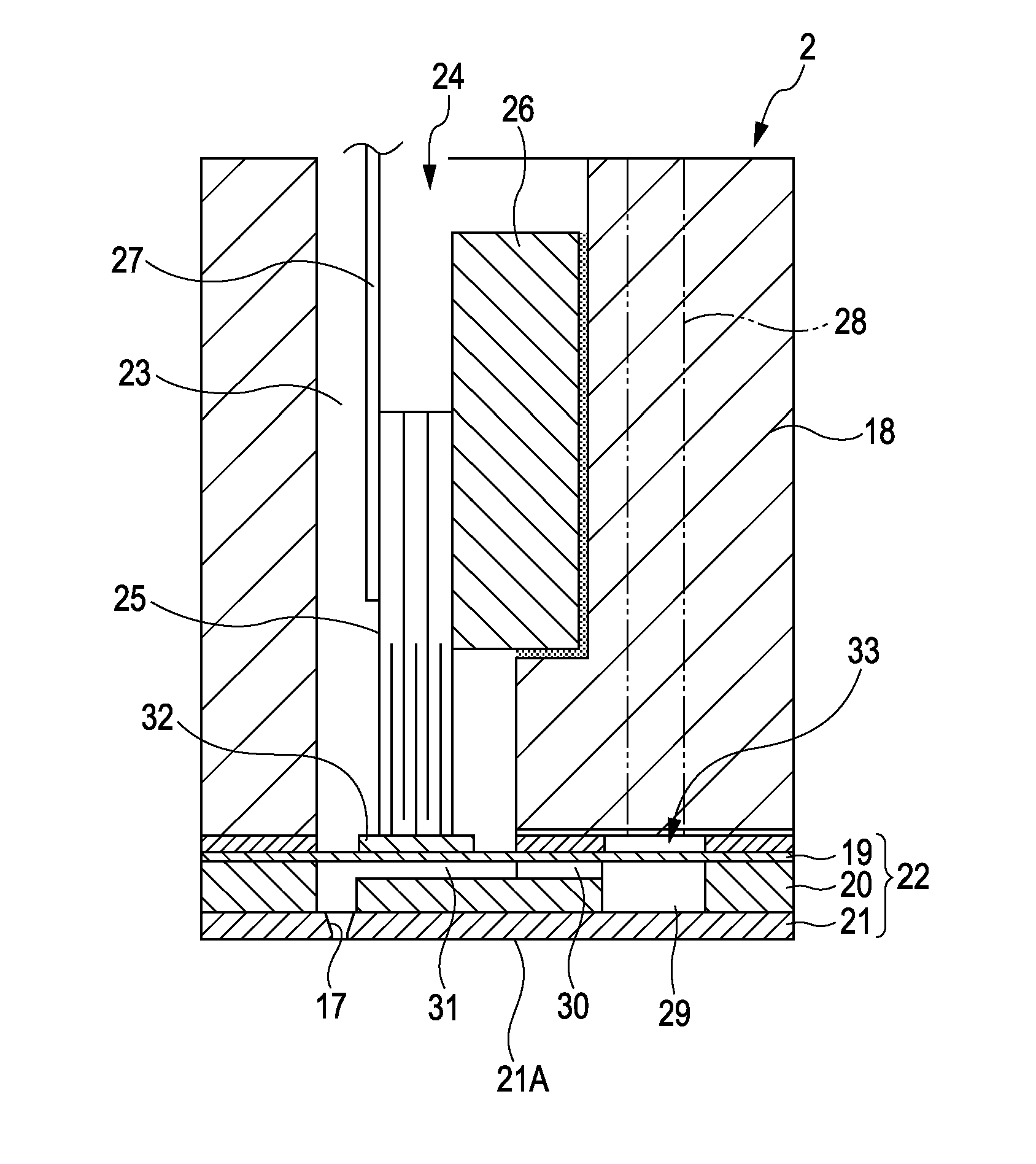

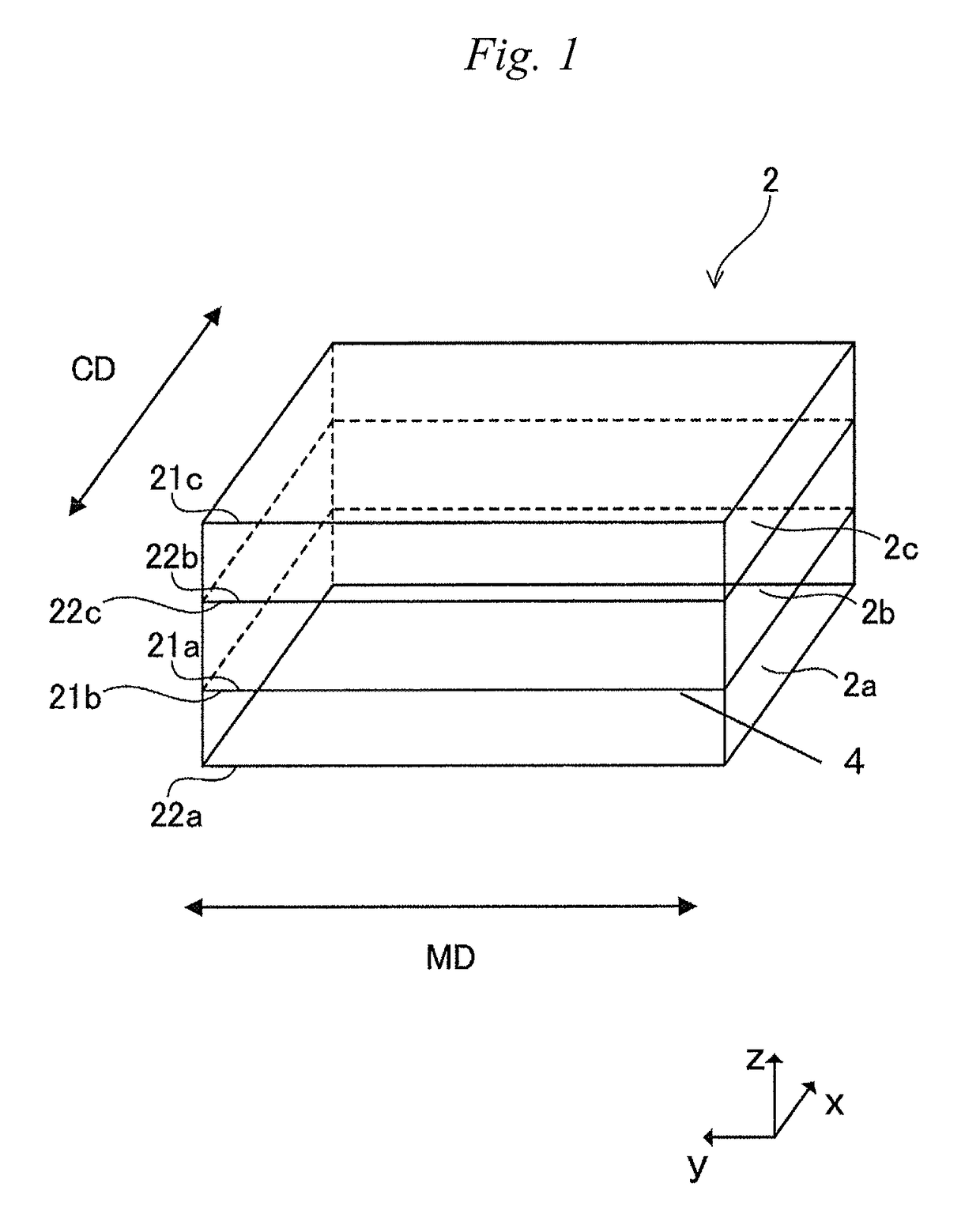

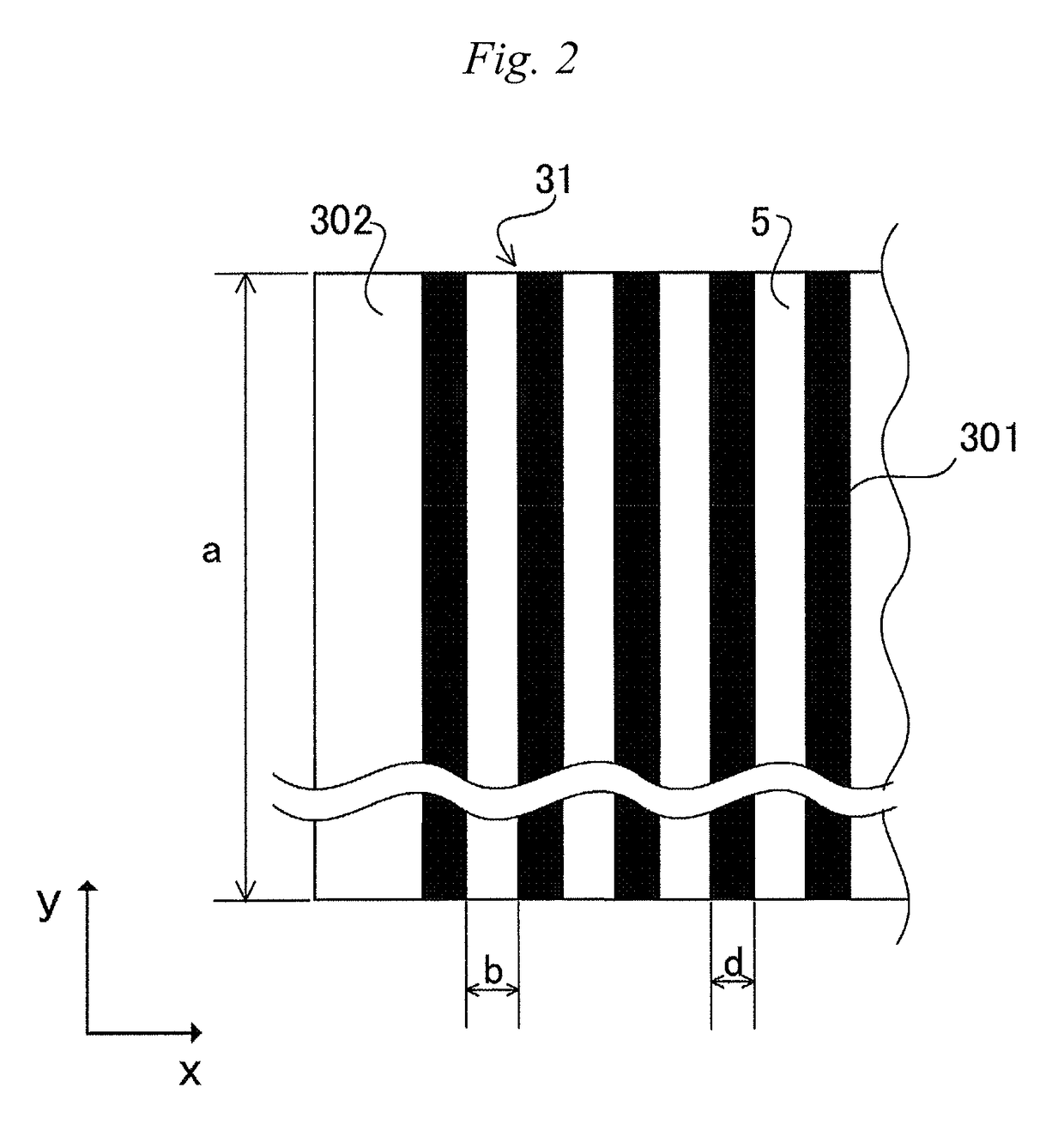

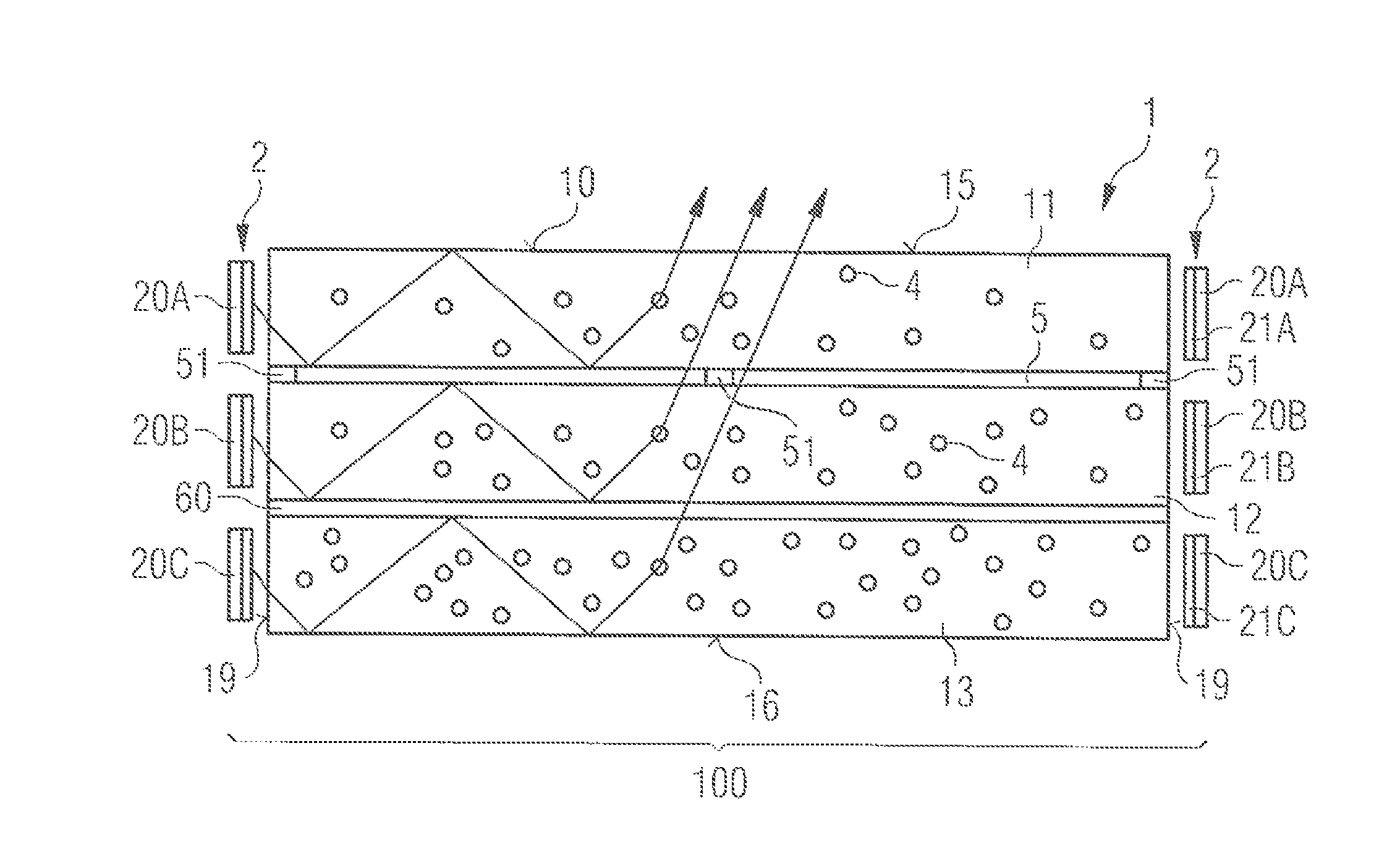

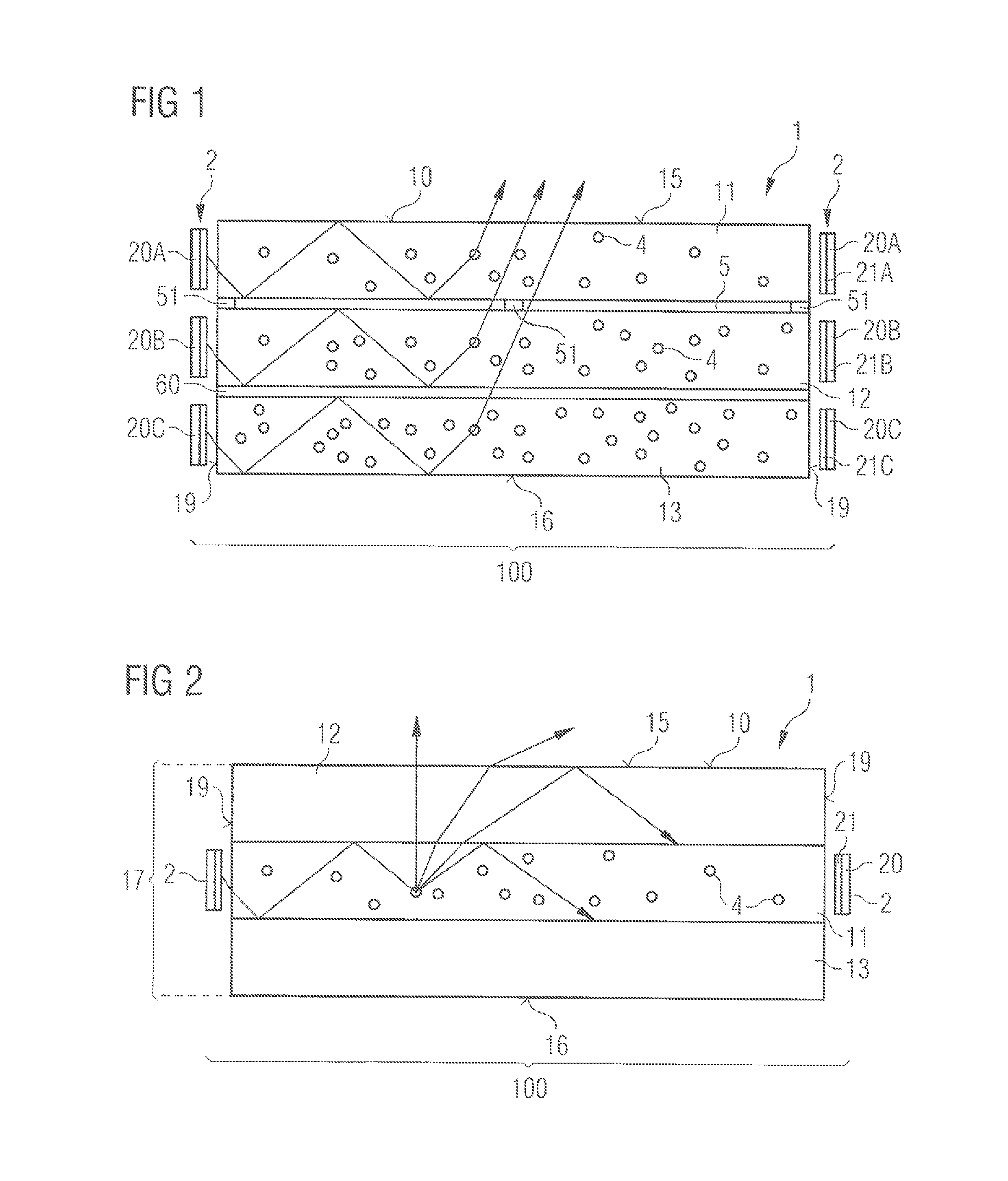

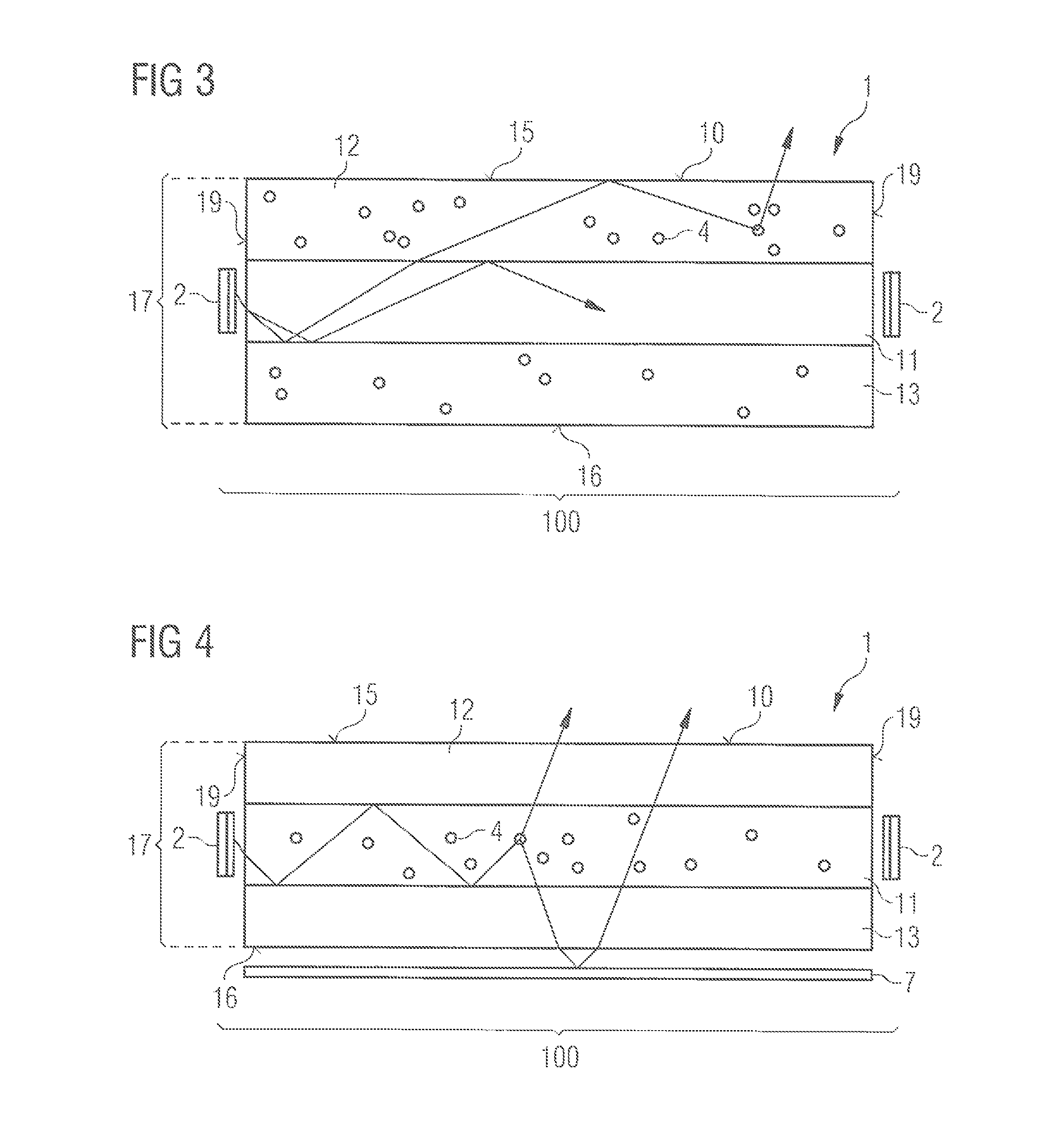

Surface Light Guide and Planar Emitter

InactiveUS20130114292A1Increase probabilityIncrease concentrationMechanical apparatusPlanar/plate-like light guidesLight guideSecondary layer

A surface light guide has a radiation exit area extending along a main extension plane of the surface light guide and is provided for laterally coupling radiation. The surface light guide includes scattering locations for scattering the coupled radiation. The surface light guide includes a first boundary surface and a second boundary surface which delimit the light conductance of the coupled-in radiation in the vertical direction. A first layer and a second layer are formed on each other in the vertical direction between the first boundary surface and the second boundary surface. Further disclosed are a planar emitter including at least one surface light guide.

Owner:OSRAM OPTO SEMICONDUCTORS GMBH & CO OHG

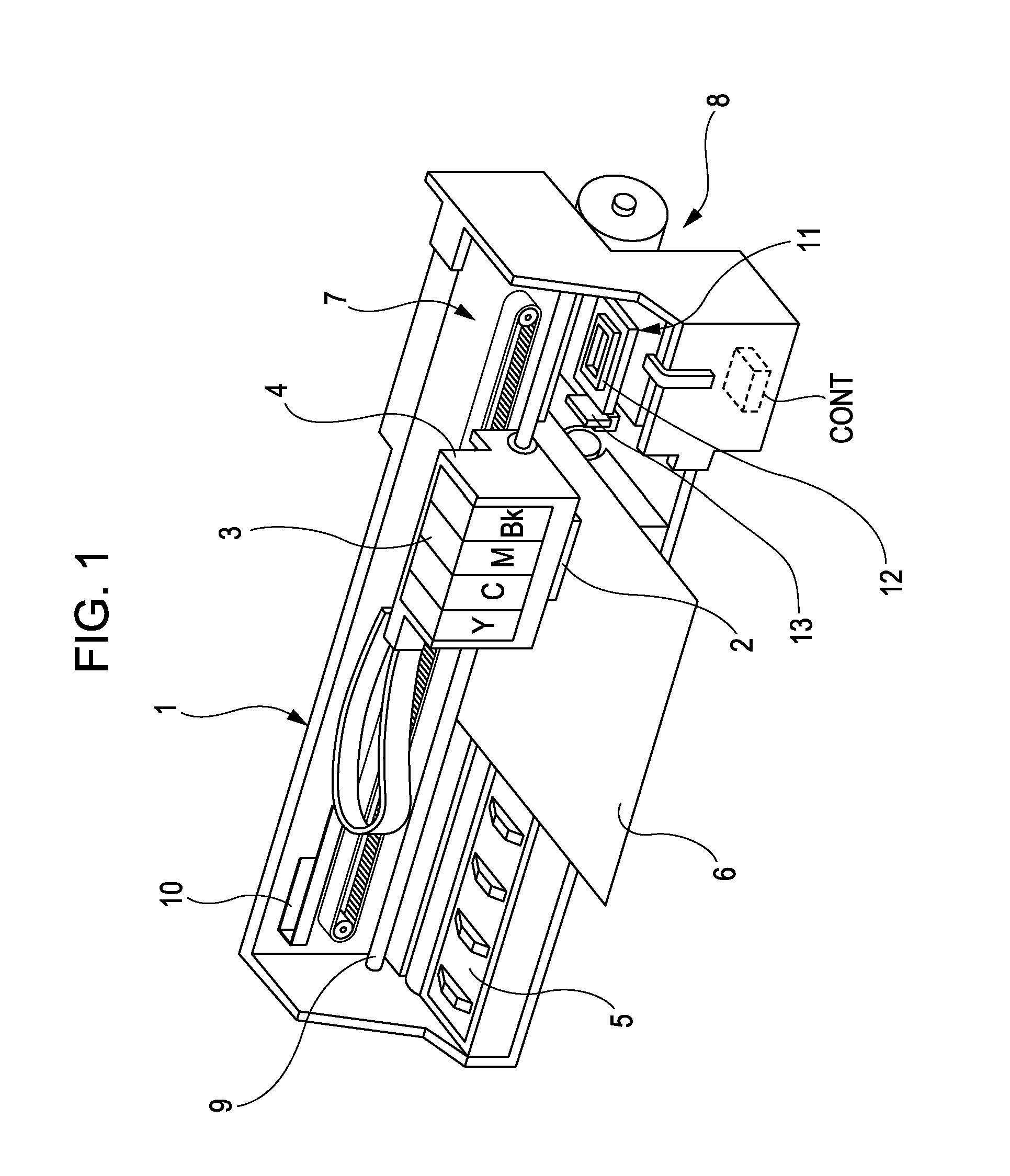

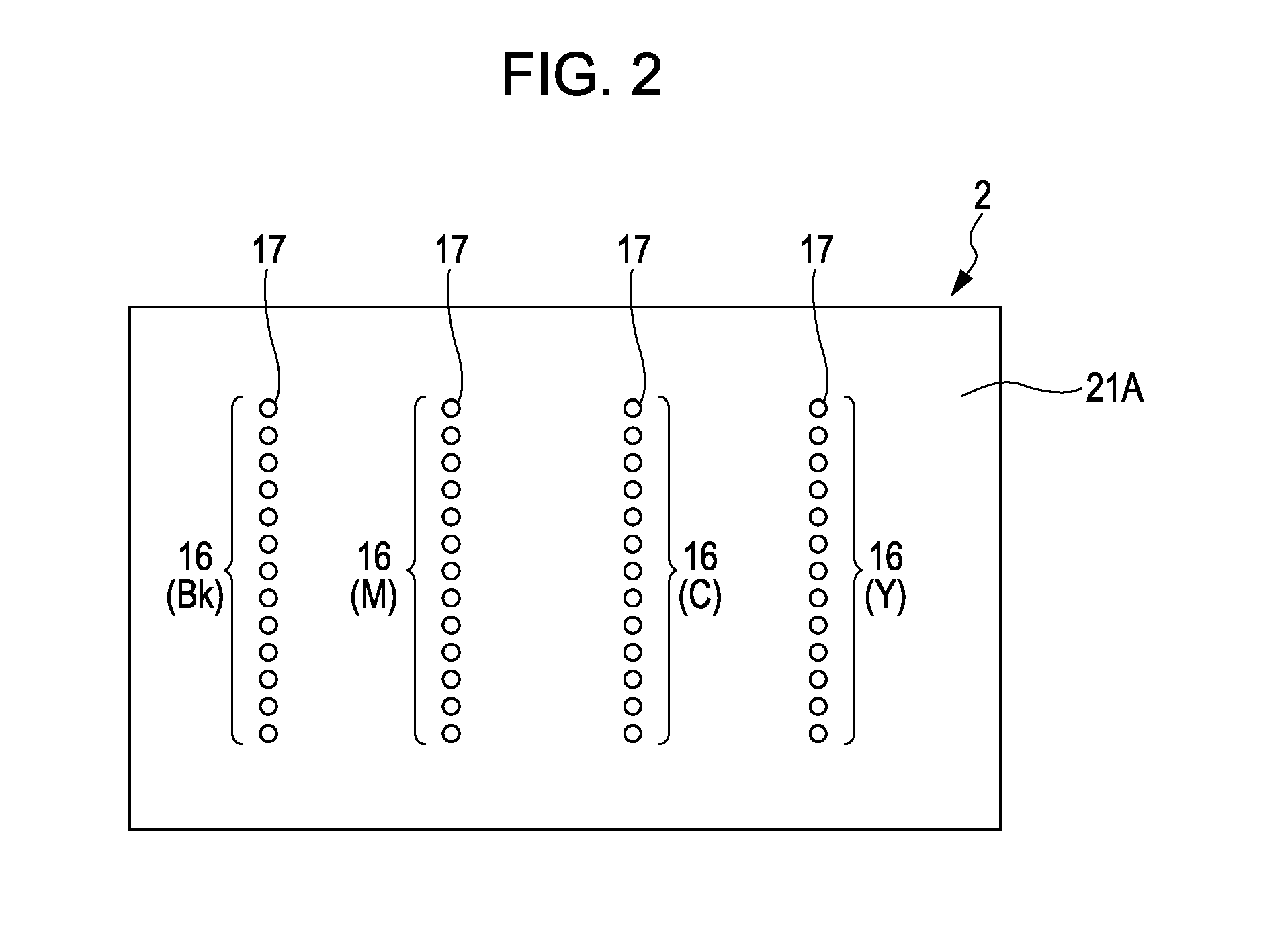

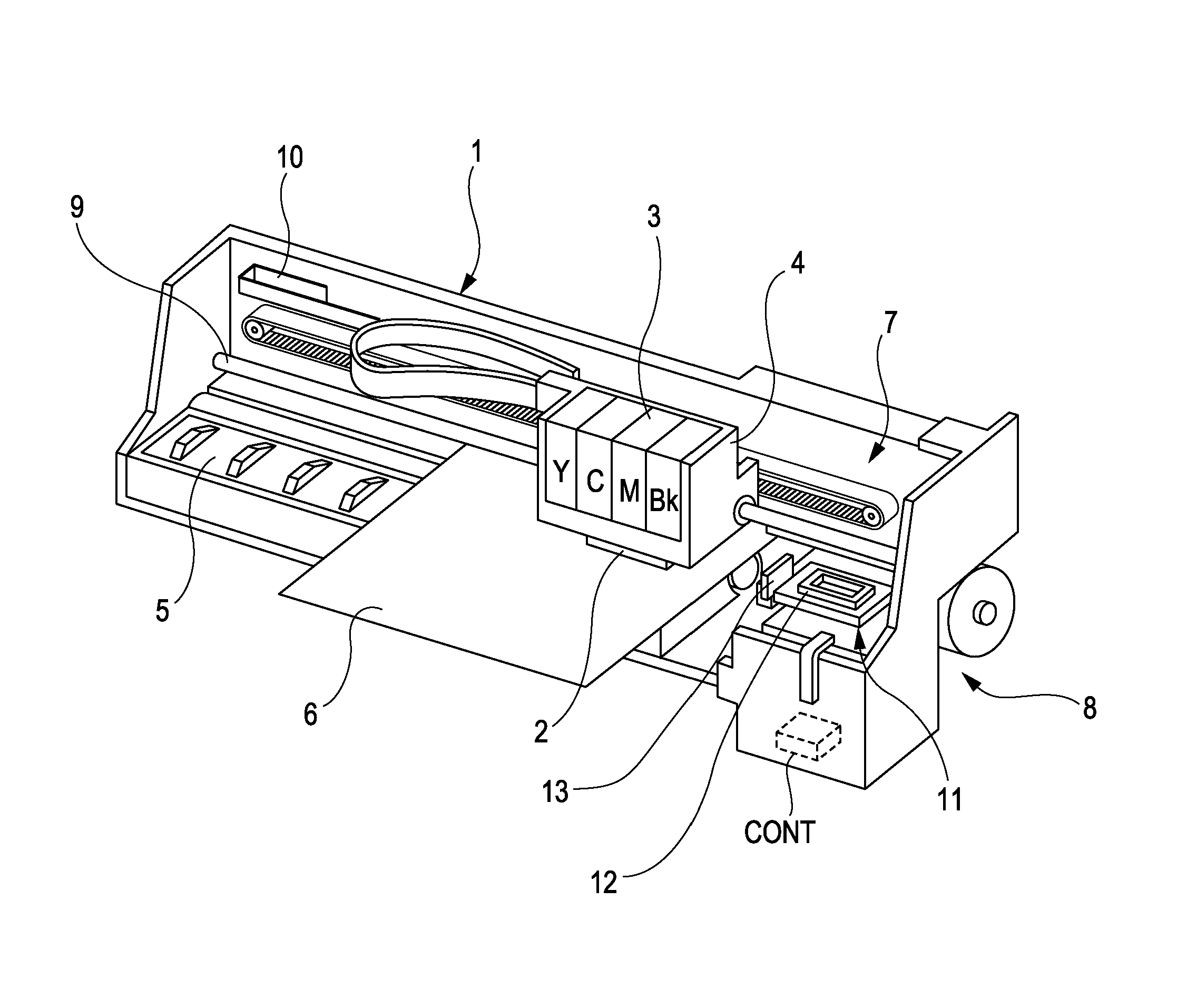

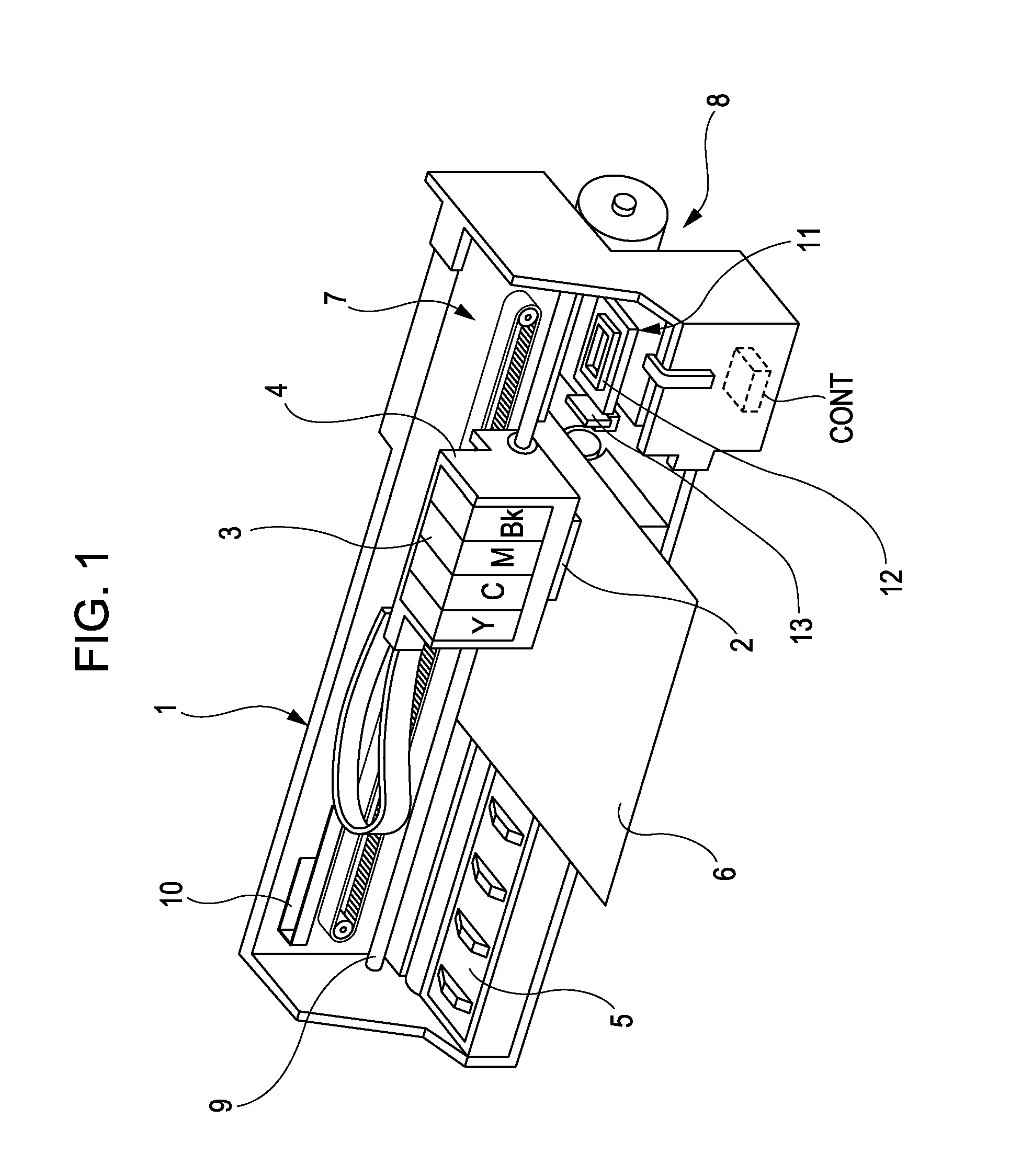

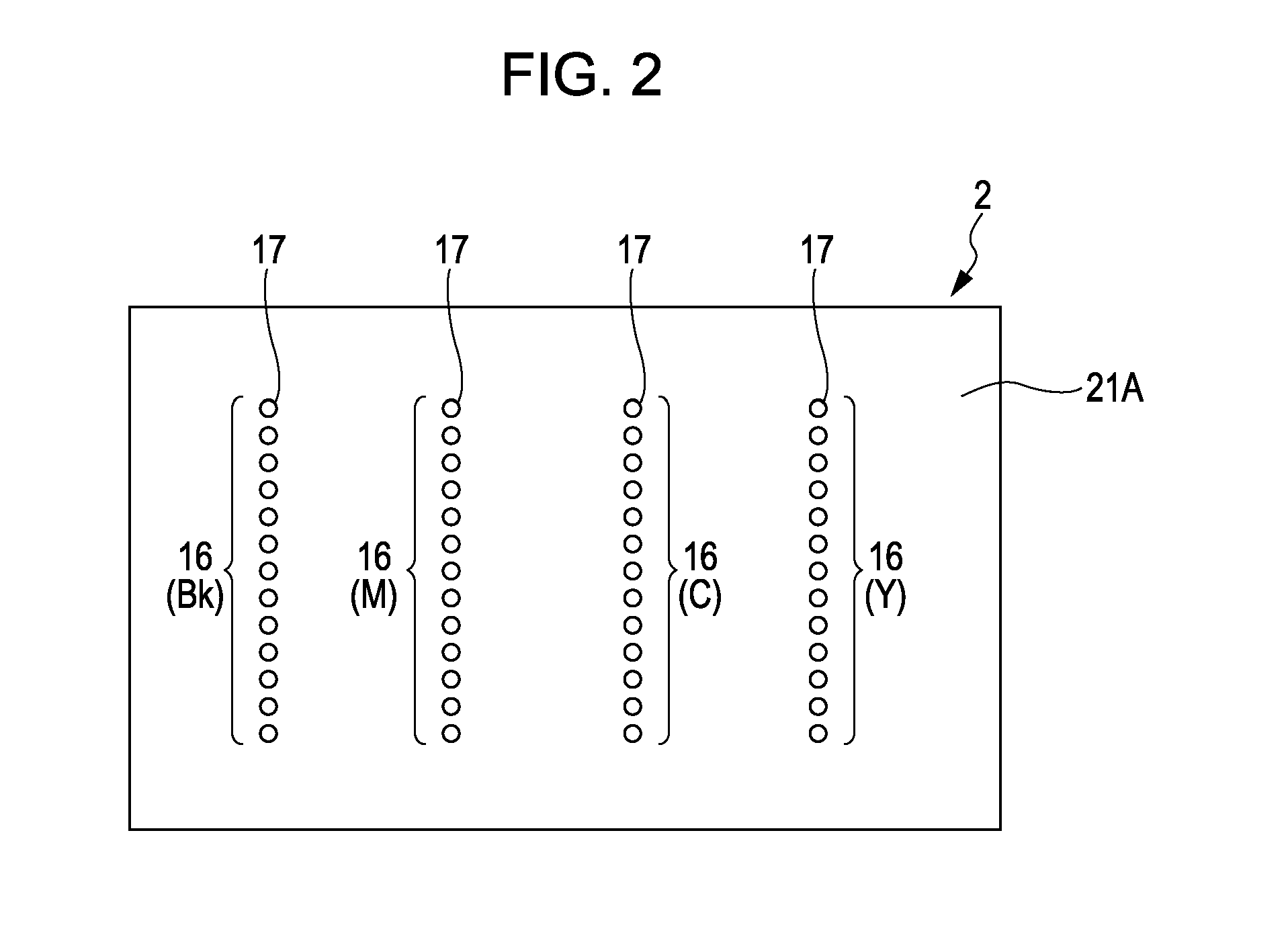

Pigment ink, ink jet recording apparatus, and ink jet recording method

ActiveUS20120162307A1Suppress satellite droplet formationHigh quality imagingInksPrintingEthyl groupEngineering

A pigment ink includes an acetylene glycol or 2-ethyl-1,3-hexanediol, and an unsaturated fatty acid, an amino acid, an alkali metal hydroxide and an amine.

Owner:SEIKO EPSON CORP

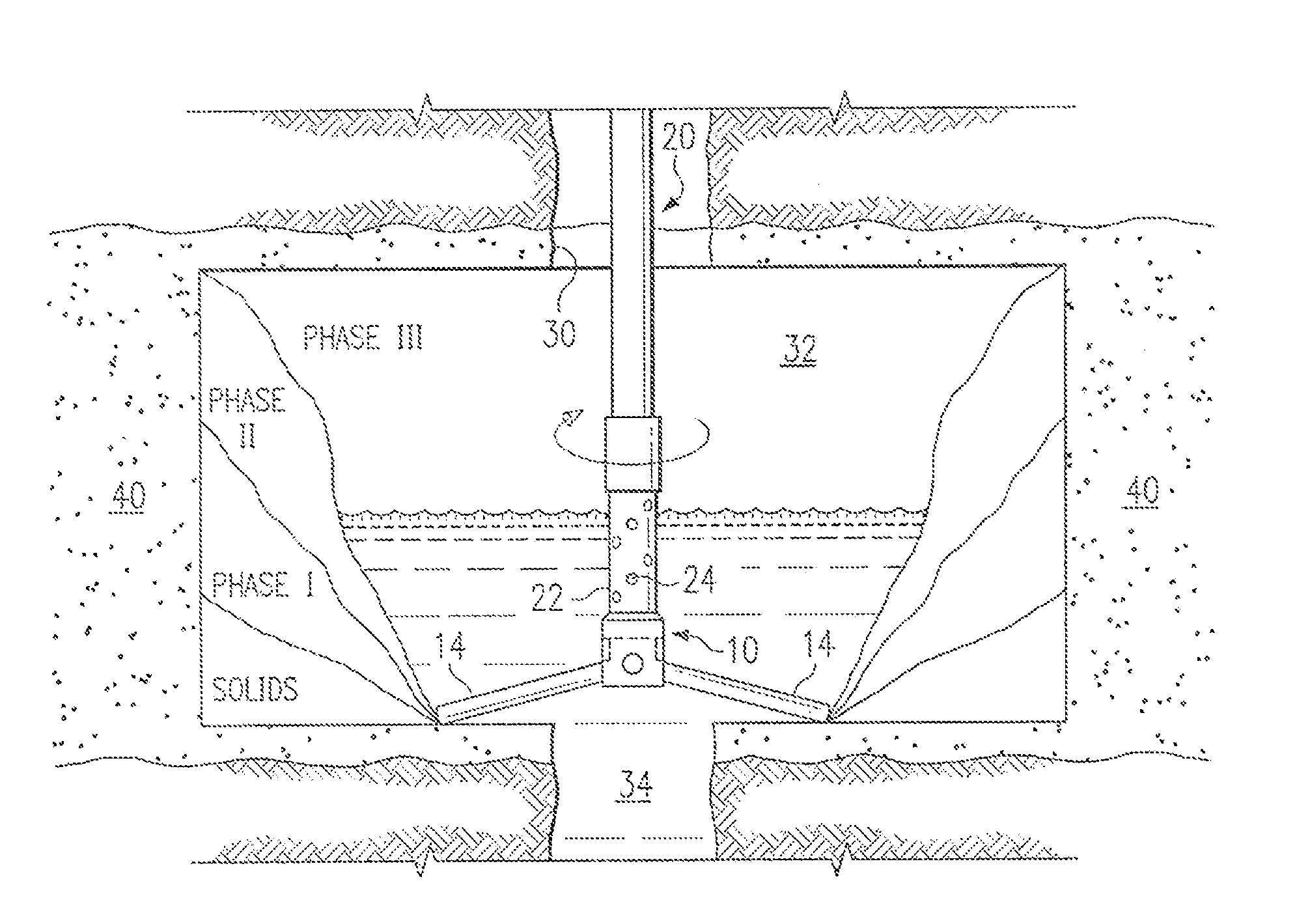

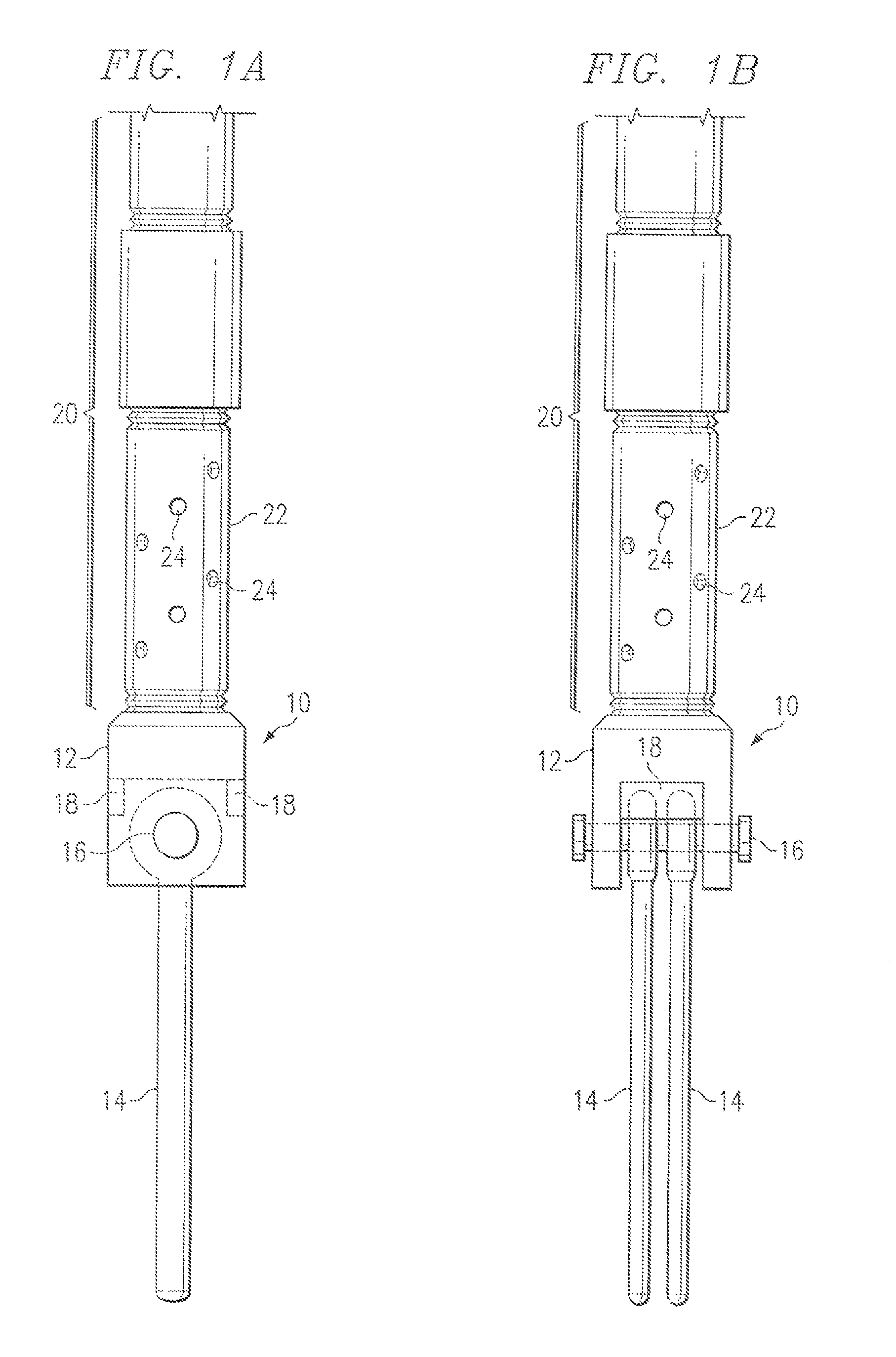

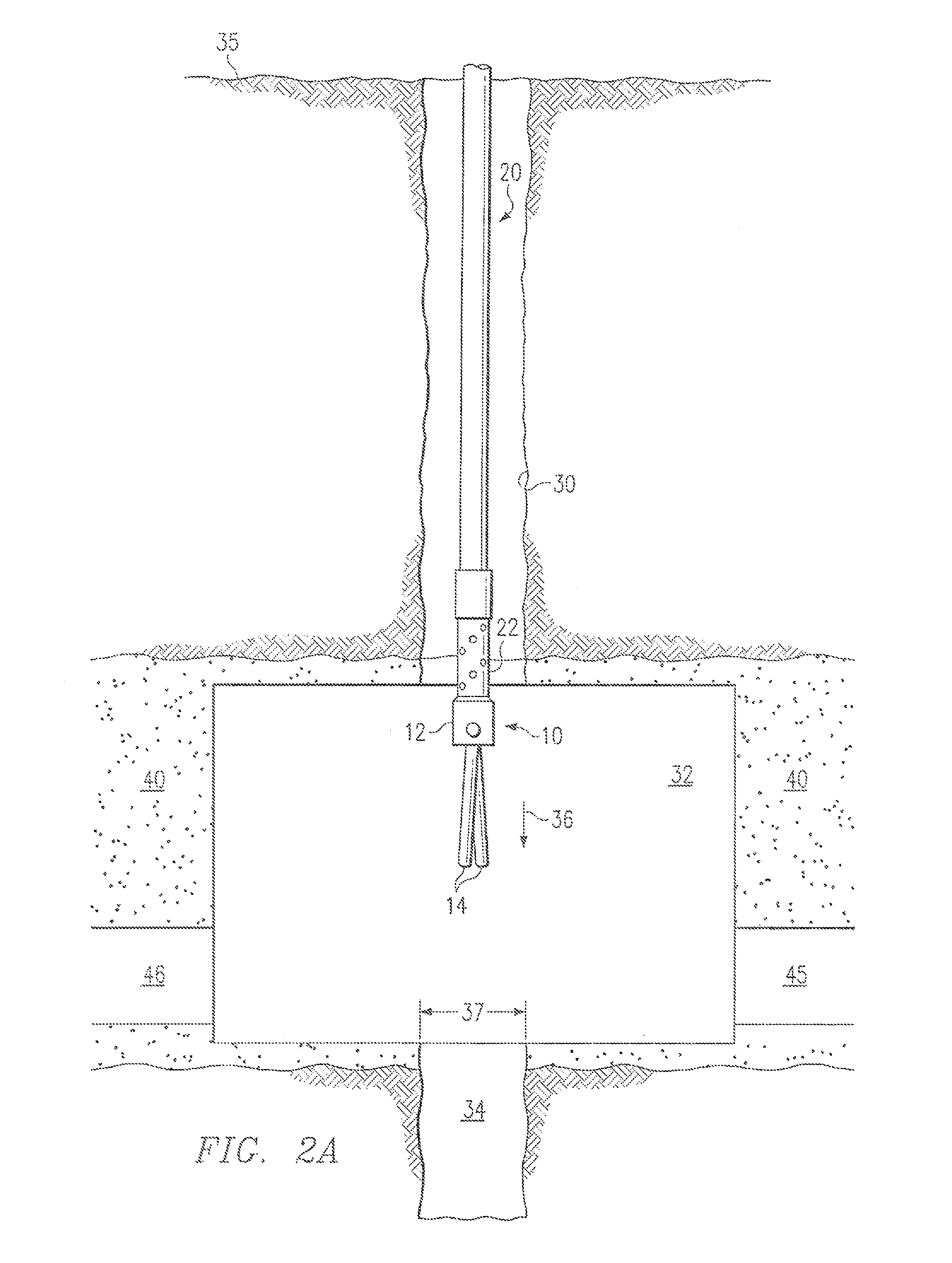

Cavity positioning tool and method

In accordance with the teachings of the present invention, a method is provided for preventing formation of sludge in a subsurface cavity having particulate laden fluid disposed therein. The method includes positioning a downhole device having a fluid agitator into the fluid of the subsurface cavity and agitating the fluid using the fluid agitator.

Owner:EFFECTIVE EXPLORATION

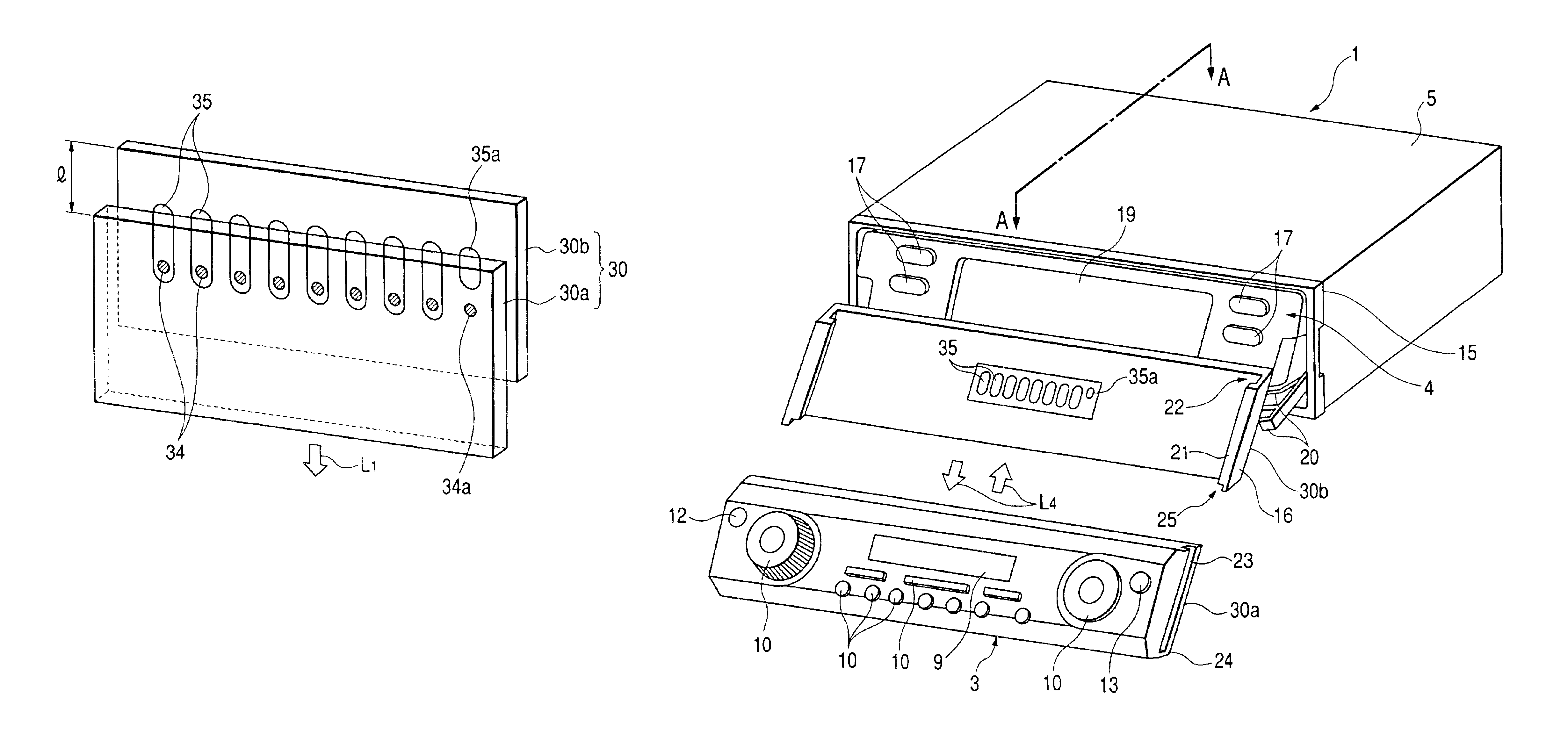

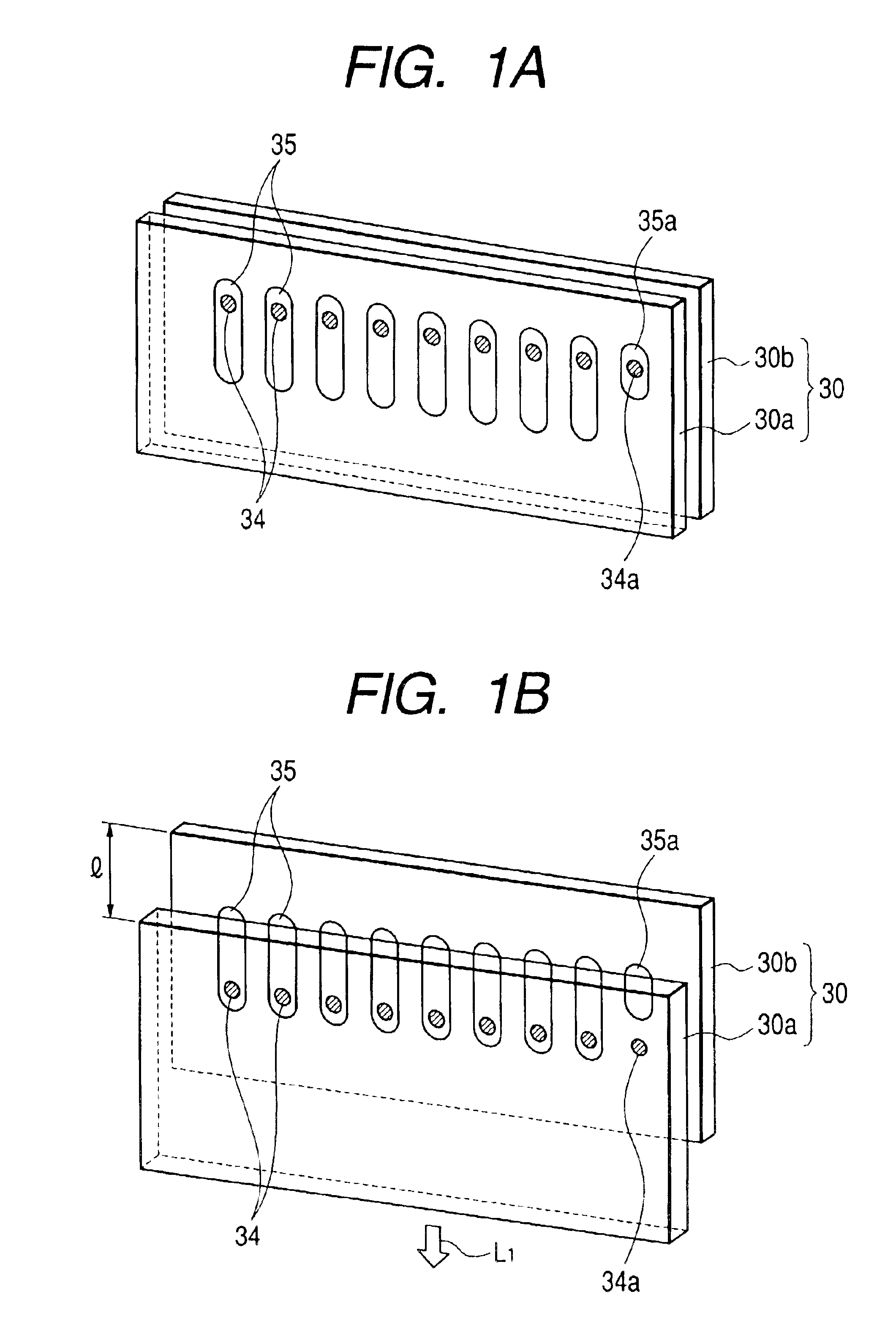

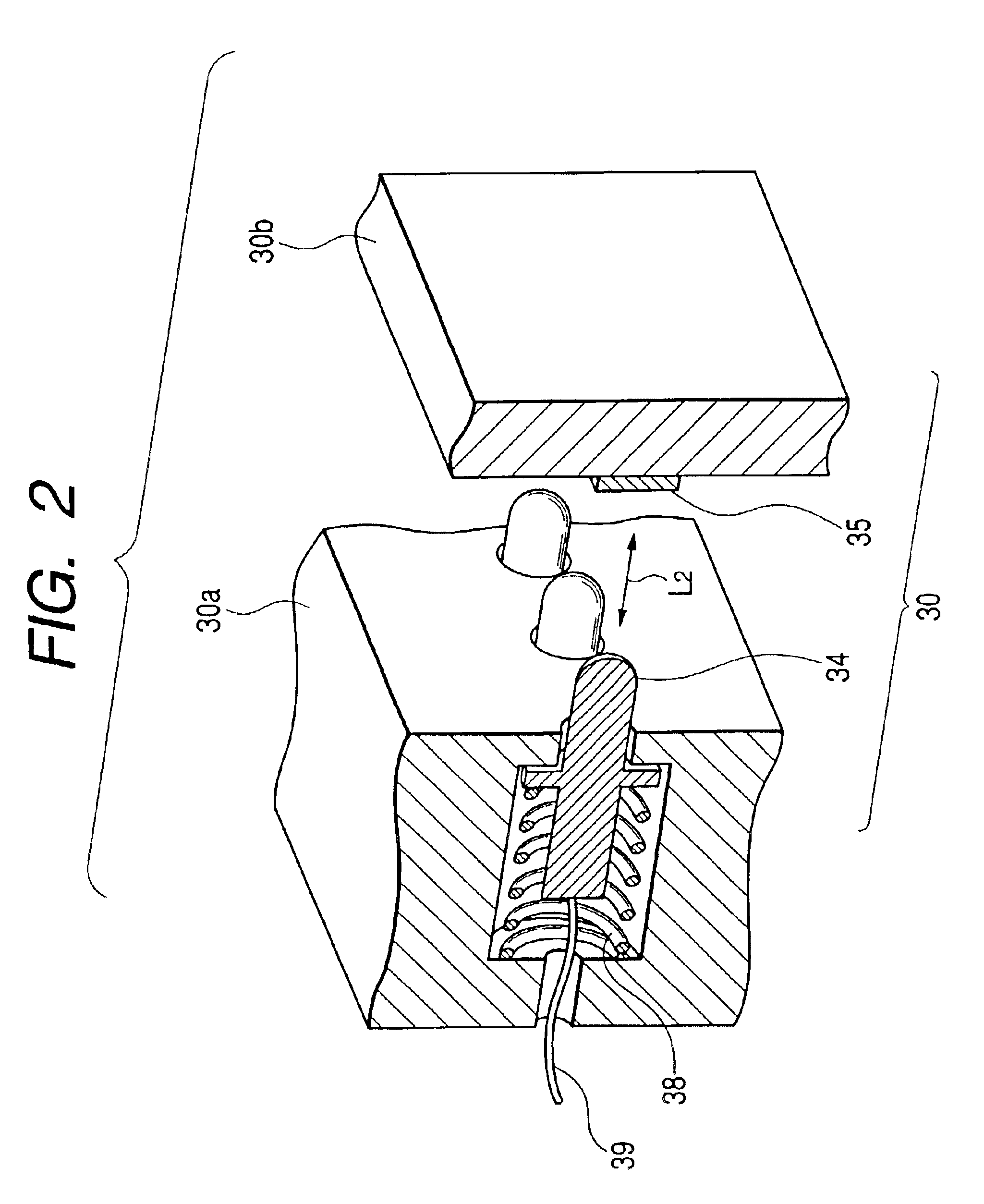

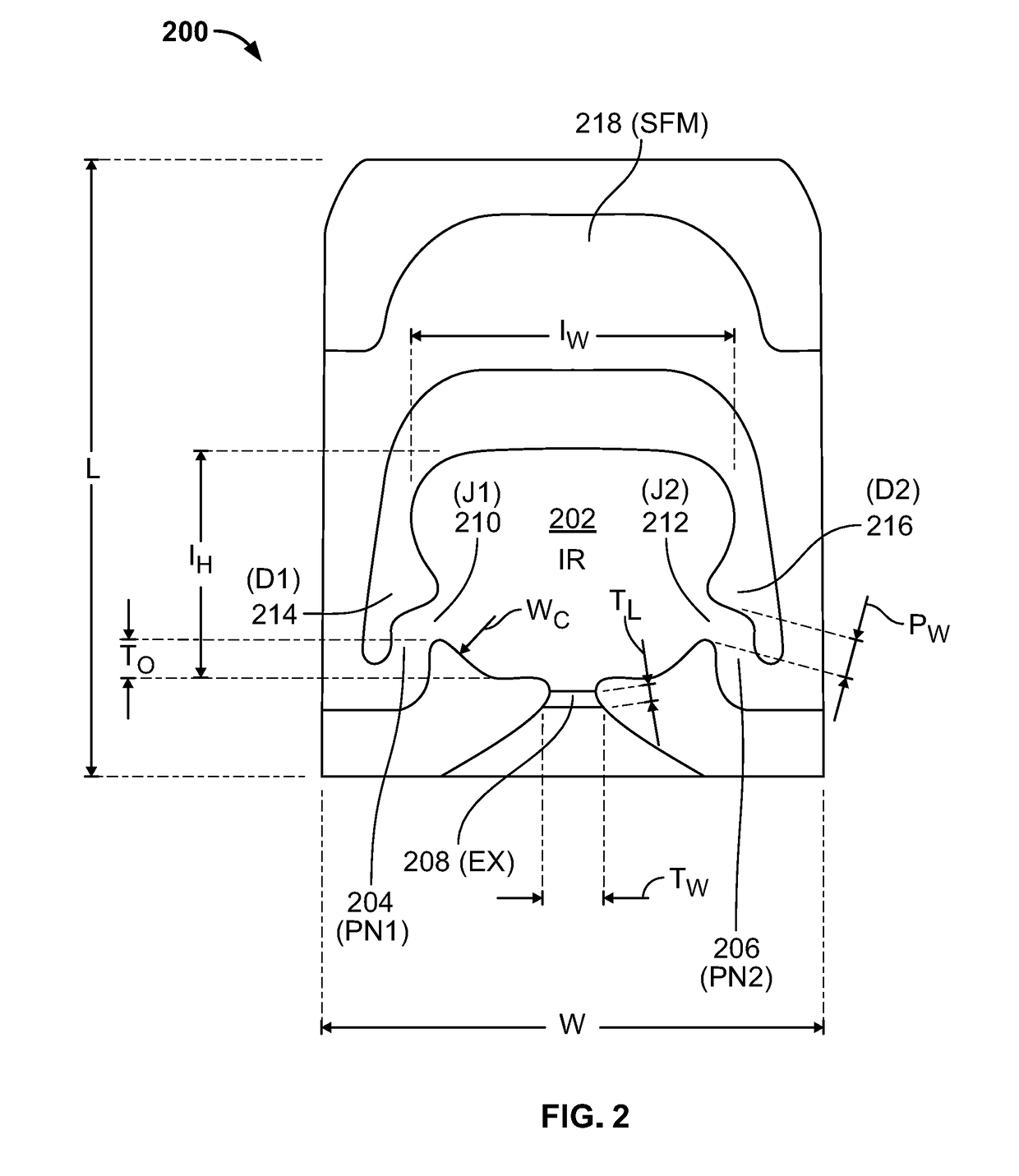

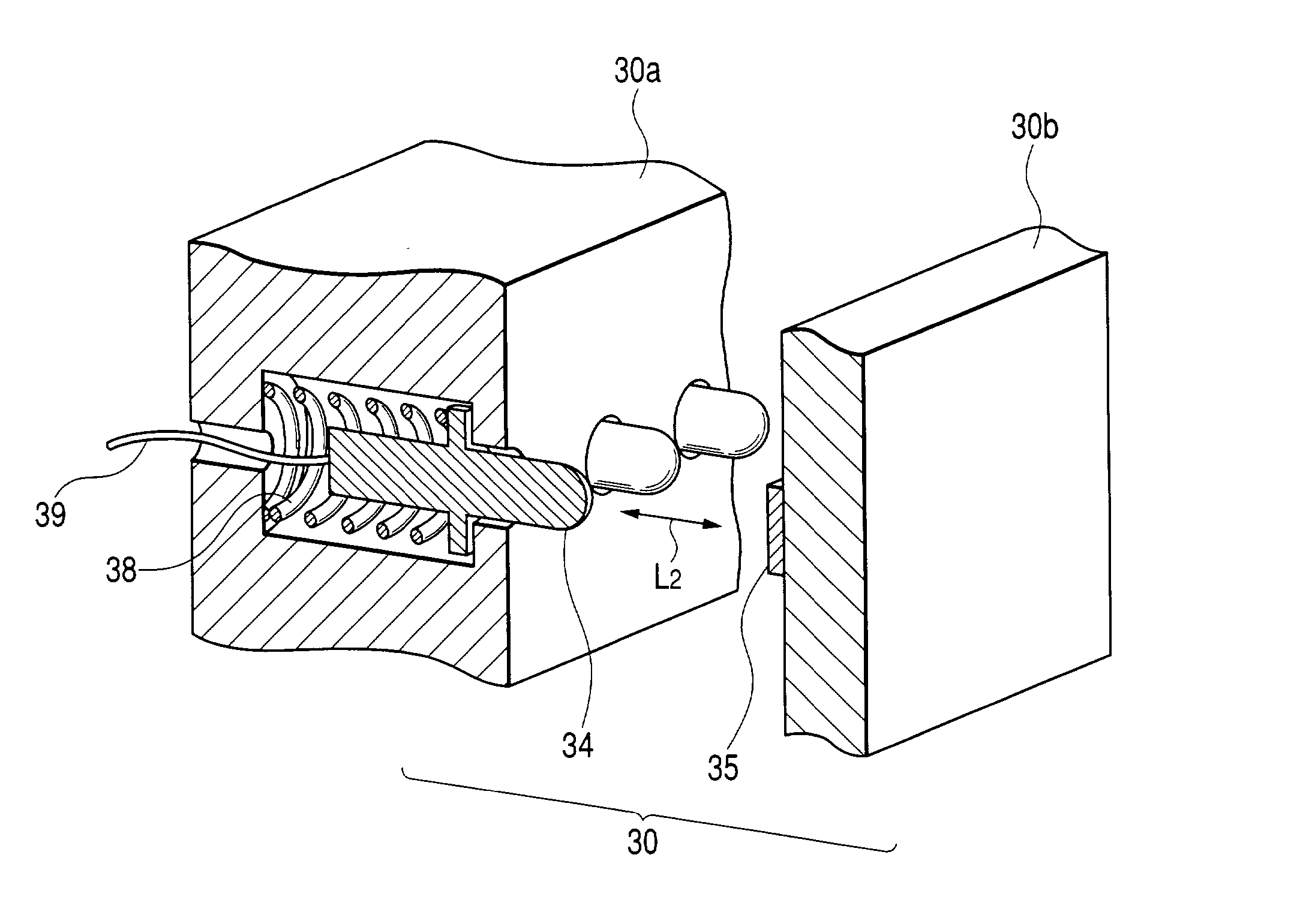

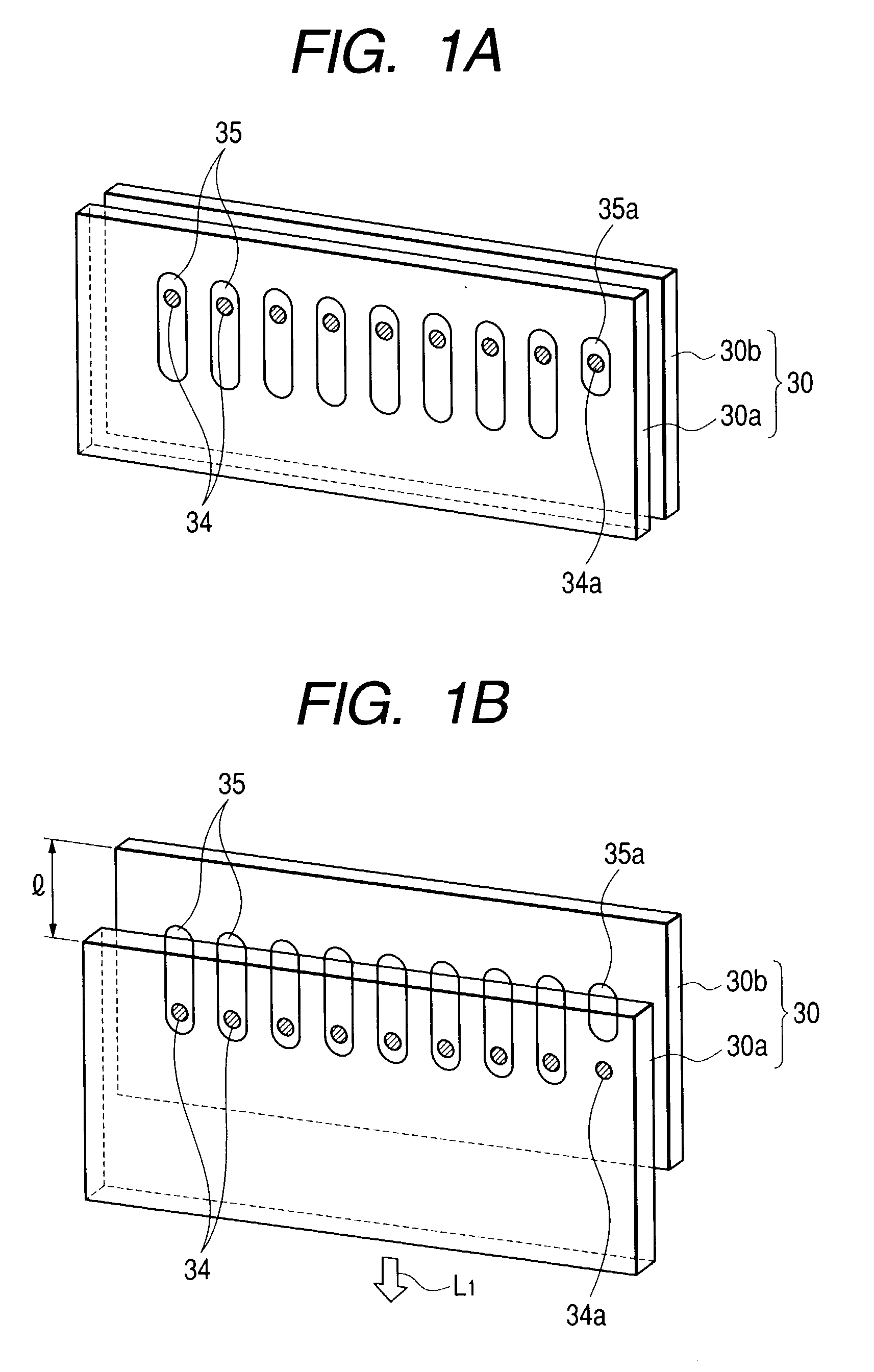

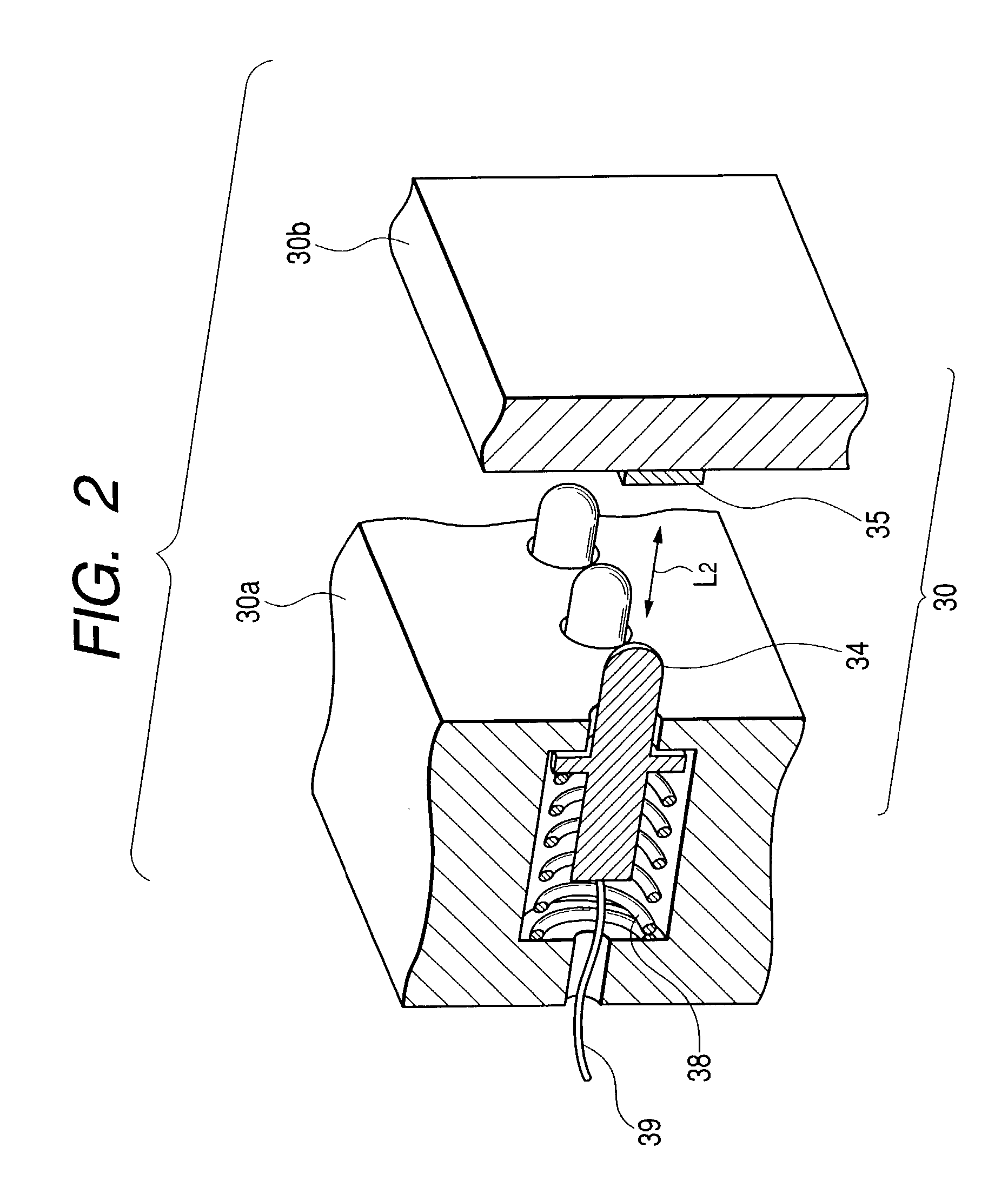

Connector, electronic equipment and control method for electronic equipment

InactiveUS6887096B2Significant formHigh densityPrinted circuit assemblingElectrically conductive connectionsEngineeringElectronic equipment

A connector has an operation unit connector that is fixed on an operation unit, and an electronic equipment main body connector that is fixed on an electronic equipment main body. The operation unit connector has plural terminals at regular intervals aligned in a row. The electronic equipment main body connector has plural electrodes at positions corresponding to the terminals at regular intervals. At least one of the electrodes is formed to be shorter than other electrodes and serves as a detecting electrode. The detecting electrode is disposed at the same upper position as the other electrodes, and shorter on the lower side.

Owner:PIONEER CORP

Semiconductor device

ActiveUS9246047B2Increase capacitanceReduce the number of timesSolid-state devicesSemiconductor/solid-state device manufacturingPower semiconductor deviceDielectric

Owner:SEMICON ENERGY LAB CO LTD

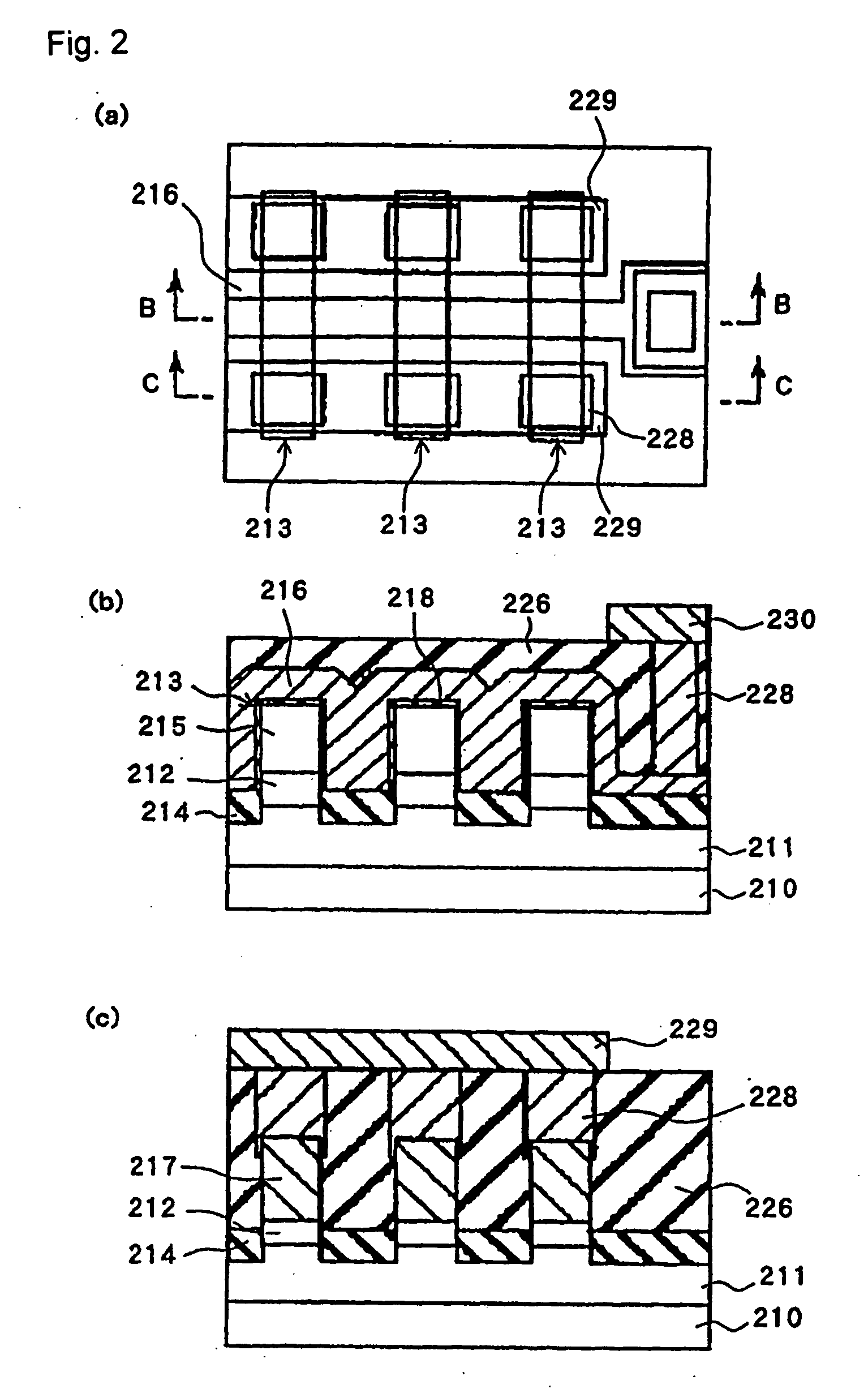

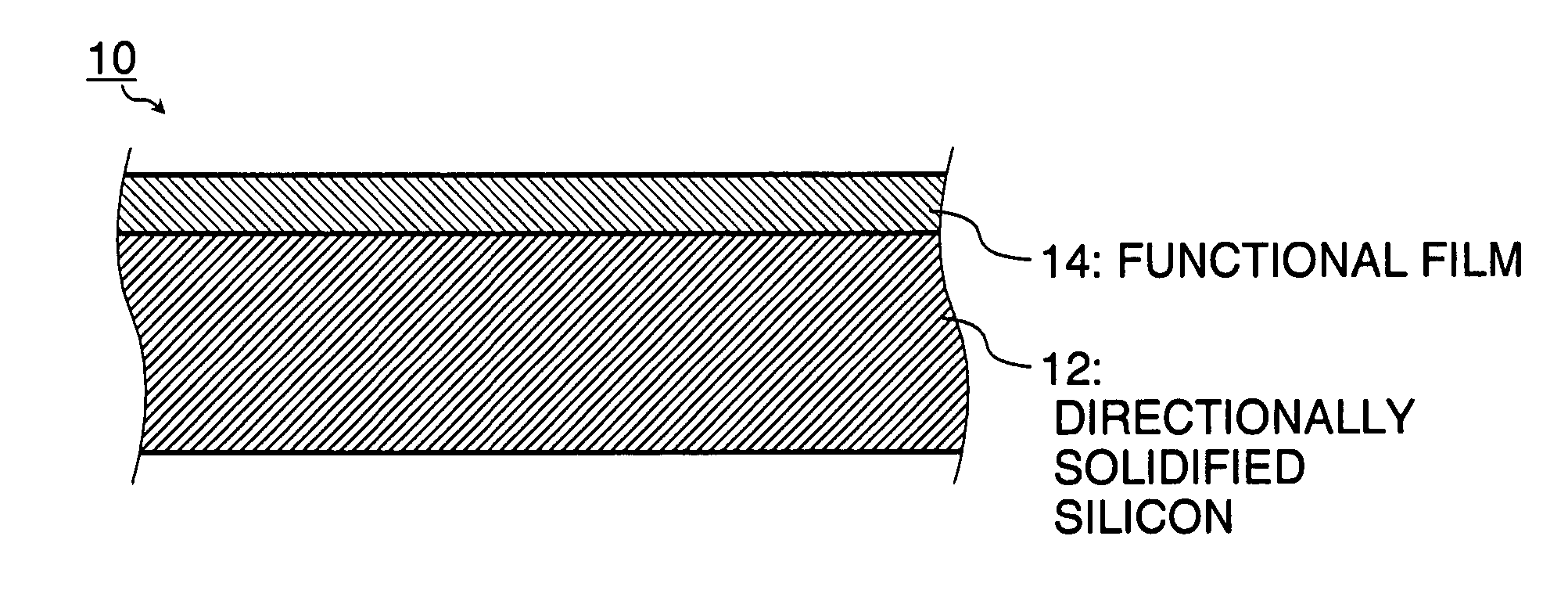

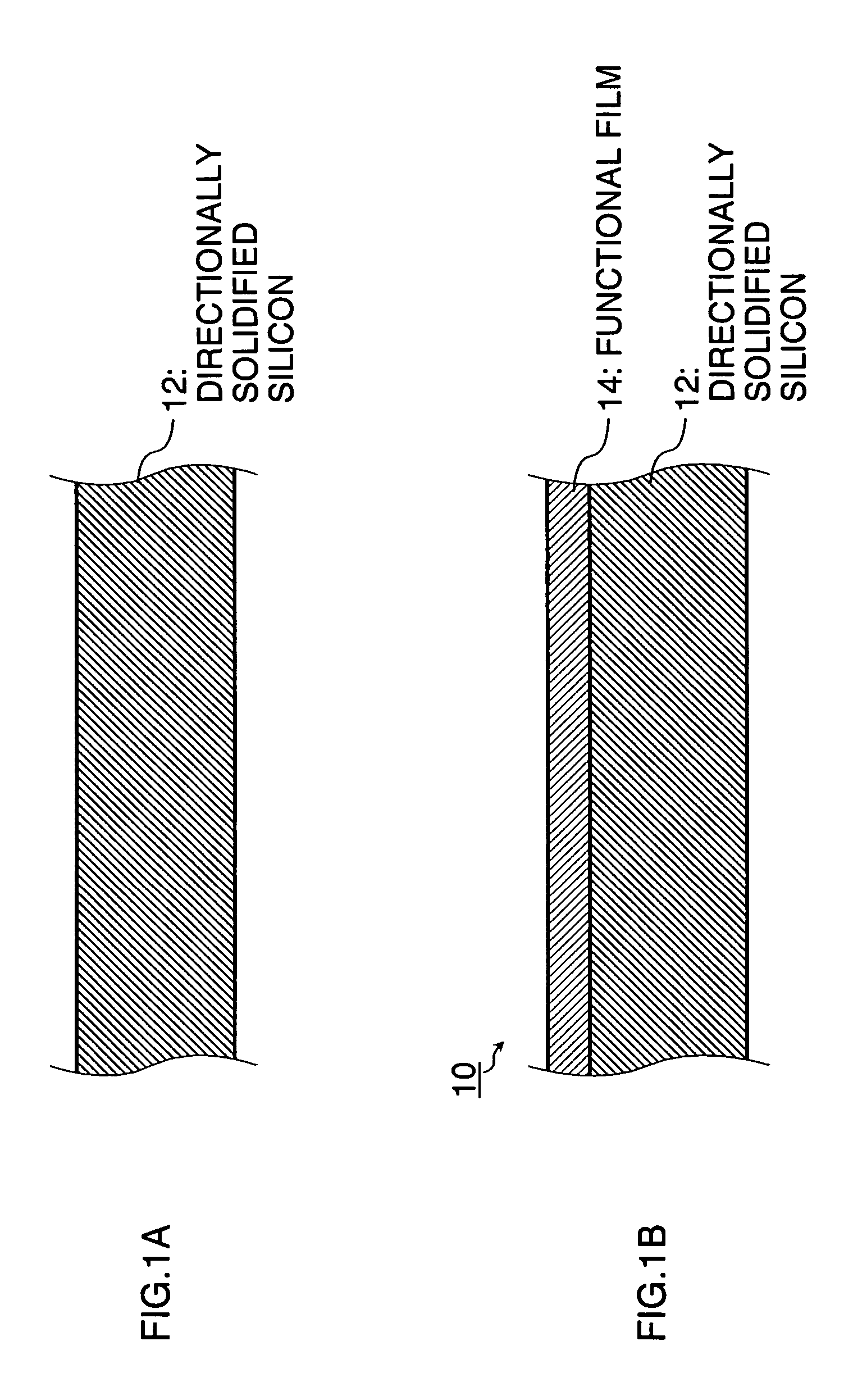

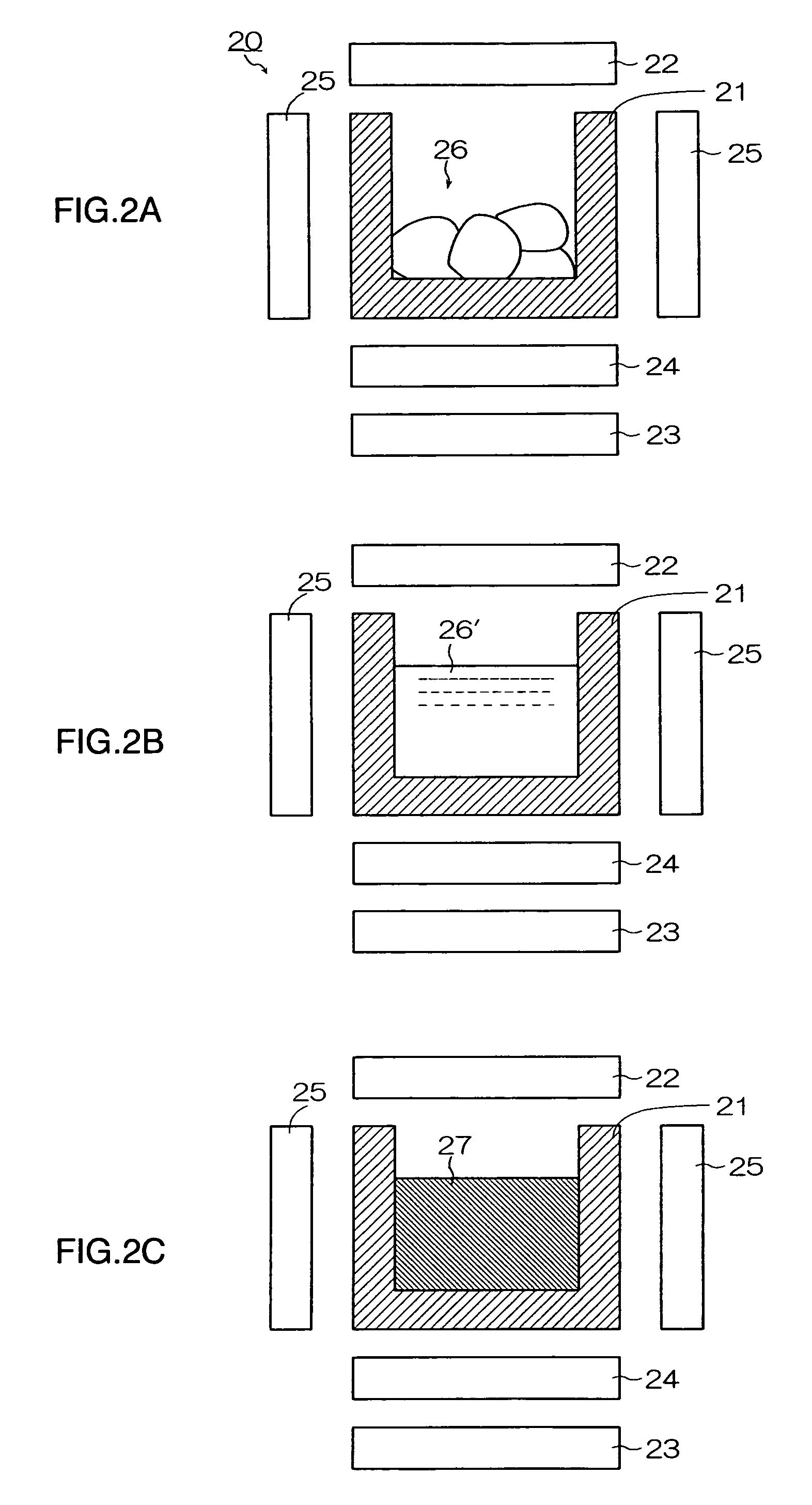

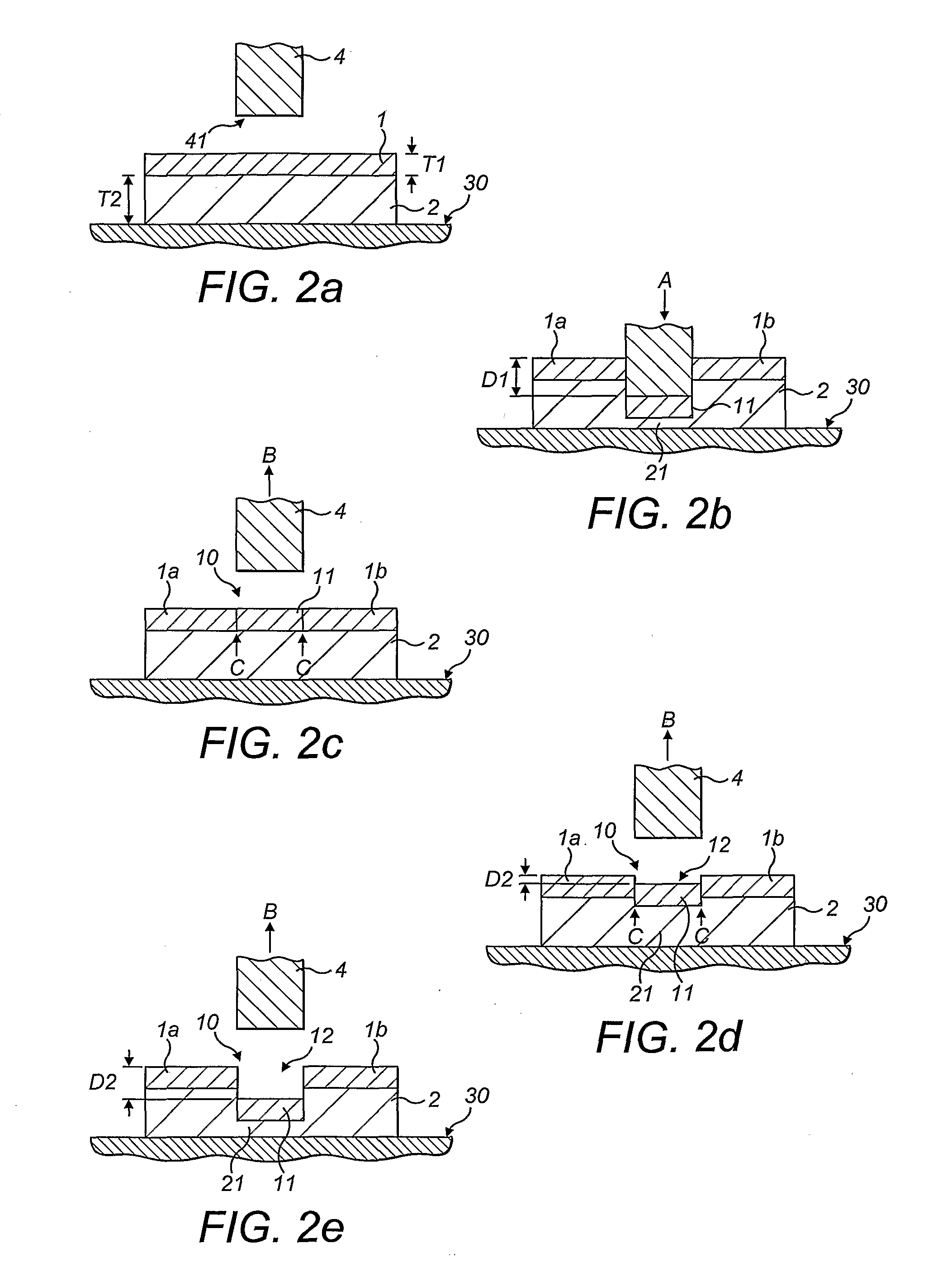

Functional structural element, method of manufacturing functional structural element, and substrate for manufacturing functional structural body

InactiveUS20070075403A1Low costQuality improvementPolycrystalline material growthSemiconductor/solid-state device manufacturingStructural elementSilicon

The functional structural element includes: a substrate member which has a surface made of directionally solidified silicon; and a functional structural body which is made of a functional material and is formed on the surface of the substrate member.

Owner:FUJIFILM CORP

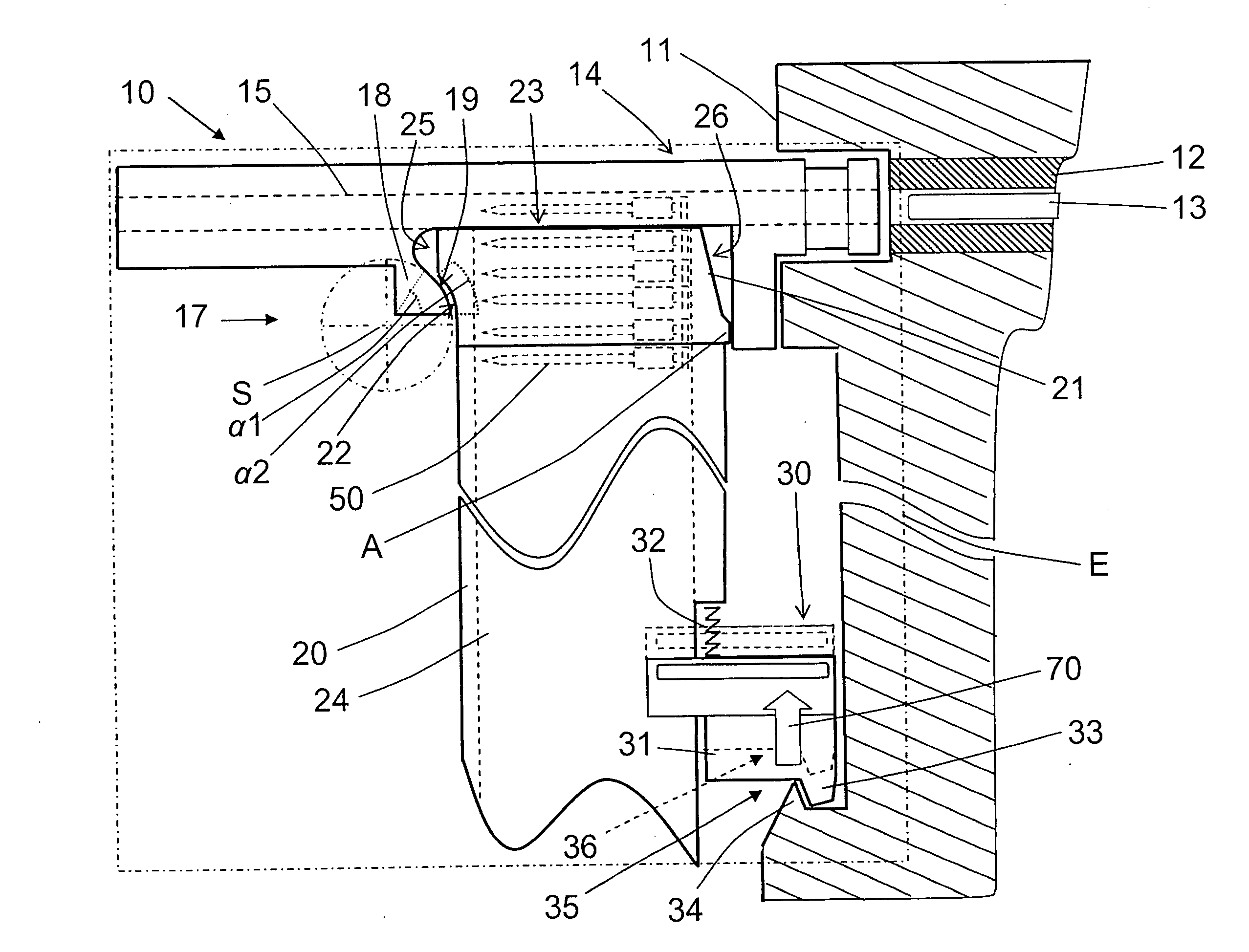

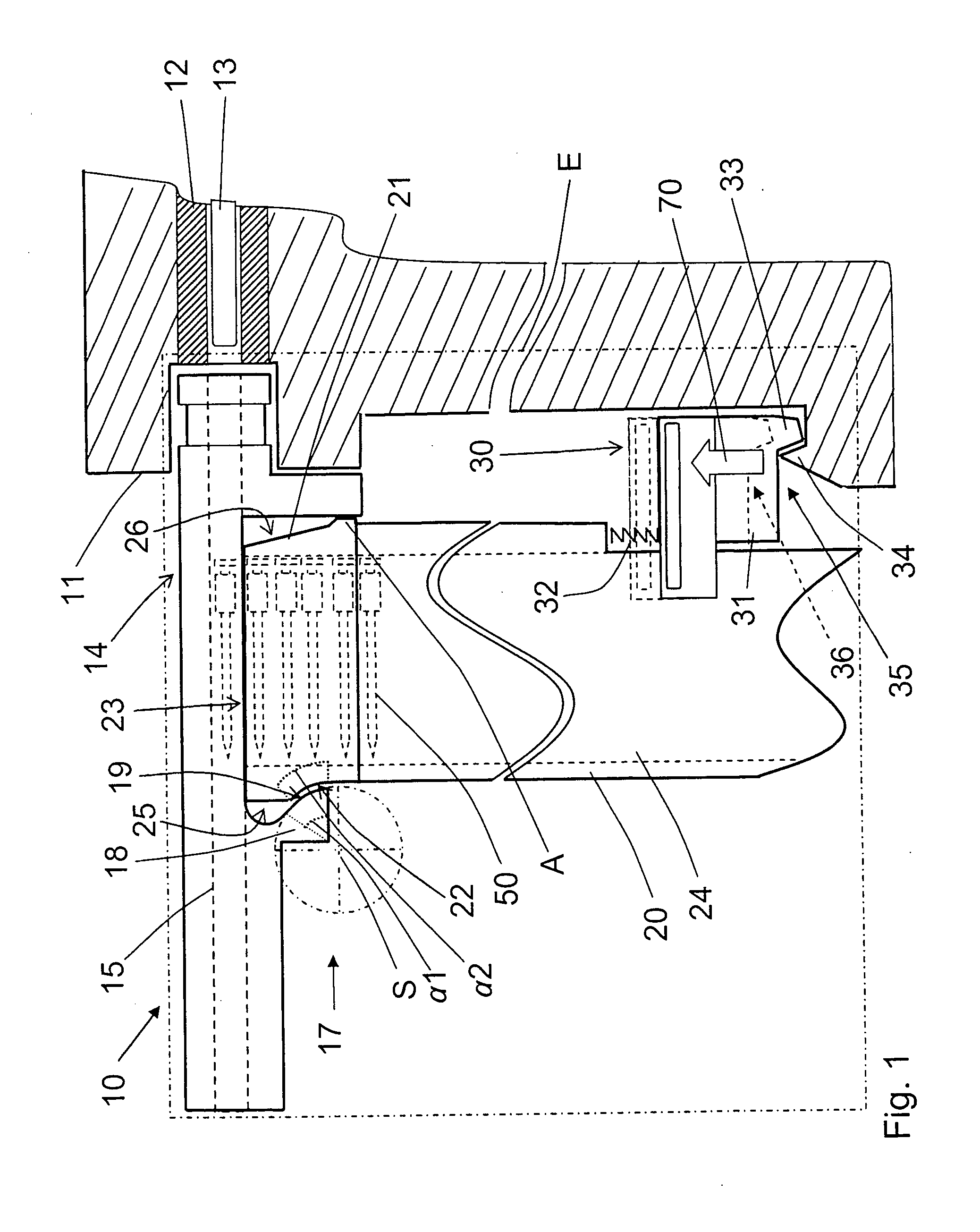

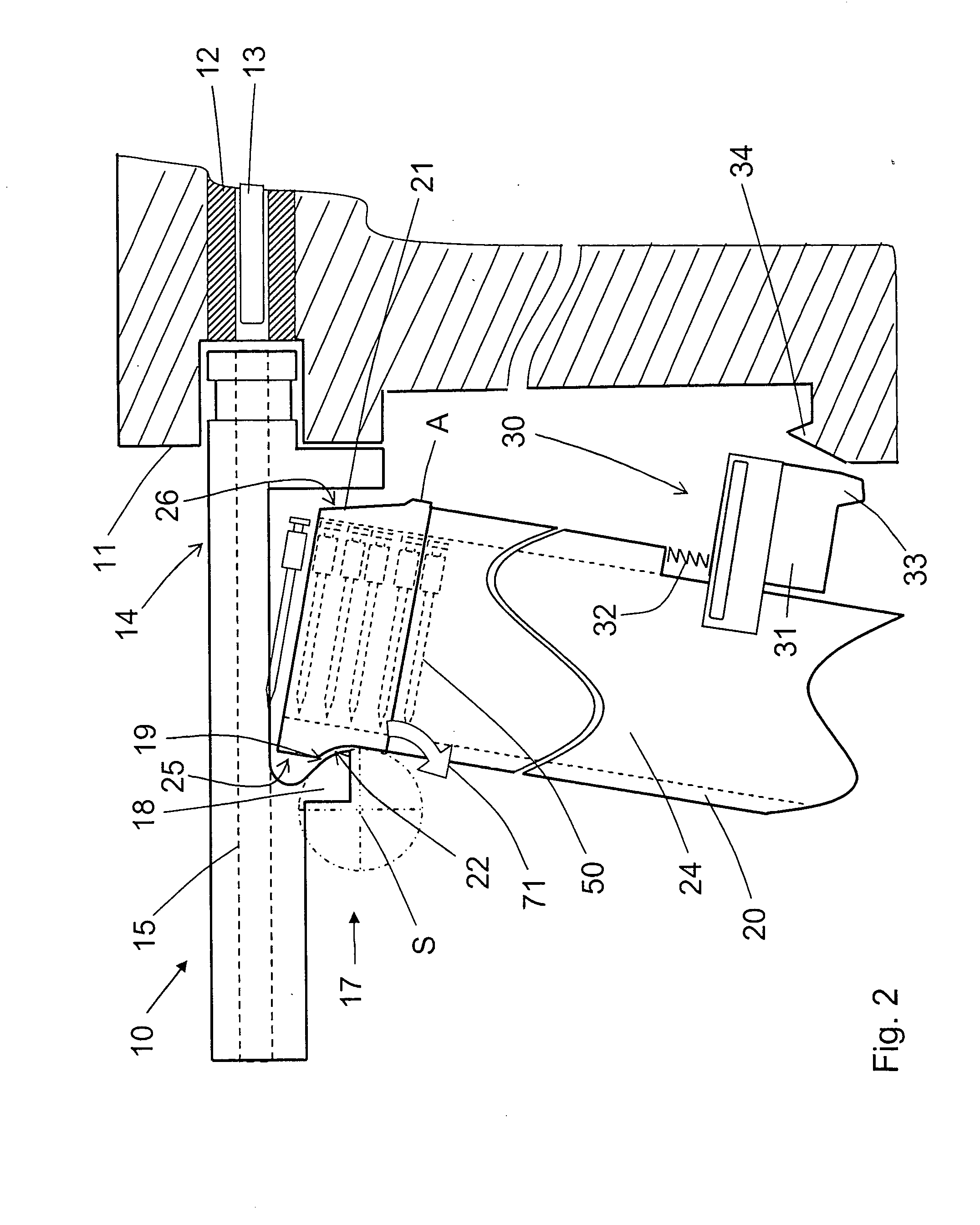

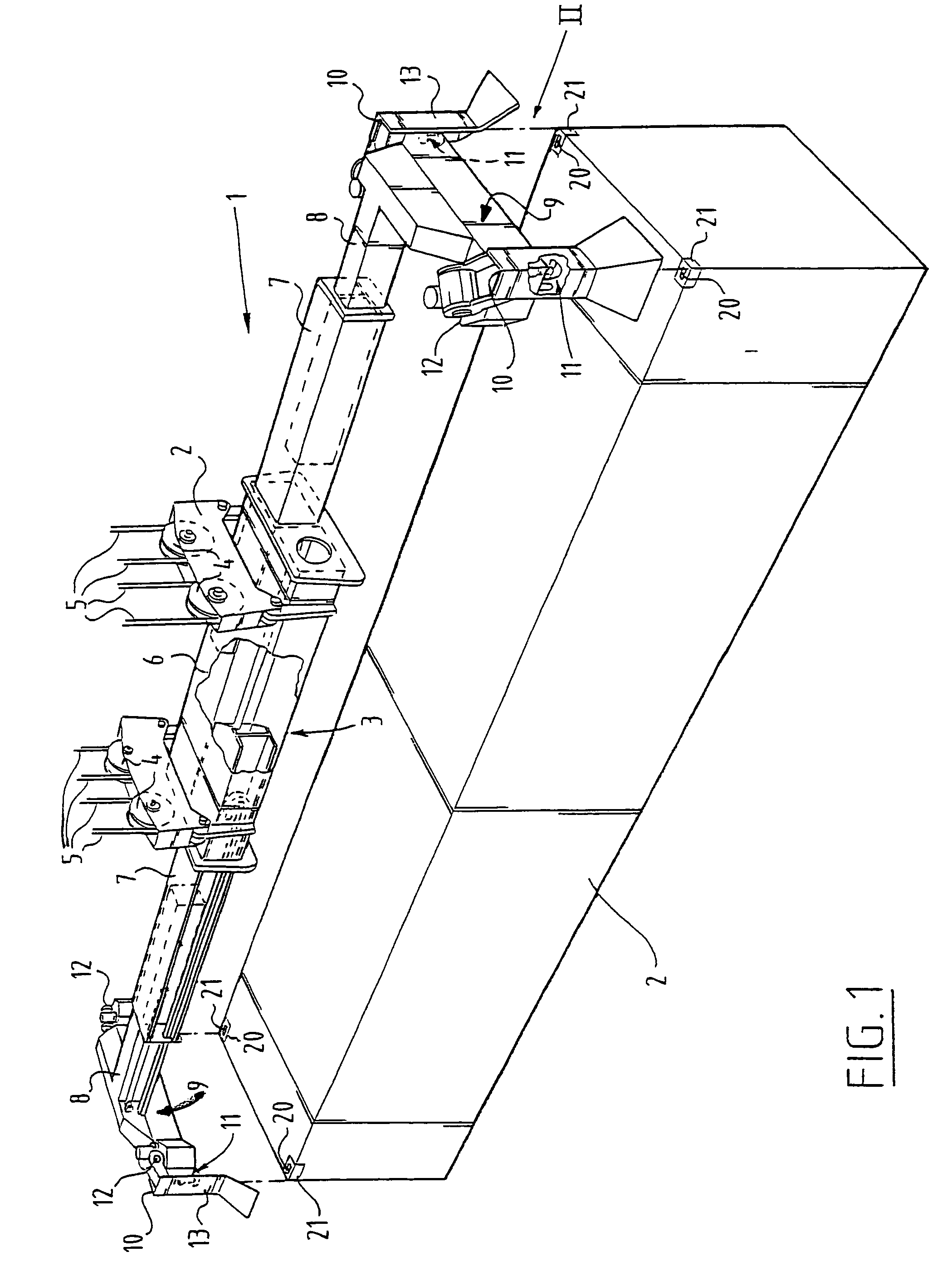

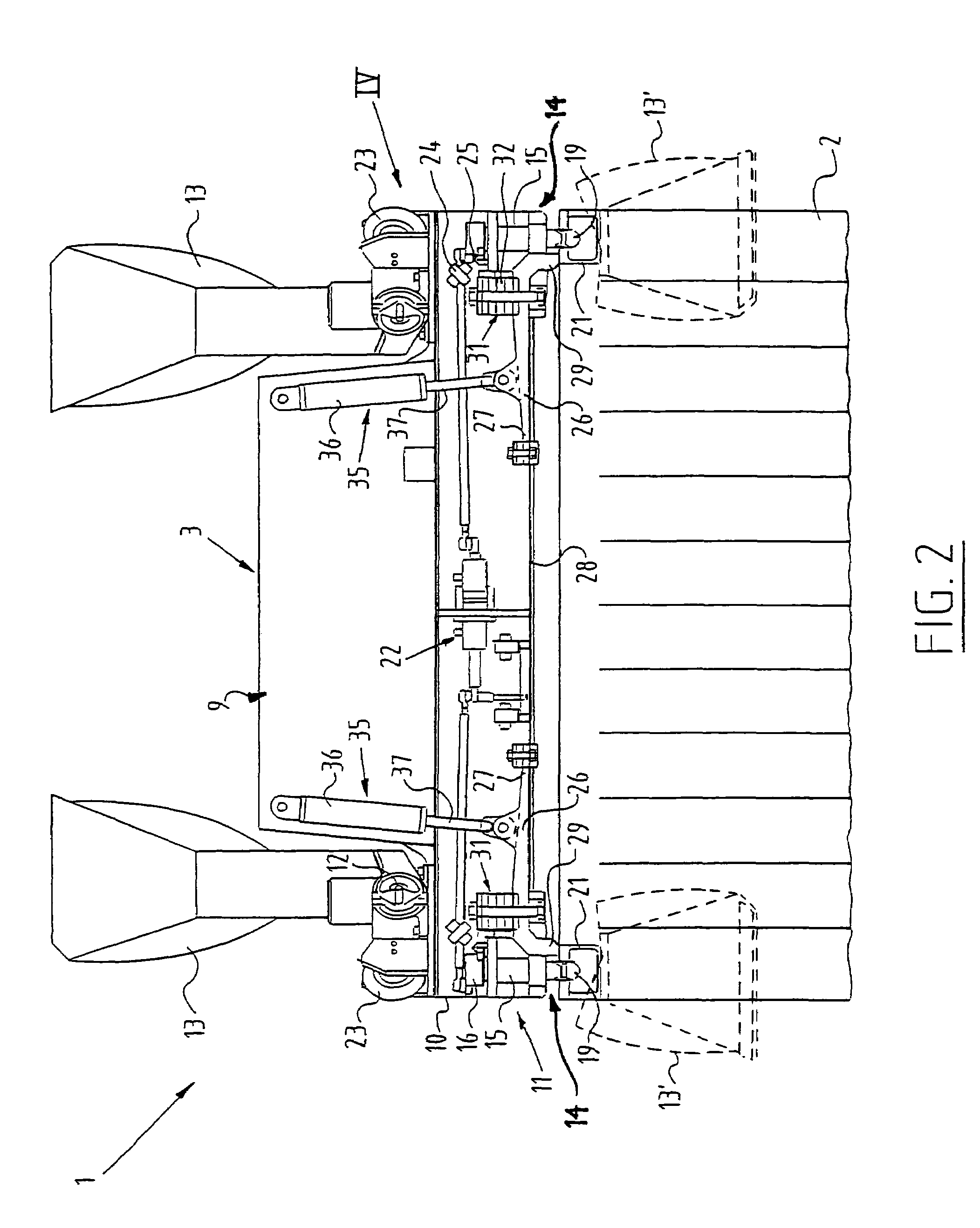

Setting tool

Owner:HILTI AG

Ventilation flap arrangement

InactiveUS20100120346A1Reduce numberSimplify assemblyAir-treating devicesVehicle heating/cooling devicesEngineeringMechanical engineering

A ventilation flap arrangement, in particular for venting a motor vehicle interior, as well as a method for producing a ventilation flap arrangement of this type, which has the method steps of providing one or more flexible cover flaps, providing a frame for holding the cover flaps, wherein the frame for a cover flap has a receiving groove formed by two side cheeks, inserting the cover flap between the two side cheeks of the receiving groove of the frame and non-detachable connection of the cover flap to the receiving groove by embossing.

Owner:EUWE EUGEN WEXLER HLDG GMBH & CO KG

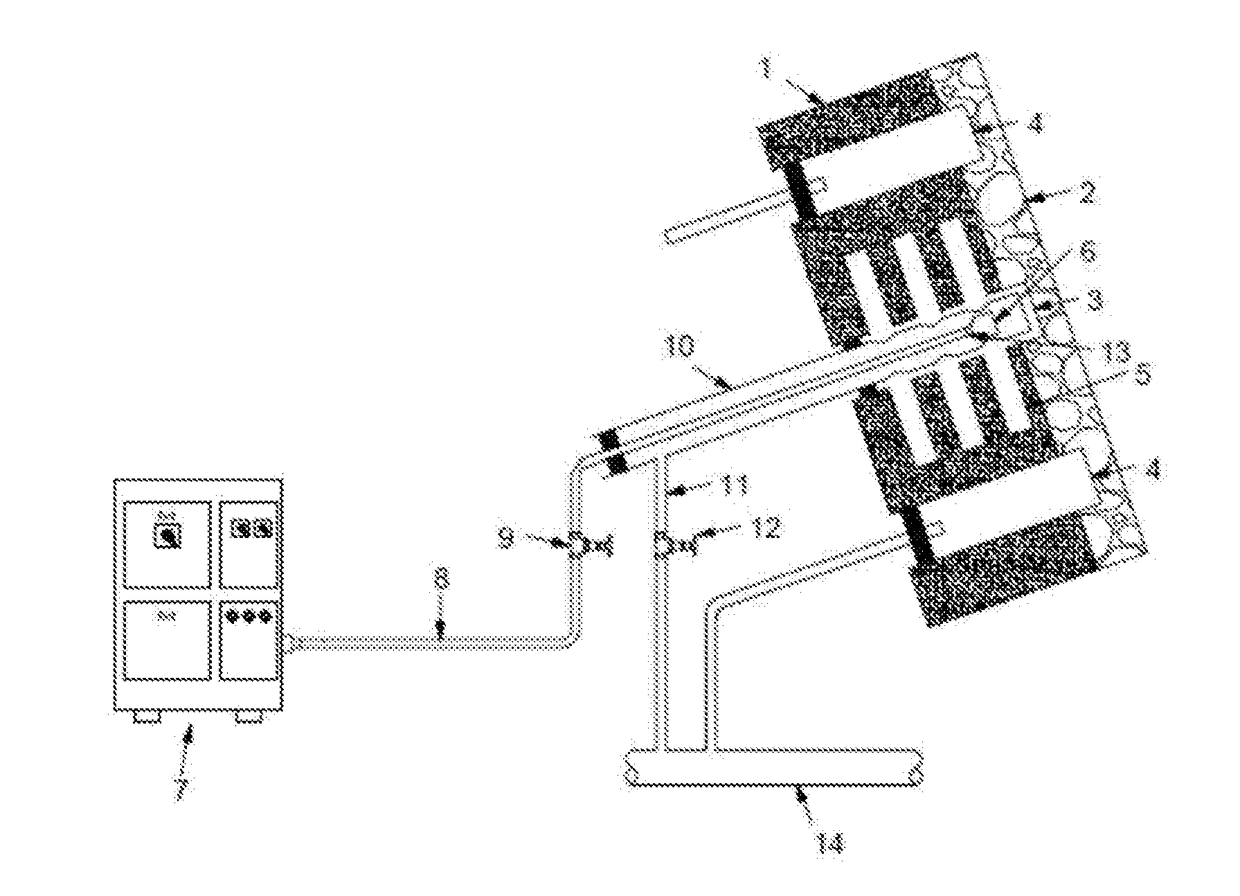

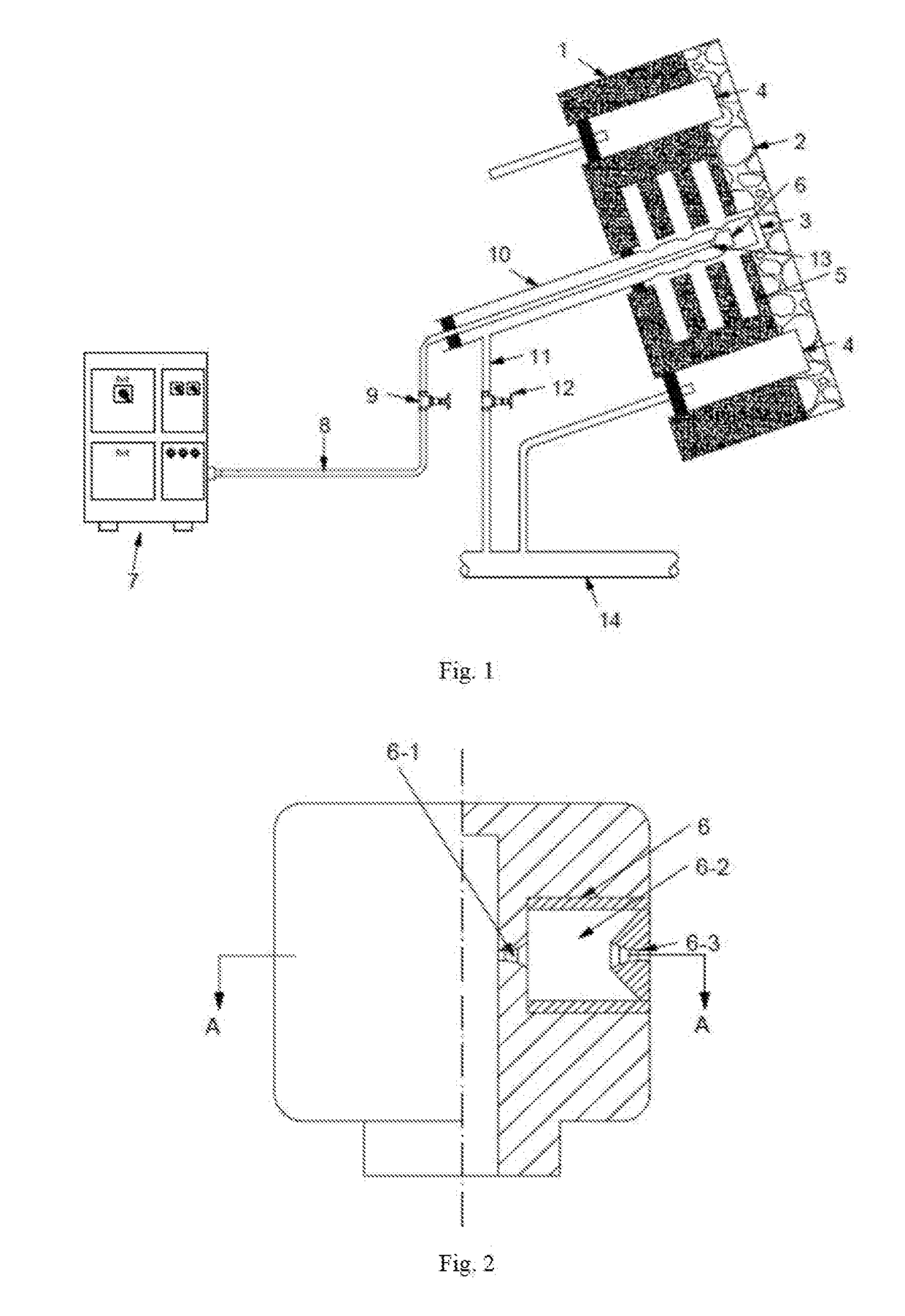

Method for integrated drilling, slotting and oscillating thermal injection for coal seam gas extraction

ActiveUS20180209255A1Easy to operateRemarkable improvement effectLiquid/gas jet drillingFluid removalEngineeringHigh pressure

A method for combining integrated drilling and slotting with oscillating thermal injection to enhance coalbed gas extraction, applicable to managing gas extraction from microporous, low-permeability, high-adsorption coal seam areas. A number of slots are formed within a thermal injection / extraction borehole by means of integrated drilling and slotting technology; a steam generator, is then used to three high-pressure, cyclically temperature-changing steam into said borehole; the steam passing through a spinning, oscillating-pulse jet nozzle forms an oscillating superheated steam, heating the coal body. The present method overcomes the limitations of simple permeability-increasing techniques, the slotting by means of hydraulic. pressure significantly increasing the pressure relief range of a single borehole and forming a fracture network that provides channels for passage of the superheated steam, while oscillating variation in steam temperature and pressure also promote crack propagation and perforation of the coal body; the combined effect of the two enhances the efficiency of gas desorption and extraction.

Owner:CHINA UNIV OF MINING & TECH

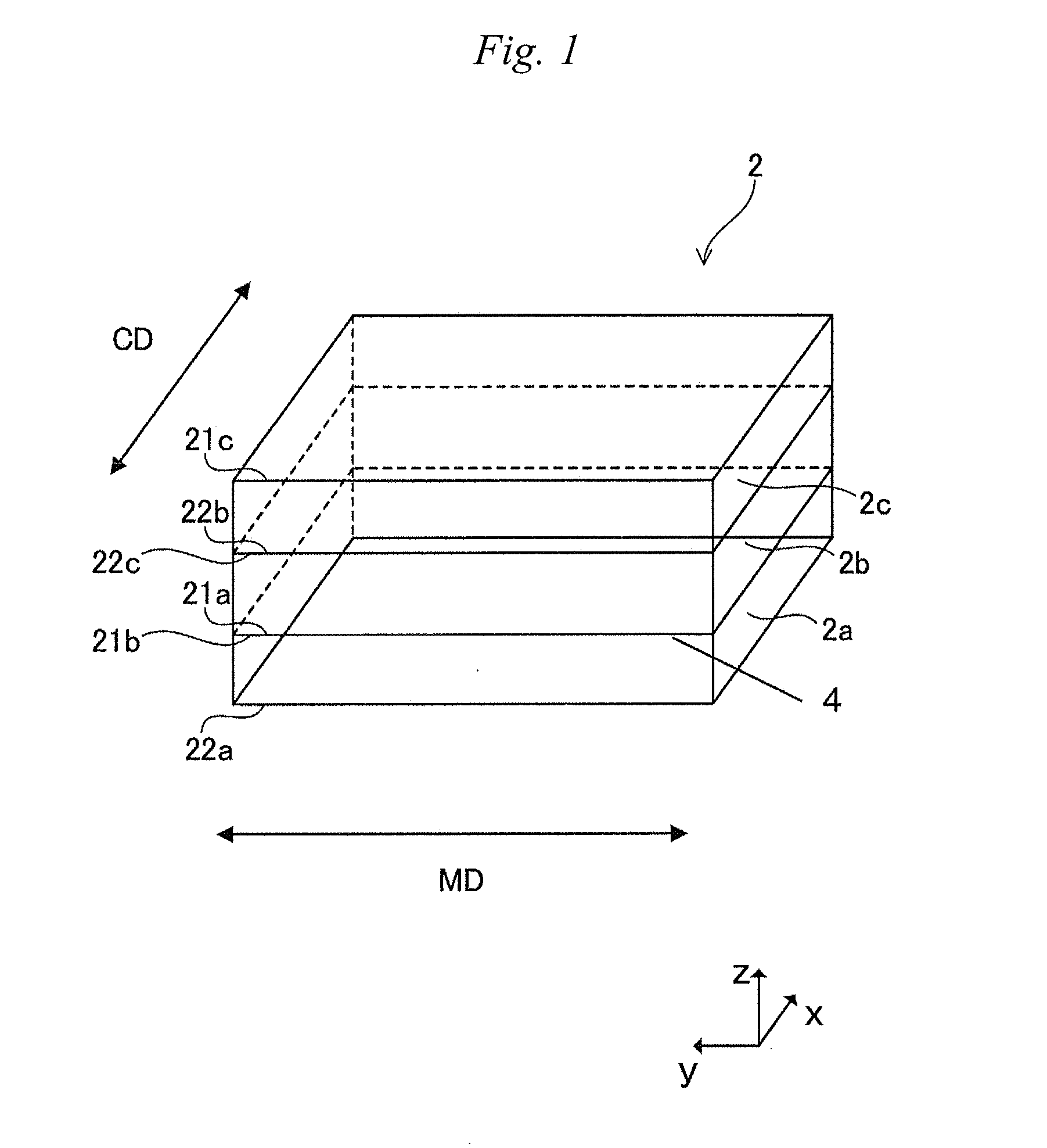

Separation membrane element

ActiveUS9808767B2High elastic modulusSignificant formSemi-permeable membranesMembranesWater collectionChemistry

A separation membrane element of the present invention includes: a water collection tube; and a plurality of separation membrane leaves stacked on each other and wound around the water collection tube, each of the separation membrane leaves includes one or more separation membranes each having a feed-side face and a permeate-side face and is configured so that the feed-side faces face each other, and a sheet having a plurality of projections fixed thereto is provided between the permeate-side faces of the separation membrane leaves stacked on each other. Regarding a height of the projections, a ratio of the maximum height to the minimum height is from 1.10 to 1.50, and a variation coefficient of the height is from 0.02 to 0.15, and an impregnation ratio of the projections into the sheet is from 10% to 100%.

Owner:TORAY IND INC

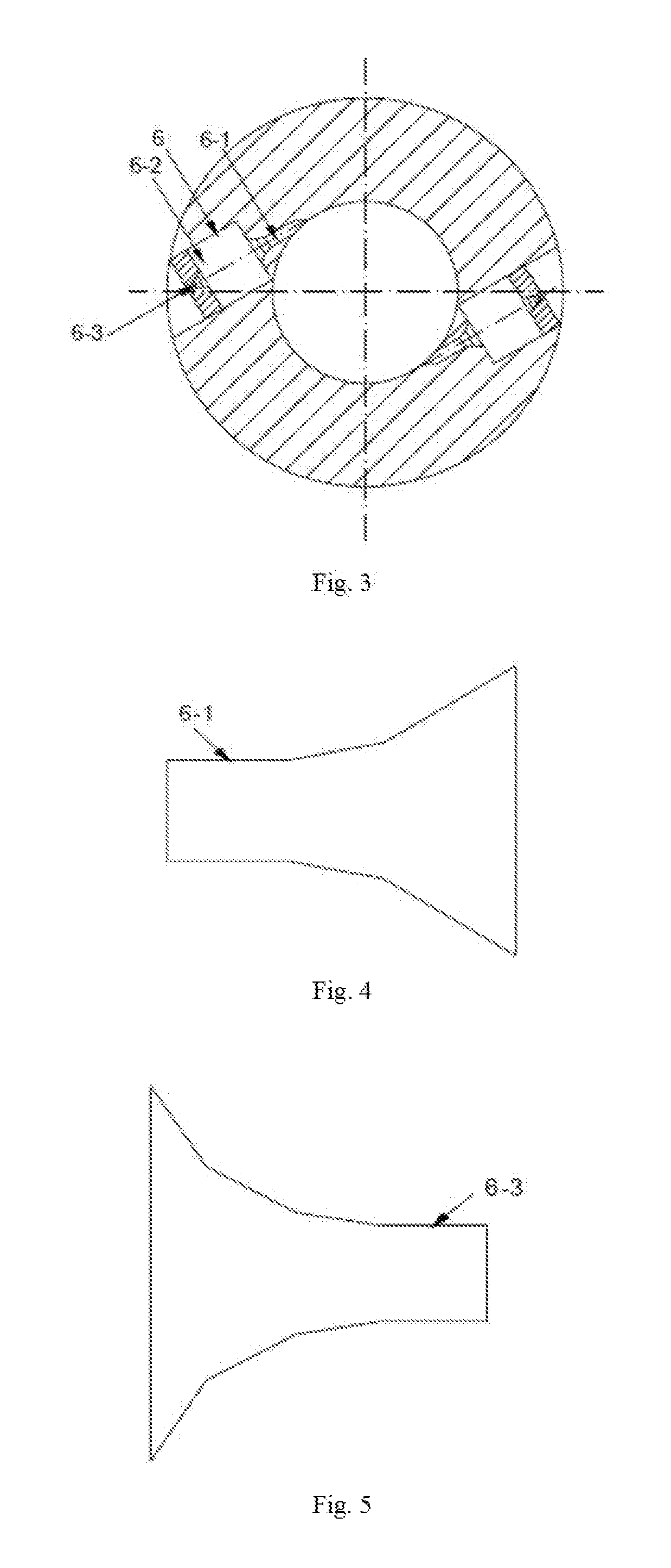

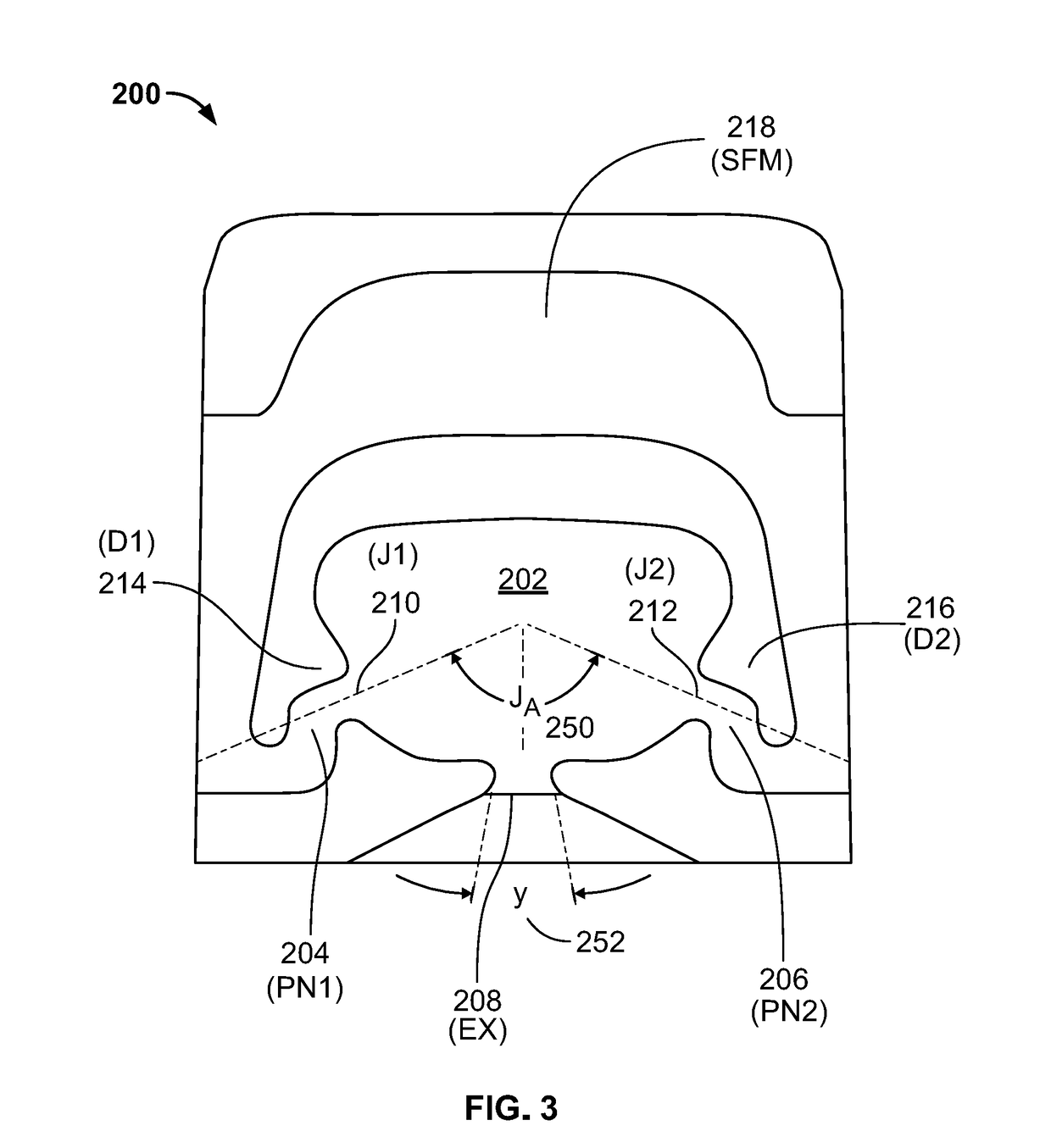

Compact low flow rate fluidic nozzle for spraying and cleaning applications having a reverse mushroom insert geometry

ActiveUS20180345299A1Desired level of performanceReduce flow rateSpray nozzlesVehicle cleaningSpray nozzleEngineering

The invention relates to various low flow rate fluidic nozzle inserts having a reverse mushroom-shaped mushroom insert geometry that are useful for a wide range of spraying and cleaning applications. In one embodiment, the present invention relates to fluidic nozzle inserts that are able to perform at low flow rates with geometrical and dimensional limitations. In still another embodiment, the present invention relates to compact fluidic nozzle inserts that provide a manner by which to attain a desired level of performance in a fluidic nozzle assembly for small scale applications at low flow rates.

Owner:DLHBOWLES INC

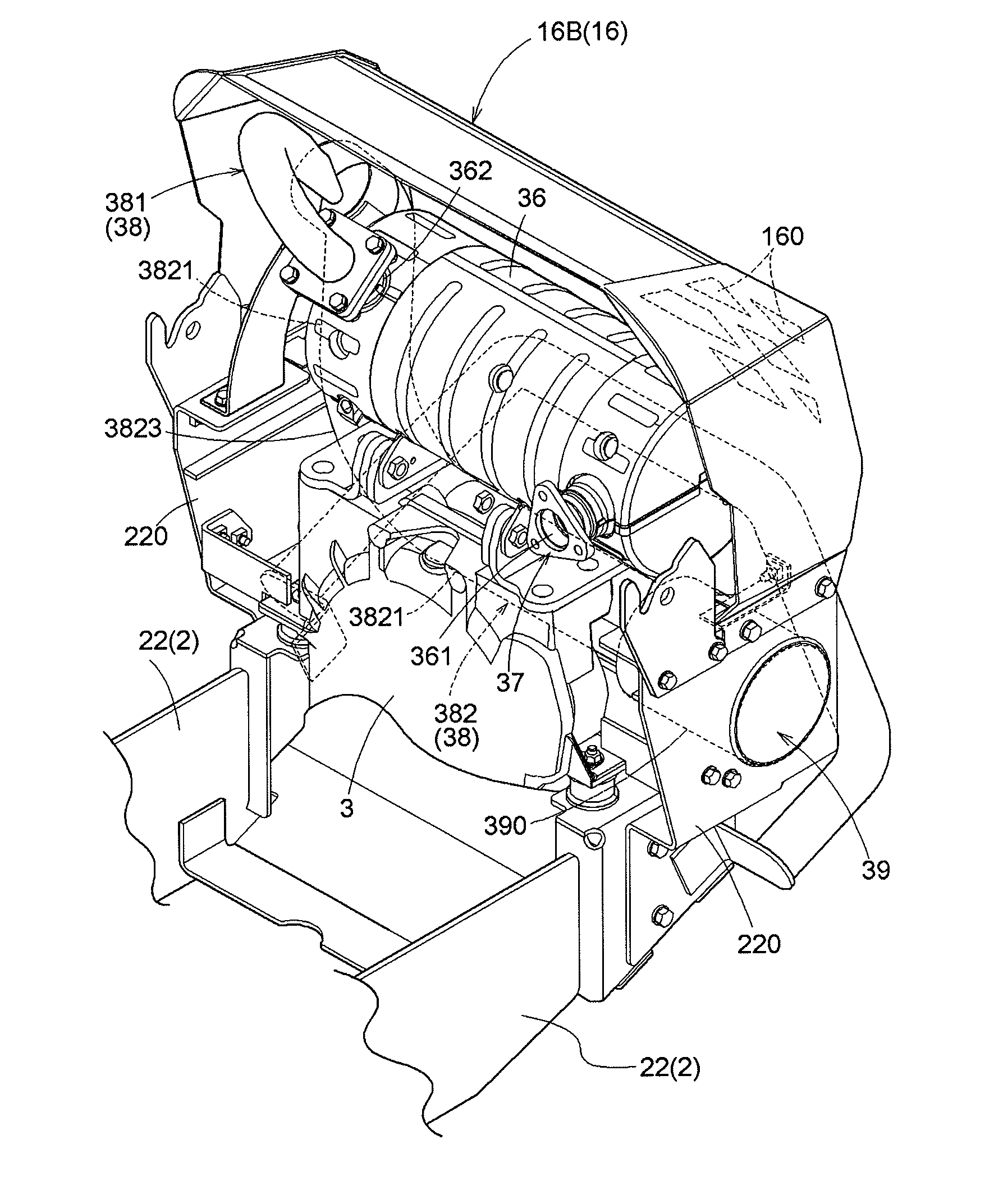

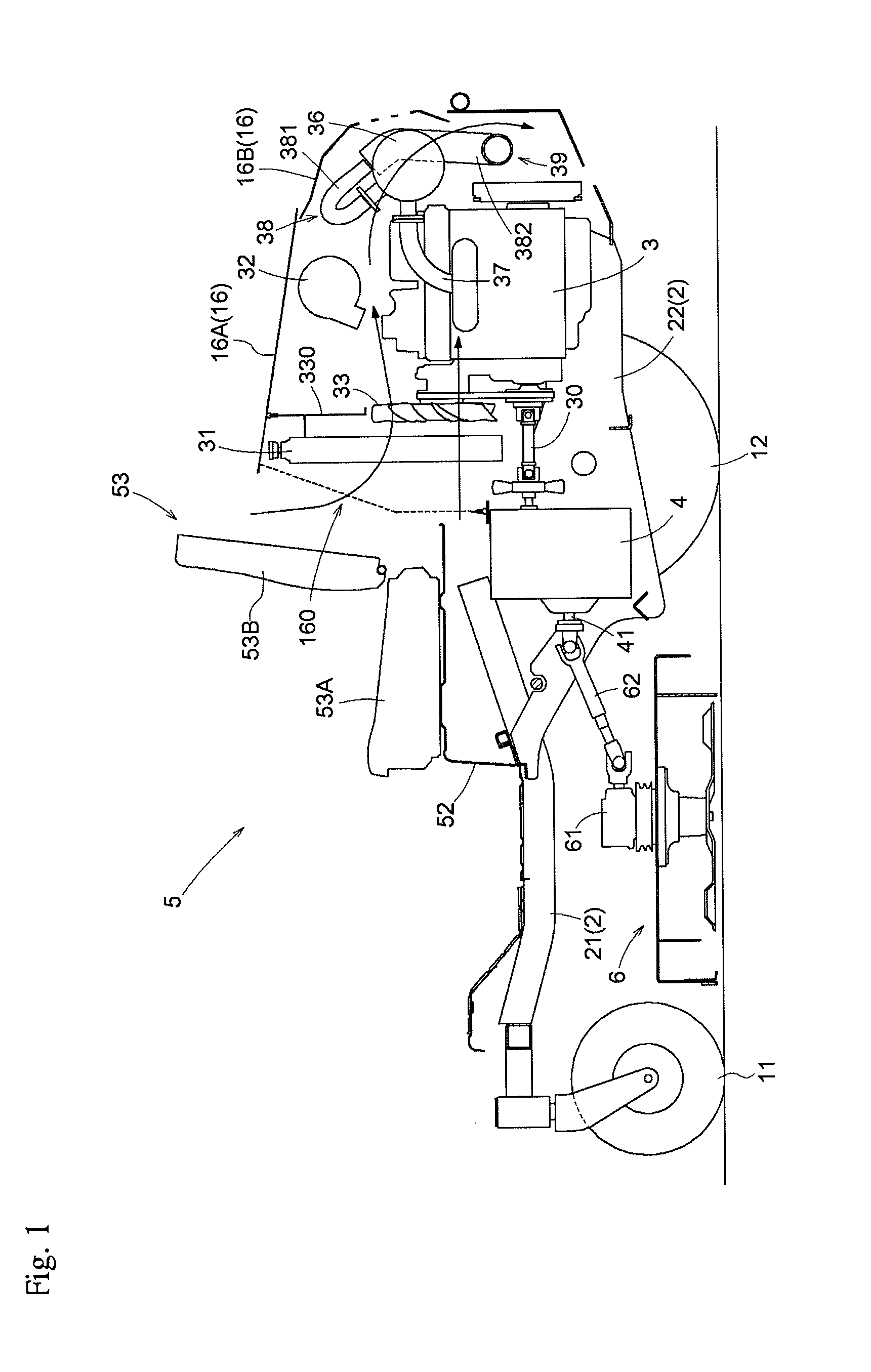

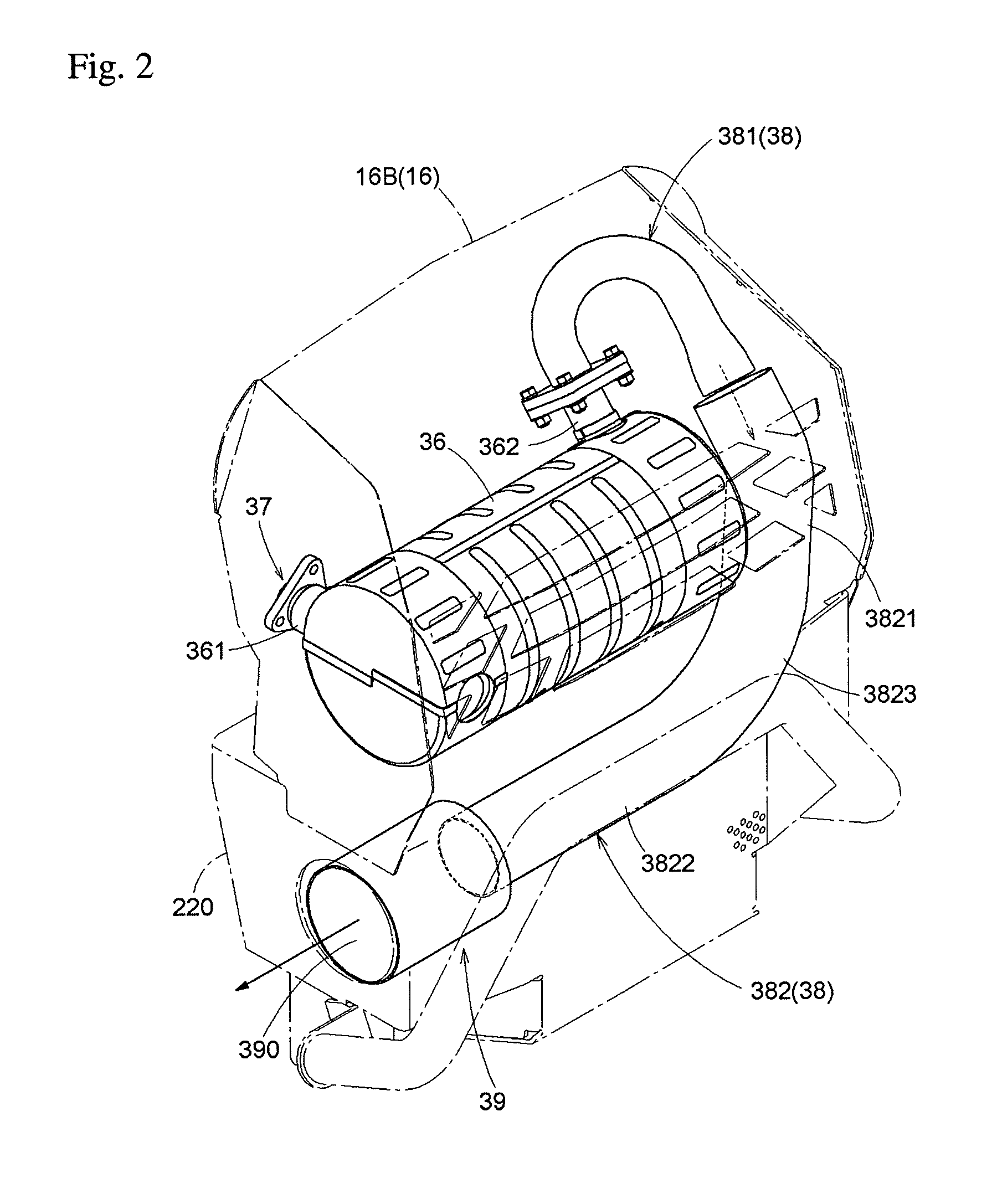

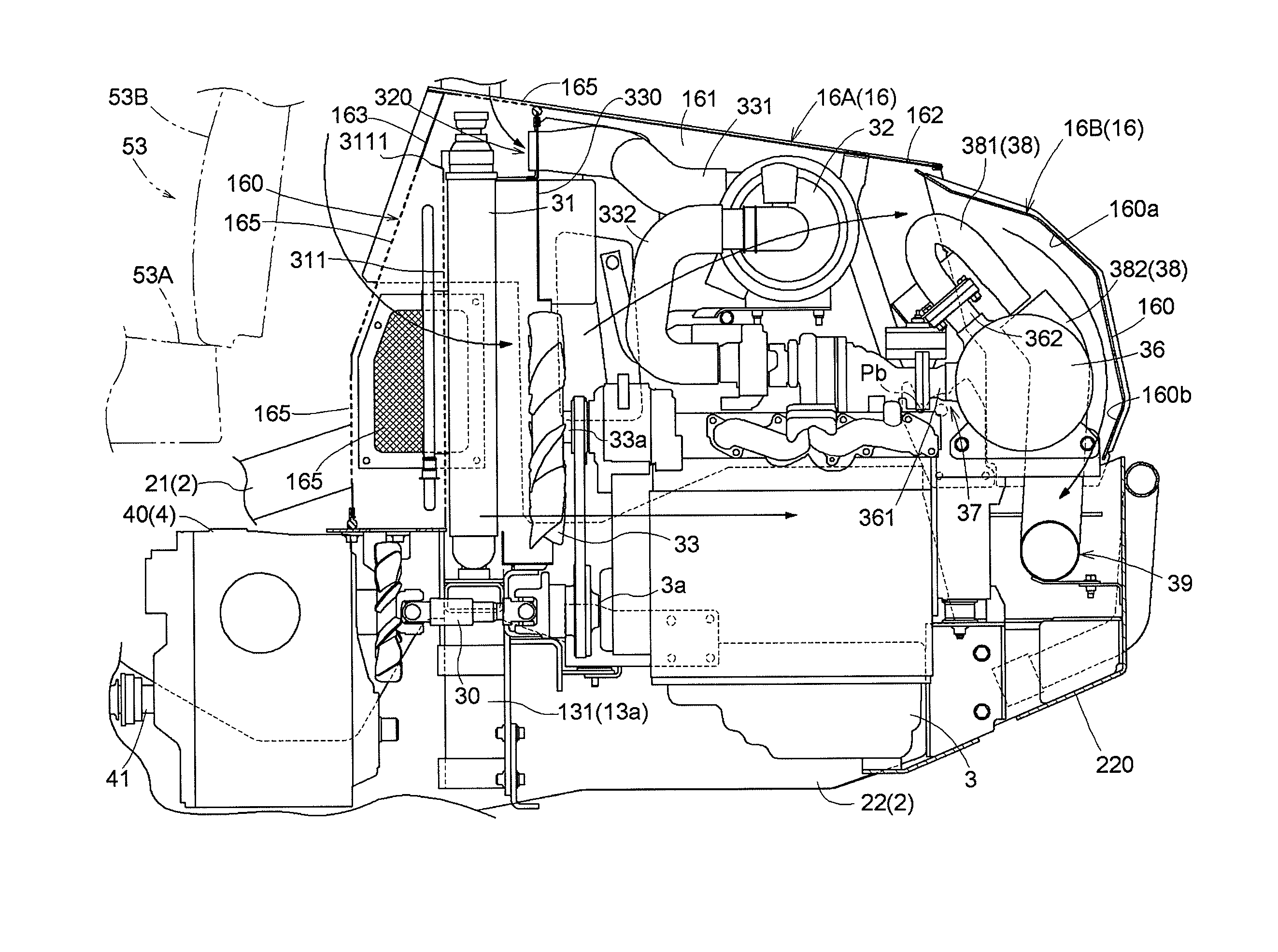

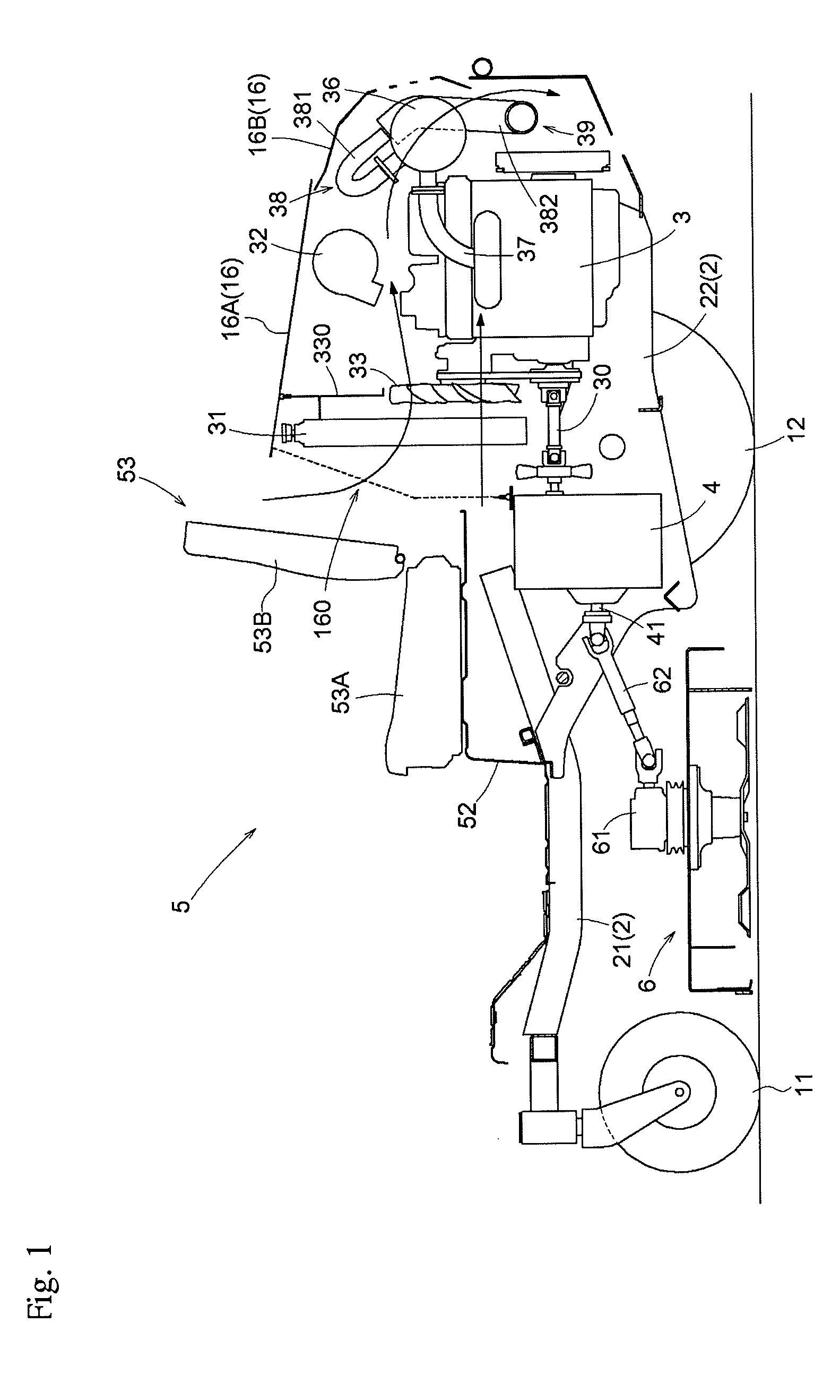

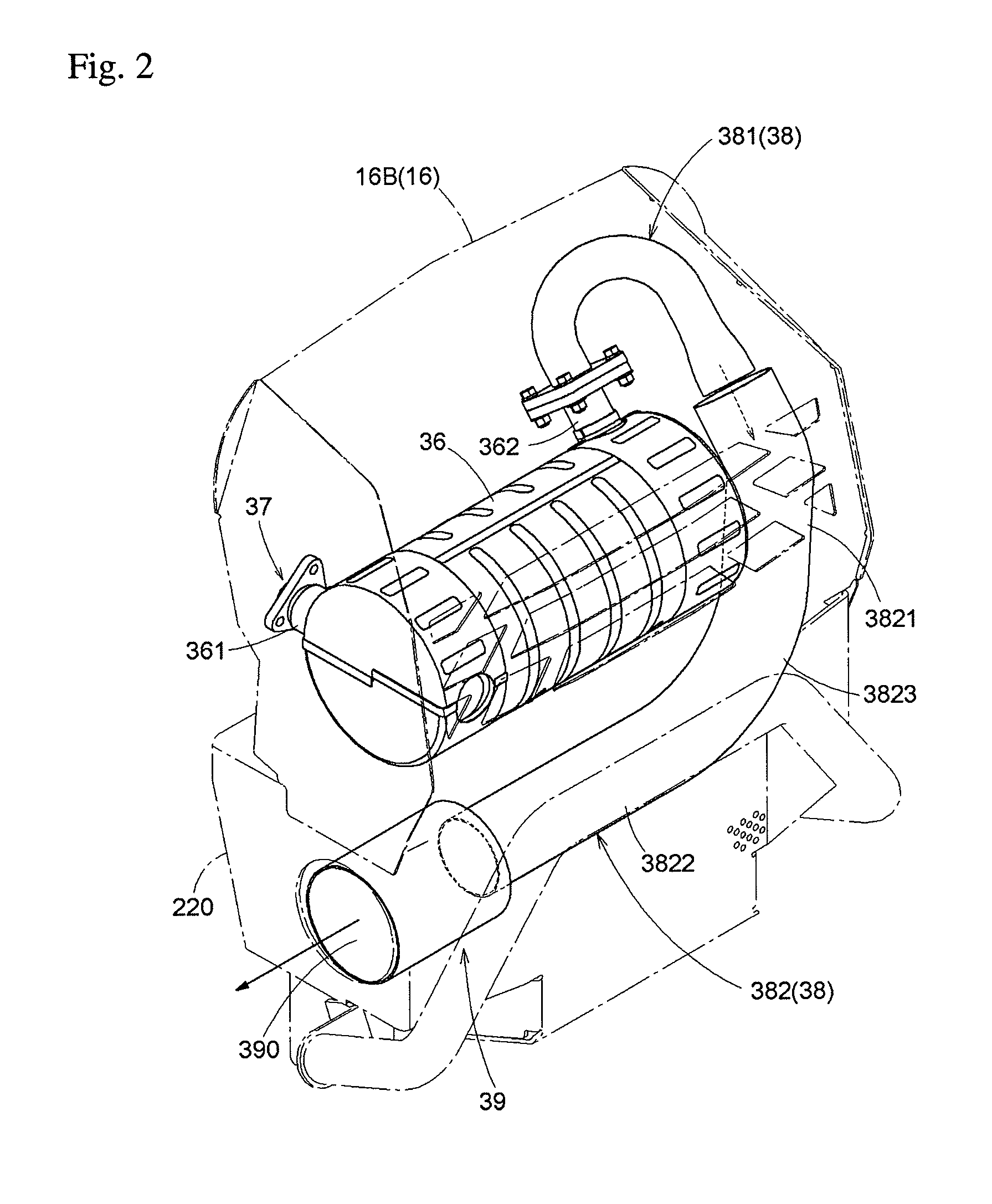

Work vehicle with improved exhaust component cooling

ActiveUS20160193912A1Reduce the temperatureSpeed up the flowInternal combustion piston enginesExhaust apparatusExhaust manifoldAutomotive engineering

A work vehicle in which a cooling fan is arranged forward of an engine and an exhaust gas purification device is arranged rearward of the engine. An inlet-side exhaust passage connects an exhaust manifold and the exhaust gas purification device. An outlet-side exhaust passage connects the exhaust gas purification device and the exhaust end portion. A first exhaust passage is coupled to the exhaust gas purification device and passes over the exhaust gas purification device to reach beside a first end portion. A second exhaust passage is coupled to the first exhaust passage and extends in a transverse direction and below the exhaust gas purification device.

Owner:KUBOTA LTD

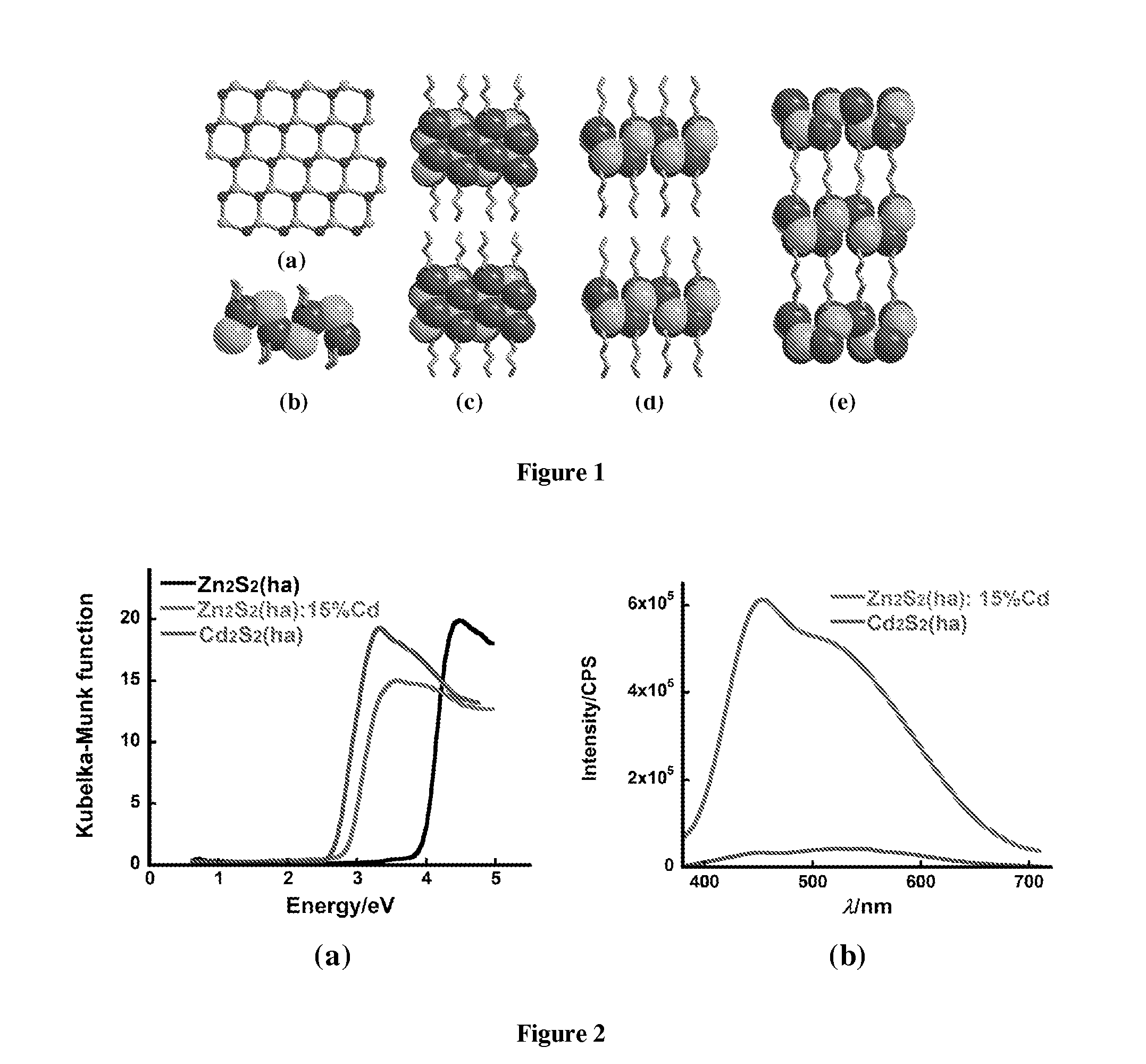

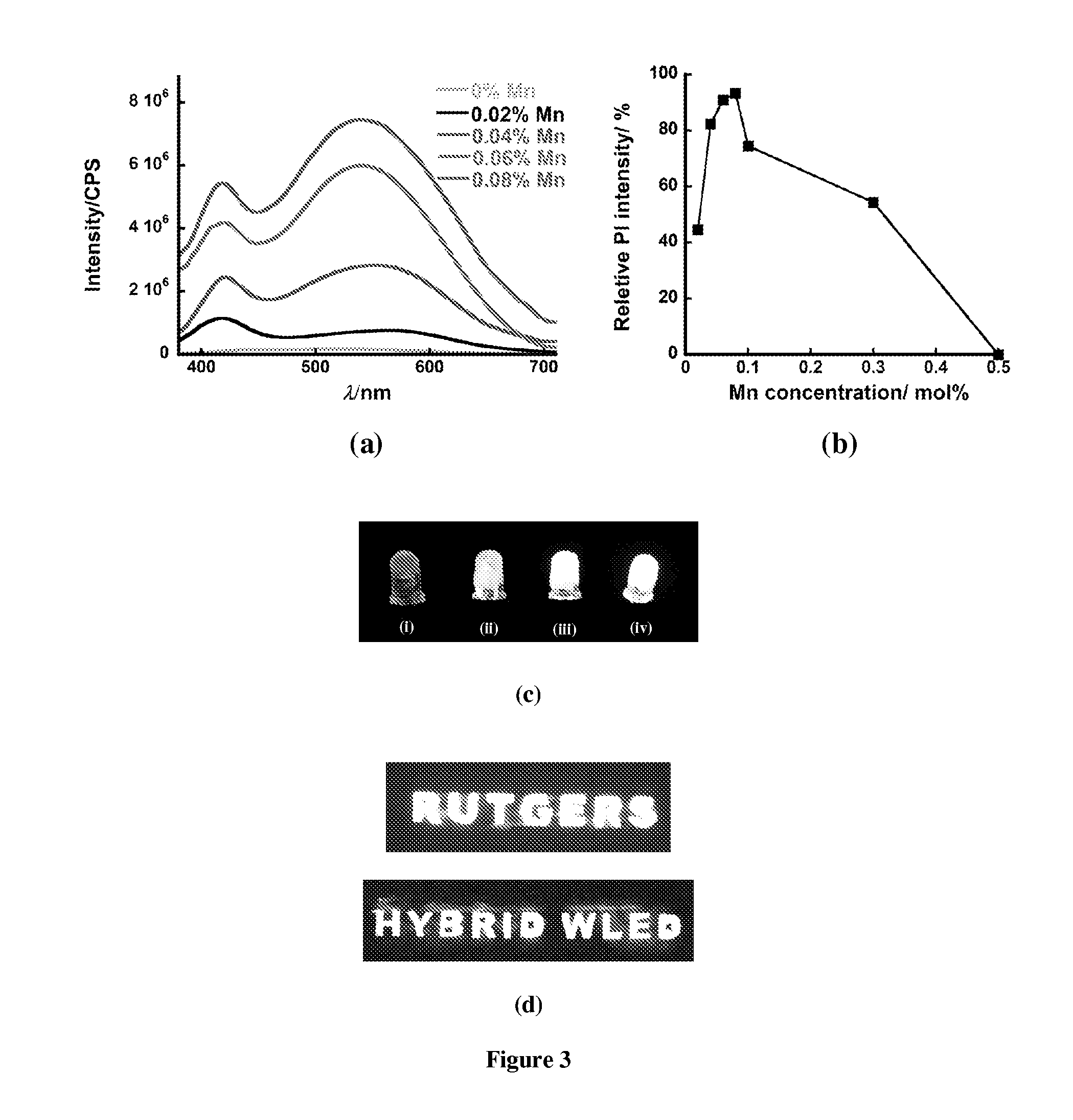

Solid-state compositions and methods for generating white light

InactiveUS20140197400A1High-efficiency in emitting white lightLow costSolid-state devicesSemiconductor/solid-state device manufacturingQuantum yieldOrganic component

This application discloses a new family of inorganic-organic hybrid semiconductor bulk materials built on periodic nanostructured 2D layers of ZnS that emit bright white light with high quantum efficiency. These ZnS-based crystalline inorganic-organic hybrid semiconductors have well defined and precisely controllable crystal structure and composition. Their optical emission properties, including intensity, quantum yield, and color quality, can be systematically tuned by varying the composition of both inorganic and organic components. Methods for preparing these materials, use of these materials as a new type of single-phased white light emitting phosphors, and their applications in making WLED devices are also disclosed.

Owner:RUTGERS THE STATE UNIV

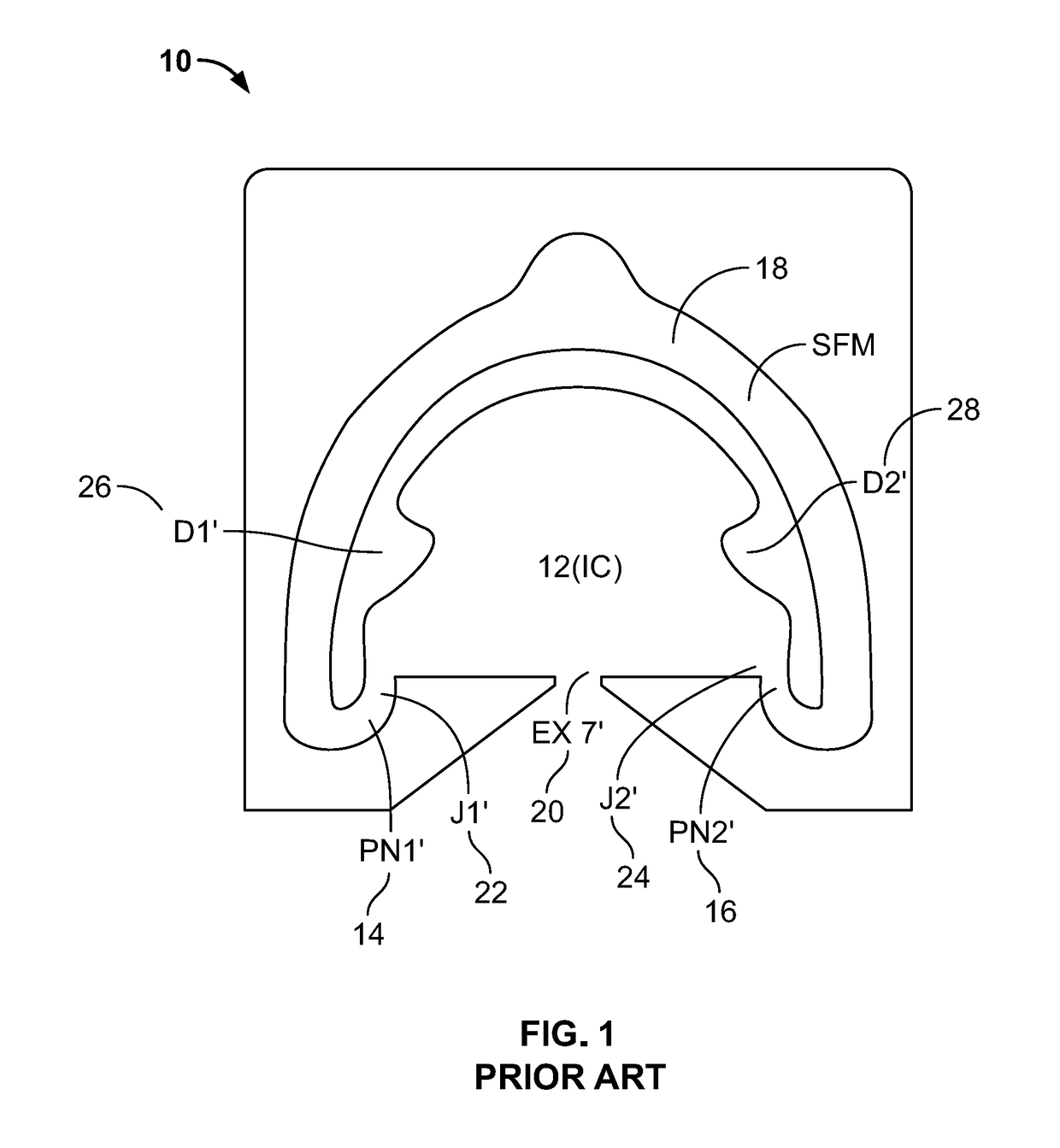

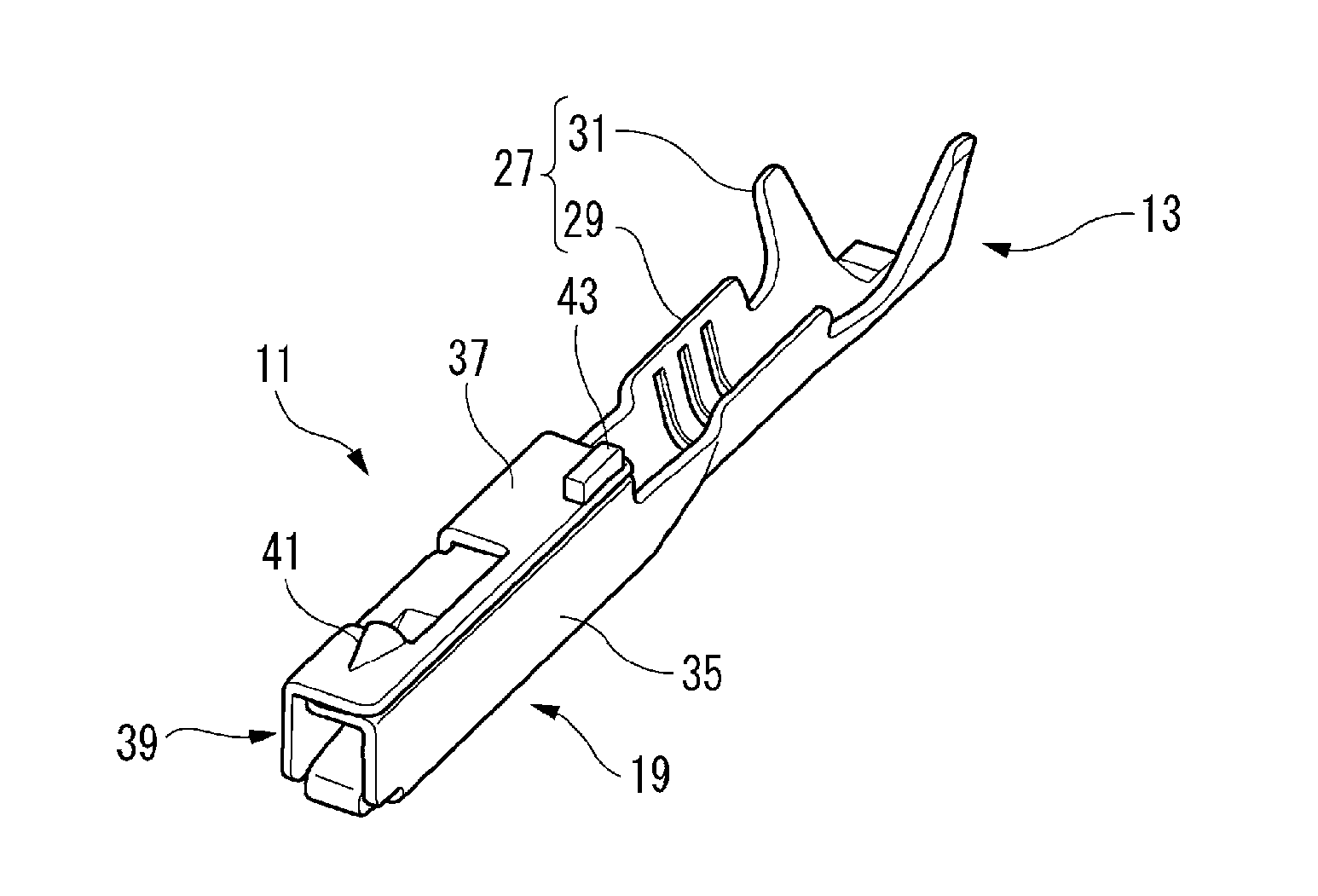

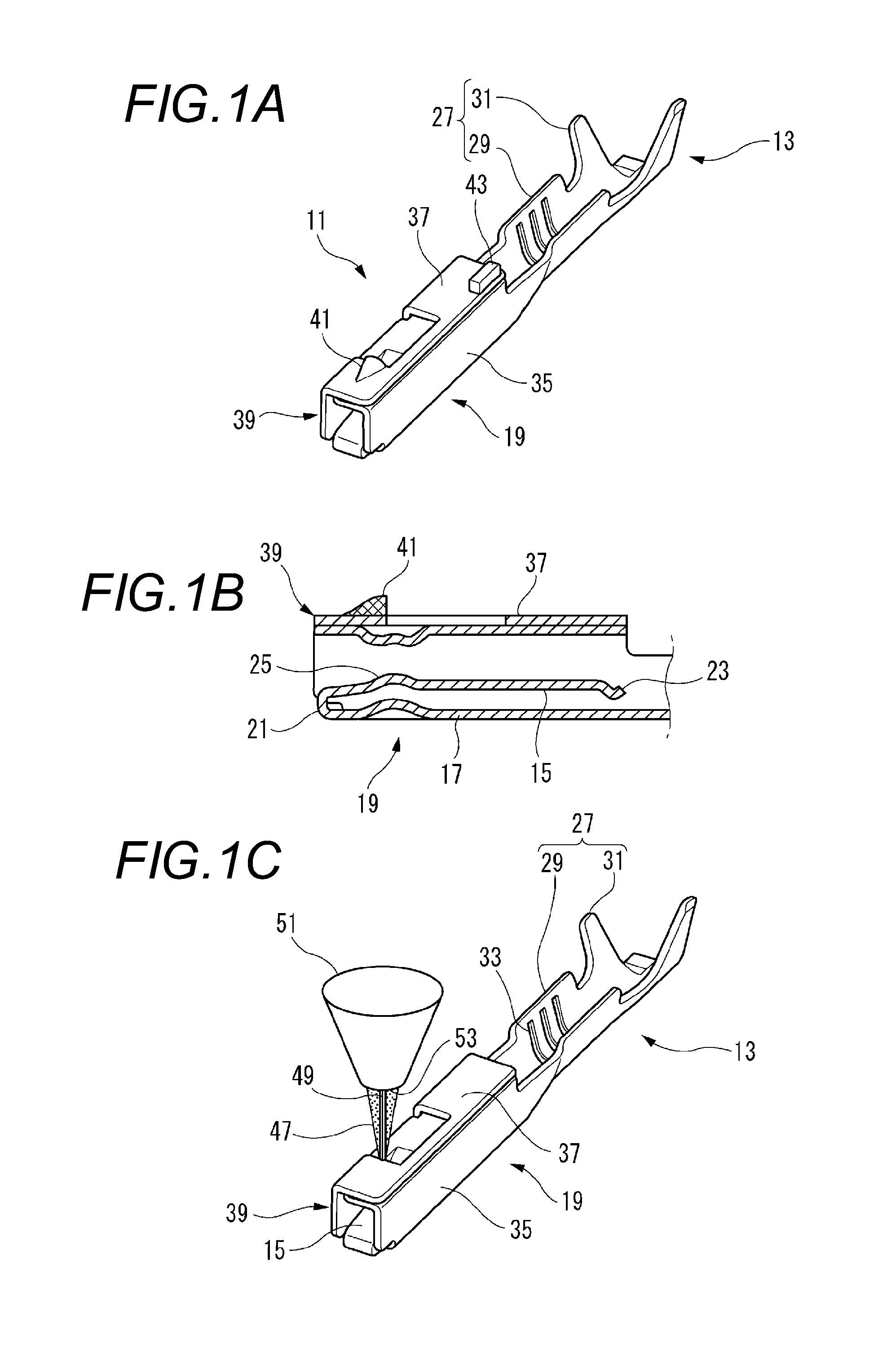

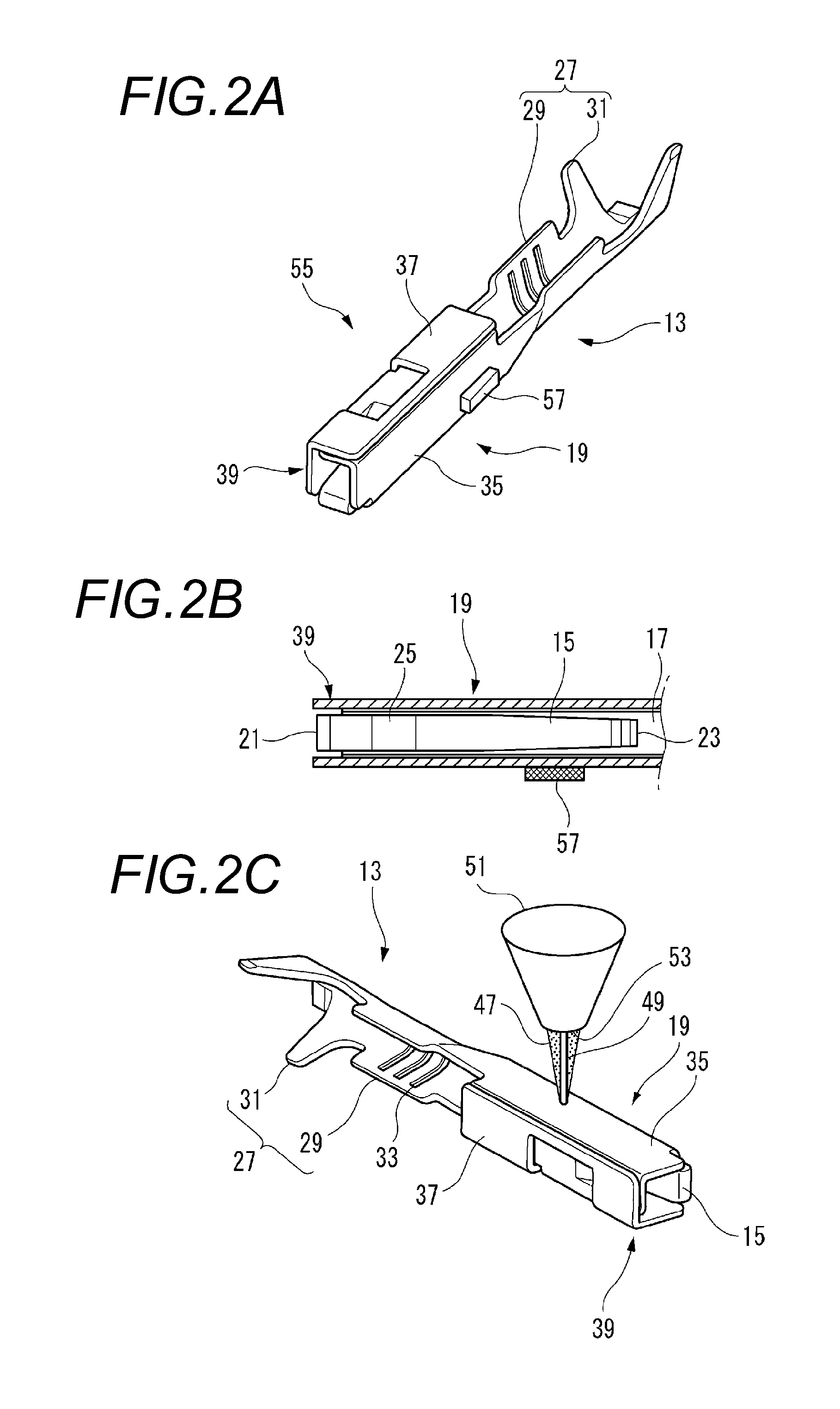

Connection terminal

InactiveUS20150244106A1Reduce typesHigh mechanical strengthContact member manufacturingIncorrect coupling preventionElectrical conductorComputer terminal

A connection terminal includes a terminal body that includes a terminal-connect part provided with a tubular box part having an opening in one end side into which a mating terminal is inserted and a conductor-connect part formed in the other end side of the terminal-connect part. The terminal-connect part and the conductor-connect part are formed integrally by a press work. A functional configuration part is allowed to protrude from and integrally formed with the box part by solid modeling.

Owner:YAZAKI CORP

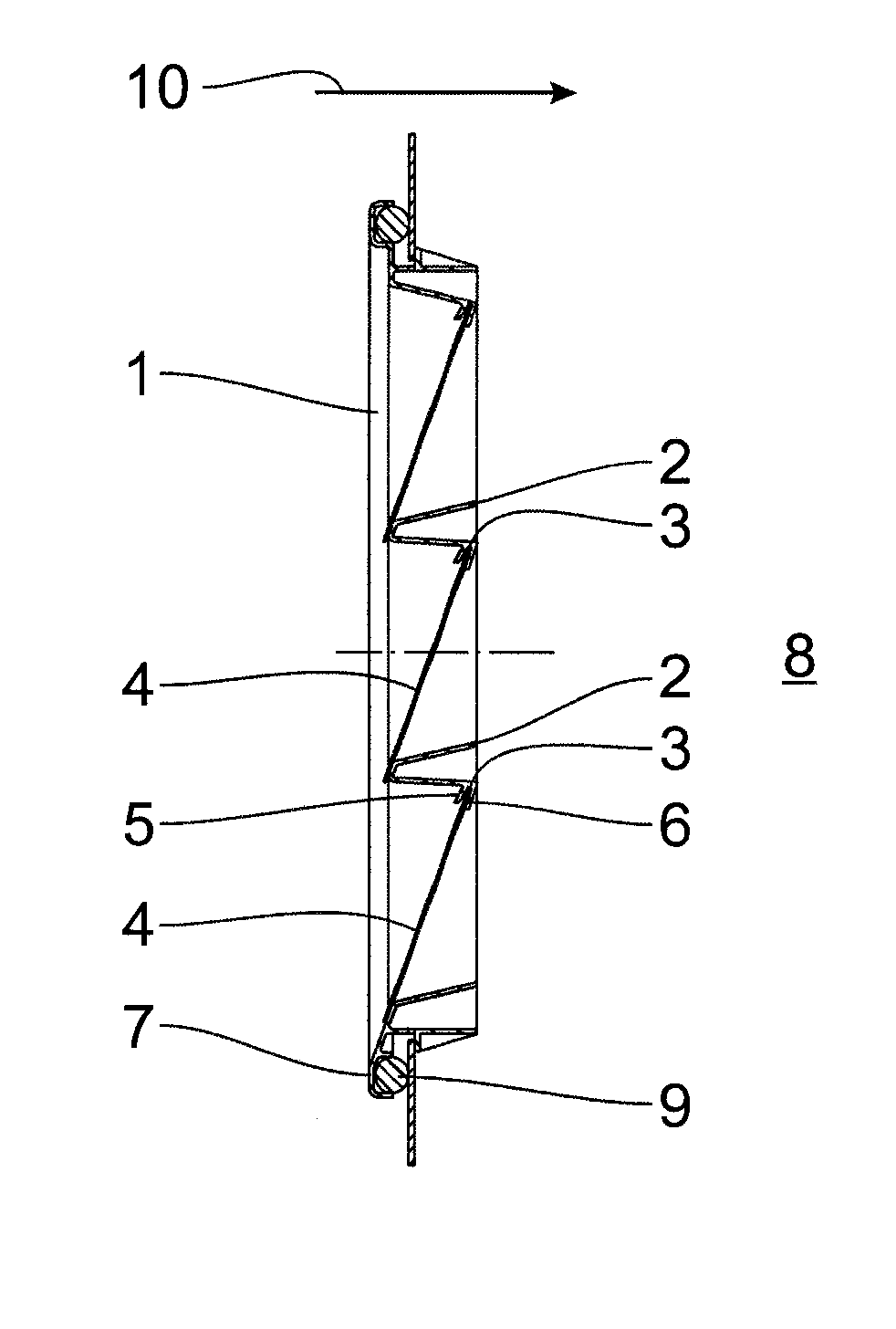

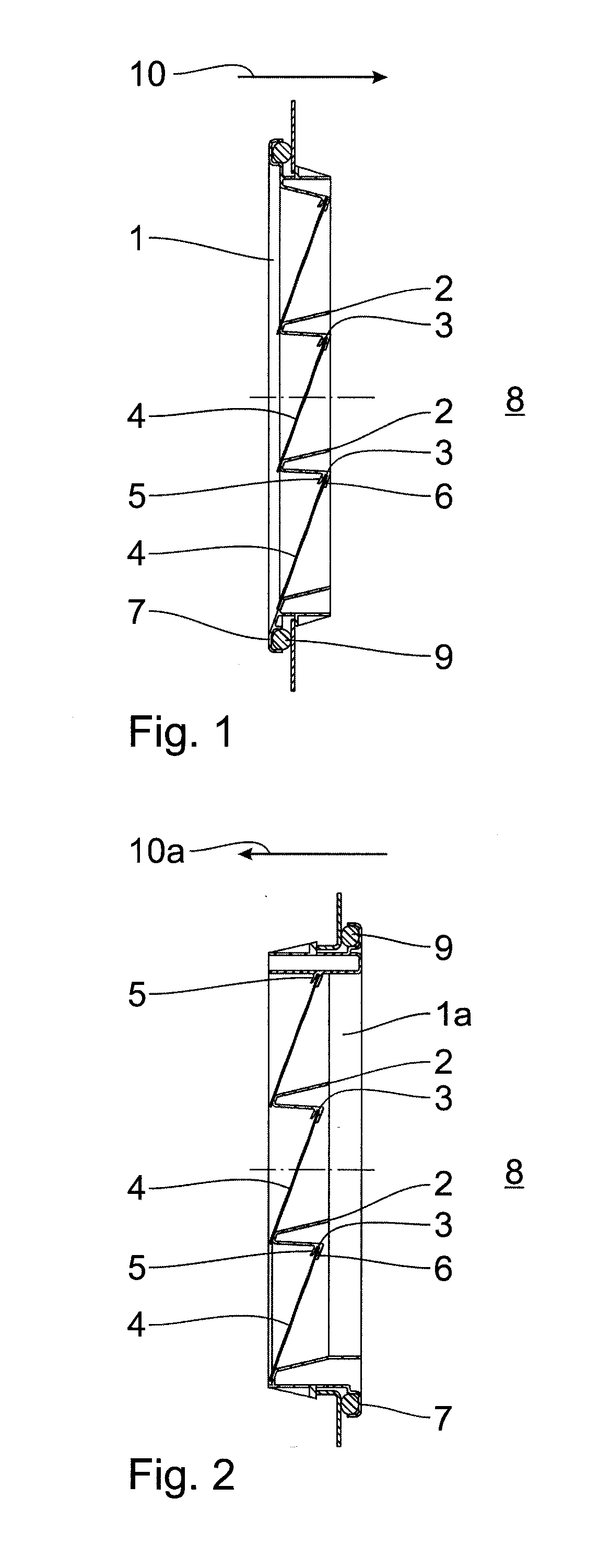

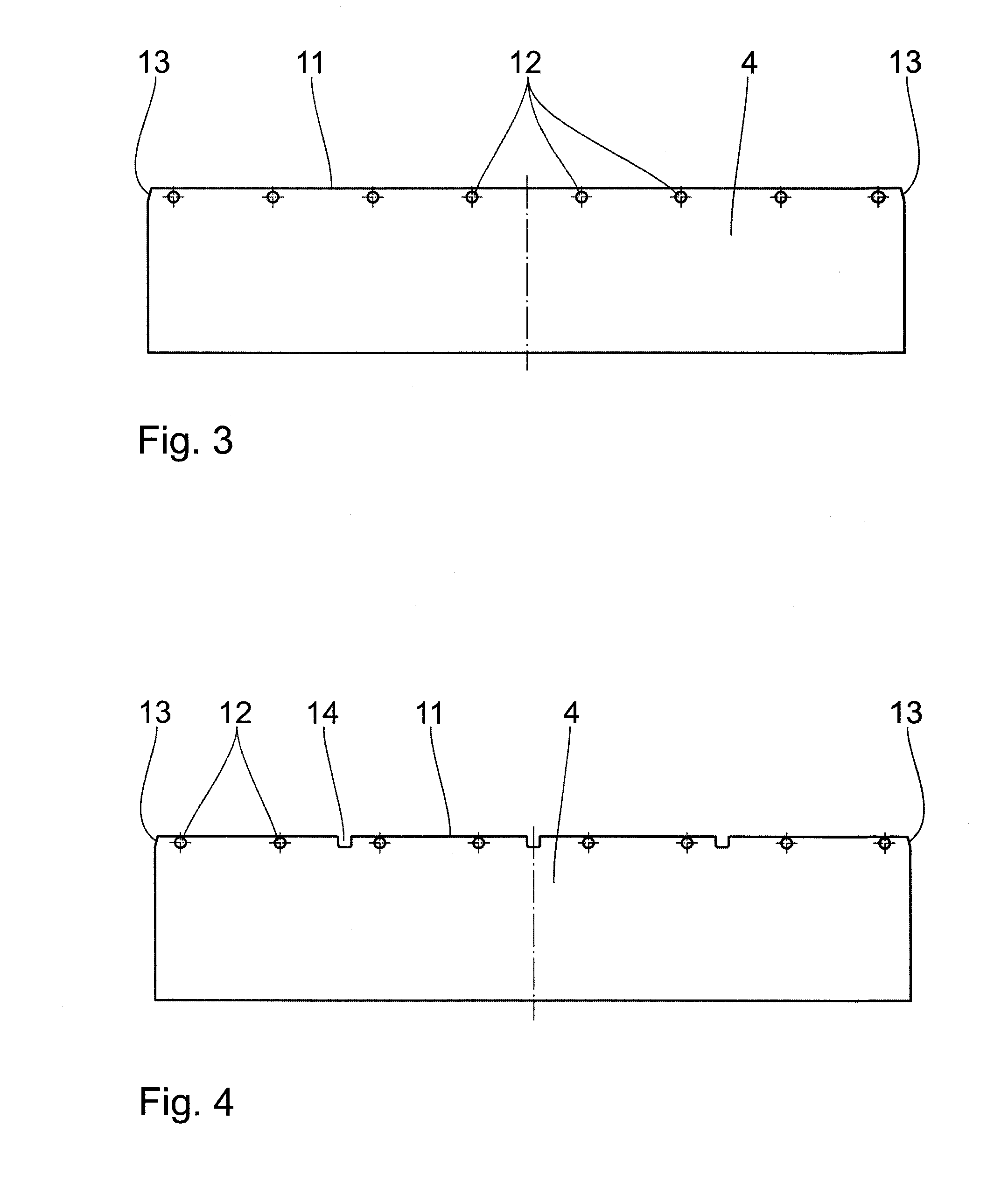

Surface light guide and planar emitter

InactiveUS8998479B2Increase probabilityIncrease concentrationMechanical apparatusPlanar/plate-like light guidesLight guideRadiation

A surface light guide has a radiation exit area extending along a main extension plane of the surface light guide and is provided for laterally coupling radiation. The surface light guide includes scattering locations for scattering the coupled radiation. The surface light guide includes a first boundary surface and a second boundary surface which delimit the light conductance of the coupled-in radiation in the vertical direction. A first layer and a second layer are formed on each other in the vertical direction between the first boundary surface and the second boundary surface. Further disclosed are a planar emitter including at least one surface light guide.

Owner:OSRAM OPTO SEMICON GMBH & CO OHG

Connector, electronic equipment and control method for electronic equipment

InactiveUS20030114033A1Significant formHigh densityPrinted circuit assemblingElectrically conductive connectionsEngineeringElectrical and Electronics engineering

A connector has an operation unit connector that is fixed on an operation unit, and an electronic equipment main body connector that is fixed on an electronic equipment main body. The operation unit connector has plural terminals at regular intervals aligned in a row. The electronic equipment main body connector has plural electrodes at positions corresponding to the terminals at regular intervals. At least one of the electrodes is formed to be shorter than other electrodes and serves as a detecting electrode. The detecting electrode is disposed at the same upper position as the other electrodes, and shorter on the lower side.

Owner:PIONEER CORP

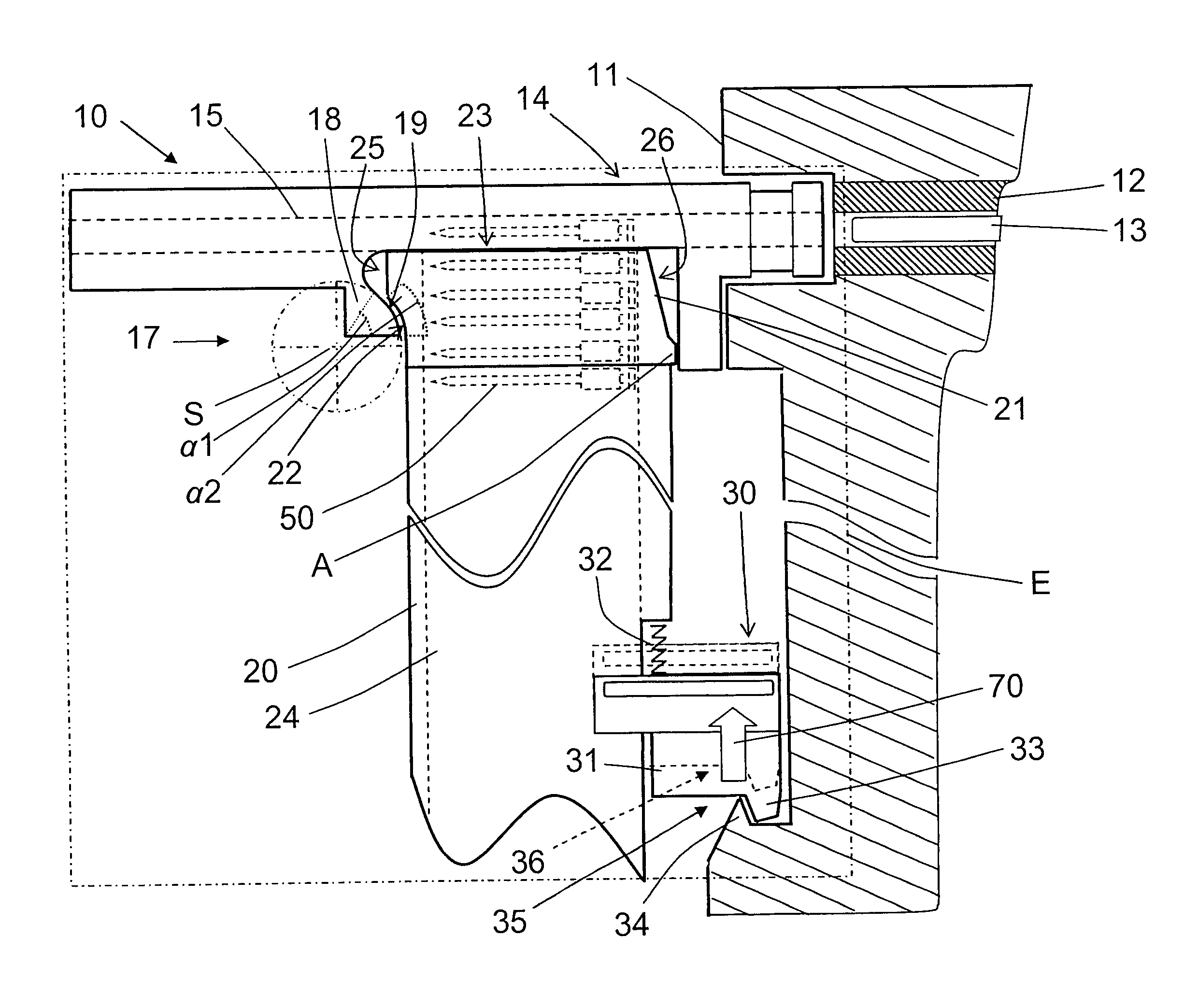

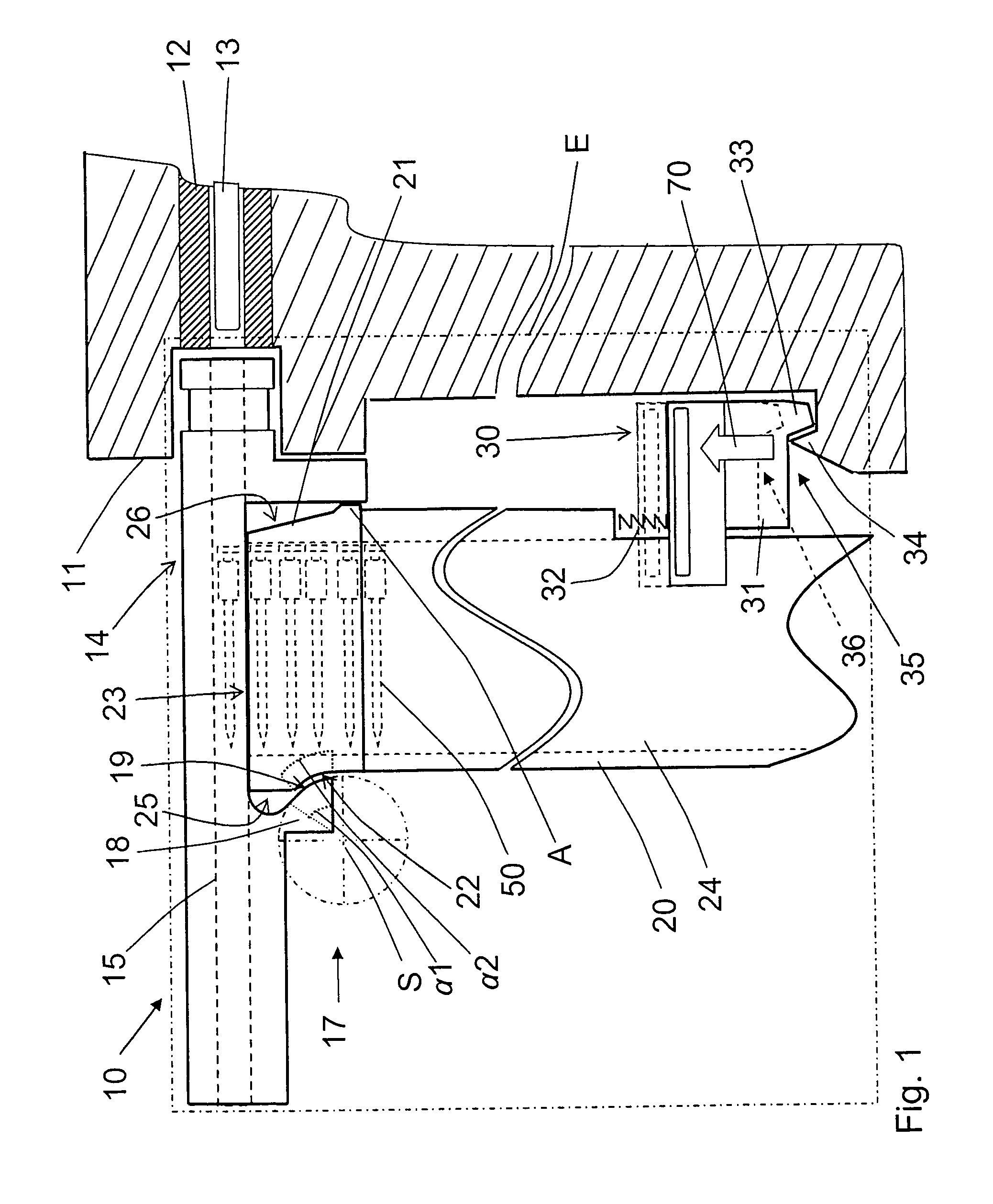

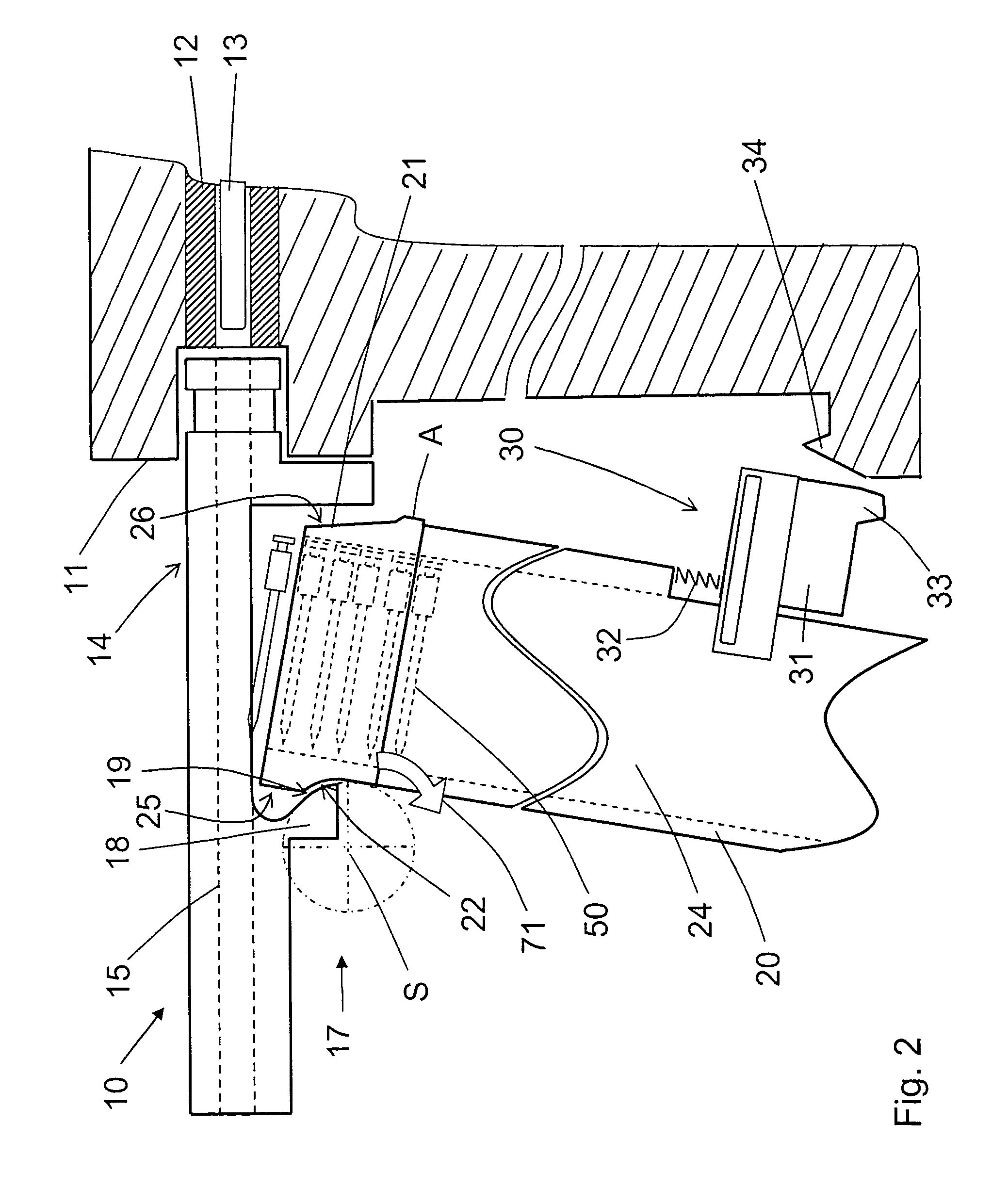

Setting tool

A setting tool for driving fastening elements in a constructional component, includes a muzzle (14), a bolt guide (15) located in the muzzle (14), a magazine (20) for fastening elements (50) and releasably mountable on the tool housing (11) and having a connection section (21) provided at an end of the magazine (20) adjacent to the muzzle (14) and with which the magazine (20) is secured to the muzzle (14), and a connection device for releasably mounting the magazine on the tool housing (11) and including a hinge bearing formed as a plug-in coupling and provided with a first support element arranged on the connection section (21) of the magazine (20) and a second support element arranged on the muzzle (14), with the hinge bearing (17) having a pivot axis (S) provided on a side of the magazine (20) remote from the housing (11), outside of the magazine (20) and outside of the muzzle (14) and extending at a right angle to a plane (E) defined by the bolt guide (15) and the magazine (20).

Owner:HILTI AG

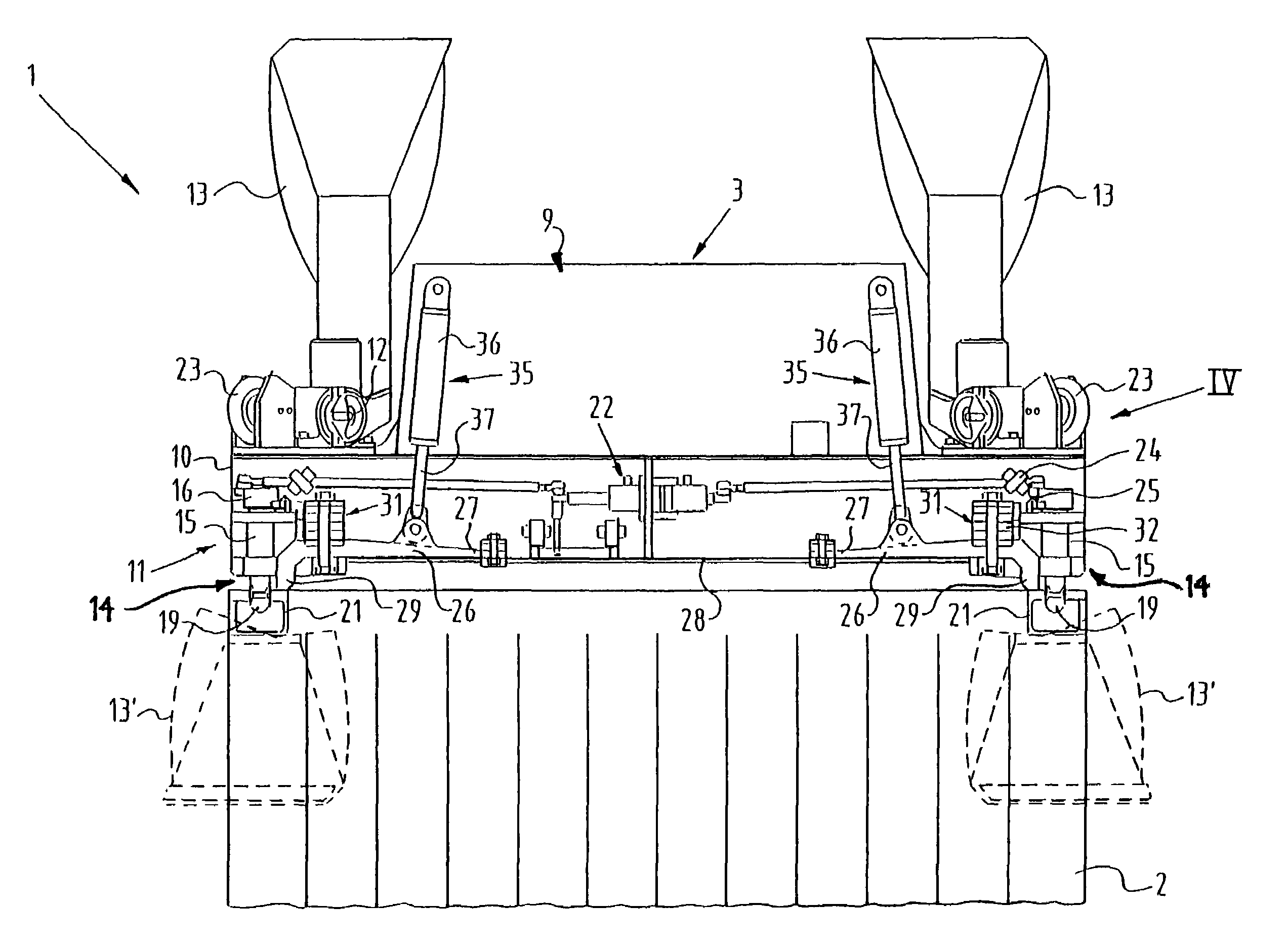

Container gripping device having contact elements for braking

InactiveUS7665784B2Significant formConsiderable dampingLoad-engaging elementsHydraulic cylinderEngineering

A device for gripping containers from above, which includes a frame which has a number of corners, twist-locks arranged close to each of the corners of the frame for gripping an upper corner of the containers, and contact elements connected to the frame, which elements are biased to a position located at least partly under the frame and which are adapted to brake the movement of the frame in the vicinity of a container when the frame is placed on the container. The presence of these contact elements allows loads on the frame to be reduced and noise nuisance to be minimized. The contact elements, which may be arranged in or on the frame and may protrude through openings formed in the frame, may be elastically deformable or may be pivotally connected to the frame. Compression springs and / or hydraulic cylinders may be arranged between the frame and the contact elements.

Owner:STINIS BEHEER

Separation membrane element

ActiveUS20160303514A1Stable permeate-sideEfficient separationMembranesSemi-permeable membranesWater collectionWater pipe

A separation membrane element of the present invention includes: a water collection tube; and a plurality of separation membrane leaves stacked on each other and wound around the water collection tube, each of the separation membrane leaves includes one or more separation membranes each having a feed-side face and a permeate-side face and is configured so that the feed-side faces face each other, and a sheet having a plurality of projections fixed thereto is provided between the permeate-side faces of the separation membrane leaves stacked on each other. Regarding a height of the projections, a ratio of the maximum height to the minimum height is from 1.10 to 1.50, and a variation coefficient of the height is from 0.02 to 0.15, and an impregnation ratio of the projections into the sheet is from 10% to 100%.

Owner:TORAY IND INC

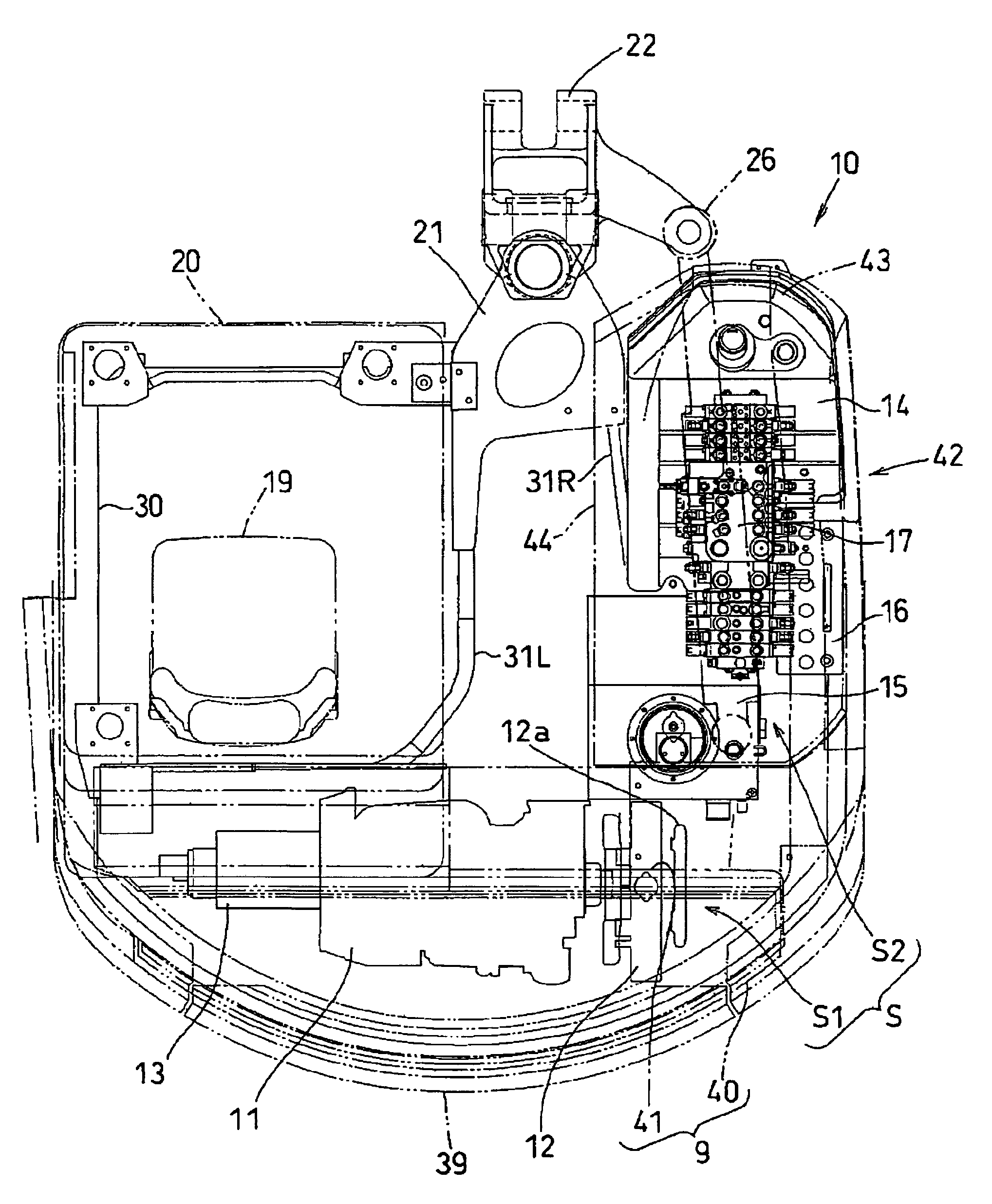

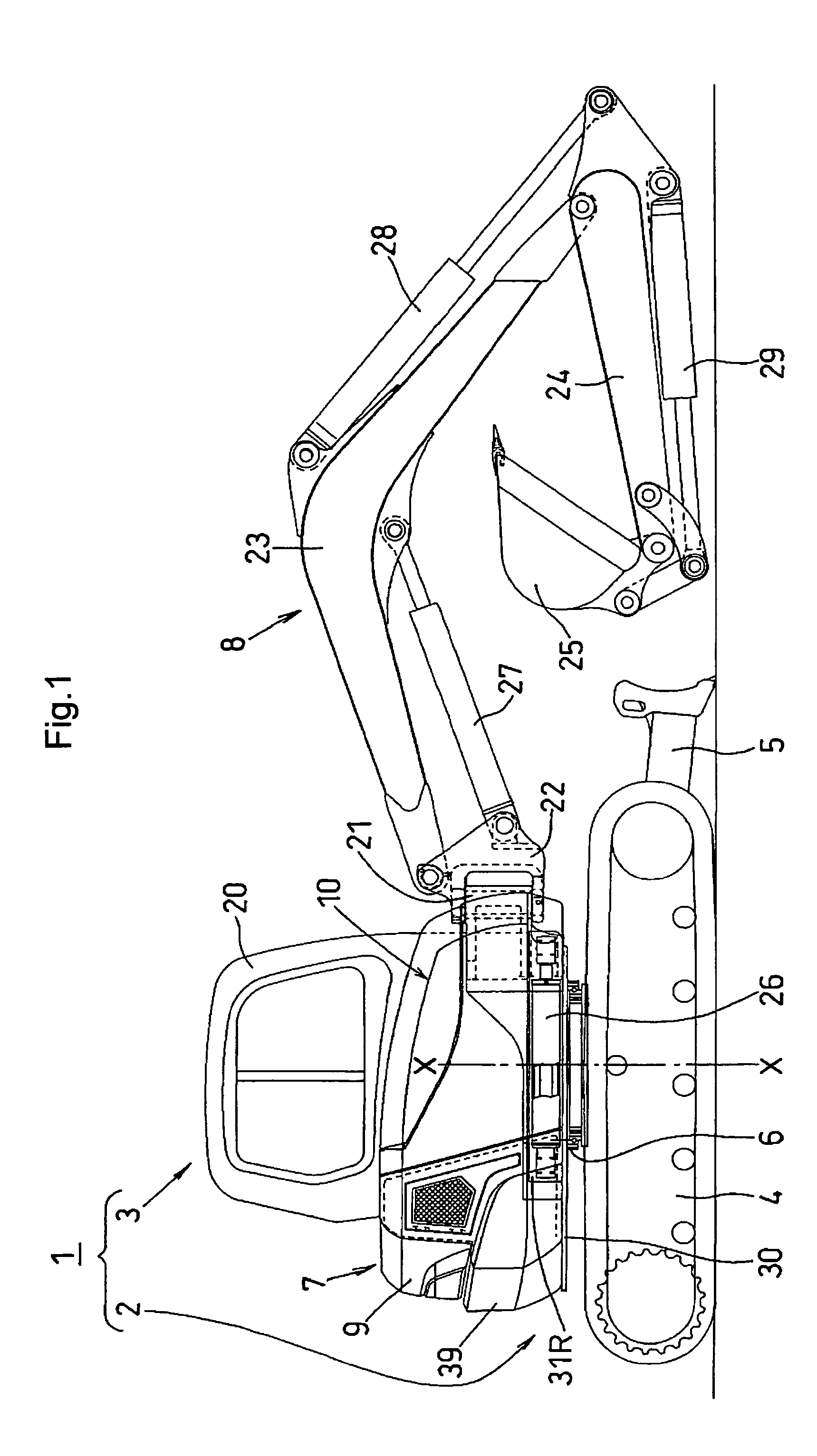

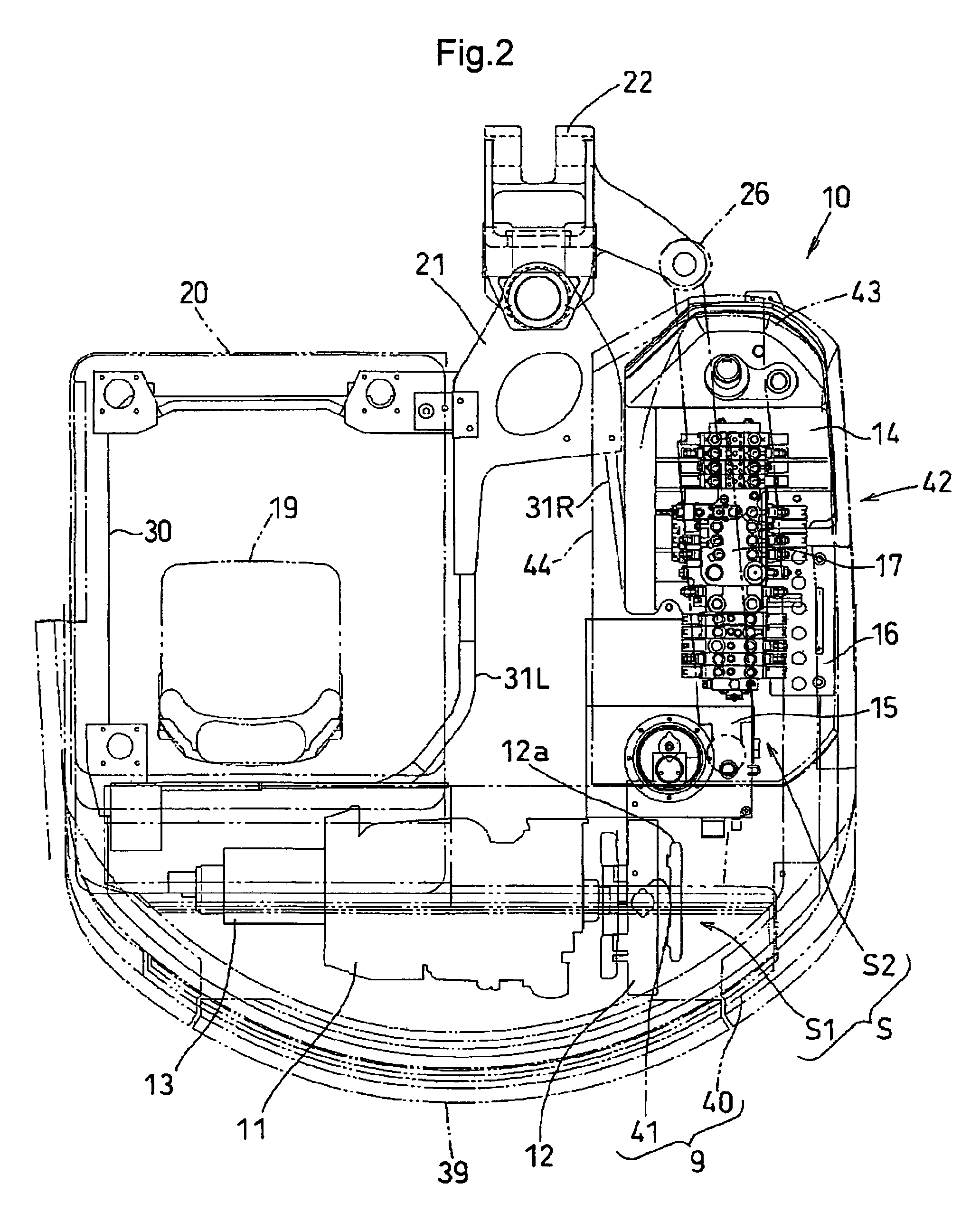

Swiveling work machine

ActiveUS7416219B2Easy maintenanceRestrict disadvantageous influence of heatTank vehiclesLarge containersFuel tankControl valves

A swiveling work machine includes a swivel deck mounted to be pivotable about a vertical axis and a side cover for covering one lateral side on the swivel deck, an accommodating space capable of accommodating a work machine accessory being provided inside the lateral cover. The accommodating space accommodates, as the implement accessory, a work oil tank, a fuel tank and a control valve unit. The work oil tank is disposed at a fore-and-aft intermediate portion on one lateral side on the swivel deck. The fuel tank is disposed forwardly of the work oil tank with forming a gap relative thereto. The control valve unit is disposed upwardly of the fuel tank and longitudinally along the fore / aft direction.

Owner:KUBOTA LTD

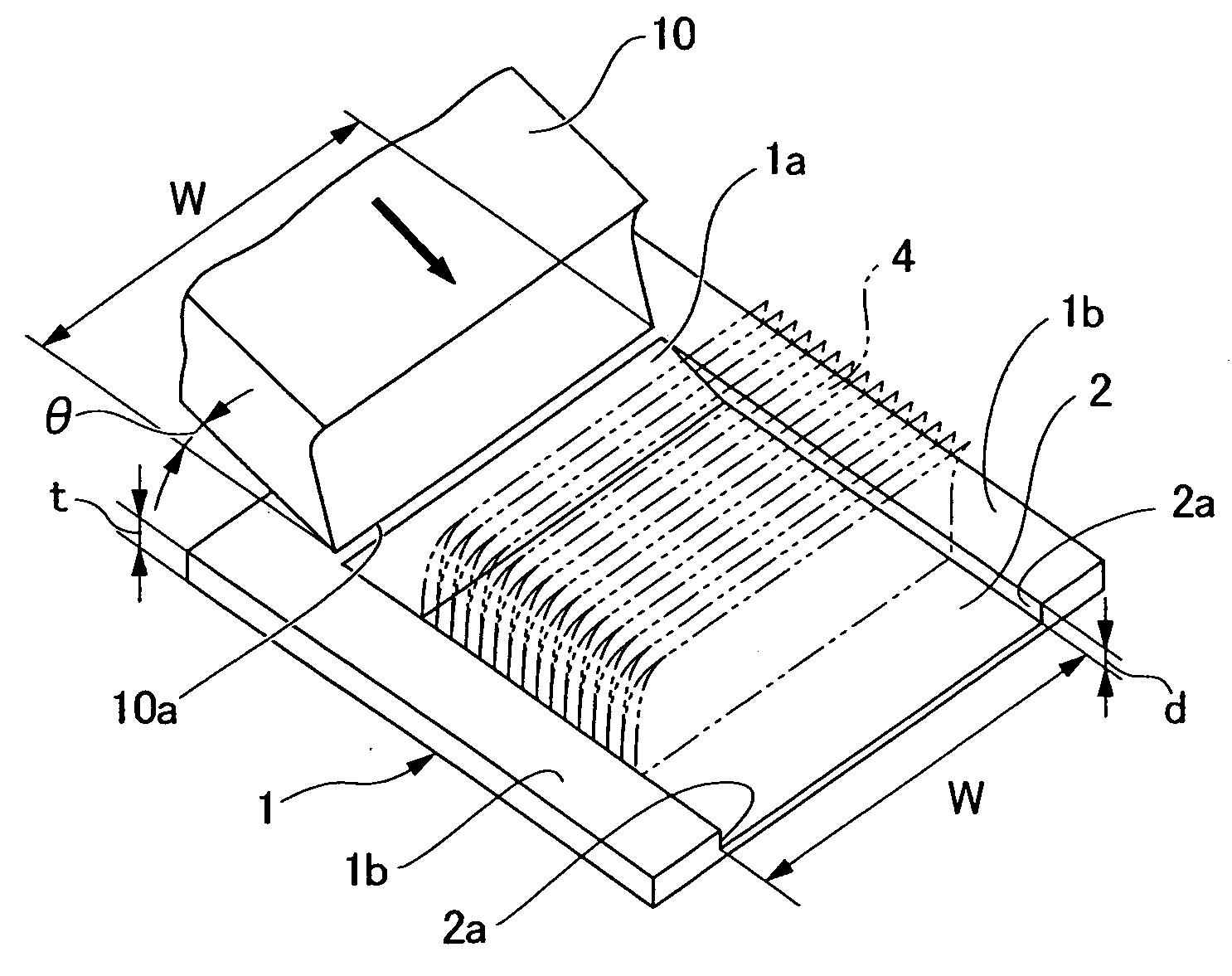

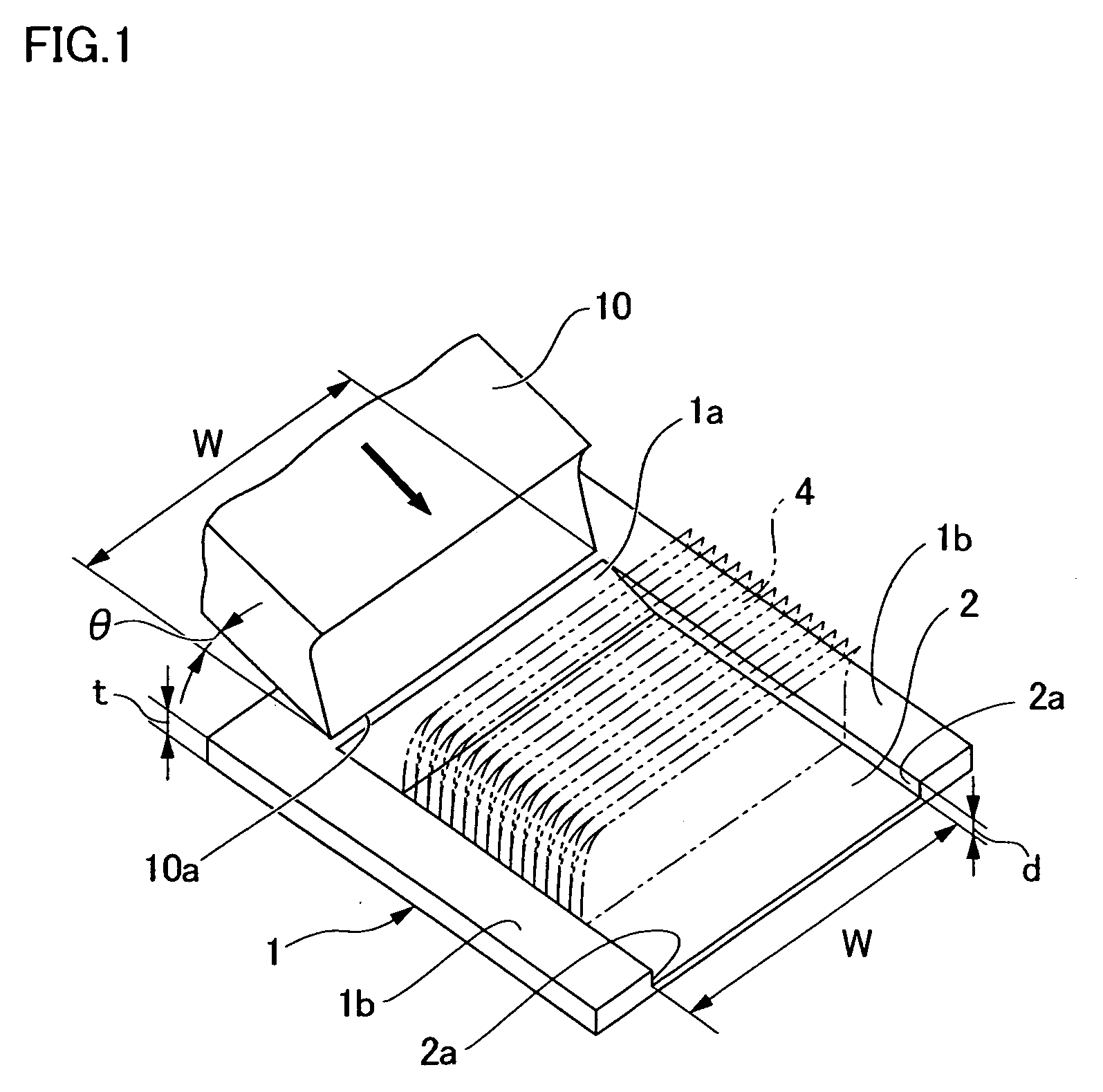

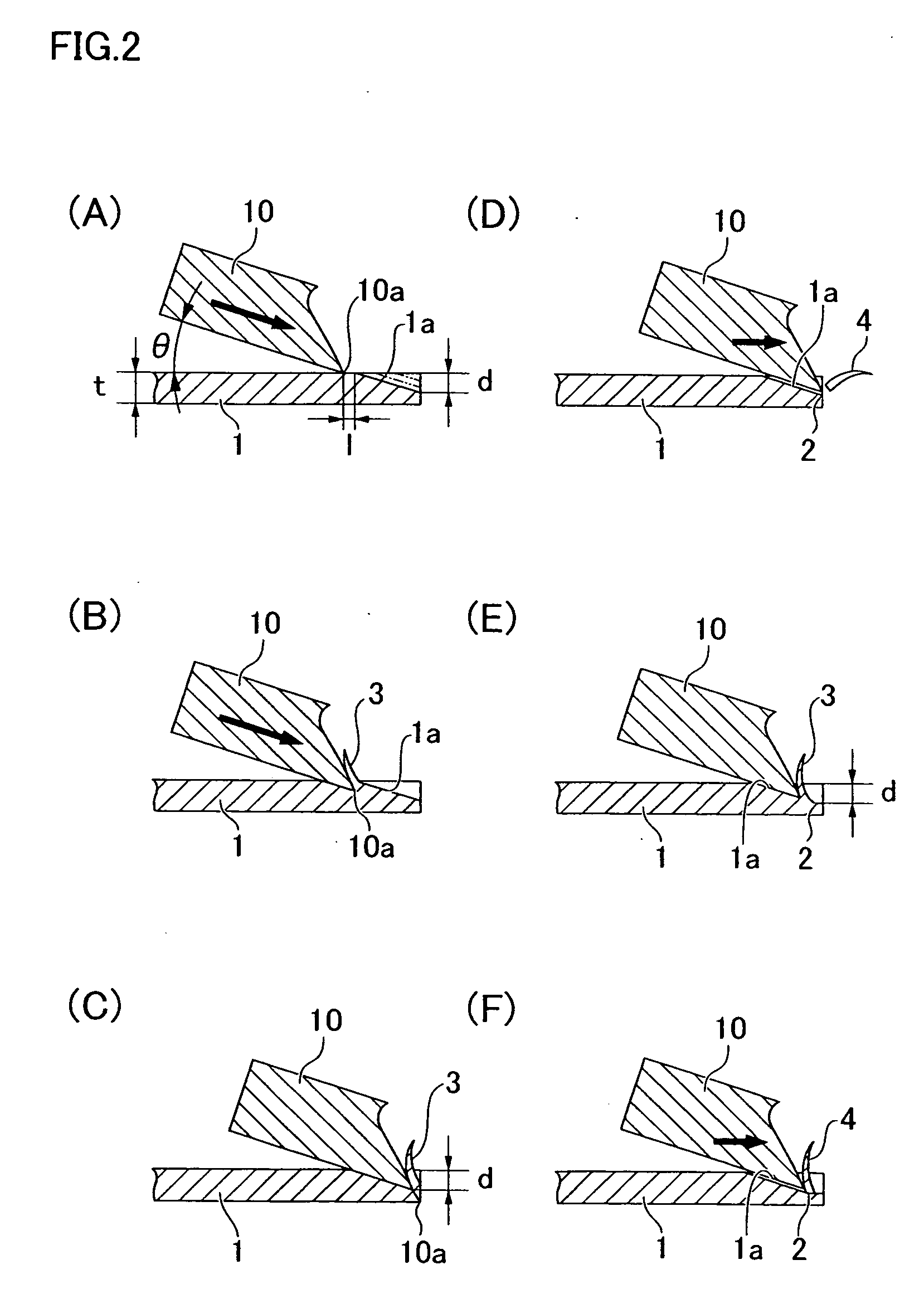

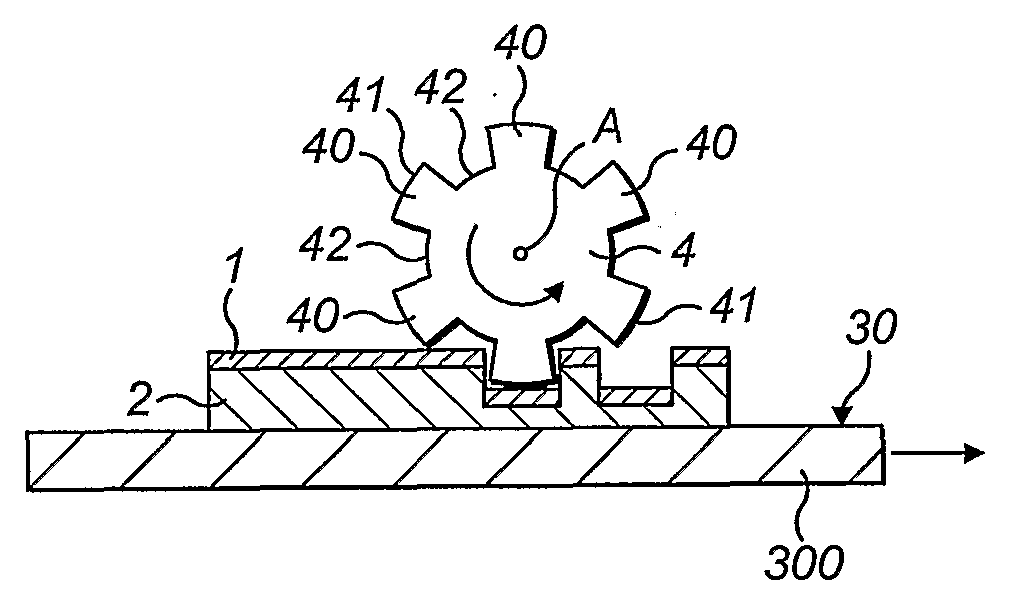

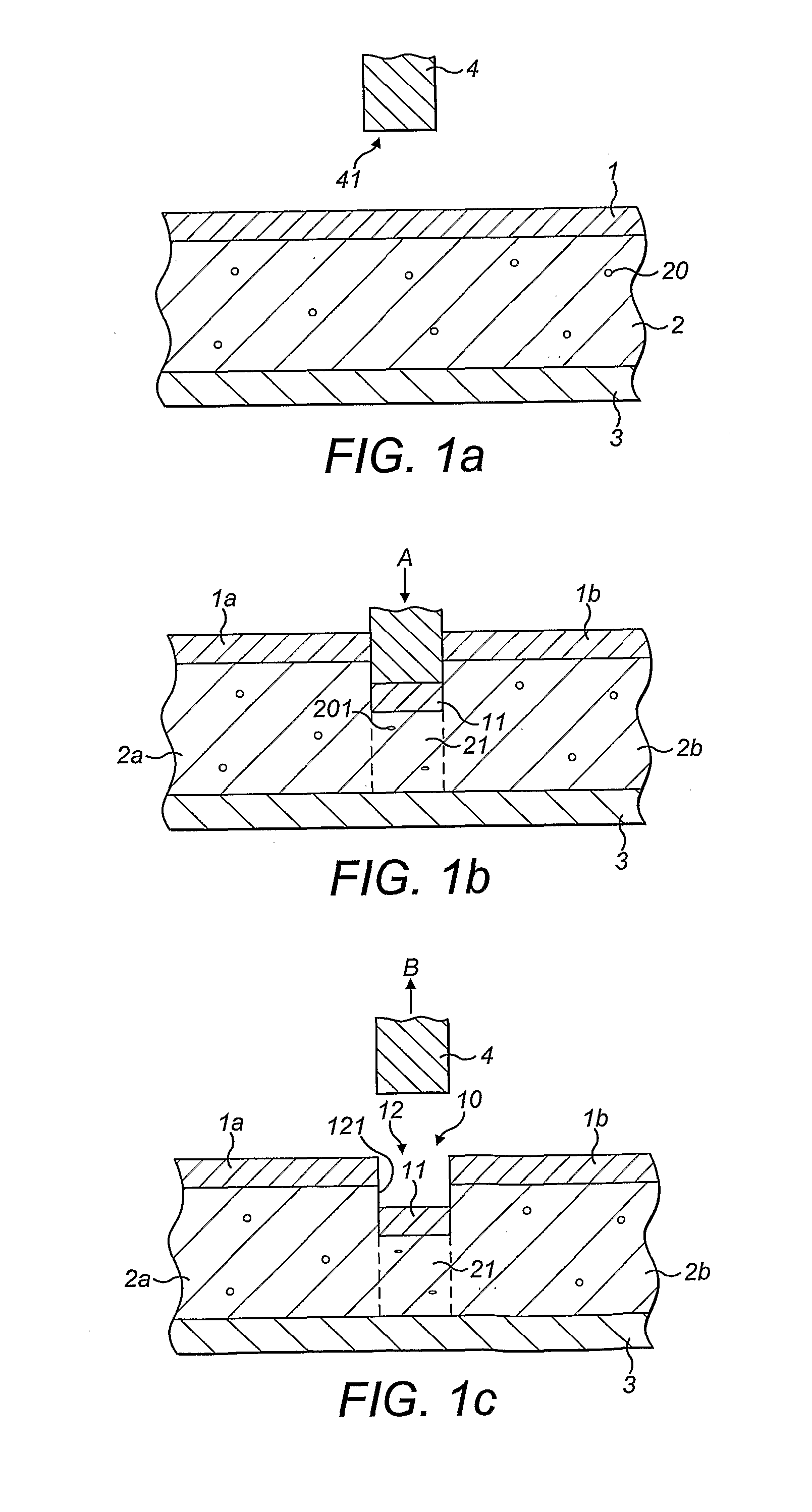

Method of forming a recess in a work

ActiveUS20080295561A1Easy to implementMinimize workPlaning/slotting machinesMetal working apparatusEngineeringMechanical engineering

In a method of forming a recess in a work, a work (1) in which the recess is to be formed is a material that can be cut. A cutting tool (10) for forming the recess is held by a moving apparatus at a prescribed angle relative to the work (1). In a fin-forming step, the cutting tool (10) is moved in a carving direction for carving the work (1) at the prescribed angle, and a thin cutting fin (3) is vertically formed. In a cutting step, the cutting tool (10) is moved in the horizontal direction, and the cutting fin 3 is cut and separated from the work 1. The fin-forming step and the cutting step are repeatedly performed in sequence, whereby a recess (2) having a prescribed depth d and area is formed in the work (1). A recess having the prescribed depth can be readily formed in the surface of the work while applying little stress, even when the area is large.

Owner:NAKAMURA IND MFG CO LTD

Pigment ink, ink jet recording apparatus, and ink jet recording method

ActiveUS8955954B2Suppress droplet formationIncrease speedMeasurement apparatus componentsInksDiethylene glycolAcetylene

A pigment ink includes an acetylene glycol or 2-ethyl-1,3-hexanediol, and an unsaturated fatty acid, an amino acid, an alkali metal hydroxide and an amine.

Owner:SEIKO EPSON CORP

Electronic devices, circuits and their manufacture

ActiveUS20120153428A1Cleanness is improvedMinimising smearingSolid-state devicesSemiconductor/solid-state device manufacturingCompressible materialSemiconductor materials

A method of manufacturing an electronic device, comprising a layer of semiconductive material and at least one insulative feature arranged to interrupt the layer of semiconductive material, comprises: providing a layer of semiconductive material, and a layer of compressible material supporting the layer of semiconductive material; and forming the or each insulative feature by a method comprising displacing a respective selected portion of the layer of semiconductive material towards the compressible material so as to compress compressible material under the or each displaced portion and separate at least partly the or each displaced portion from undisplaced semiconductive material.

Owner:PRAGMATIC PRINTING

Work vehicle with improved exhaust component cooling

ActiveUS9469189B2Speed up the flowPass smoothlyInternal combustion piston enginesExhaust apparatusExhaust manifoldAutomotive engineering

Owner:KUBOTA CORP

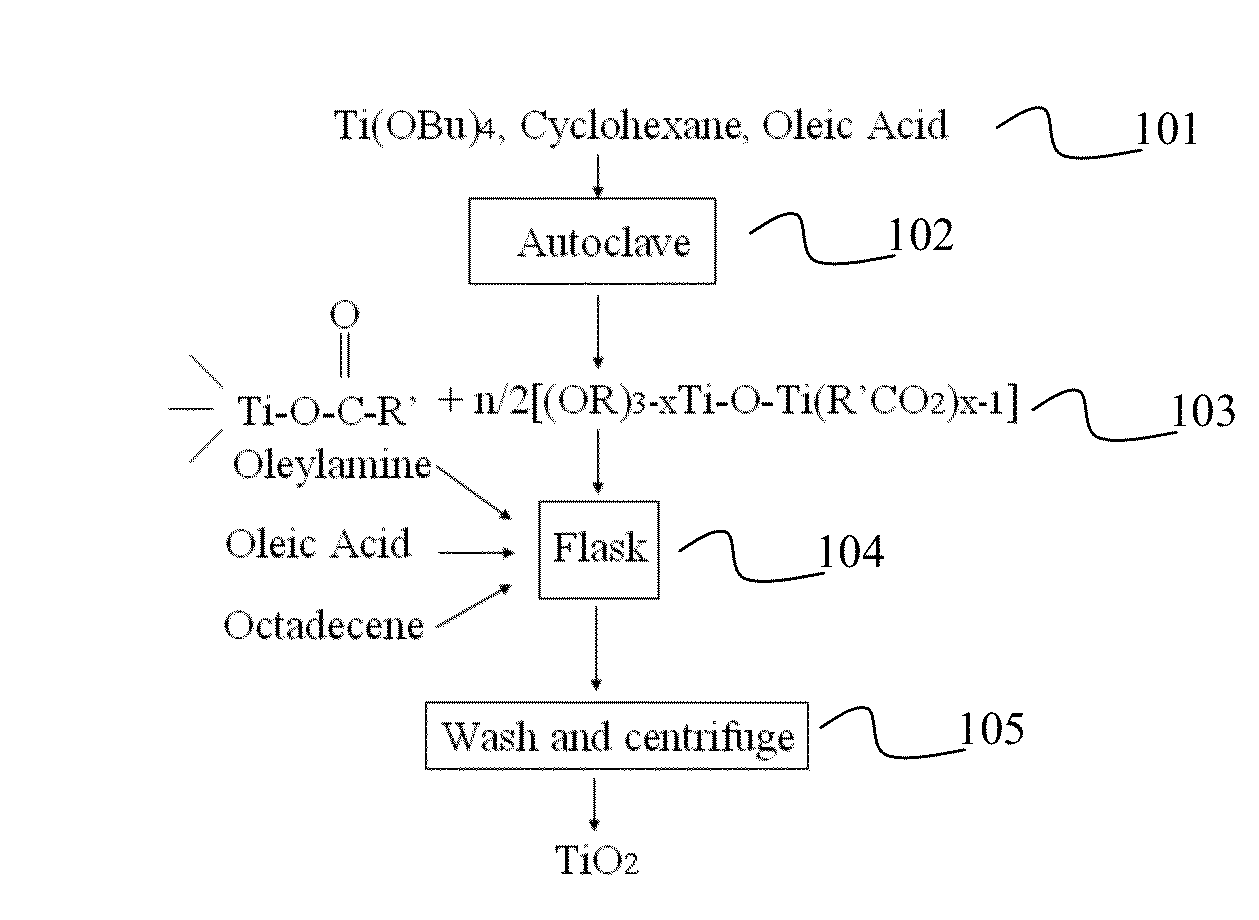

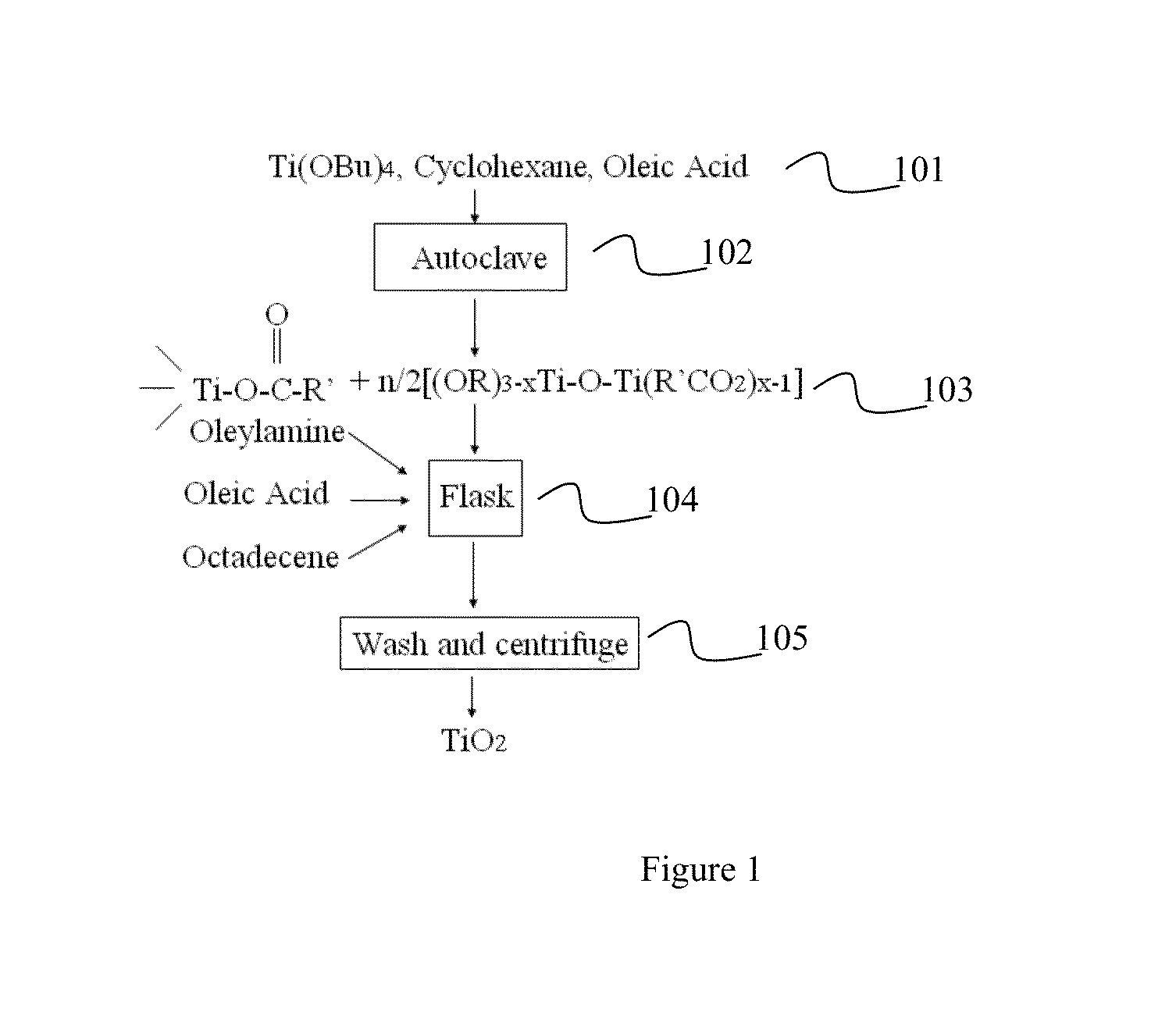

Method for synthesising a nano-product

ActiveUS8840863B2Increase temperatureLarge diameterMaterial nanotechnologyOxide/hydroxide preparationSolubilityWavelength

A method for the synthesis of nano-products, such as atomic titanium oxide wires. The method allows wires of anatase titanium oxide wires to be formed in a range of tunable diameters and aspect ratios in the nanometer and subnanometer size scales. The method also allows the titanium wires to be capped by oleic acid to enhance dispersing and solubility. The method allows the titanium wires to be surface doped with nitrogen species to enhance stability and functionality such as enhanced absorption in the visible wavelength region, which is useful for photodegradation of organic wastes in water by sunlight.

Owner:THE HONG KONG UNIV OF SCI & TECH

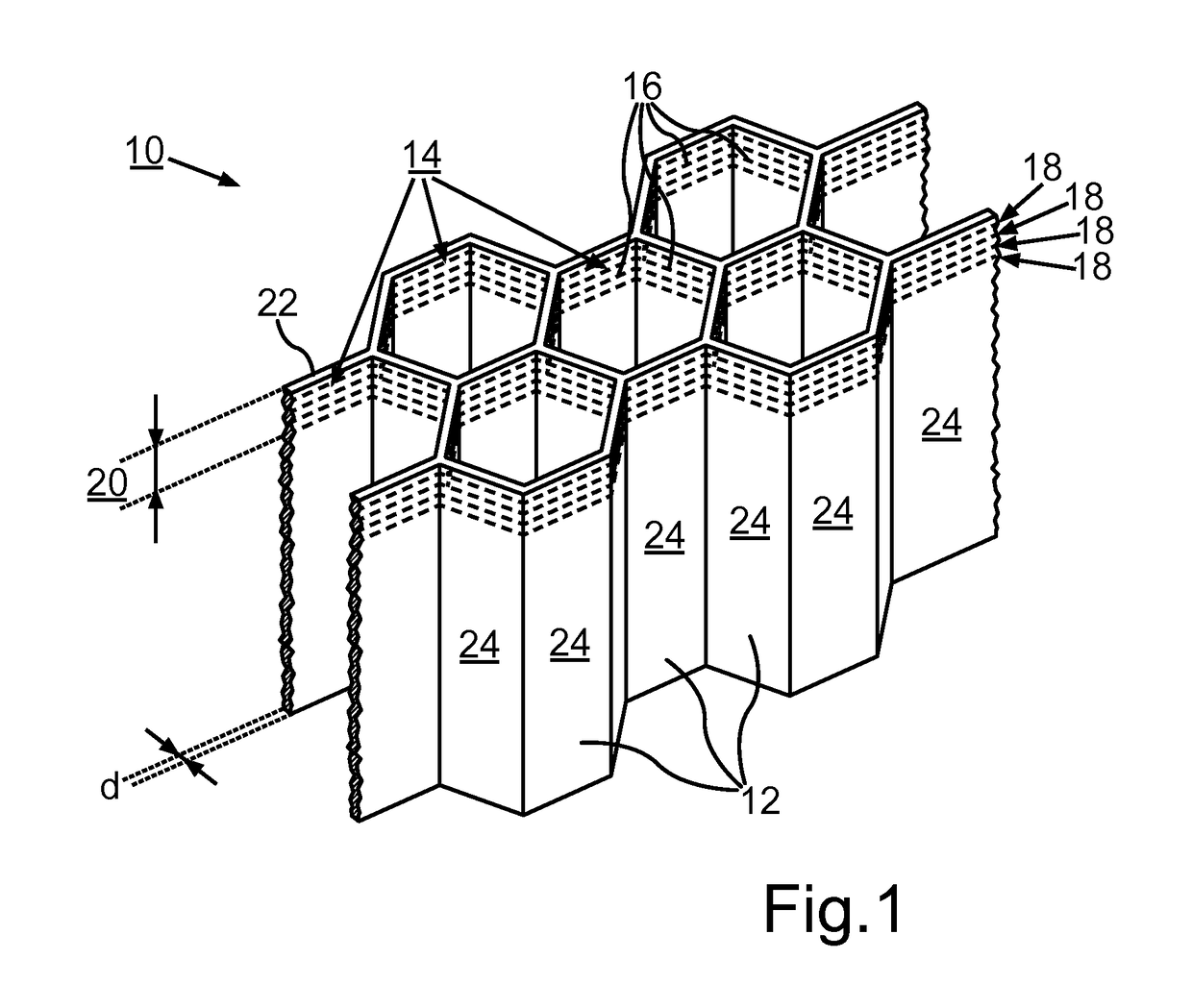

Seal, method for producing a seal and turbomachine

ActiveUS10184346B2Simple sealing structureImprove running-inTurbinesAdditive manufacturing apparatusEngineeringMechanical engineering

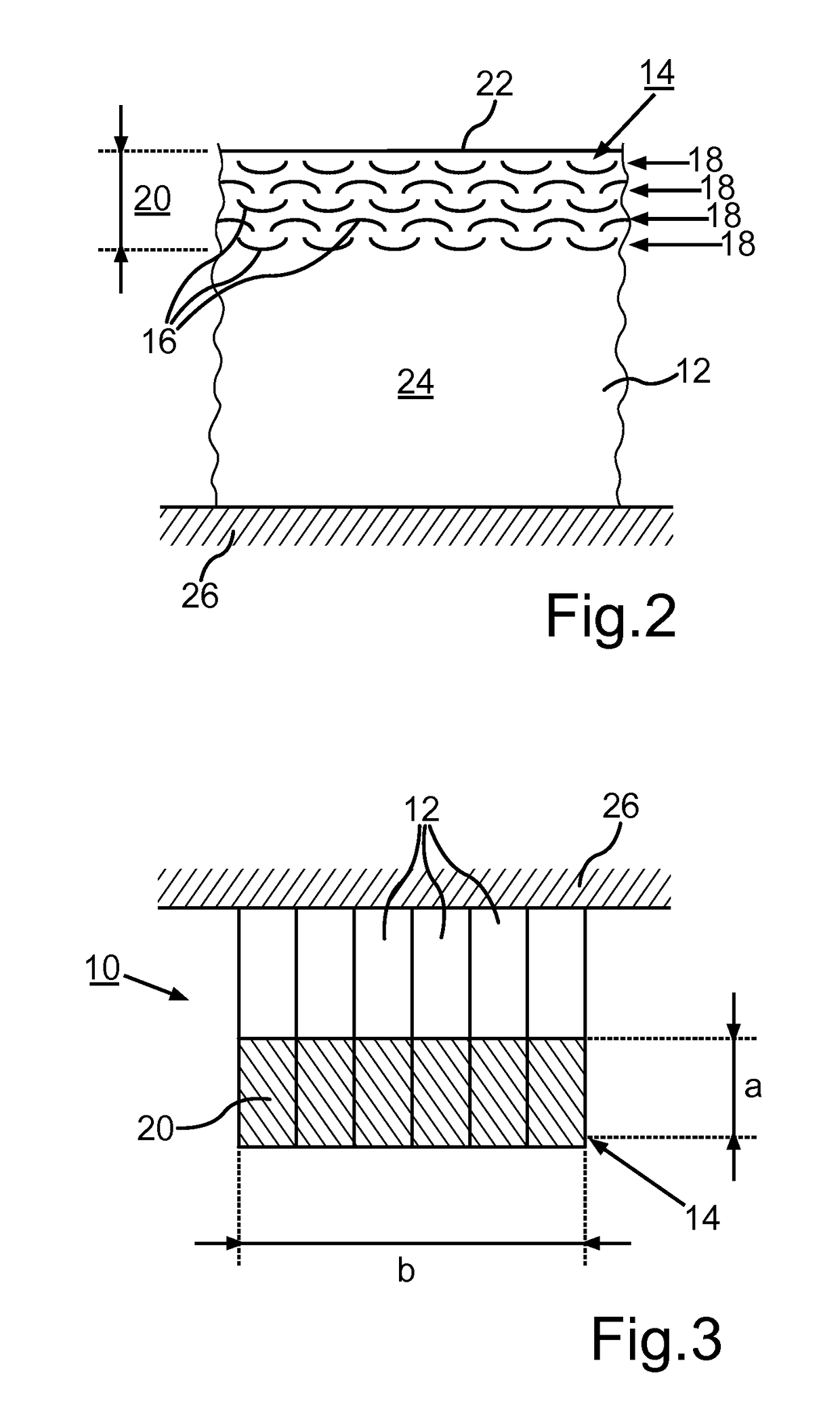

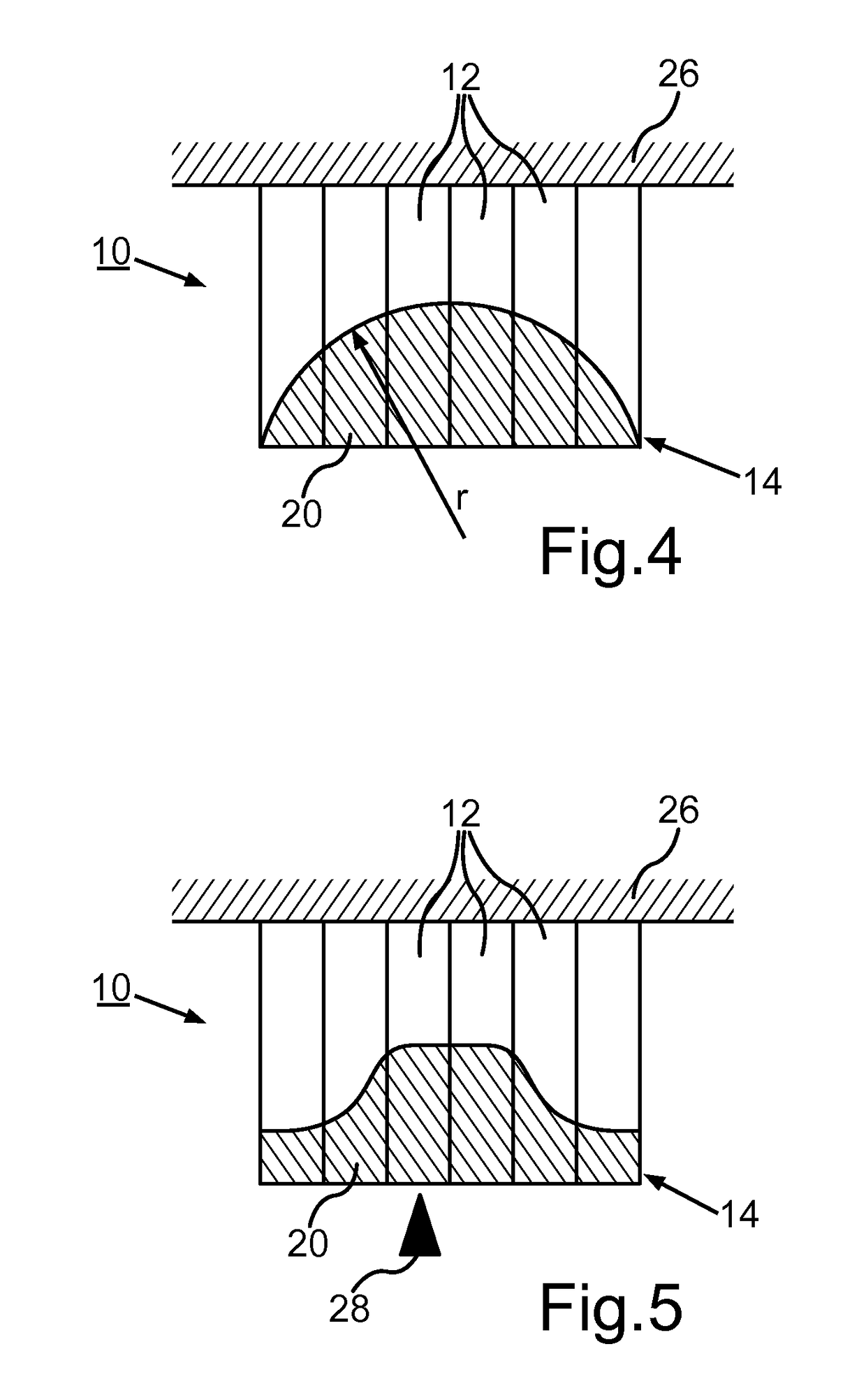

The invention relates to a seal (10) for sealing a gap between a stationary component and a moving component, in particular for sealing a radial gap between a rotor and a stator of a turbomachine, comprising at least one sealing segment (12) with an edge zone (14) facing the gap, whereby the seal (10) is produced layer-by-layer by a free-forming method, in particular a generative or additive method. A plurality of pre-defined weak regions (16) is formed in the edge zone (14) of the sealing segment (12). In addition, the invention relates to a method for producing a seal (10) as well as a turbomachine.

Owner:MTU AERO ENGINES GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com