Method for shape correction of high-temperature alloy thin-wall aeroengine casing part through electric arc heating

An arc heating and high-temperature alloy technology, applied in metal processing, metal processing equipment, forming tools, etc., can solve the problems of restricting matching, complex process, long calibration cycle, etc., saving tooling design and manufacturing costs, and simple process. , the effect of short correction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

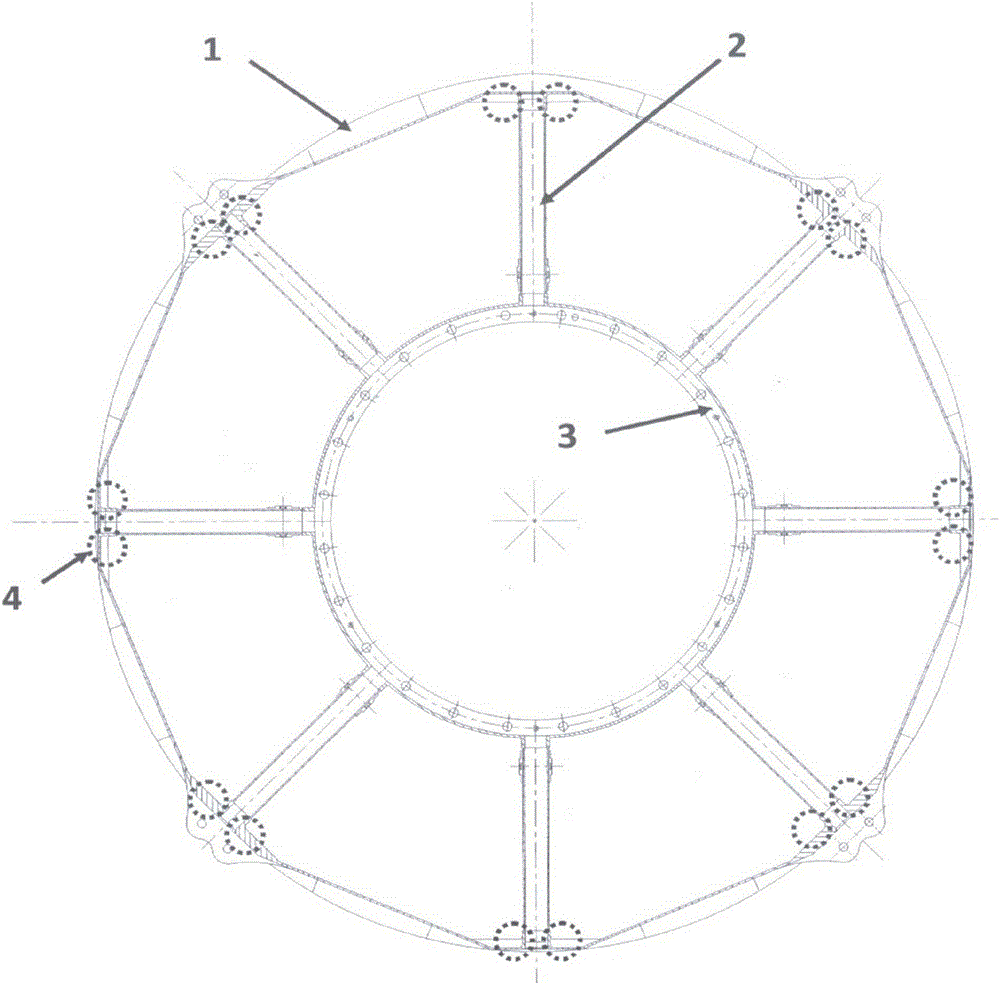

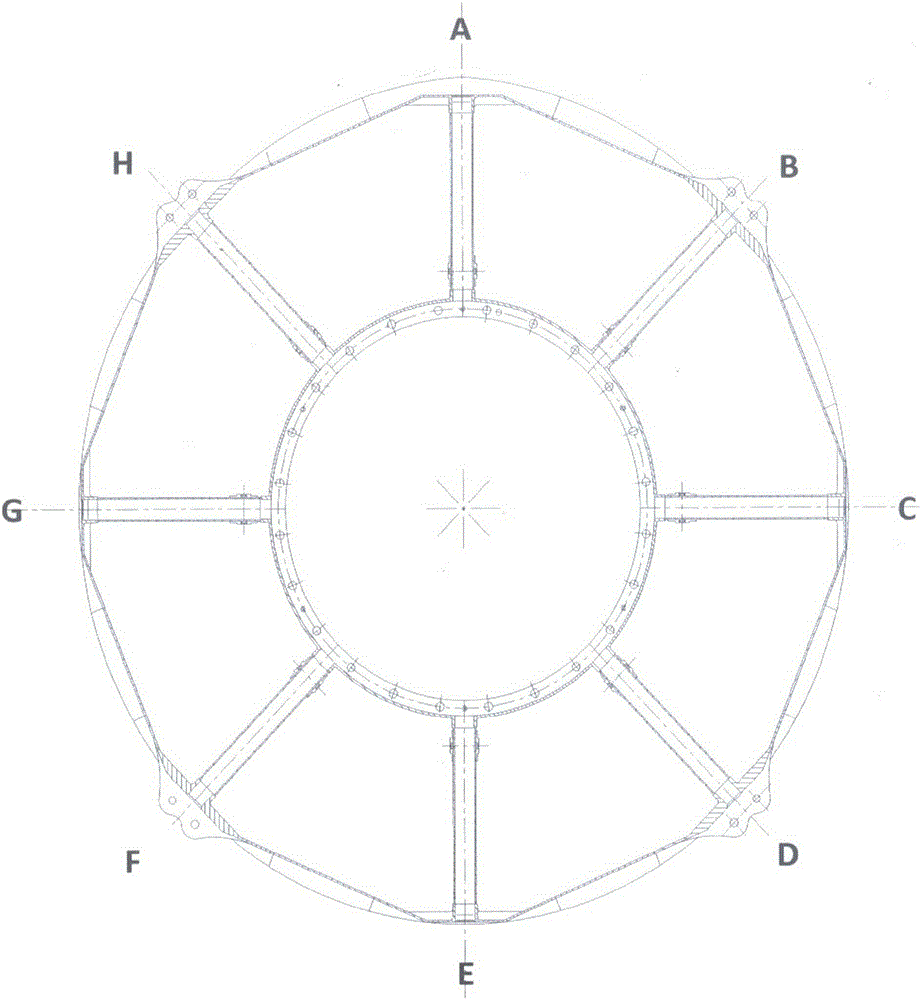

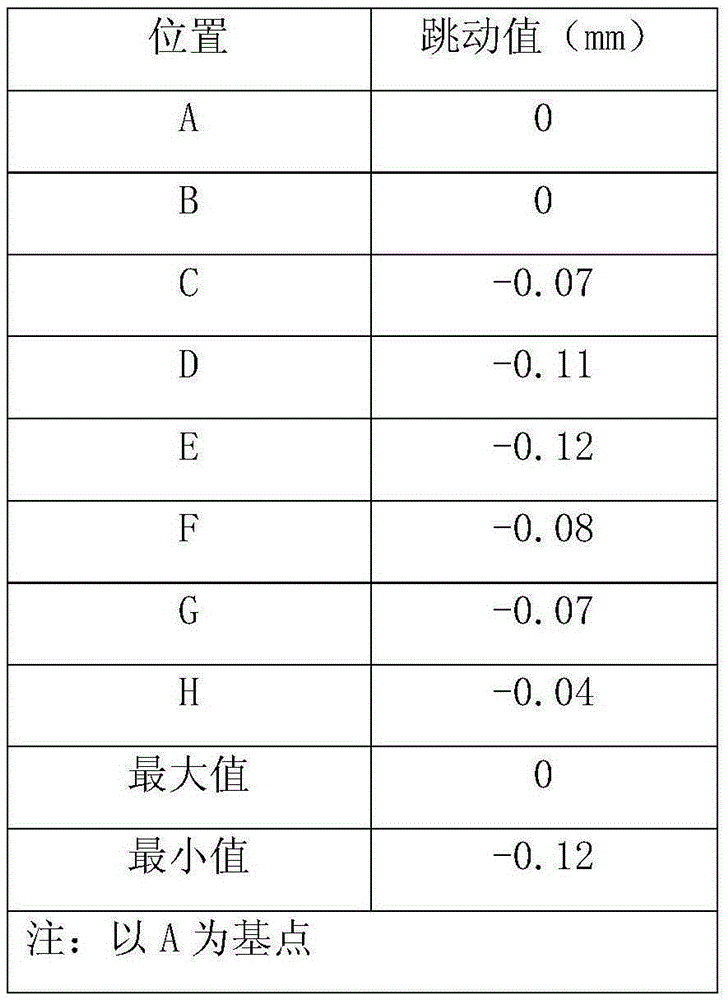

[0025] Taking a superalloy thin-wall casing part as an example, its structure is as follows figure 1 As shown, it is composed of an outer casing 1, eight supporting tubes 2 and an inner ring 3; wherein, the outer casing 1 is a thin-walled weldment composed of castings and sheet metal parts, and the overall structure is approximately octagonal. Under the influence of welding stress, it will not only deform itself, but also drive the supporting pipe 2, resulting in deformation of the inner ring 3. At the same time, due to assembly requirements, the roundness of the inner ring 3 has stricter requirements than that of the outer casing 1, and the radial runout value measured by the dial indicator must be less than 0.08mm. The reinforcing rib 4 is an elongated protruding structure at the junction of the outer casing 1 and the support tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com