Nano sheet self-assembled MoS2 nano hollow material and preparation and application of MoS2 nano hollow material serving as lithium storage electrode material

A hollow, nano-technology, applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effect of good product appearance, simple and easy operation, and improved lithium storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: MoS 2 Preparation of Nanohollow Materials

[0033] Put 0.865g, 0.515g, and 1.930g of molybdenum oxide, sodium fluoride, and potassium thiocyanate in sequence in water-ethanol (36mL water / 12mL ethanol, V / V=3:1) mixed solvent, and stir evenly for 0.5h . Transfer to a 60mL polytetrafluoroethylene reactor and seal, and react at 200°C for 16h. The reaction product was washed with deionized water and absolute ethanol, centrifuged and dried under vacuum at 60°C for 6 hours to obtain MoS 2 nano hollow materials.

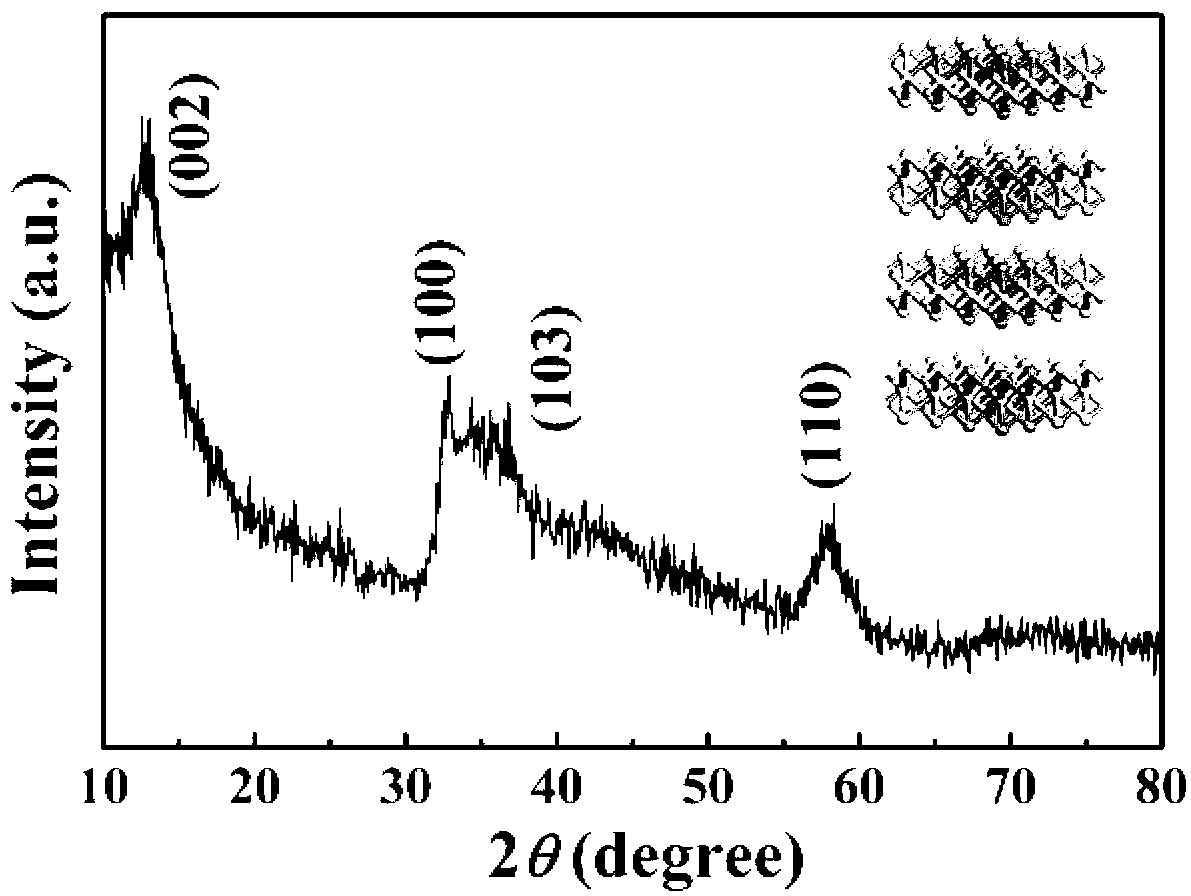

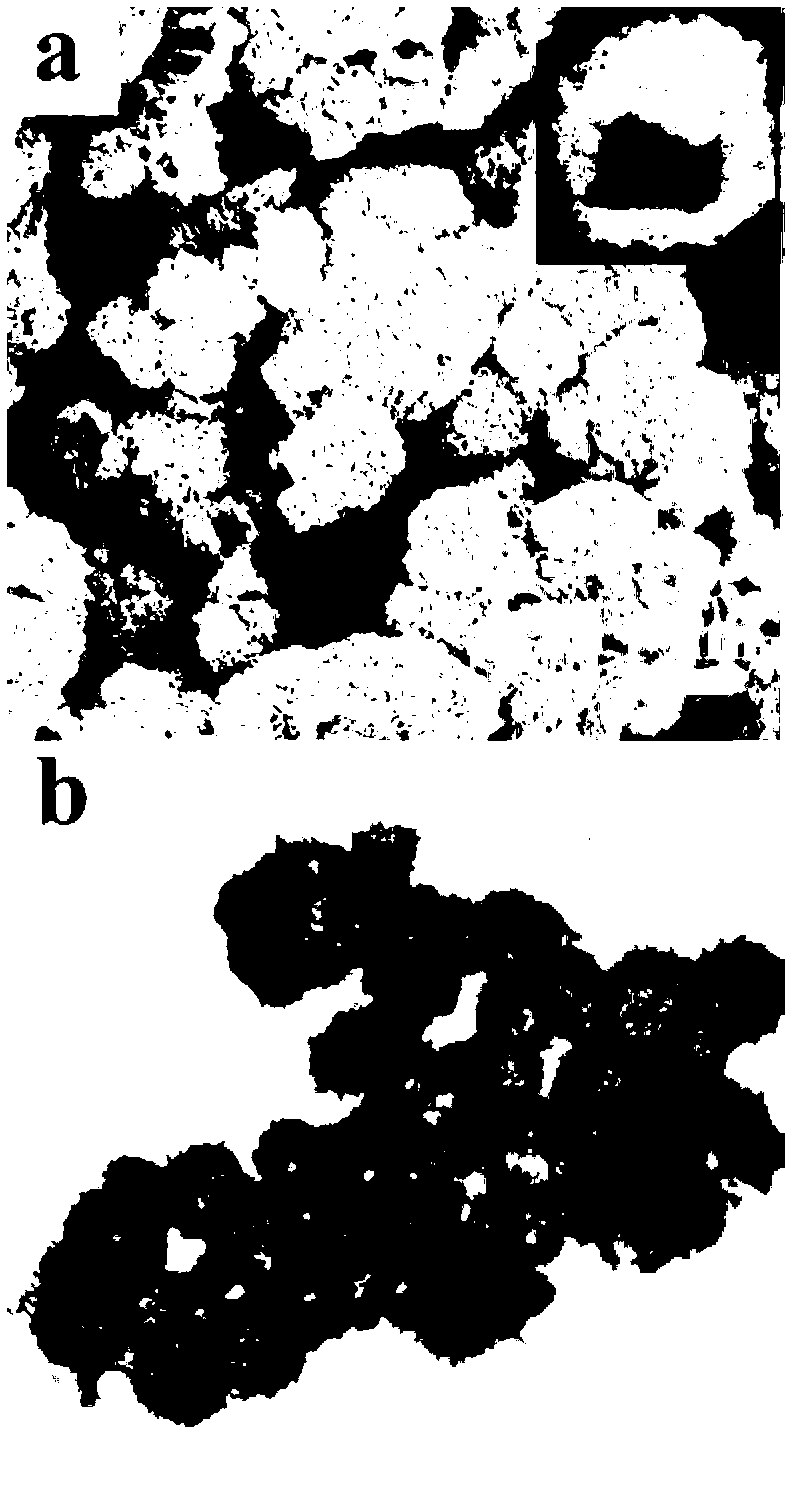

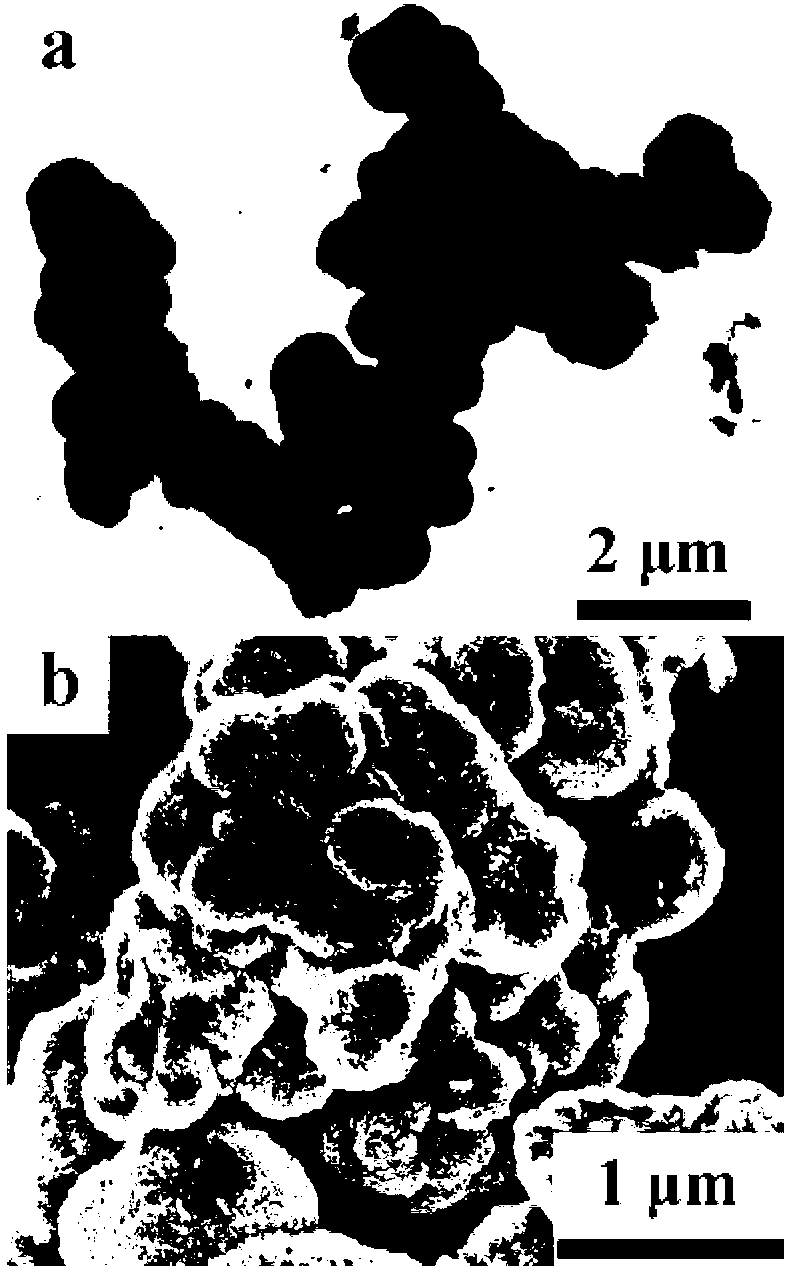

[0034] The resulting MoS 2 The XRD spectrum of nano hollow material products is as follows figure 1 shown; the resulting MoS 2 The transmission electron microscope and scanning electron microscope photos of nano hollow materials are as follows: figure 2 shown.

[0035] Control sample: MoS 2 Preparation of nanosolid materials

[0036] Mix molybdenum oxide, sodium fluoride, and potassium thiocyanate (0.865g, 0.515g, 1.930g) in 50mL of water-glyceri...

Embodiment 2

[0043] Mix molybdenum oxide, sodium fluoride, and potassium thiocyanate (0.865g, 0.515g, 1.930g) into a 50mL water-ethanol mixed solvent reaction system, and the volume ratio of the mixed solvent is water / ethanol=3 / 1 or 1 / 1. Stir evenly for 0.5h and transfer to a 60mL polytetrafluoroethylene reactor, seal it, and react at 140~220°C for 17h. The reaction product is washed with deionized water and absolute ethanol, centrifuged and dried at 60°C for 8h in vacuum. Get MoS 2 nano hollow materials.

Embodiment 3

[0044] Example 3: MoS 2 Preparation of Nanohollow Materials

[0045] Mix 0.865g of molybdenum oxide, 0.515g of sodium fluoride, and 1.930g of potassium thiocyanate, add it to a 50mL water-ethanol mixed solvent reaction system (the volume ratio of water / ethanol is 1 / 2), and seal it in the polytetrafluoroethylene reaction system. In the kettle, react at 200°C for 18h, the product is washed with deionized water and absolute ethanol, centrifuged and vacuum-dried at 60°C for 6 hours, and finally a black powder product is obtained, that is, MoS 2 nano hollow materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com