Duplex pipeline compensator

A technology of double pipeline and compensator, which is applied to expansion compensating devices, pipe components, pipes/pipe joints/pipe fittings for pipelines, etc. flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

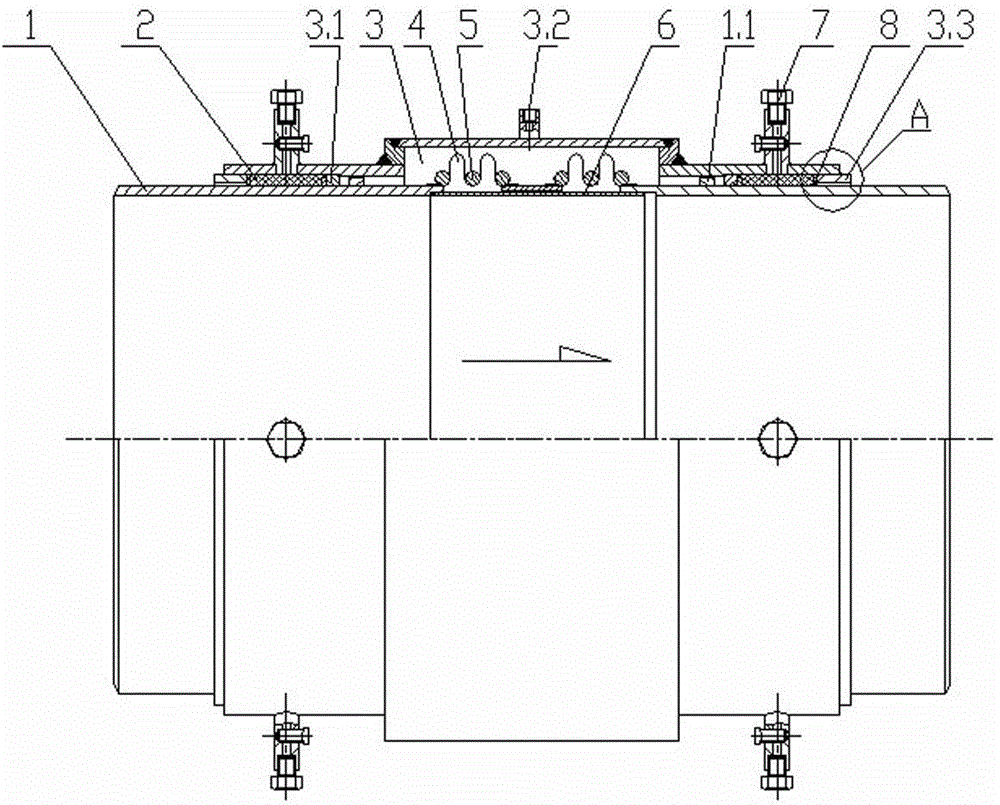

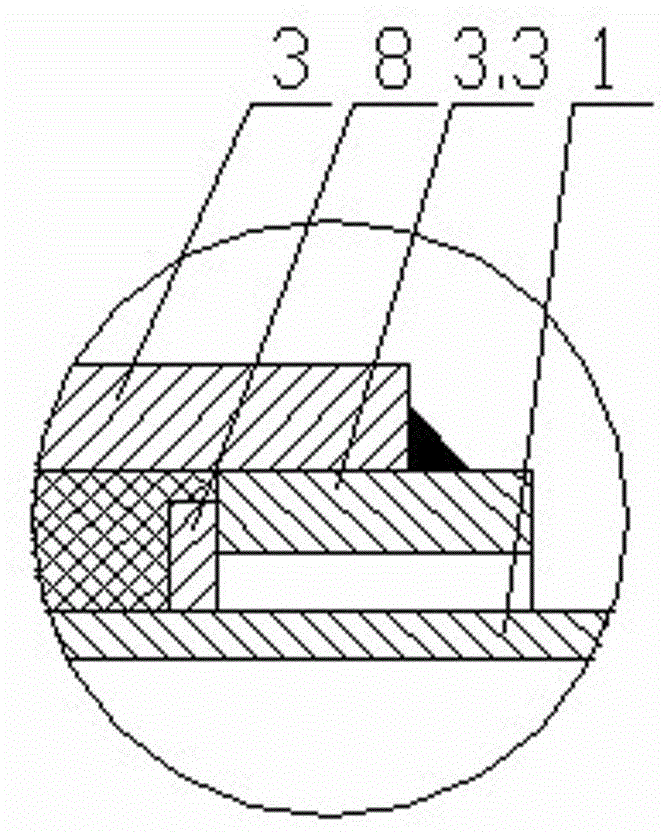

[0019] figure 1 The composite pipeline compensator shown in the figure has a diameter of 3500mm and is matched with the diversion pipeline of a hydropower station in the south. The composite pipeline compensator is composed of two different types of compensators, which include inner pipe 1, packing 2, outer shell 3, bellows 4, armor ring 5, liner 6, filling port 7 and slip ring 8. The bellows 4 is a typical thin-walled elastic element. In order to further strengthen the bellows 4, an armor ring 5 is placed inside the outer trough of the bellows 4 in the lying position. Two corrugated pipes 4 of the same specification are connected in series coaxially, and a liner 6 is provided on the inner wall of the two connected corrugated pipes 4 to conduct flow. The shell 3 is a cylindrical body with a large middle and small ends. The middle sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com