Involute cylindrical spiral gear mechanism parameterization analysis method

An involute cylinder and analysis method technology, which is applied in the fields of electrical digital data processing, special data processing applications, instruments, etc., can solve the problem of difficulty in grasping the distribution characteristics and changing laws of gear teeth stress, large verification workload, and waste of labor costs. and other problems, to achieve the effect of shortening the design time, ensuring the calculation accuracy, and reducing the workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

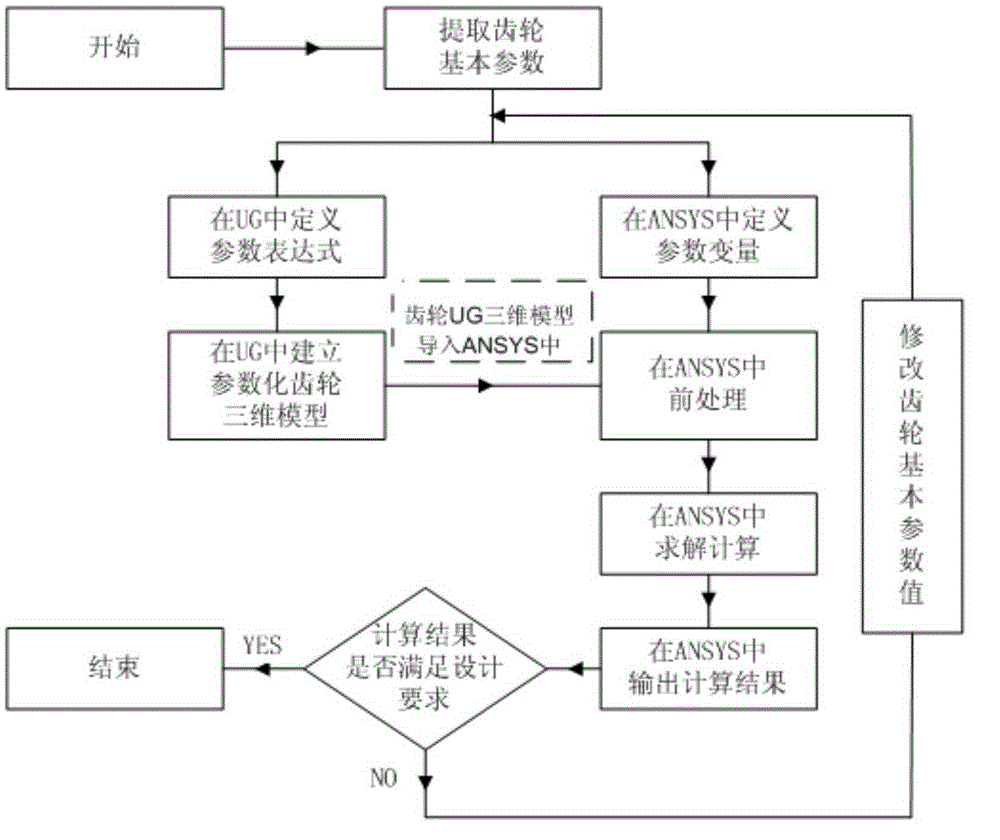

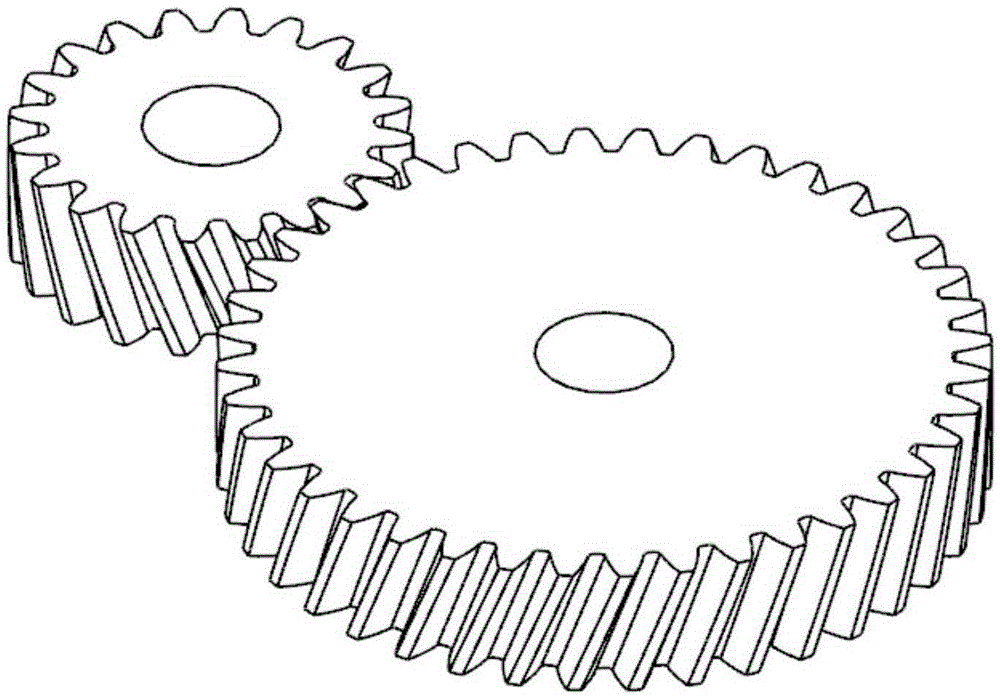

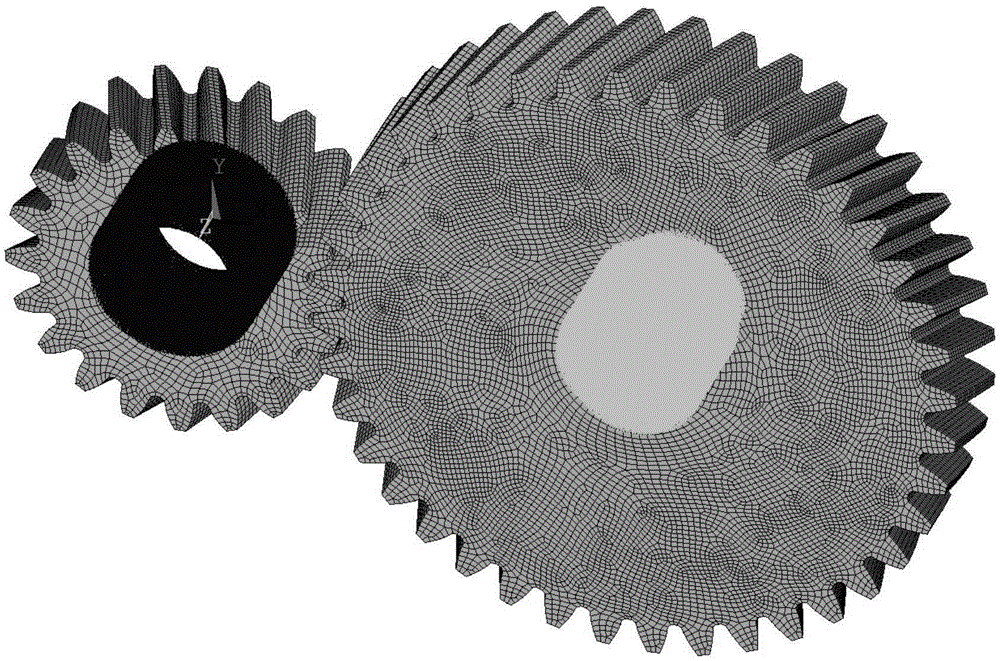

[0026] see Figure 1 to Figure 3 , a parametric analysis method of involute cylindrical helical gear mechanism, the three-dimensional software used in the present invention is UGnx10.0, and the finite element analysis software is ANSYS15.0, and the detailed steps are as follows:

[0027] 1. Extract basic parameters: comprehensively analyze various parameters affecting the work of the involute cylindrical helical gear mechanism, integrate and classify, extract helical gear geometric parameters, material characteristic parameters, load characteristic parameters and finite element model parameters by category, and prepare the following table 1-5.

[0028] Table 1 Geometric parameters of driving gear

[0029]

[0030] Table 2 Geometric param...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com