Oxide-graphite interlayer compound, preparation method thereof, electrode and battery

An interlayer compound, graphite interlayer technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problem of no obvious increase in battery energy density, little progress in research on carbon cathode materials, and no market competitiveness. problem, to achieve the effect of good electrical conductivity, high thermal conductivity, and improved energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The second aspect of the present invention provides a kind of preparation method of above-mentioned oxide-graphite interlayer compound, it comprises the following steps:

[0031] 1) Mix flake graphite with a particle size of less than 300 meshes and precursors of silicon oxide, aluminum oxide or titanium oxide in a weight ratio of 1:2 to 1:4 evenly.

[0032] Since it is impossible to directly insert silicon oxide, aluminum oxide or titanium oxide into the graphite structure layer, the present invention uses precursors of silicon, aluminum, titanium oxides.

[0033] The precursor of silicon oxide, aluminum oxide or titanium oxide is one of silane coupling agent, aluminate, titanate compound or aluminum trichloride, preferably n-octyltriethoxysilane (English name: Triethoxyoctylsilane; trade name: silane coupling agent), distearoyl isopropoxy aluminate (English name: Distearoyl IsopropoxyAluminate; trade name: aluminate coupling agent), isopropyl trihard Fatty acid titan...

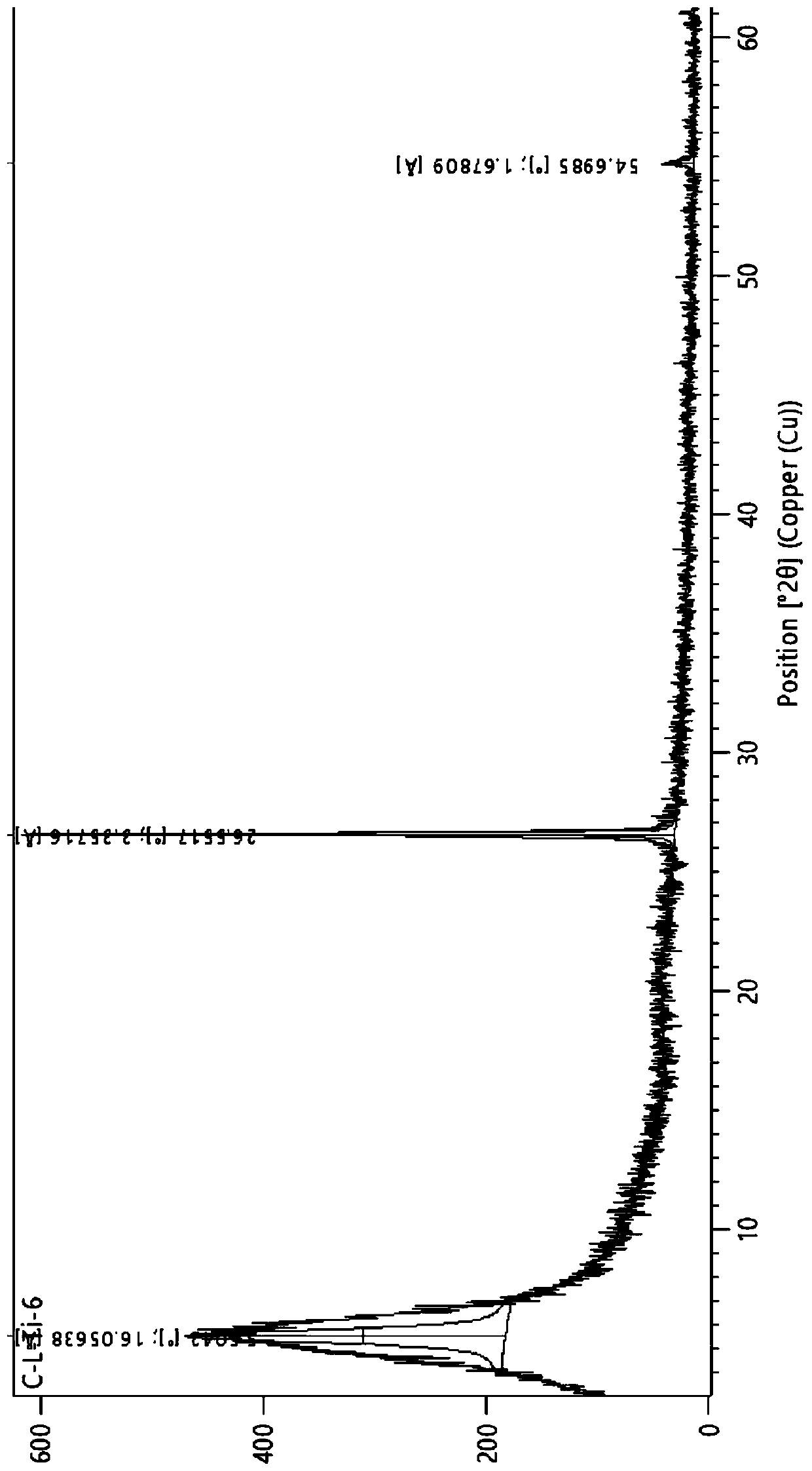

Embodiment 1

[0075] 1) Mix flake graphite with a particle size of less than 300 mesh and n-octyltriethoxysilane in a weight ratio of 1:2, and put it into a mill.

[0076] 2) After grinding for 2 hours, take the material out and place it in a closed container to bathe in water vapor for 2 hours.

[0077] 3) After the material is taken out from the container, it is dried in an oven, then kept at a constant temperature in a muffle furnace at 120°C for 3 hours, and cooled to room temperature to obtain a silicon oxide-graphite intercalation compound.

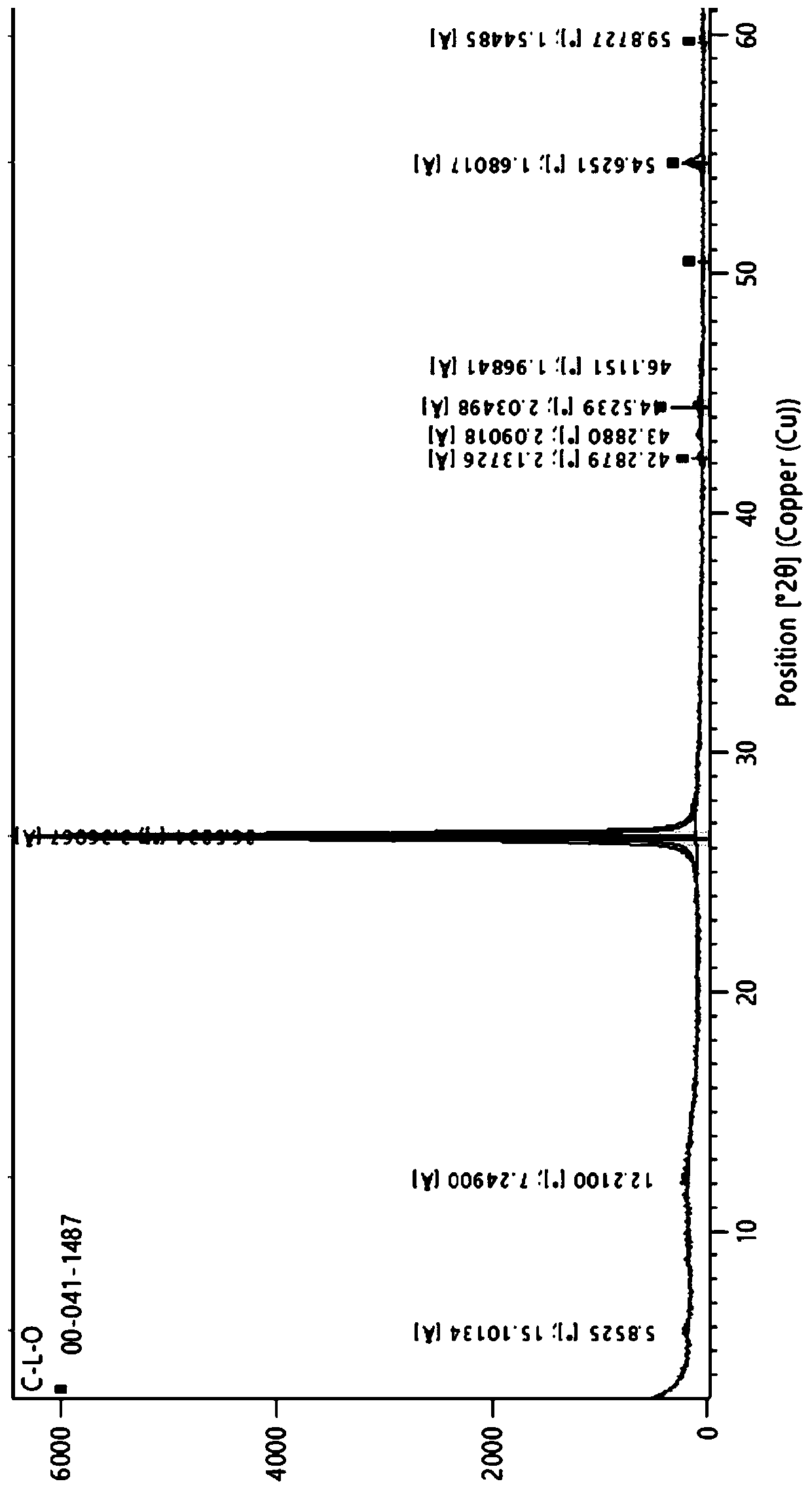

Embodiment 2

[0079] 1) Mix flake graphite with a particle size of less than 300 mesh and distearoyloxyisopropoxyaluminate at a weight ratio of 1:4, heat to 60°C, and put it into a mill.

[0080] 2) After grinding for 6 hours, take the material out and place it in a closed container to bathe in water vapor for 6 hours.

[0081] 3) After the material is taken out from the container, it is dried in an oven, then kept at a constant temperature in a muffle furnace at 400°C for 1 hour, and cooled to room temperature to obtain an alumina-graphite interlayer compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com