Insulative cast-in-situs vapour barrier multilayer roofing with composite structure and constructing method thereof

A multi-layer composite and construction method technology, applied in the direction of roof covering layer, roof insulation material, building roof, etc., can solve the problems of high price, high requirements on light steel material, high engineering cost, and achieve the solution of strength and thermal insulation, The effect of improving thermal insulation performance and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

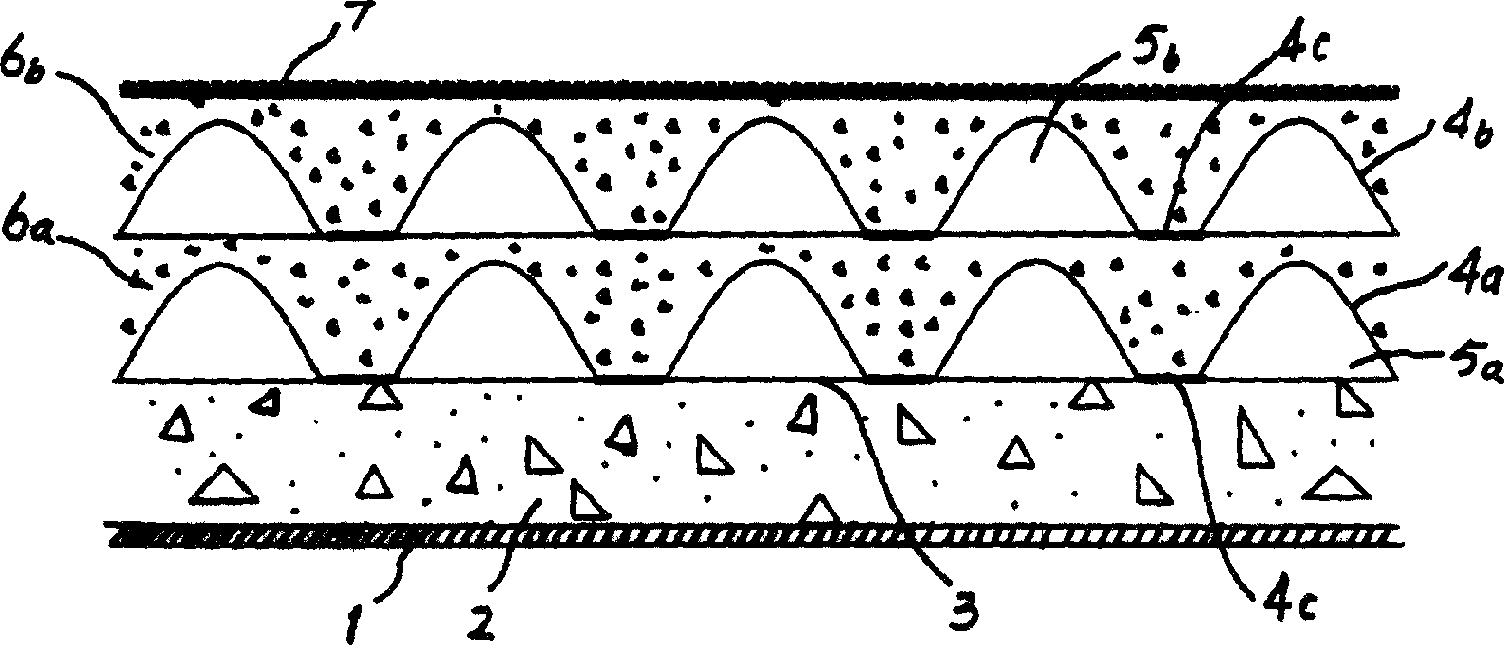

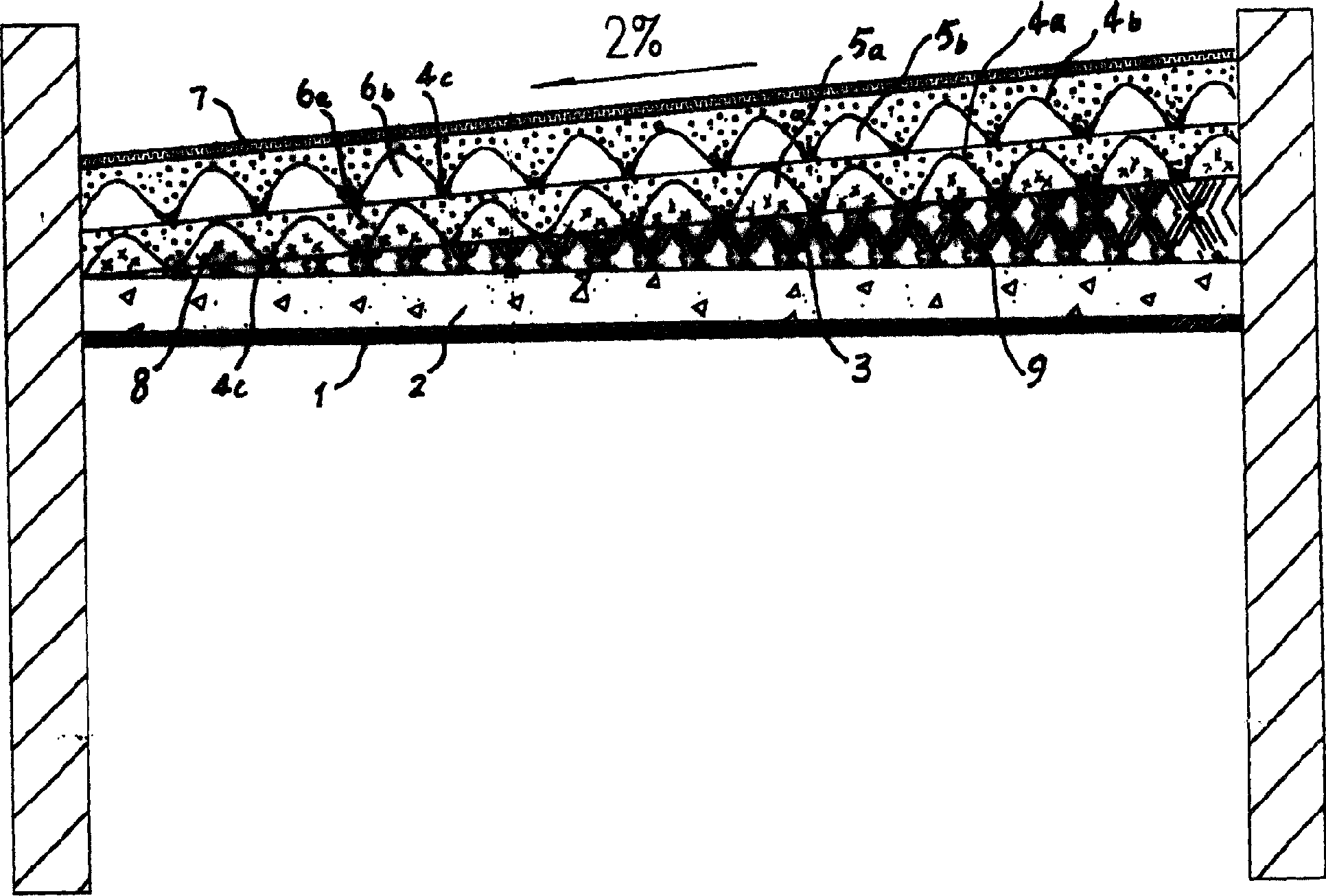

[0020] Example 1. Combining the attached figure 2 The structure and construction method of the thermal insulation roof of the present invention are further described: the reinforced concrete roof slab (2) is an internal plastering layer (1), and the floor slab (2) after construction is divided into slags to find slopes (slope 2%) , then select plastic cloth to spread on the slag slope to form an air barrier layer (3), then dry-lay expanded perlite 40mm thick to form a dry layer (8), then cover the first shell layer of expanded polystyrene (4a ) (thickness of the shell plate is 5 to 8mm, and the height of the shape is 80mm), so that the foot (4c) of the supporting shell layer is in contact with the plastic cloth, and the polyphenylene magnesium cement composite foam is cast on the first supporting shell layer (4a). Foam material (the inventor has applied for a patent, the application number is 02133070.0) and scraped to form the first cast-in-place layer (6a), and the first ai...

example 2

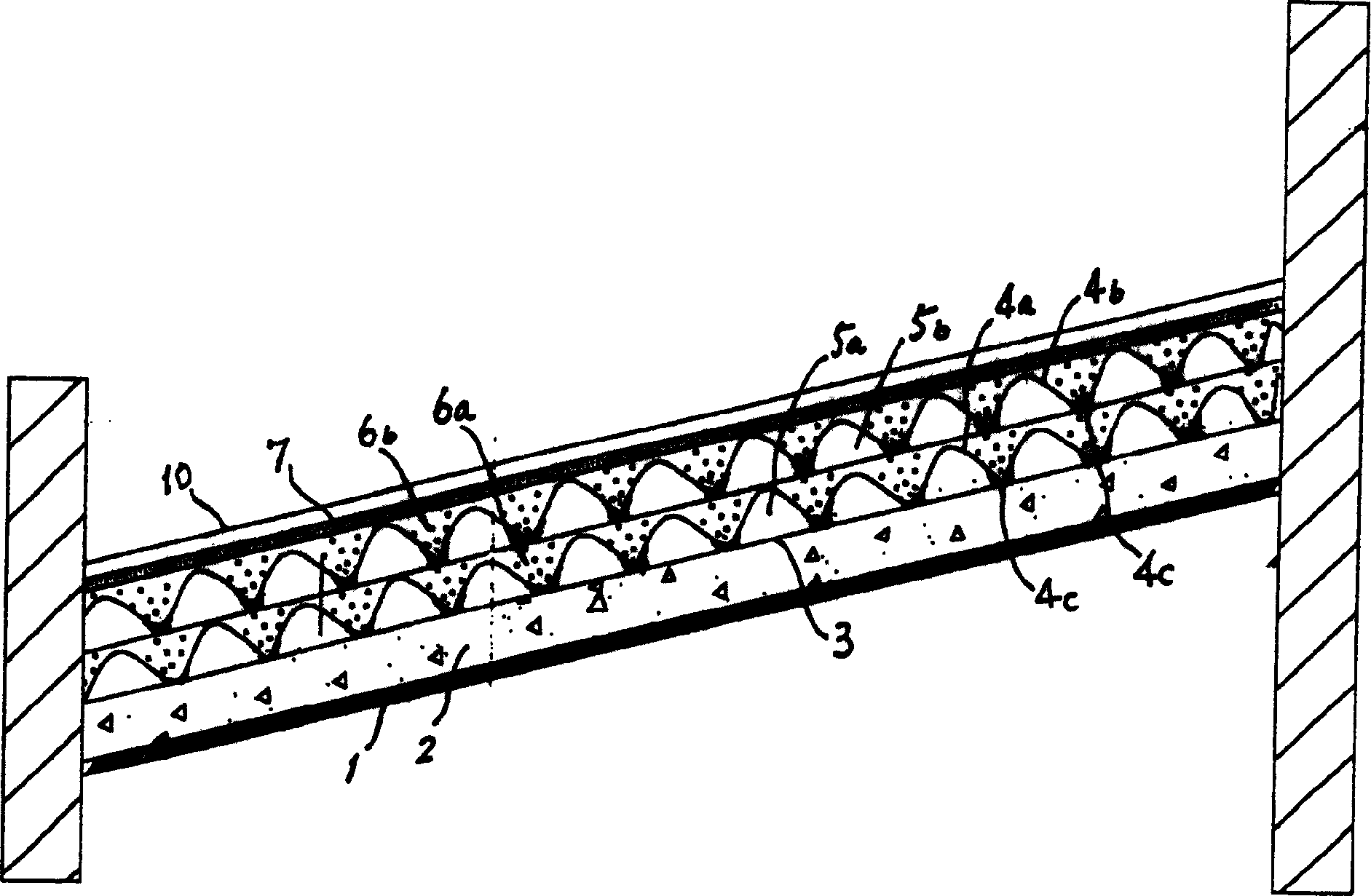

[0021] Example 2. Combining the attached image 3 The composition and construction method of the heat-insulating roof of the present invention are further described:

[0022] Below the reinforced concrete roof slab (2) is an internal plastering layer (1). Paint the emulsified asphalt oil 0.5mm thick on the roof slab (2) after construction to form an air barrier layer (3), and then cover the first shell layer (4a) of expanded polystyrene (thickness 5-8mm) , appearance height 60mm), let the foot (4c) of the first supporting shell layer (4a) contact with the air barrier layer (3), and cast polystyrene cement composite foam on the first supporting shell layer (4a) Foam material (the inventor has applied for a patent, the application number is 03134154.3) and scraped off to form the first cast-in-place layer (6a). Form the first air interlayer (5a) below its first supporting shell layer (4a), and close it by the separation seam, repeat the above-mentioned operation on the first c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com