Direct driving type belt conveyer

A belt conveyor, direct drive technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of troublesome speed regulation and control, high investment cost, high operating cost, etc., to improve efficiency, reduce operating cost, and occupy an area little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further description will be made below in conjunction with the embodiments and accompanying drawings.

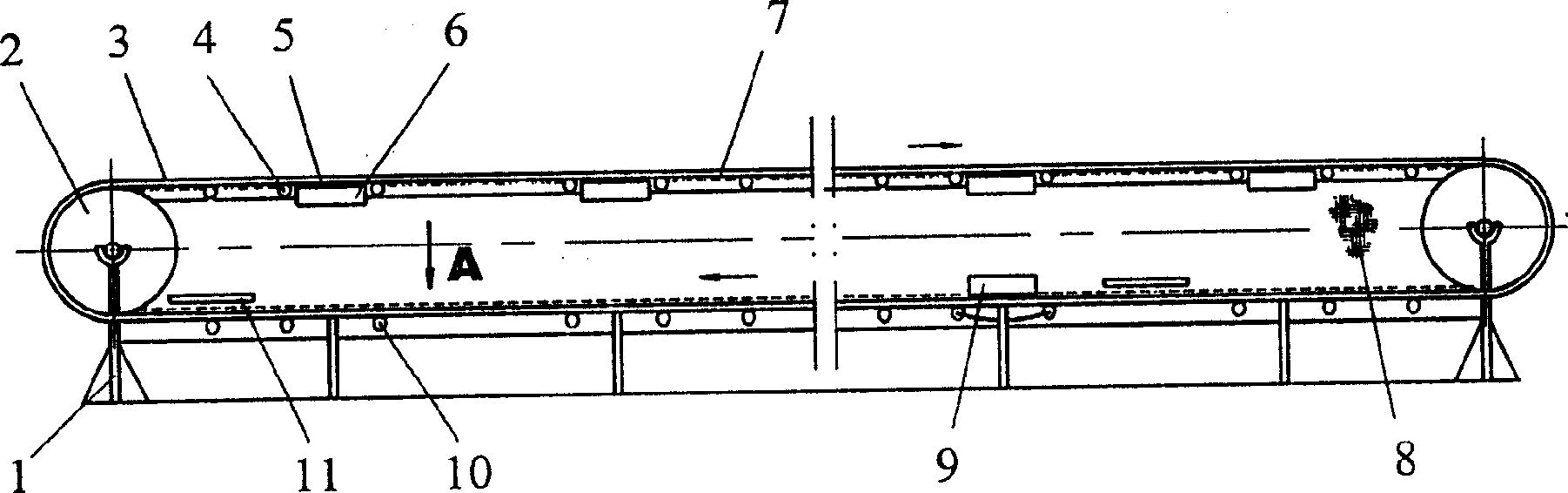

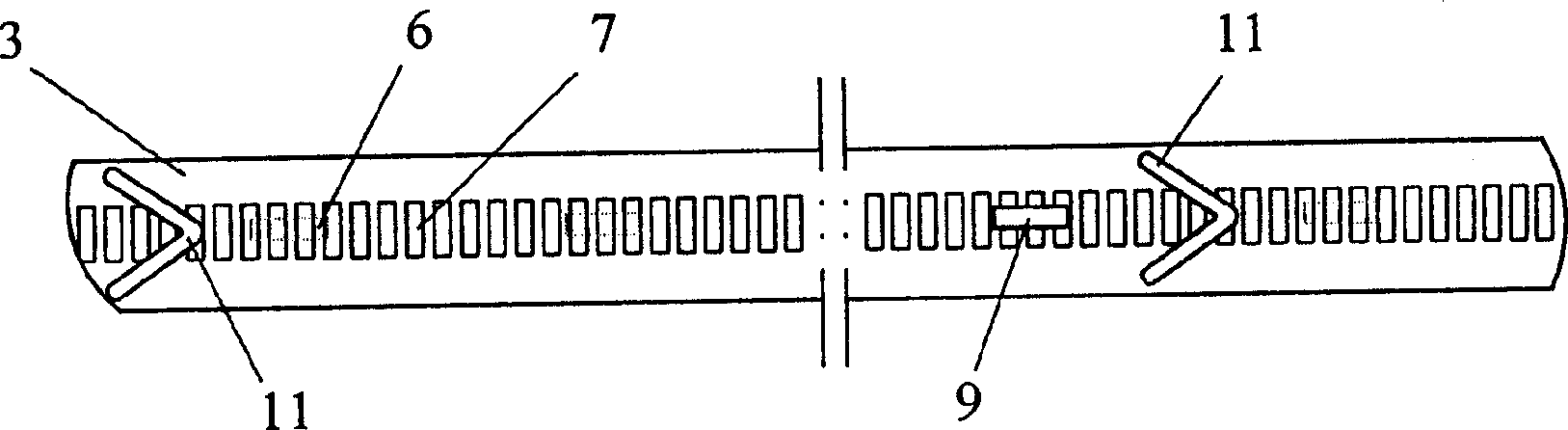

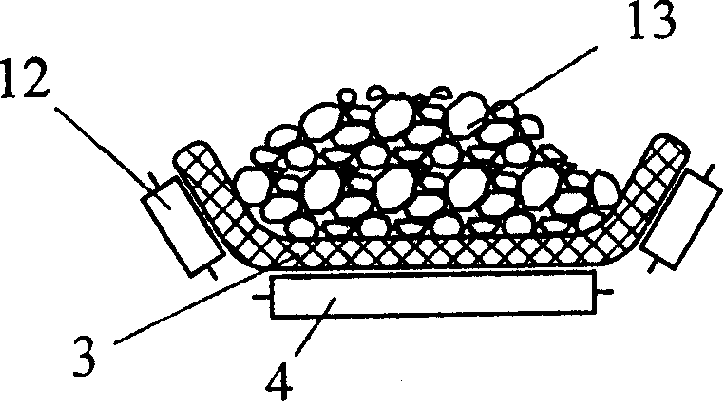

[0027] See attached figure 1 . This is a basic structural diagram of an embodiment of a direct drive belt conveyor. It includes a bracket 1, a roller 2, a conveyor belt 3, a roller 4, a power motor and its control device, and it is characterized in that the motor is a linear motor 6, and the body of the linear motor and its primary are distributed along the centerline of the conveyor belt and the roller They are installed together on the bracket; the secondary 7 corresponding to the primary is installed on the inner side of the endless conveyor belt, and the secondary plates are horizontally arranged in an intermittent and closed arrangement along the longitudinal direction of the conveyor belt. 5 represents the conveyor belt running gap positioning wheel. The 8th, be located at support both sides, make the wallboard or guard net that lateral enclosure usefulness. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com