Hydraulic cylinder displacement transducer in lifting eye

A technology of displacement sensor and hydraulic cylinder, applied in the direction of fluid pressure actuating device, etc., can solve the problem of lack of built-in opening detection device, and achieve the effect of ensuring detection accuracy, high reliability, and easy maintenance and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

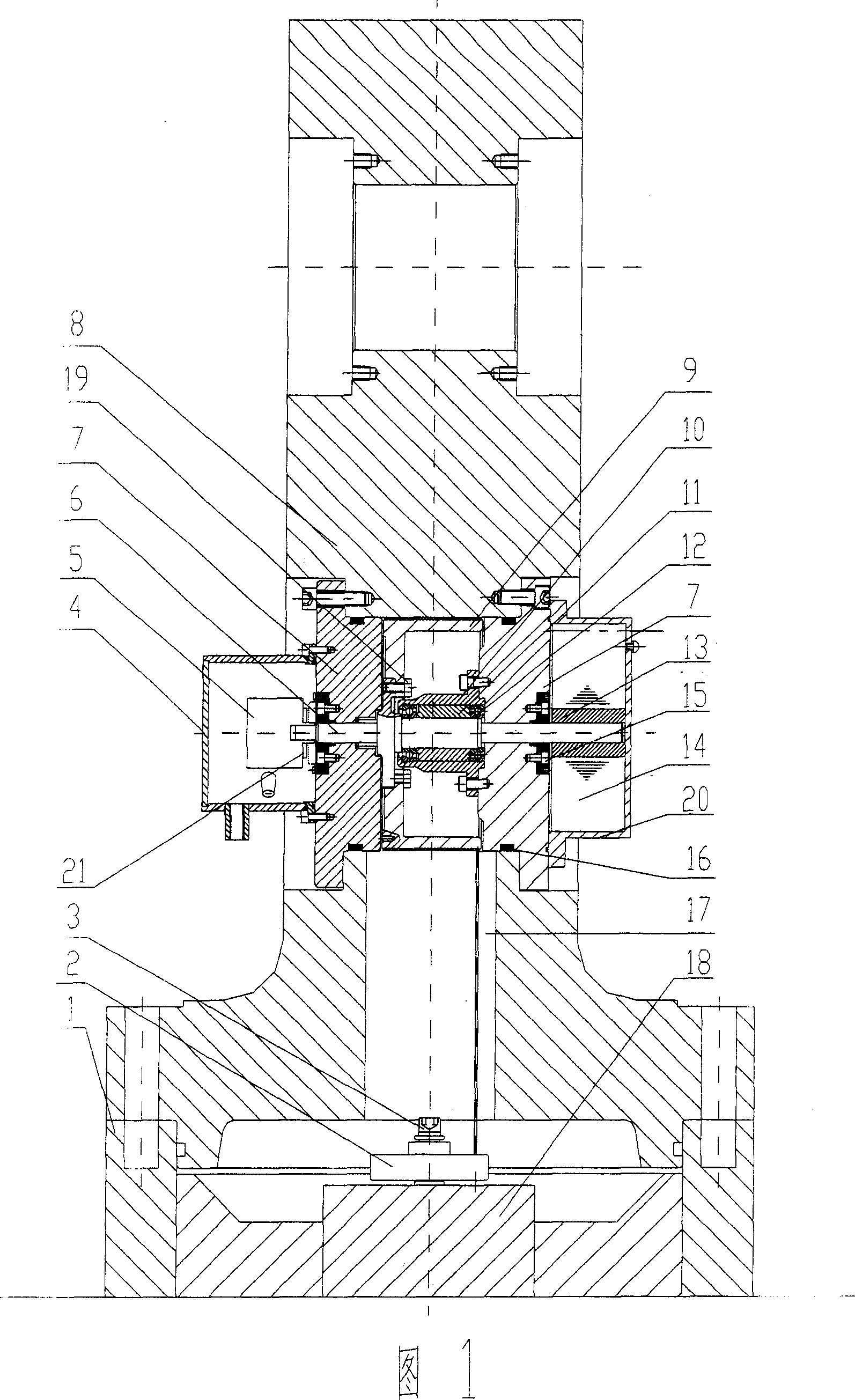

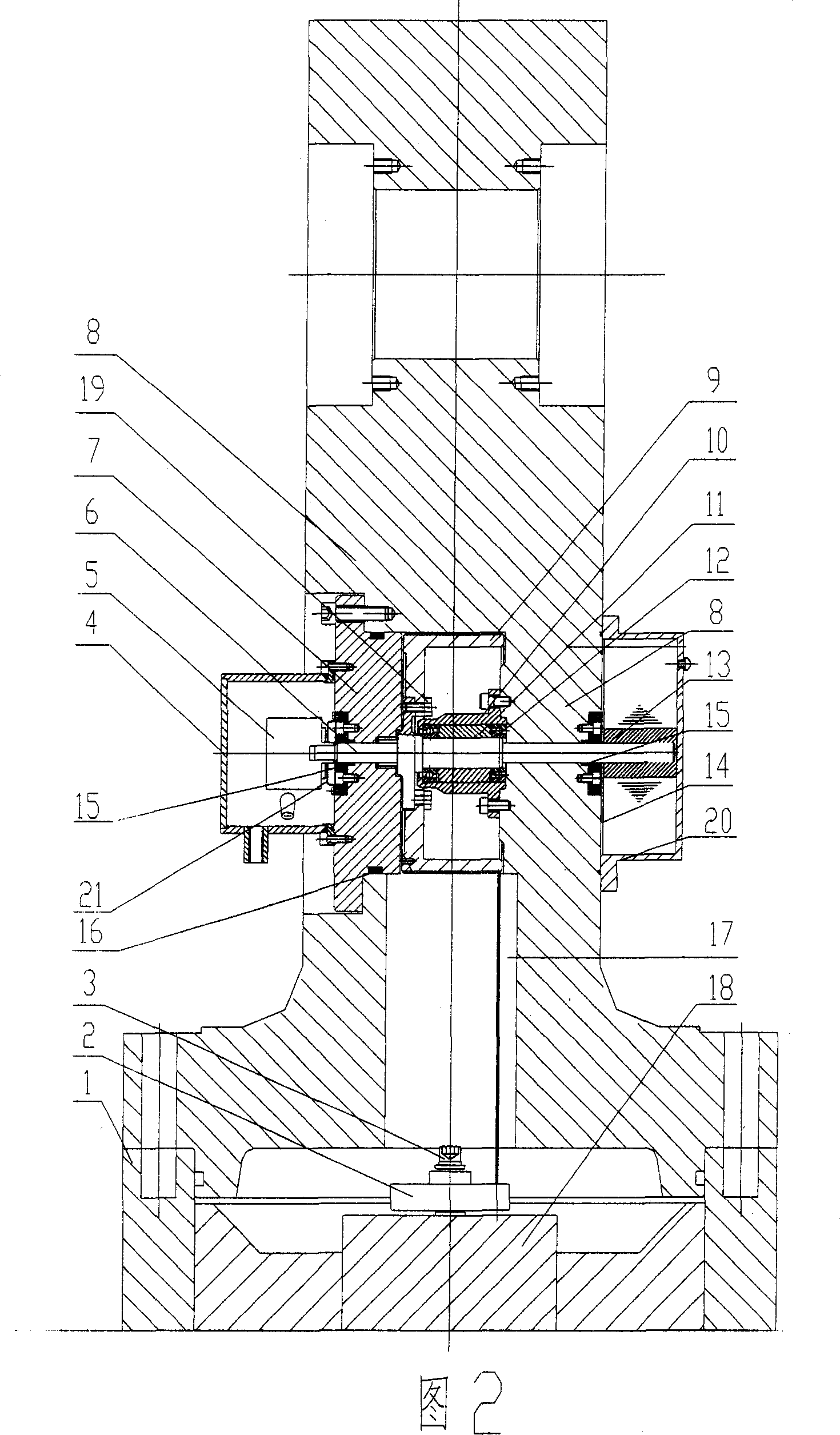

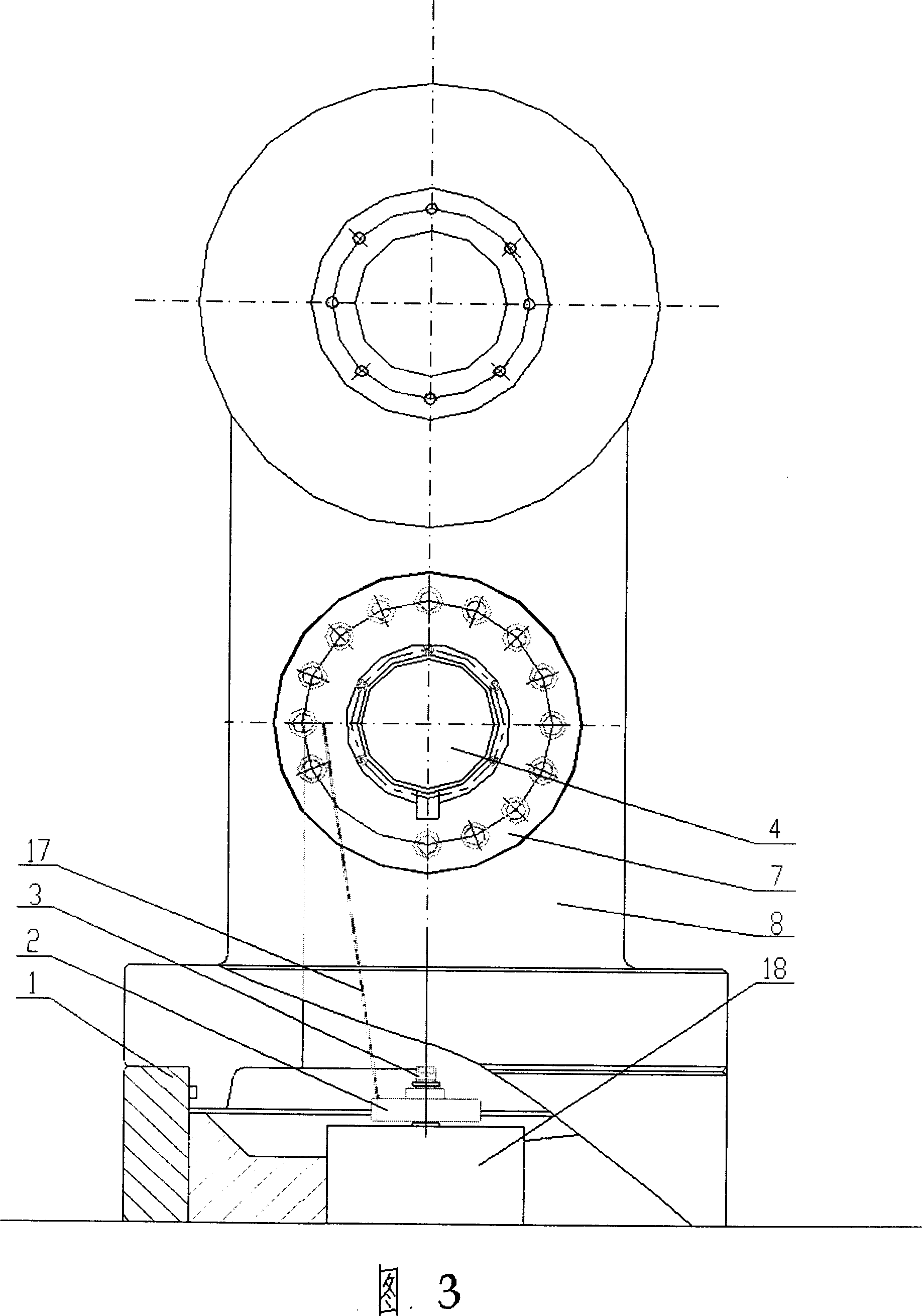

[0045] Figure 1 is a structural sectional schematic diagram of Embodiment 1 of a hydraulic cylinder displacement sensor placed in the lifting lug of the present invention;

[0046] The hydraulic cylinder includes a hydraulic cylinder body 1 , a lifting lug 8 , a piston 18 and a displacement sensor; the lifting lug 8 is fixed at one end of the hydraulic cylinder 1 .

[0047] The displacement sensor includes a displacement sensor rotation assembly, a displacement sensor measurement assembly and a spring 14 .

[0048] The displacement sensor rotating assembly is connected with the piston 18, and the spring controls the movement of the piston through the matching connection with the displacement sensor rotating assembly. The displacement sensor measuring assembly cooperates with the displacement sensor rotating assembly to measure the displacement stroke of the piston 18.

[0049] The displacement sensor rotating assembly also includes a rotor 9, a rotating main shaft 6 and a cabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com