Preparing method of high- capacity intermediate phase coal micro powder

A technology of mesophase carbon micropowder and mesophase carbon microspheres, which is applied in the field of preparation of high-capacity mesophase carbon micropowder, can solve the problems of not very significant product yield, complicated preparation process, and difficult to obtain ingredients, etc., to achieve The preparation method is simple and feasible, the adaptability is good, and the effect of comprehensive performance is excellent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The mesophase carbon microsphere raw material is pulverized and pretreated to obtain mesophase carbon microsphere raw powder with a particle size of 20 μm;

[0027] Under stirring, alternately add mesophase carbon microsphere green ball powder 200kg and graphitization catalyst SiO 2 Mix 16kg evenly, and mix with 60kg of petroleum pitch below 0.1mm in the kneading pot;

[0028] Carry out kneading treatment at 160°C for 1 hour. After the kneading is completed, press it into a 4mm tablet in a tablet press, and then crush it into particles with a particle size of less than 100 μm, and hot isostatically press it into a block;

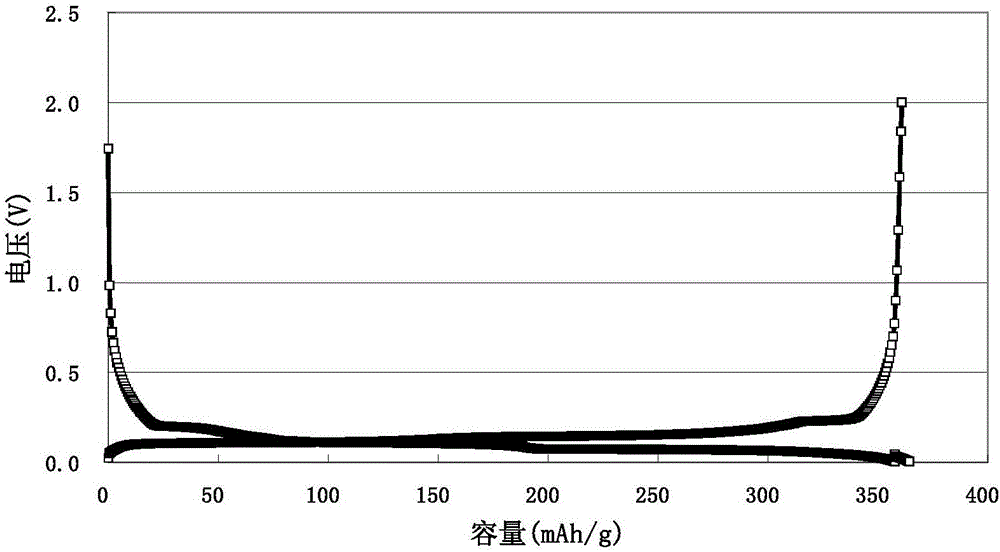

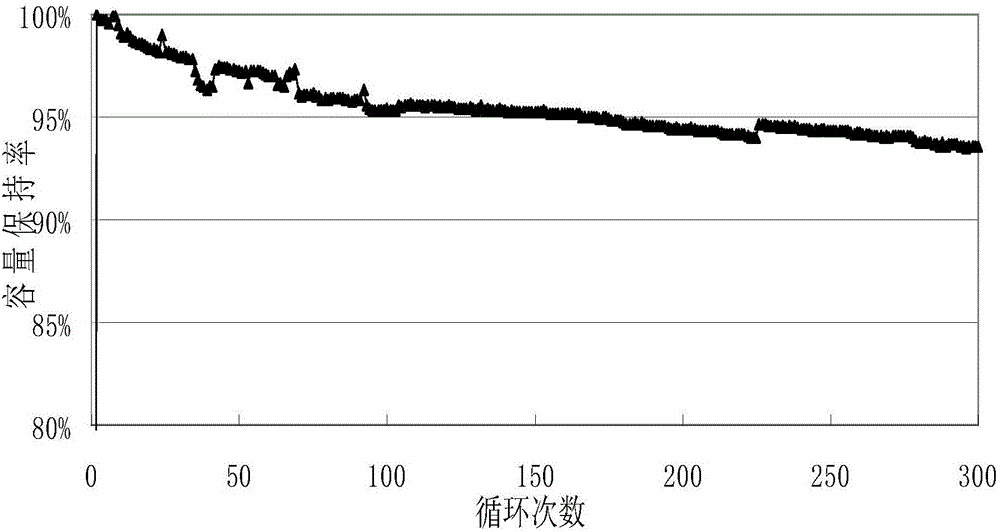

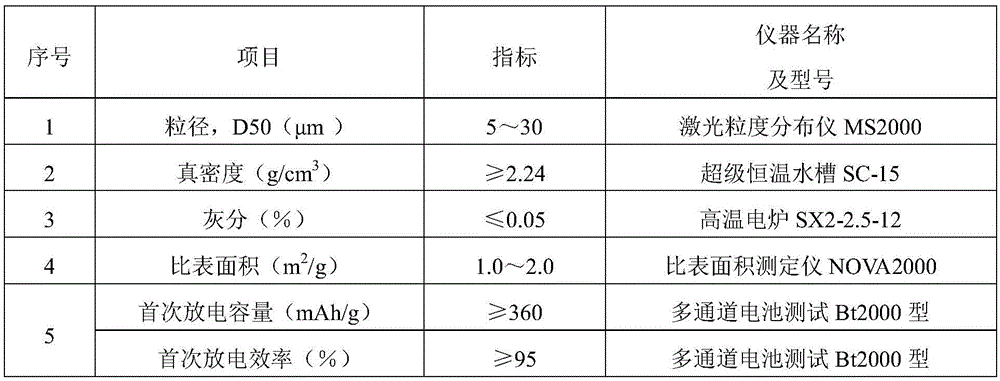

[0029] Then carry out high-temperature catalytic graphitization treatment at 2800°C for 36 hours to obtain mesophase carbon powder with a particle size D50 of 17.8 μm. The half-cell capacity is 362.5mAh / g, and the first-time efficiency is 95.8%.

Embodiment 2

[0031] The mesophase carbon microsphere raw material is pulverized and pretreated to obtain mesophase carbon microsphere raw powder with a particle size of 30 μm;

[0032] Under stirring, alternately add 200kg of mesophase carbon microsphere green ball powder and 6kg of graphitization catalyst SiC, mix evenly, and mix with 20kg of petroleum pitch powder below 0.1mm into the kneading pot;

[0033] The kneading process was carried out at 160°C for 1 hour. After the kneading was completed, it was pressed into a tablet shape of 3 mm in a tablet machine, and then crushed into particles with a particle size of less than 100 μm, and hot isostatically pressed into a block.

[0034] Then carry out high-temperature catalytic graphitization treatment at 3000°C for 48 hours to obtain mesophase carbon powder with a particle size D50 of 18.3 μm, a half-cell capacity of 363.1mAh / g, and an initial efficiency of 95.2%.

Embodiment 3

[0036] The mesophase carbon microsphere raw material is pulverized and pretreated to obtain mesophase carbon microsphere green pellet powder with a particle size of 25 μm;

[0037] Under stirring, alternately add mesophase carbon microsphere green ball powder 200kg and graphitization catalyst SiO 2 Mix 10kg evenly, and mix with 100kg coal tar pitch powder below 0.1mm in the kneading pot;

[0038] Carry out kneading treatment at 160°C for 1 hour. After the kneading is completed, press it into a tablet shape of 5 mm in a tablet machine, and then crush it into particles with a particle size of less than 100 μm, and hot isostatically press it into a block;

[0039] Then carry out high-temperature catalytic graphitization treatment at 3200°C for 48 hours to obtain mesophase carbon powder with a particle size D50 of 17.4 μm, a half-cell capacity of 365.0mAh / g, and an initial efficiency of 95.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com