Battery pack online discharge maintenance device and method

A battery pack and battery technology, applied in battery circuit devices, circuit devices, current collectors, etc., can solve the problems of high maintenance costs of battery packs, a large number of operators, energy waste, etc., and achieve the effect of reducing time costs and labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

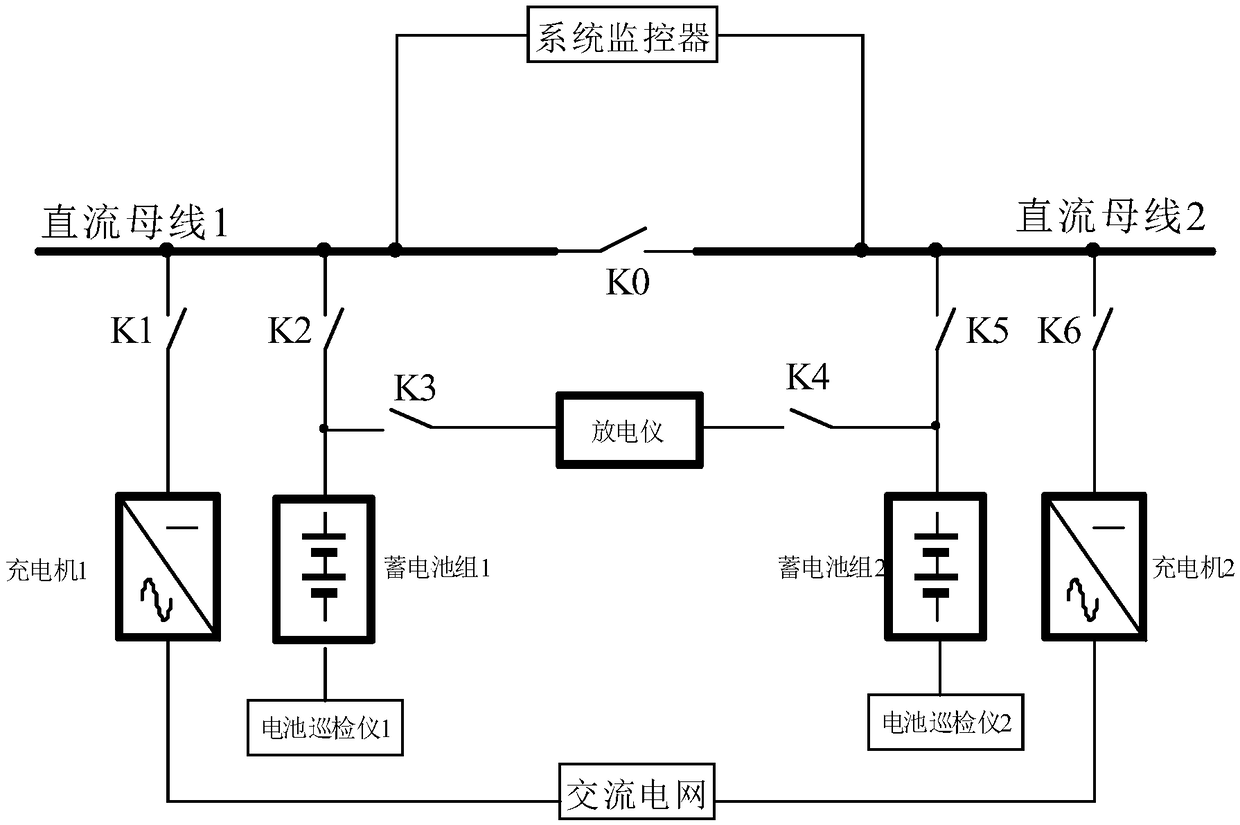

[0042] Embodiment 1 of the present invention provides an online discharge maintenance device for a battery pack, which is applied to a DC system.

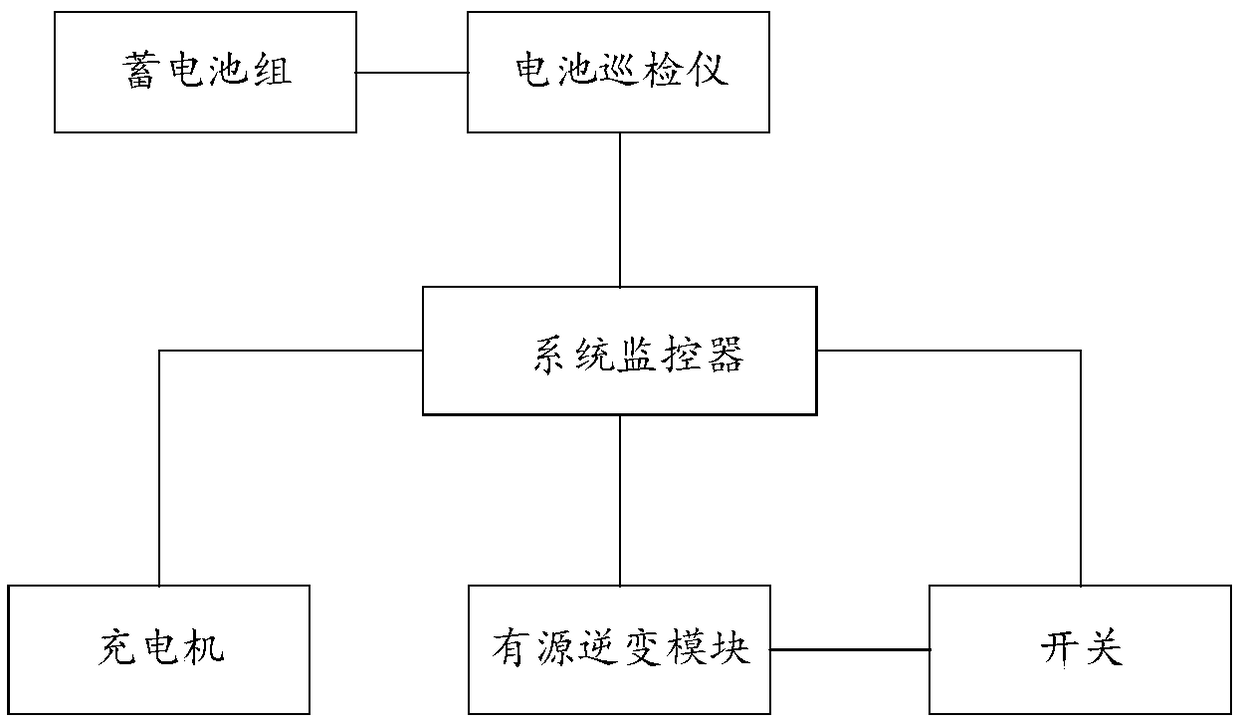

[0043] see figure 2 The structural block diagram of the online discharge maintenance device for the battery pack shown includes: a system monitor, a charger, a battery inspection instrument, a switch and an active inverter module.

[0044] Such as figure 2 The shown active inverter module includes a DC port and an AC port, and an isolation transformer is provided inside for electrical isolation between the DC port and the AC port. The charger can be composed of an electric operating power supply and a high-frequency switching power supply module in parallel. When the DC power supply system is in normal operation, it supplies power to the load of the DC bus and charges the battery pack. The system monitor switch is respectively connected to the DC port of the active inverter module and the battery pack, and the AC port of the ac...

Embodiment 2

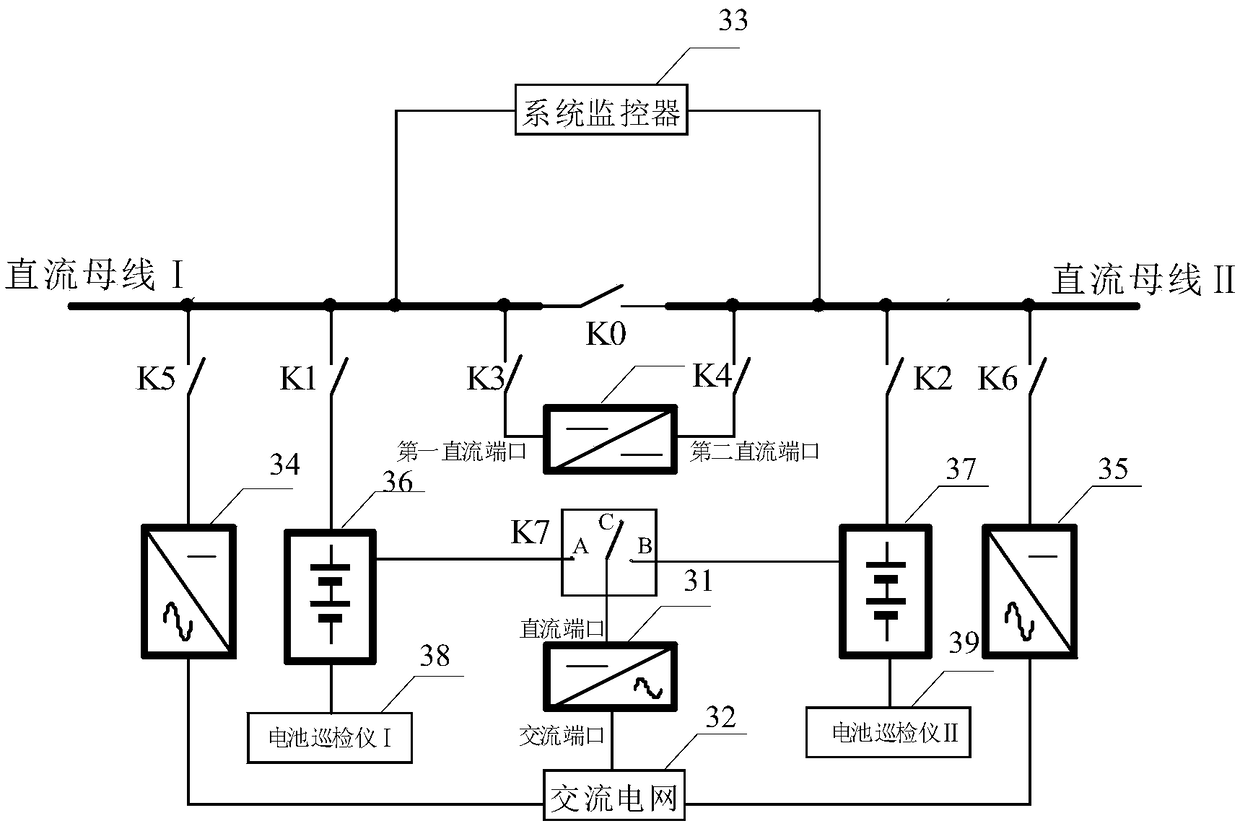

[0060] Embodiment 2 of the present invention provides an online discharge maintenance device for a battery pack, which is applied to a DC system.

[0061] see image 3 The structural block diagram of the online discharge maintenance device for battery packs shown, including: a bidirectional DCDC module 30 and a system monitor 33,

[0062] The bidirectional DCDC module 30 includes a first DC port and a second DC port, and is provided with an isolation transformer inside to realize electrical isolation between the first DC port and the second DC port. Wherein, the first DC port and the second DC port are respectively connected to the DC bus I and the DC bus II, and both the first DC port and the second DC port are ports whose input and output working states can be switched. It can realize the transfer of energy from the high-voltage end to the low-voltage end between the DC bus I and the DC bus II.

[0063] The system monitor 33 is used to set the switching conditions of the i...

Embodiment 3

[0073] Embodiment 3 of the present invention provides an online discharge maintenance method for a battery pack, and the online discharge maintenance device for a battery pack is applied to a DC system.

[0074] see Figure 4 The flow chart of the online discharge maintenance method for the battery pack shown is applied to the online checking discharge device for the battery pack provided in Embodiment 1 above, and the method includes the following steps:

[0075] Step S41 , when the battery pack meets the online maintenance condition, the system monitor sends an online discharge maintenance command of the battery pack to the charger, the switch and the active inverter module.

[0076] For specific online maintenance conditions, please refer to the content of the above-mentioned embodiment 1.

[0077] Step S42, when receiving the battery pack online discharge maintenance instruction, the charger controls the output voltage to be lower than the terminal voltage of the battery ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com