Heat exchange element and heat exchanger produced therewith

a technology of heat exchange element and heat exchanger, which is applied in the direction of tubular element, lighting and heating apparatus, stationary conduit assembly, etc., can solve the problems of inability to heat transfer, small heat exchange output, and disruption of forming boundary layers, etc., and achieves enhanced heat exchange output (power) and reduced pressure loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

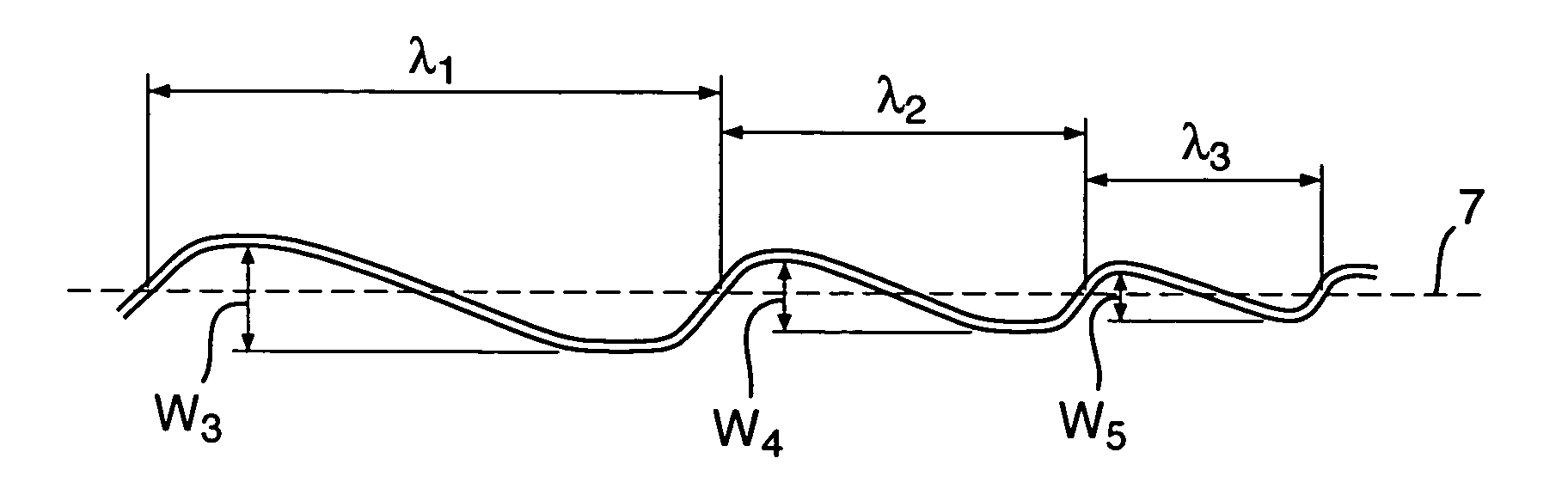

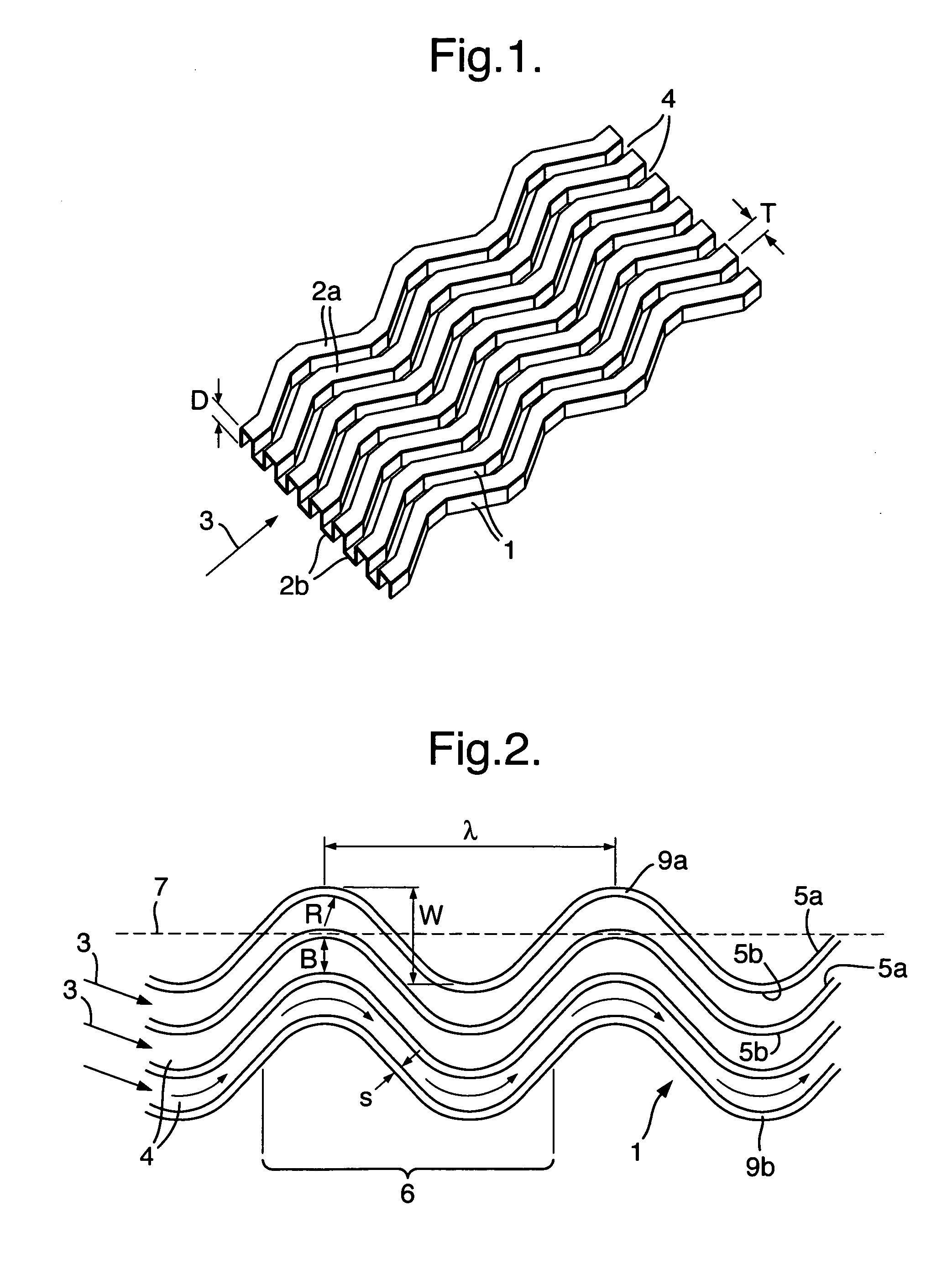

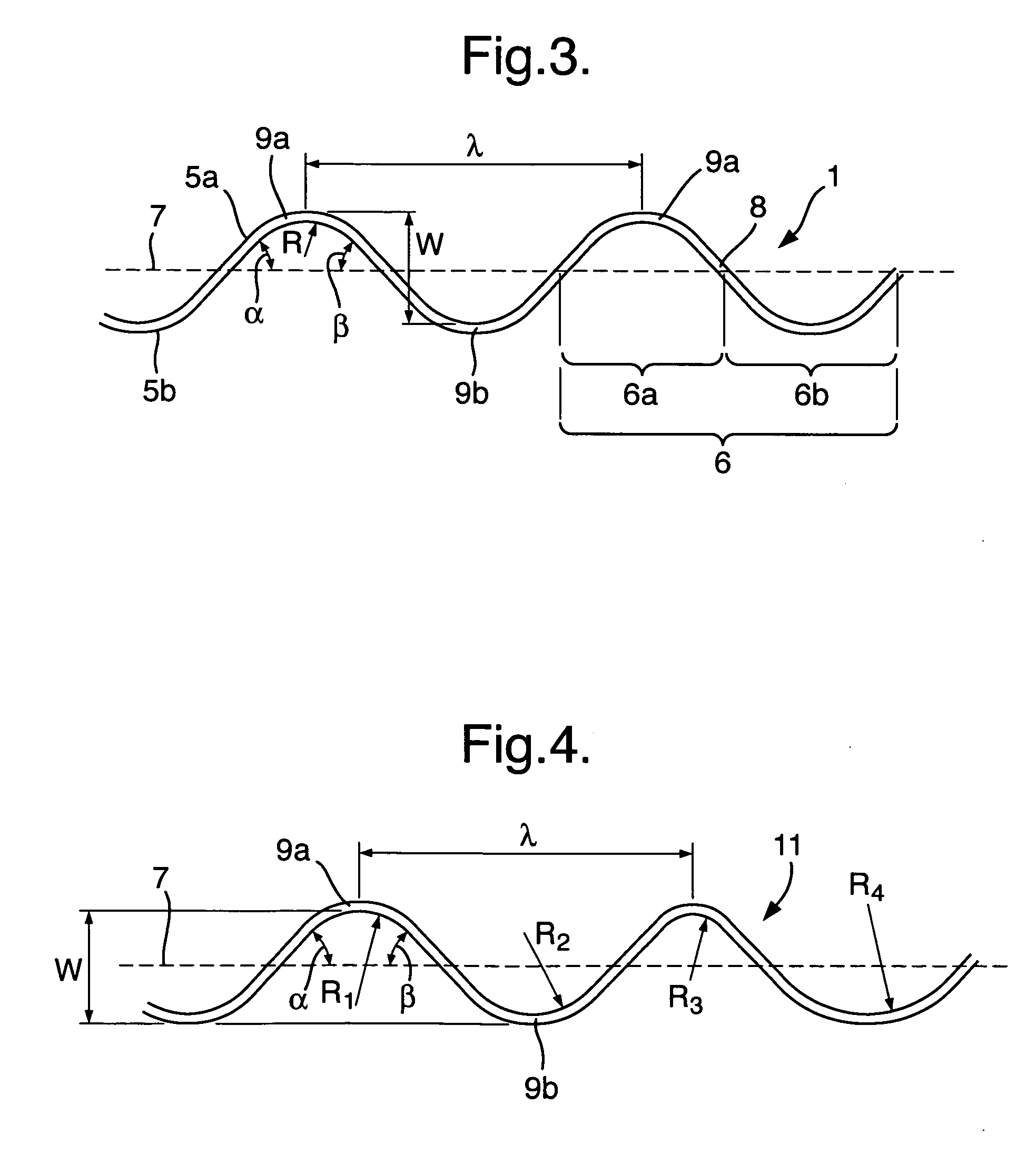

[0021]FIG. 1 to 3 show a heat exchange element according to the invention and according to an embodiment deemed to be the best one up to now. The heat exchange element comprises a plurality of adjacent, heat-transferring walls 1 which are preferably disposed parallel to each other. The walls 1 are formed by thin plates which have a height D (FIG. 1) and a thickness S (FIG. 2) and are connected to each other in a meandering shape at their upper and lower longitudinal edges in FIG. 1 by upper and lower, likewise plate-shaped connecting portions 2a, 2b. In a longitudinal direction of the heat exchange element indicated by arrows 3, a plurality of adjacent flow channels 4 for a fluid, which have U-shaped cross-sections, is consequently produced, these flow channels 4 respectively being delimited by two adjacent walls 1 and, in addition in FIG. 1, alternately by an upper or lower connecting portion 2a, 2b.

[0022] The flow channels 4 are open at their front and rear ends in the longitudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com