Three-dimensional storing and conveying line for green bodies

A conveying line and three-dimensional technology, which is applied in the field of sanitary ceramics production equipment, can solve the problems of time-consuming, semi-finished green blanks, a large number of manual operations, and labor costs, and achieve the effects of reducing labor intensity, improving maintenance efficiency, and reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

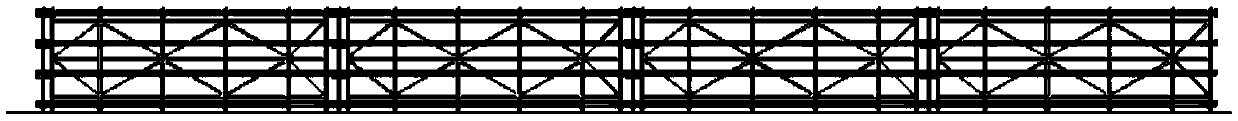

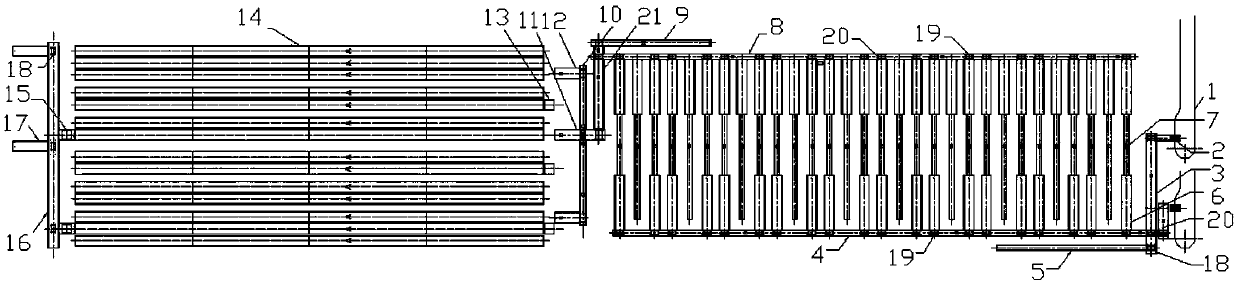

[0019] The present invention consists of a suspension line 1, an off-line transfer machine 2, a sorting and identification line 3, a repair and inspection incoming goods diversion line 4, an explosion cache line 5, a repair and inspection incoming goods line 6, a fluent bar repair and inspection line 7, and an outgoing Goods merging line 8, residual product line 9, horizontal conveying line 21, conveying line 10, multi-storey storage entrance sorting line 11, multi-storey storage entrance conveying line 12, incoming goods translation elevator 13, multi-storey storage line 14, outgoing Translation elevator 15, multi-layer storage shipment diversion line 16, multi-layer storage shipment line 17 and other devices are composed.

[0020] As shown in the figure, the off-line transfer machine 2 is located under the suspension line 1, and the off-line transfer machine 2 is connected to one end of the sorting identification line 3. Ends are vertically connected, and the burst cache lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com