Flowmeter with movable annular rotor

A rotameter and annular technology, which is applied in the field of annular movable rotameters, can solve the problems of limited working conditions of the medium, large noise and vibration, easy jamming and easy wear, etc., to achieve convenient disassembly, time saving, and no vibration Good effect with noise, reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

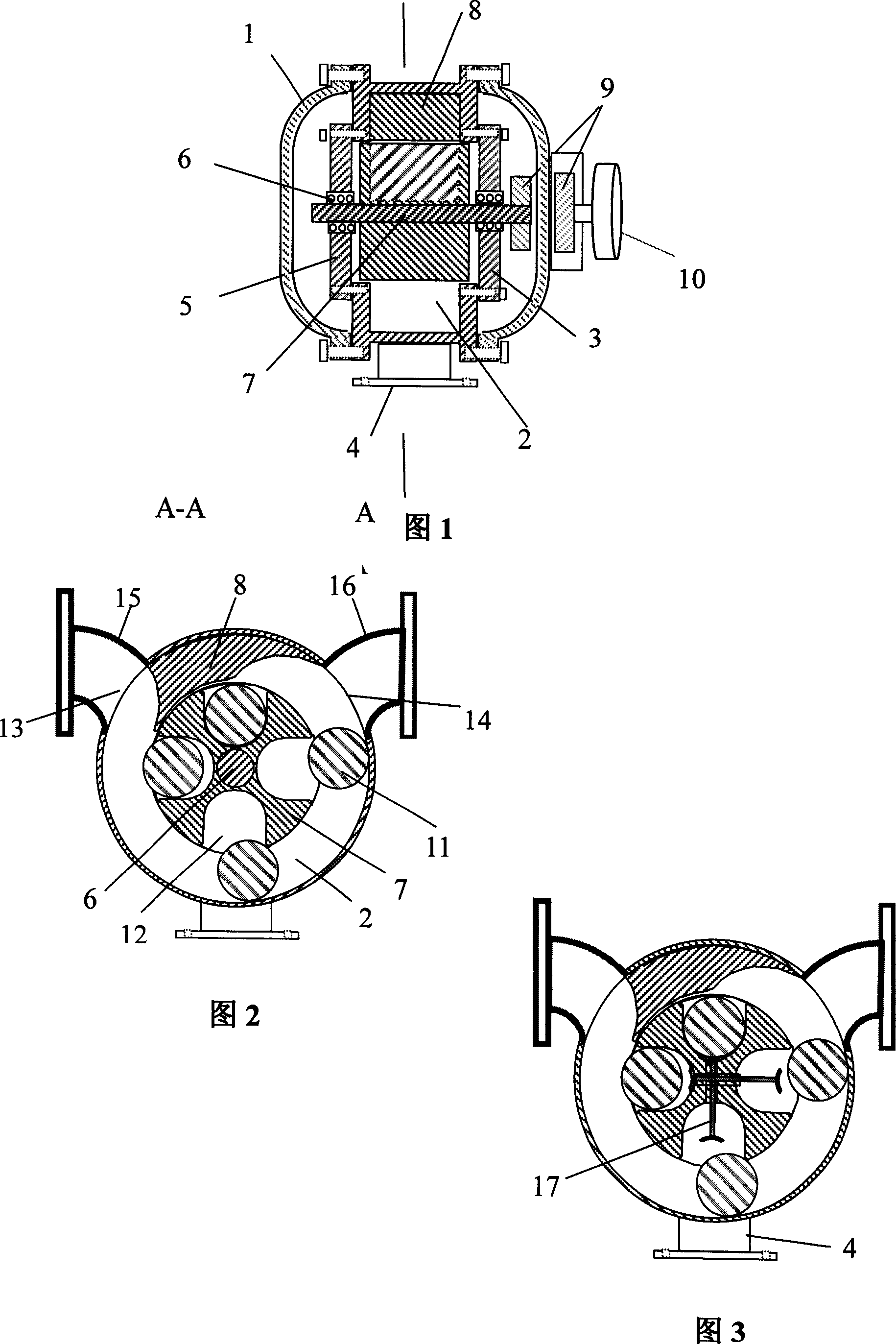

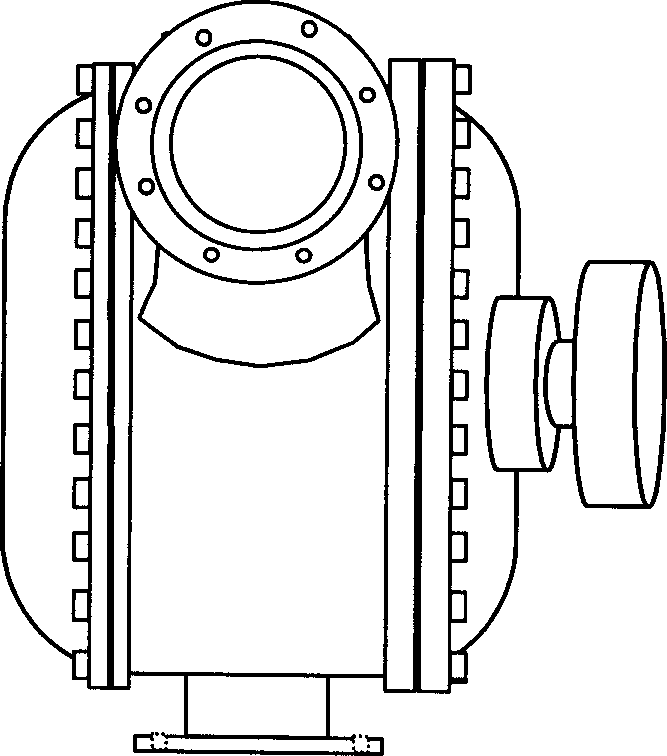

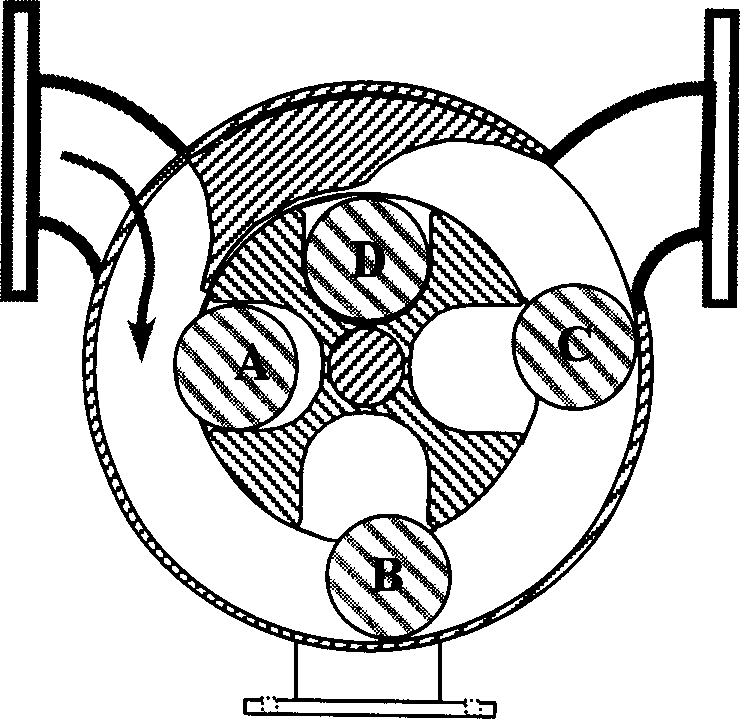

[0033] Referring to Figures 1, 2, and 4, the present invention provides an annular movable rotameter, which includes a main body 1, front and rear end covers 3, 5 arranged along the axial direction of the main body, and the main body 1 Placed on the base 4; the front and rear end covers 3,5 of the main body 1 are provided with a central shaft 7, the central shaft 7 is placed on the center bearing 6 on the front and rear end covers 3,5, and the outer wall of the central shaft 7 and the inner wall of the main body 1 An annular metering chamber 2 is formed between them; at least three rotor chambers 12 are recessed on the axial outer wall of the central rotating shaft 7, and a movable rotor 11 is accommodated in the axial direction of the central rotating shaft 7 in the rotor chamber 12. The diameter of the rotor 11 is greater than the thickness of the annular metering chamber 2, and smaller than the accommodating depth of the rotor chamber 12; A metering space with a fixed volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com