Large-flow ultraviolet fluid sterilizer

An ultraviolet disinfection and ultraviolet technology, which is applied in chemical instruments and methods, light water/sewage treatment, water/sewage treatment, etc. and other problems, to achieve the effect of improving pressure tolerance, improving disinfection effect, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments are described in detail below in conjunction with the accompanying drawings.

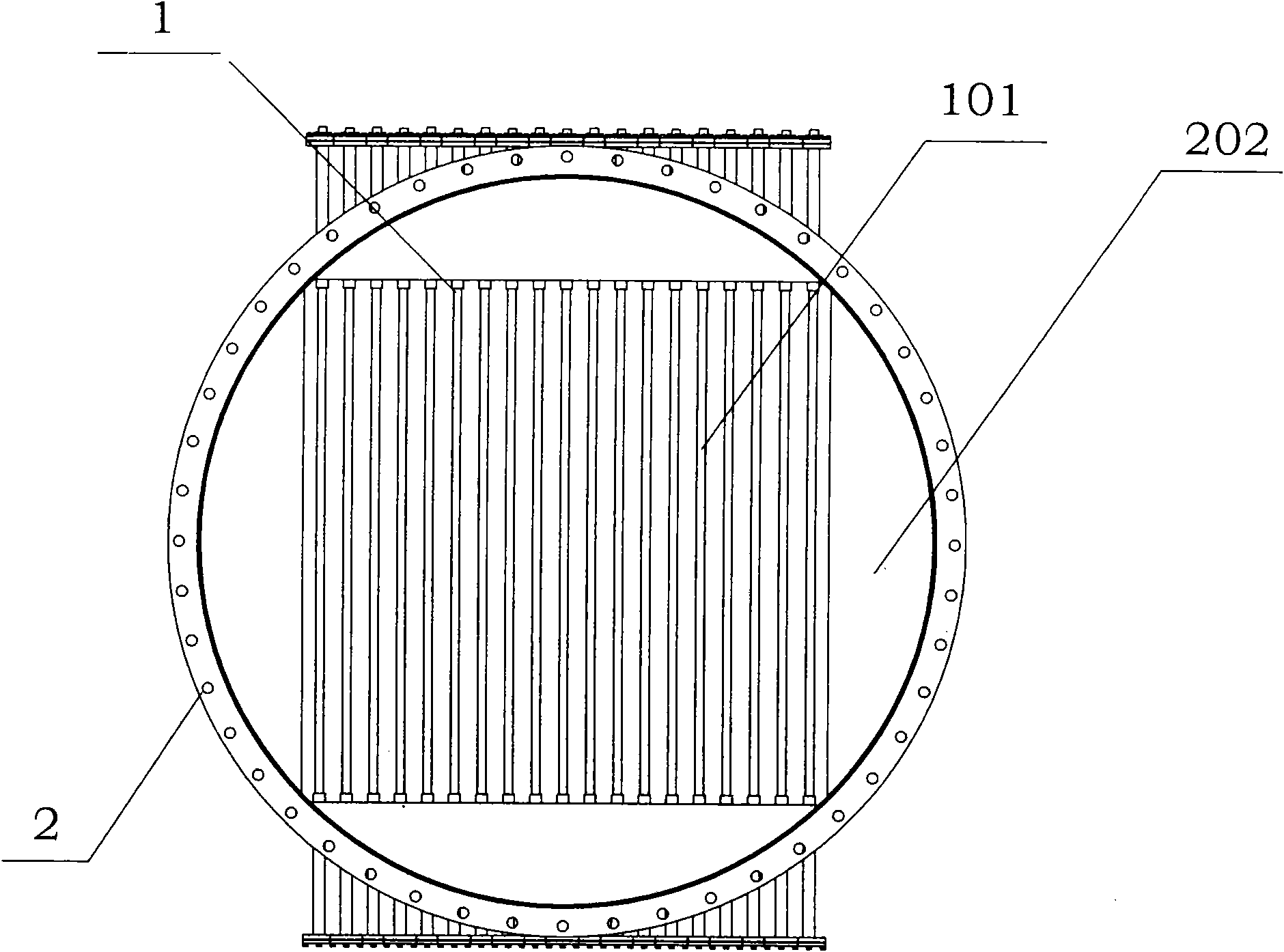

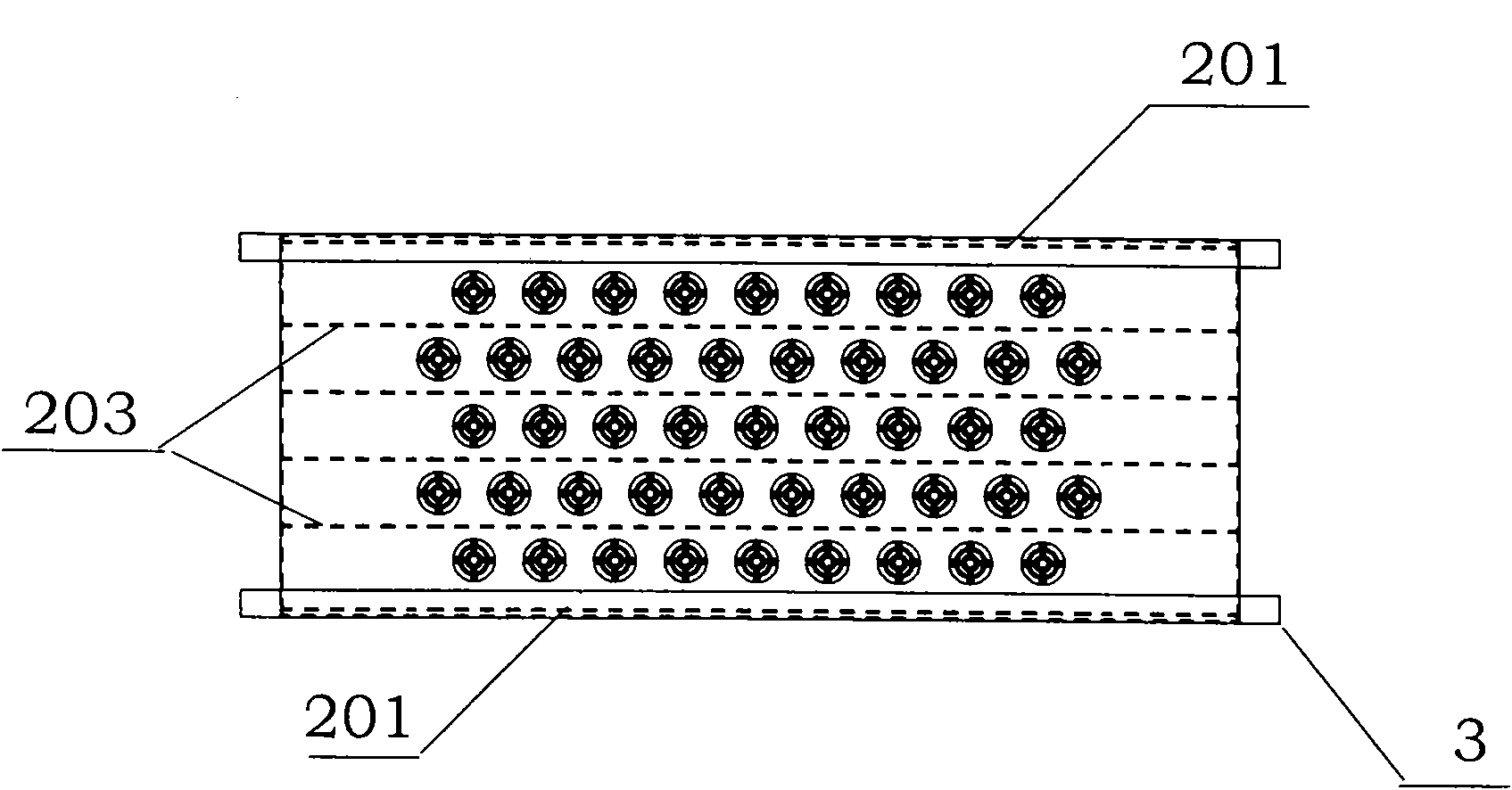

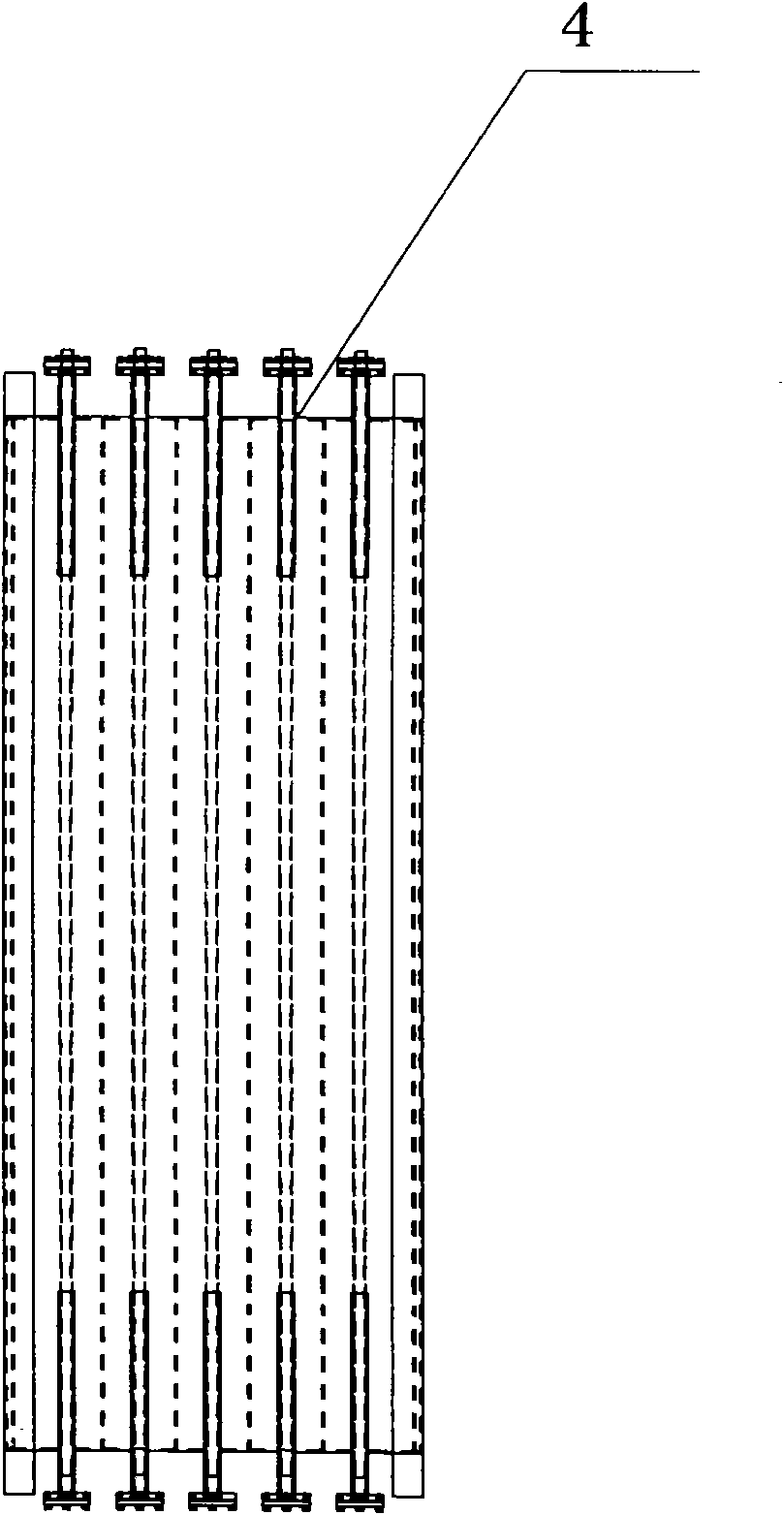

[0024] Such as figure 1 , 2 . The large-flow ultraviolet fluid sterilizer shown in 3 adopts a modular structure, each module includes at least one ultraviolet disinfection module 1 and an installation fixture 2 for the ultraviolet disinfection module, and each ultraviolet disinfection module 1 includes at least one ultraviolet lamp tube 101, the main body of the installation and fixing device 2 is a pipeline through which the sterilized fluid can pass, and several ultraviolet disinfection module installation holes 4 are arranged on the pipeline wall, and one or two end faces 201 of the installation and fixing device 2 are provided with The baffle plate 202 extending from the outer periphery of the end surface toward the center of the end surface, and the end surface 201 where the baffle plate 202 is located has a water outlet 203 for the fluid to be sterilized to pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com