Power supplier assembling structure of lighting device

A technology for power supplies and lighting devices, which is applied to parts of lighting devices, lighting devices, electric light sources, etc., can solve problems such as increased processing costs, reduce production costs, reduce the use of parts, and save mold design and manufacturing The effect of fees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

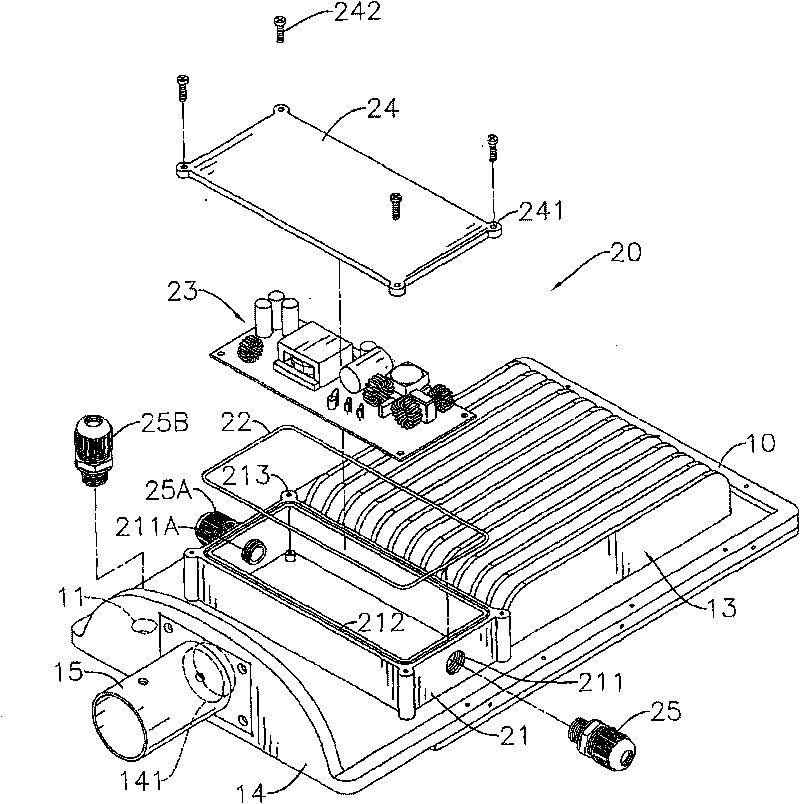

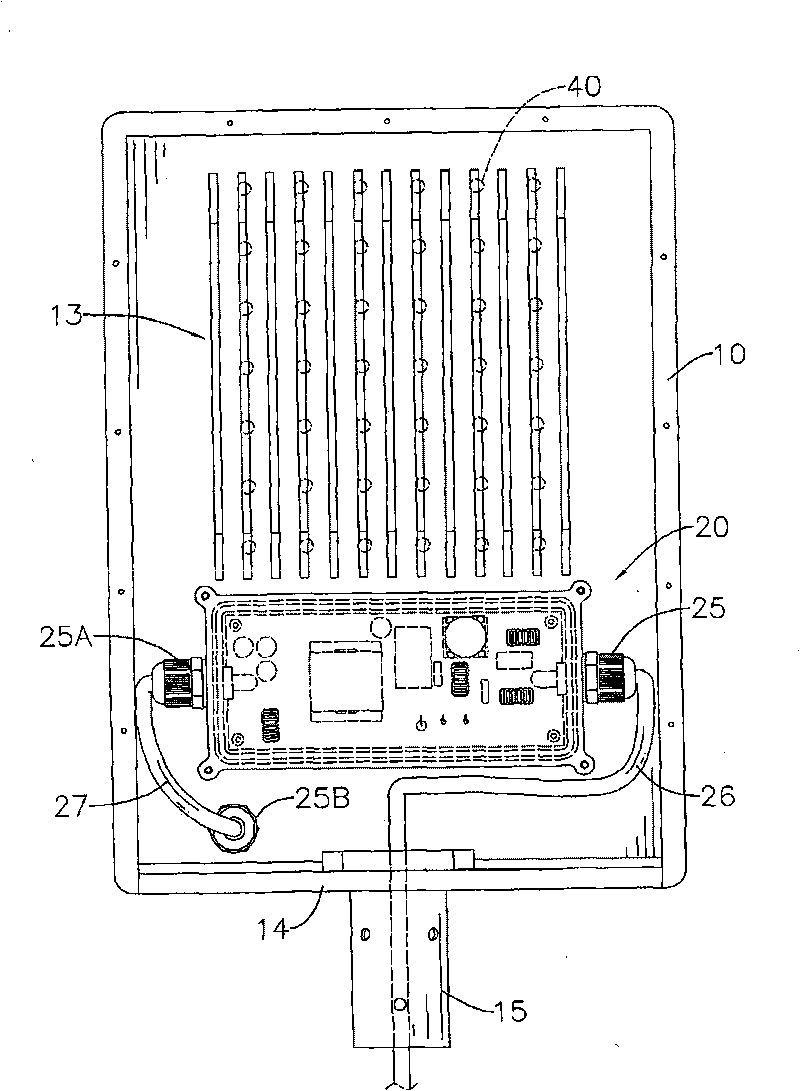

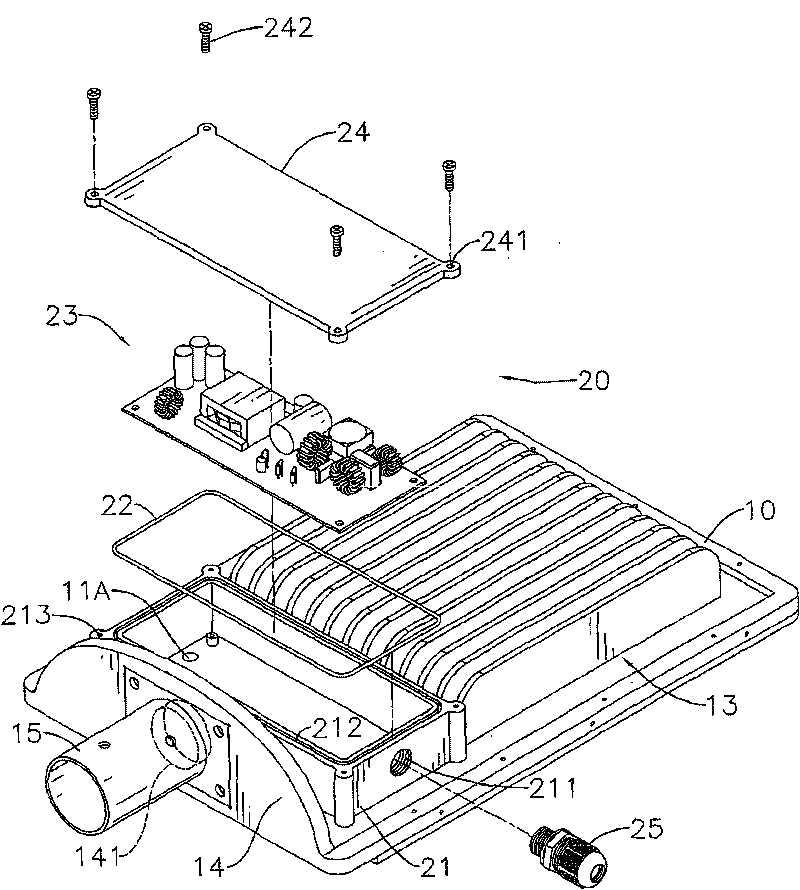

[0044] see figure 1 and figure 2 As shown, the first embodiment of the present invention includes a substrate 10 and a power supply 20 disposed on the substrate 10, wherein:

[0045] The base plate 10 is a plate body, which is formed with a through hole 11 penetrating through the base plate 10, and a heat sink group 13 protrudes from one side of the plate, and an LED lamp 40 can be further arranged on the other side plate. One side end of the substrate 10 is bent and extended to form a side plate 14, and a through guide hole 141 is further formed on the side plate 14, and a mounting bracket 15 in the form of a hollow tube is provided on the side plate 14 and corresponds to in the guide hole 141;

[0046] The power supply 20 includes a casing 21, a gasket 22, a power module 23, a cover 24, two waterproof connectors 25, 25A, an AC cable 26 and a DC cable 27, wherein:

[0047]The casing 21 is integrally formed and protrudes from the side plate surface of the aforementioned b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com