A long-life knife gate valve

A long-life, knife-shaped technology, applied to sliding valves, valve devices, engine components, etc., can solve the problems of gate valve damage, seal failure, screwing, etc., and achieve the effect of online maintenance and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

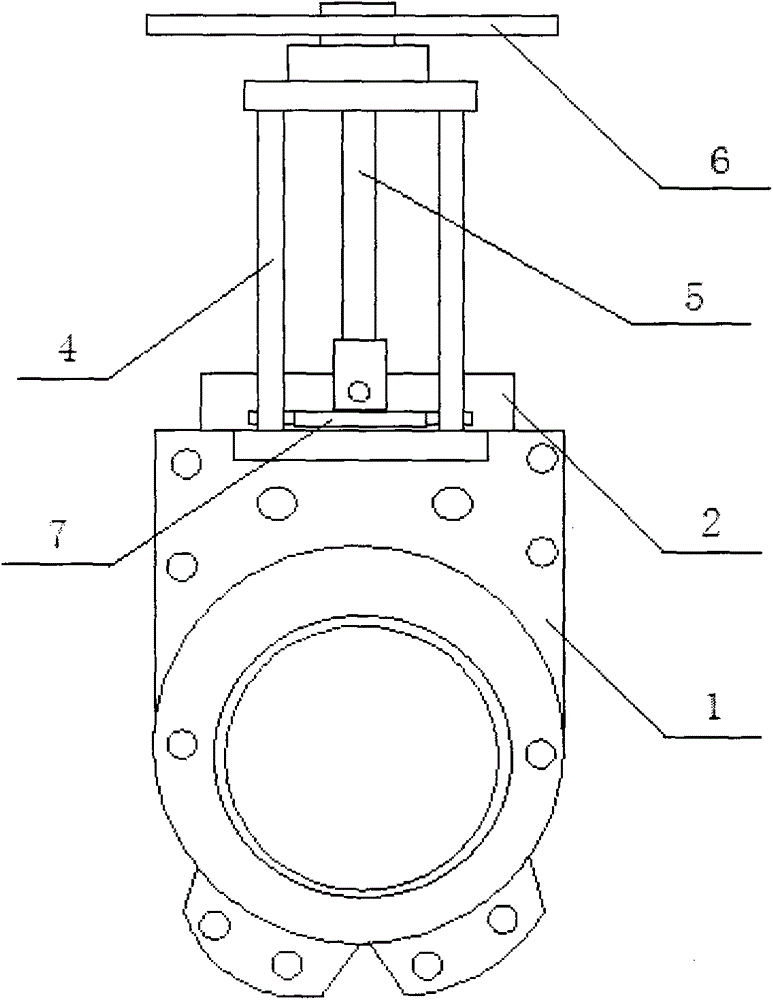

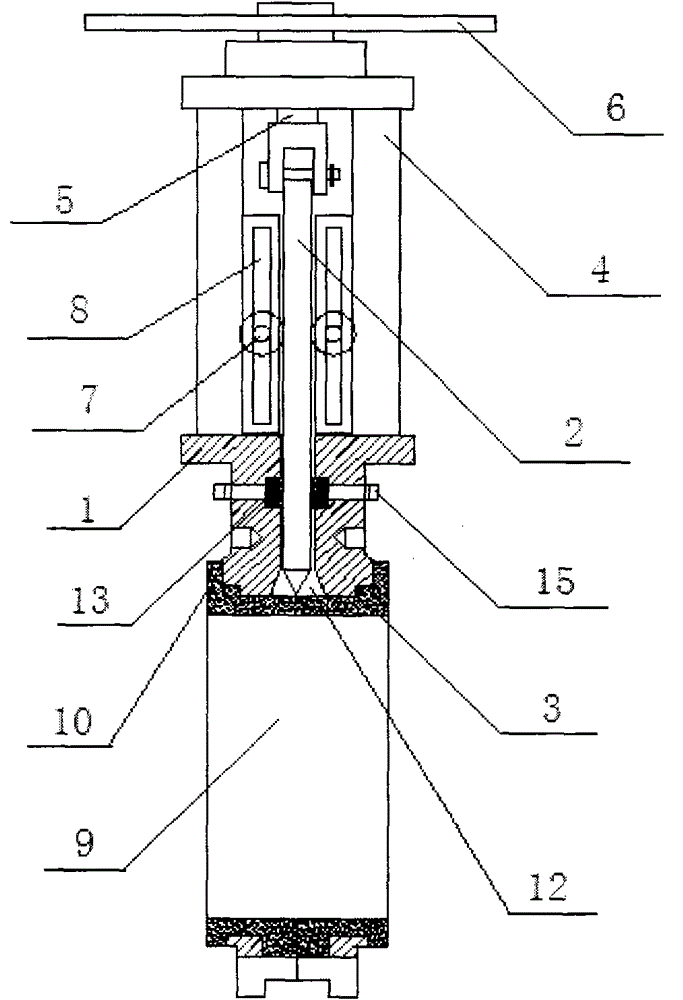

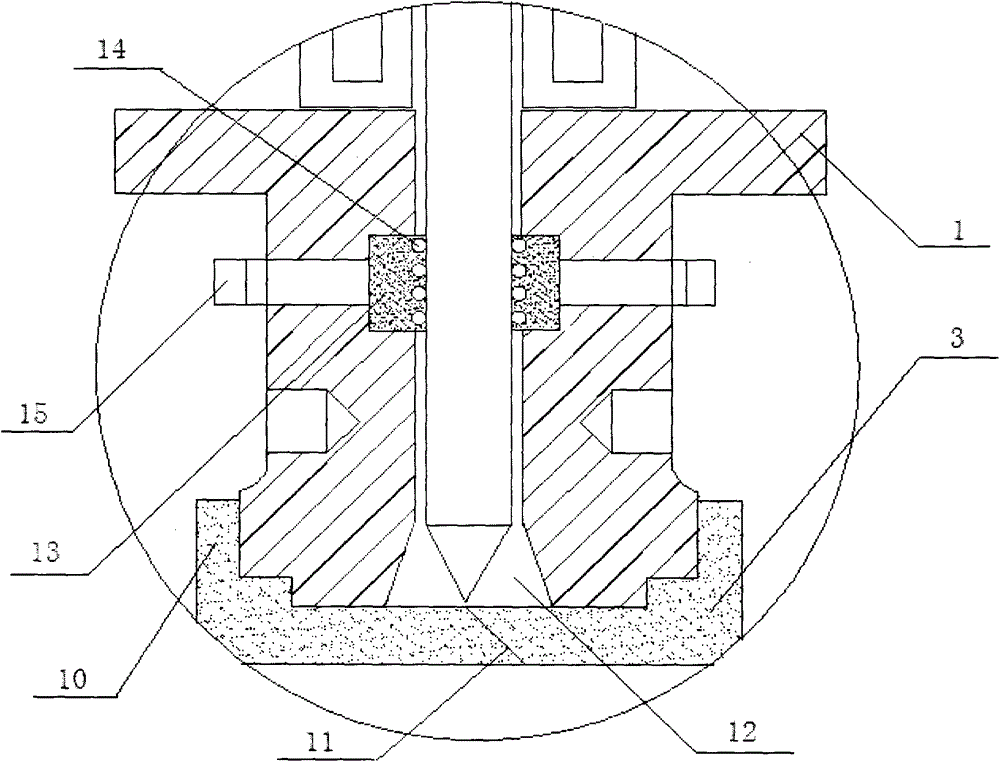

[0016] Such as figure 1 , 2 A long-life knife-shaped gate valve shown in . Support frame 4, valve stem 5, transmission member 6, balance rod 7, valve stem 5 is installed in the middle of support frame 4, its upper end is connected with transmission member 6, and its lower end is connected with gate plate 2, and the support frame 4 is located on both sides of gate plate 2 There is a sliding groove 8, and the two ends of the balance bar 7 are installed in the movable groove 8, and are in rolling contact with the gate plate 2; the gate plate 2 is installed on the valve body 1, and the valve body 1 is divided into a symmetrical front half valve body and the rear half valve body, the upper part of the inner wall of the valve cavity 9 where the front half valve body and the rear half valve body are located is set as a stepped structure, and the lower part is set as a platform structure; the sealing ring 3 is an elastic sealing ring, which is set as two independent rings Body, its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com