Sub-chamber back blowing bag type dust collector with reciprocating movement back blowing air port

A technology of bag dust collector and reverse air outlet, which is applied in the direction of separation method, dispersed particle separation, dispersed particle filtration, etc., which can solve the problems that are prone to failure, and the dust cleaning mechanism of the bag dust collector cannot realize chamber-by-chamber mouth-to-mouth dust cleaning , complex structure and other problems, to achieve the effect of prolonging the service life, simple structure and simple dust cleaning mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

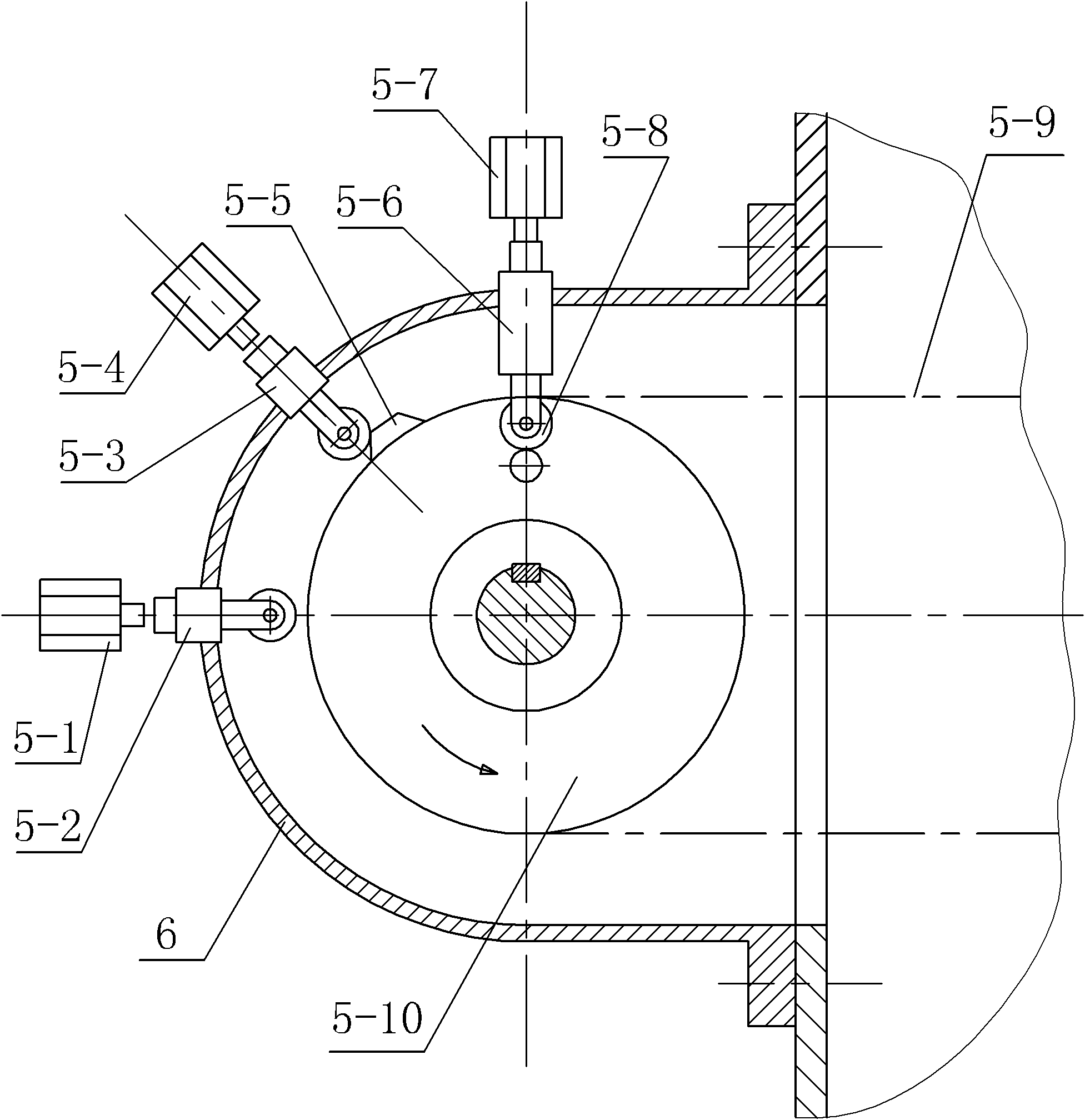

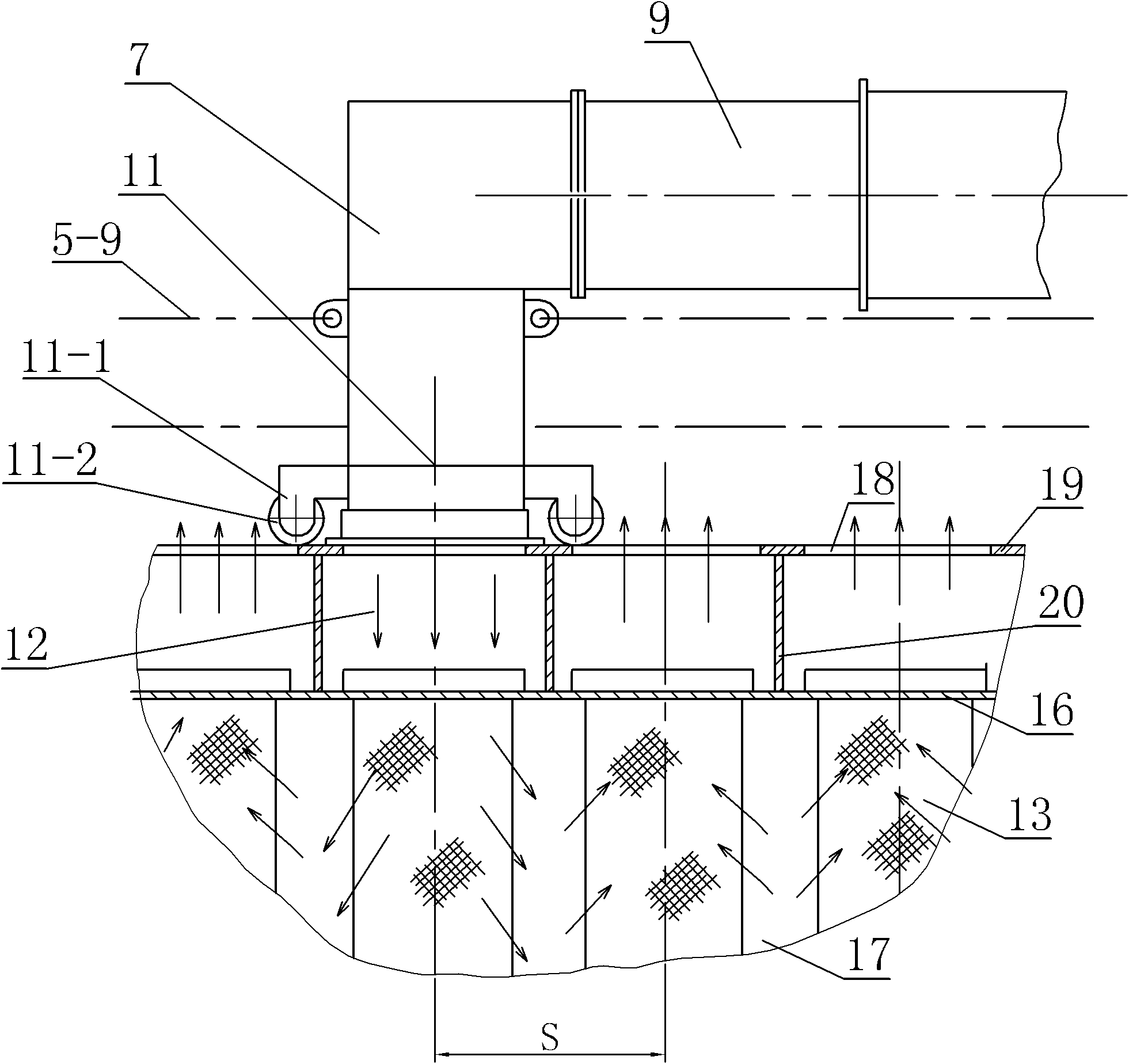

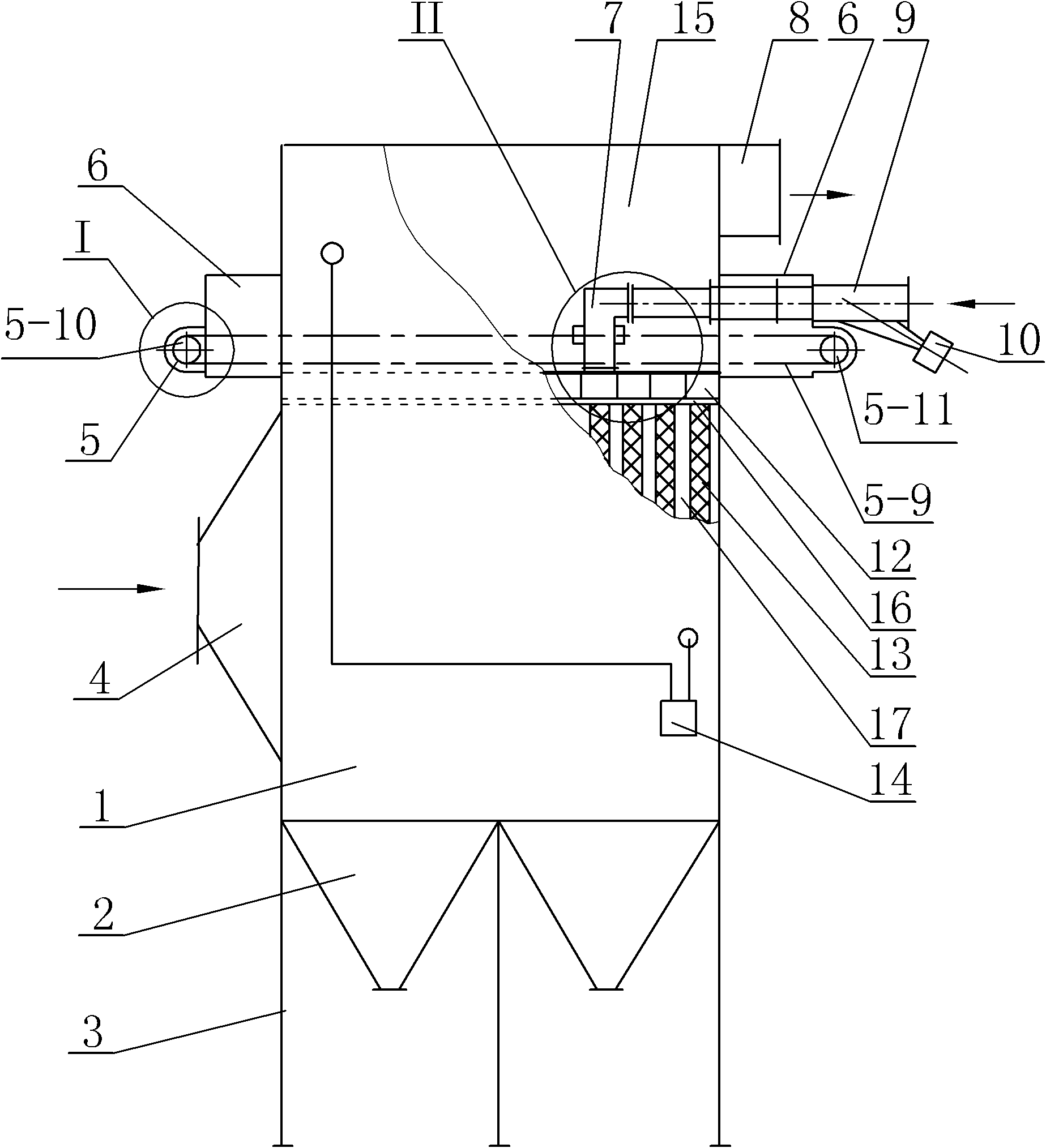

[0019] Specific implementation mode two: as Figure 1~3 As shown, the sub-chamber reverse blowing and dust cleaning device in this embodiment also includes a sliding support member 11 placed in the clean air chamber 15, and the sliding support member 11 is composed of a support frame 11-1 and four pulleys 11-2. The support frame 11-1 is fixed on the outer side wall of the movable anti-air outlet 7, the pulley 11-2 is installed on the bottom end of the support frame 11-1, and the pulley 11-2 is in contact with the upper end surface of the cover plate 19 , the pulley 11-2 slides along the upper end surface of the cover plate 19 (the upper end surface of the cover plate 19 acts as a “track”). Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 2

[0020] Specific implementation mode three: as Figure 1~4 As shown, the transmission mechanism 5 in this embodiment includes a chain 5-9, a driving sprocket 5-10 and a driven sprocket 5-11. The transmission mechanism 5 is placed above the sliding support member 11, and the chain 5-9 Connect with the connecting ear on the side wall of the movable anti-blowing outlet 7; the speed-regulating motor 22 in the compartment anti-blowing dust cleaning device drives the driving sprocket 5-10 to rotate; the transmission mechanism 5 and the telescopic anti-blowing pipe 9 The air inlet end of the air inlet is installed on the housing 6 of the compartment back blowing and dust cleaning device fixed on the two outer walls of the upper part of the box body 1. When the chain 5-9 traction movable type anti-blow outlet 7 back-blowing and dust-cleaning, the telescopic anti-blow pipe 9 is also pulled along with expansion and contraction, guarantees the unimpeded flow of back-blowing air. Other co...

specific Embodiment approach 3

[0021] Specific implementation mode four: as Figure 1~5 As shown, the dust remover in this embodiment also includes a sound wave generator 10, and the sound wave generator 10 is installed at the air intake end of the telescopic back-blow pipe 9; the installation position of the sound wave generator 10 ensures that the blowback dust At this time, the sound wave enters the inner surface of the filter bag along with the blowback airflow, and the direction of the low-frequency sound wave emitted by the sound wave generator 10 is consistent with the direction of the blowback airflow. The acoustic wave generator 10 and the chamber-by-chamber back-blowing and dust-cleaning device carry out mouth-to-mouth positioning and dust-cleaning of the chambers together, realizing the chamber-by-chamber back-blowing sound wave-assisted dust removal of the bag filter. The sound wave generator is installed at the inlet end of the blowback pipe. When blowback is used to remove dust, the sound wave e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com